Table of Contents

Advertisement

Quick Links

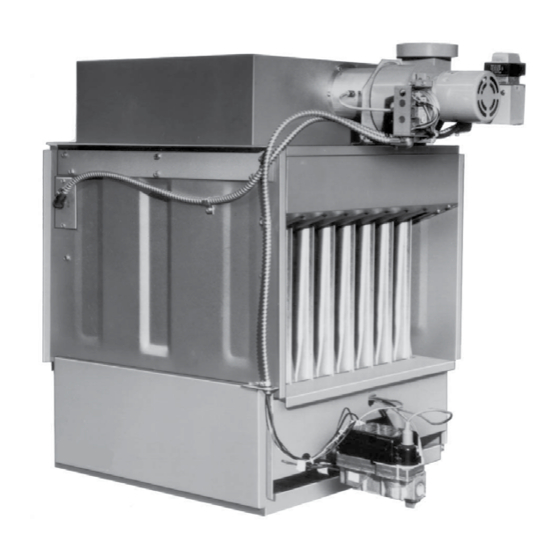

INSTALLATION/OPERATION/MAINTENANCE FOR INDOOR

POWER-VENTED DUCT FURNACE

• Failure to follow safety warnings exactly could result in serious injury, death, or property

damage.

• Improper installation, adjustment, alteration, service, or maintenance can cause serious injury,

death, or property damage.

• Installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call the fire department.

DO NOT DESTROY. PLEASE READ CAREFULLY. KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

MODEL EEDU

⚠ DANGER ⚠

FIRE OR EXPLOSION HAZARD

WHAT TO DO IF YOU SMELL GAS

Revision: I-EEDU (02-21) 150492-A

Supersedes: I-EEDU (02-17) PN150492R8

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Reznor EEDU

- Page 1 Revision: I-EEDU (02-21) 150492-A Supersedes: I-EEDU (02-17) PN150492R8 INSTALLATION/OPERATION/MAINTENANCE FOR INDOOR POWER-VENTED DUCT FURNACE MODEL EEDU ⚠ DANGER ⚠ FIRE OR EXPLOSION HAZARD • Failure to follow safety warnings exactly could result in serious injury, death, or property damage. • Improper installation, adjustment, alteration, service, or maintenance can cause serious injury, death, or property damage.

-

Page 2: Table Of Contents

Electrical Connections for Field-Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 I-EEDU (02-21) 150492-A... -

Page 3: General Information

Table 1. Related Technical Manuals Available from Factory Distributor Type Form Replacement parts P-EEDU 263547 Optional hanger kit installation I-OPT-HK 98346 Replacement kit for discontinued fan control CP-Thermocore 1-FC 20918 Propane gas conversion CP-GC Parts 143147 Also available at www.reznorhvac.com . I-EEDU (02-21) 150492-A... -

Page 4: Important Safety Information

• Installation should be done by a qualified agency in accordance with the instructions in this manual and in compliance with all codes and requirements of authorities having jurisdiction. • The instructions in this manual apply only to the model EEDU duct furnace. Warranty Refer to the limited warranty form in the literature bag provided with the unit . -

Page 5: Unit Location

Figure 1 and as listed in Table NOTE: For further details or other approved methods on supplying combustion air to a confined space, refer to the National Fuel Gas Code ANSI Z223.1a (latest edition). I-EEDU (02-21) 150492-A... -

Page 6: Hazards Of Chlorine

• Remember, chlorine is heavier than air . This fact should be kept in mind when determining installation locations of heating equipment and building exhaust systems . Dimensions Unit dimensions are shown in Figure 2 and listed in Table 3 . All dimensions are in inches (mm) . I-EEDU (02-21) 150492-A... - Page 7 Figure 2. Unit Dimensions I-EEDU (02-21) 150492-A...

-

Page 8: Clearances

Unit weights are listed in Table 5. Unit Weights Unit Size 075, 100 Net Weight (Pounds (kg)) 104 (47) 126 (57) 128 (58) 150 (68) 172 (78) 194 (88) 216 (98) 262 (119) 306 (139) 328 (149) I-EEDU (02-21) 150492-A... -

Page 9: Installation

(16222), fuse box (12697), fuse box cover (12698), hole plugs—quantity three (16451) All of the makeup air options also require a shipped-separate fan control (option CQ1, PN 57960), which should be at the job site . I-EEDU (02-21) 150492-A... -

Page 10: Pre-Installation Modifications

. Remove support bracket screws and slide entire baffle assembly out of heat exchanger . b . Reinstall screws to plug holes . c . For unit sizes 075–100, conversion is complete . Proceed to step 3 . I-EEDU (02-21) 150492-A... - Page 11 . Fill in field conversion label (PN 263310) from literature bag . b . Adhere label to unit on clean dry surface adjacent to rating plate . 4. Test unit for proper operation ensuring that air throughput is in accordance with Table I-EEDU (02-21) 150492-A...

