Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Nibe F2015

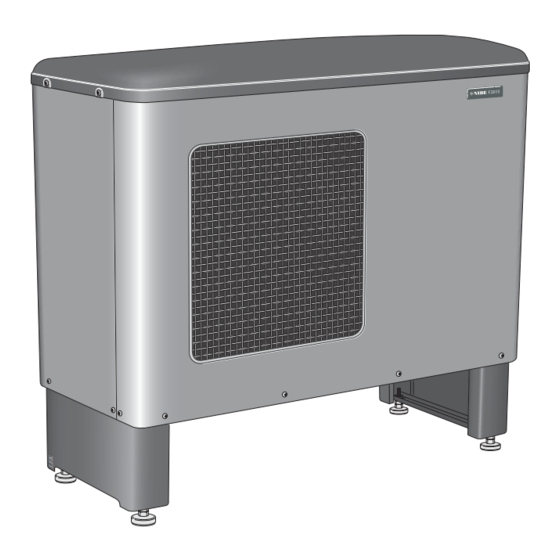

- Page 1 MOS GB 1008-3 INSTALLATION AND MAINTENANCE INSTRUCTIONS F2015 F2015 031239...

-

Page 3: Table Of Contents

F2015 docked to the oil-fired/pellet boiler together with SMO Electrical circuit diagram 10 and water heater (floating condensing) 1x230V 6-11 kW Several F2015 together with SMO 10 and water heater (floating condensing) Technical specifications F2015 docked to an electric/oil boiler (floating condens-... - Page 4 General General In order to get the greatest benefit from your heat pump F2015 you should read through the For Home Owners section in this Installation and Maintenance Instruction. F2015 is a basic heat pump for heating small houses, apartment blocks and small industrial premises. Outdoor air is used as a heat source.

-

Page 5: For Home Owners

Nordic climate. F2015 utilises the outside air so there is no be connected if SMO 10 is present. need for bore holes or coils in the ground. F2015 has an automatic 2-stage capacity control of the fan (does not apply F2015 can both heat hot water effectively at high outdoor to F2015-6 kW, which only has one fan speed). -

Page 6: Maintenance Routines General

Check, dur- ing the cold months of the year, to make sure that there isn't a build up of ice or frost under F2015. The Condensation water trough KVT 10 accessory is available for management and removal of condensation. -

Page 7: For The Installer

F2015 can be adjusted The distance between F2015 and the house wall must be at and read off in SMO 10 . least 350 mm. Clearance in front of F2015 should be at least Fritt utrymme bakom Fritt utrymme Min. -

Page 8: Pipe Connections General

Pipe installation must be carried out in accordance with cur- F2015 -6, 8, 11 rent norms and directives. F2015 operates up to a return temperature of about 50 °C Tryckfall and an outgoing temperature of about 58 °C from the heat... -

Page 9: Docking General

F2015 docked with VVM 300 (fixed condensing) SÄV FIGHTER 2020 VVM 300 F2015 -6, -8 and -11 can be connected to VVM 300. F2015 NOTE is controlled by VVM 300. F2015 works with floating con- densing against the heating system and prioritises hot water To prevent interference, sensor cables and communic- charging in VVM 300. -

Page 10: F2015 Docked To The Oil-Fired/Pellet Boiler Together With Smo 10 And Water Heater (