-

Page 12: Reverse Airflow Conversion

. Cover all original factory-made limit control holes using field-supplied sheet metal plate . Do not leave any open holes in side panel or heat exchanger bottom . Unit is now ready for installation with airflow from front to rear (gas valve side) . I-EEDU (02-21) 150492-A... -

Page 13: Condensate Drain Installation

Coupling of furnaces is done using optional coupling kits, which are listed in Figure 8 Table furnaces together as follows . Item numbers in parentheses refer to Table 8. Optional Furnace Coupling Kits Option For Number of Units 57963 82654 82655 82656 I-EEDU (02-21) 150492-A... - Page 14 Bolt Hex head, 3/8-16 × 1-1/4-inch-long 5095 Lockwasher Split ring 5197 Spotweld — Plate Filler 57964 Screw Sheet metal, #10 × 1/2-inch-long 11813 Quantities listed are for option CR1 coupling kit (PN 57963) for two furnaces . I-EEDU (02-21) 150492-A...

- Page 15 Figure 10. Front View of Coupled Furnaces Table 10. Coupled Furnace Front View Dimensions Dimension A Unit Size Millimeters Inches 075, 100 14-5/8 125, 140 17-3/8 20-1/8 22-7/8 25-5/8 28-3/8 33-7/8 39-3/8 1000 44-7/8 1140 Figure 10 . I-EEDU (02-21) 150492-A...

-

Page 16: Mounting Furnace

• To determine the center line for the hangers, refer to dimension A listed in Table 10 . THREADED ROD THREADED SOCKET 15/32-INCH HOLE HANGER (SEE DETAIL A) BRACKET LOCKWASHER DETAIL A DETAIL B Figure 11. Suspension-Mounting of Single Furnace I-EEDU (02-21) 150492-A... -

Page 17: Base-Mounting

. Drill new leg bracket holes in rear . HANGER BRACKET (STANDARD POSITION) DETAIL A 10 INCHES (254 mm) 12 INCHES (305 mm) HANGER BRACKET (BASE-MOUNTING POSITION) DETAIL B Figure 12. Base-Mounting Single Furnace I-EEDU (02-21) 150492-A... -

Page 18: Piping Connections

Table 11. Gas Supply Line Sizes Diameter of Pipe (Inches) 1-1/4 1-1/2 Length of Pipe Natural Natural Natural Natural Natural Natural Propane Propane Propane Propane Propane Propane (Feet) Cubic Feet per Hour 1100 2100 1281 1650 1007 1450 1270 1105 1050 I-EEDU (02-21) 150492-A... -

Page 19: Supply Piping Connections

1 . Determine model number and rated input (BTUh) from unit’s rating plate . 2 . Determine appropriate orifice replacement (refer to Table 13) for installation elevation . 3 . Unthread existing gas orifices from gas manifold . I-EEDU (02-21) 150492-A... - Page 20 4 . Thread replacement gas orifices into gas manifold . To prevent cross-threading, hand-tighten orifices into gas manifold until snug and then tighten one-half to one turn using wrench . ⚠ DANGER ⚠ DO NOT use an open flame to check for gas leaks. I-EEDU (02-21) 150492-A...

-

Page 21: Conversion To Lp (Propane)

Vent Termination (Vent Pipe and Vent pipe manufacturer’s instructions for joining double-wall pipe . Refer to the Cap) section for installing a vent cap to double-wall pipe . I-EEDU (02-21) 150492-A... -

Page 22: Rotating Venter Outlet

NOTE: A minimum of 12 inches (305 mm) of straight pipe is required at the venter outlet (or tran- sition fitting) before installing an elbow in the vent system. An elbow should never be attached directly to the venter. I-EEDU (02-21) 150492-A... -

Page 23: Vent Termination (Vent Pipe And Vent Cap)

17, and Figure 18 . Instructions follow for connecting double-wall (type B) pipe to a vent cap or to a single-wall or category III vent pipe . Figure 15. Vertical Vent Termination—Single-Wall Vent Run and Single-Wall Terminal End I-EEDU (02-21) 150492-A... - Page 24 INSTALLATION—CONTINUED Vent Connections—Continued Vent Termination (Vent Pipe and Vent Cap)—Continued Figure 16. Vertical Vent Termination—Single-Wall Vent Run and Double-Wall Terminal End Figure 17. Horizontal Vent Termination—Single-Wall Vent Run and Single-Wall Terminal End I-EEDU (02-21) 150492-A...

- Page 25 DETAIL B) until bead of sealant contacts inner pipe to create sealed joint . Figure 20, DETAIL c . Drill three small holes—spaced equally around double-wall pipe—below sealant ring (see C) and insert 3/4-inch-long sheet metal screws to secure joint . Do not overtighten screws . I-EEDU (02-21) 150492-A...

-

Page 26: Vent Termination Clearances

. Absent any local codes, distance must comply with National Fuel Gas Code Z223 .1 . Table 15 Refer to to ensure that horizontal vent terminal location complies with minimum clearance requirements . NOTE: Local codes supersede all provisions in these instructions and in National Fuel Gas Code Z223.1. I-EEDU (02-21) 150492-A... -

Page 27: Duct Connections

. The covers for the openings must be attached in such a manner as to prevent leakage (refer Ductwork-to-Furnace Connections section) . I-EEDU (02-21) 150492-A... - Page 28 Figure 21. Ductwork Connection Dimensions (Refer to Table Table 16. Ductwork Connection Dimensions Dimension G Unit Size Millimeters Inches 075, 100 12-1/2 125, 140 15-1/4 20-3/4 23-1/2 26-1/4 31-3/4 37-1/4 42-3/4 1086 Refer to Figure 21 . I-EEDU (02-21) 150492-A...

-

Page 29: Duct Furnace Airflow

. • Proper arrangements of blower and duct furnace with respect to angle of approach of the duct connection and the arrangement of the discharge opening of the blower are shown in Figure 22 . I-EEDU (02-21) 150492-A... - Page 30 INSTALLATION—CONTINUED Duct Connections—Continued Duct Furnace Blower Connections—Continued STRAIGHT THROUGH AIR BLOWER CONNECTION BLOWER CONNECTION WITH ELBOWS UP OR DOWN BLOWER CONNECTION WITH ELBOWS RIGHT OR LEFT Figure 22. Duct Furnace Blower Connections I-EEDU (02-21) 150492-A...

-

Page 31: Bypass Duct Construction

4300 4550 4800 Figure 23 . NOTE: Not all capacities are covered above . If your installation is not covered, consult your distributor or the factory representative to determine the appropriate size of the bypass duct . I-EEDU (02-21) 150492-A... -

Page 32: Ductwork-To-Furnace Connections

• To prevent leakage, ensure that duct joints are sealed as shown in Figure 24, DETAIL B. • The seals between the furnace and the duct must be mechanical U-channels as shown in Figure 24, DETAIL C. DETAIL A DETAIL C DETAIL B Figure 24. Connecting Ductwork to Furnace I-EEDU (02-21) 150492-A... -

Page 33: Electrical Connections

(refer to Table 6). Two field-supplied sheet metal screws are needed to secure the plate. 3 . Follow instructions shown in Figure 25, DETAIL A to install sensor bulb in discharge duct . I-EEDU (02-21) 150492-A... -

Page 34: Option Ag8, Ag9, Or Ag15: Discharge Air Temperature Sensor Installation

AG8 and AG9 include a sensor and mixing tube and makeup air option AG15 (two-stage valve with remote ductstat) include a box and sensor holder (PN 115850) . Install the sensor in the ductwork as follows . DETAIL A: OPTIONS AG8 AND AG9 DETAIL B: OPTION AG15 Figure 26. Discharge Air Temperature Sensor I-EEDU (02-21) 150492-A... - Page 35 . Slide holder into ductwork and secure box portion of holder to ductwork using four field-supplied #6 sheet metal screws . c . Attach field-supplied cable connector to box, connect sensor wire, and attach box cover . I-EEDU (02-21) 150492-A...

-

Page 36: Thermostat Installation

Safe operation of this unit requires proper venting flow. NEVER bypass combustion air proving switch or attempt to operate the unit without the venter running and the proper flow in the vent system. Hazardous conditions could result. I-EEDU (02-21) 150492-A... -

Page 37: Limit Switch

. The fan control provides additional safety by keeping the fan in operation in the event that the gas valve fails to close when the thermostat is satisfied . • To ensure that the fan can continue to operate, the power supply to the heater MUST NOT be interrupted except when servicing the heater . I-EEDU (02-21) 150492-A... - Page 38 . Some thermostats are provided with this feature . Multiple units controlled from a single thermostat are turned off in the same manner . 1/8 HOLE CONTROL 13/16 HOLE INSPECTION PANEL CONDUIT DETAIL A DETAIL B Figure 29. Fan Control Installation I-EEDU (02-21) 150492-A...

-

Page 39: Gas Control Valve

. • Depending on the option selection, the factory-installed sensor is either field-connected by capillary tubing to the unit-mounted ductstat (option AG3) or electrically-connected to a remote electronic remote temperature selector (option AG15) . I-EEDU (02-21) 150492-A... -

Page 40: Optional Electronic Modulation

. AG7 is identified as MV-1, AG8 is identified as MV-3, AG9 is identified as MV-4, and AG21 is identified as MV-A . • Refer to the wiring diagram supplied with the furnace for proper wiring connections . I-EEDU (02-21) 150492-A... -

Page 41: Pilot And Ignition Systems

120 seconds . • The lockout feature has a 1-hour retry or requires manual reset by interruption of the control circuit . • Propane units require the spark ignition with lockout . I-EEDU (02-21) 150492-A... - Page 42 • Ignition controller with lockout for option AH3 gas control (UTEC #1003-514, PN 257010) is shown in 33, DETAIL A . Figure • Recycling ignition controller for option AH2 gas control (UTEC #1003-638A, PN 257009) is shown in DETAIL B . DETAIL A DETAIL B Figure 33. Ignition Controllers I-EEDU (02-21) 150492-A...

-

Page 43: Operation

Turn ON the electric and gas supply to the furnace . Adjust the thermostat or ductstat so that a call for heat exists . Observe operating sequence listed in Table 20 for complete sequencing of safety pilot and ignition . I-EEDU (02-21) 150492-A... -

Page 44: Post-Startup Checklist

. Measure and adjust the manifold gas pressure as follows: NOTE: A manometer (fluid-filled gauge) with an inches water column scale is recommended for gas pressure measurement rather than a spring-type gauge due to the difficulty of maintaining the calibration of a spring-type gauge. I-EEDU (02-21) 150492-A... -

Page 45: Burner Air Adjustment (Propane Units Only)

⚠ DANGER ⚠ Failure to install and/or adjust air shutters according to directions could cause property damage, personal injury, and/or death. NOTE: During regular service, check the main burner ports, the carryover assemblies, and the orifices for cleanliness. I-EEDU (02-21) 150492-A... -

Page 46: Maintenance

‰ Check soundness of vent system and replace parts as necessary (annually at minimum) . ‰ Check wiring for damage and replace as necessary (annually at minimum) . Maintenance Procedures ⚠ CAUTION ⚠ Use only factory-authorized replacement parts. I-EEDU (02-21) 150492-A... -

Page 47: Operating Gas Valve Maintenance

• If pilot flame is short and/or yellow, check pilot orifice for blockage caused by lint or dust accumulation. • When re-installing a vertical spark pilot, be sure to include the pilot hole cover plate (see Figure 35, DETAIL B). I-EEDU (02-21) 150492-A... - Page 48 Do not attempt to disassemble the ignition controller. There are no field-replaceable components in the control enclosure. j . Check electronic spark ignition wire leads to ensure good connections and no insulation damage . I-EEDU (02-21) 150492-A...

-

Page 49: Heat Exchanger Cleaning

. Brush up and down within tubes until all soot is removed . Clean outside space between lower portions of heat exchanger tubes to remove any accumulated dust or light deposits using air hose or brush . I-EEDU (02-21) 150492-A... -

Page 50: Venter Maintenance

If 24V is available to ignition controller and all other causes have been eliminated, replace ignition control 8 . Optional lockout device interrupting control Reset lockout by interrupting control at thermostat circuit by above causes 9 . Faulty combustion air proving switch Replace combustion air proving switch I-EEDU (02-21) 150492-A... - Page 51 1 . Improper motor pulley and/or adjustment Check air throughput (refer to Duct Furnace Airflow section) motor cuts 2 . Improper static pressure in the duct system Adjust duct system dampers out on 3 . Low voltage Check power supply overload I-EEDU (02-21) 150492-A...

-

Page 52: Installation Record (To Be Completed By Installer)

If you need additional assistance, contact the Distributor listed above. • For more information, contact your Factory Representative. Specifications and illustrations subject to change without notice or incurring obligations . ©2021 Nortek Global HVAC LLC, O’Fallon, MO . All rights reserved . I-EEDU (02-21) 150492-A...

Need help?

Do you have a question about the EEDU and is the answer not in the manual?

Questions and answers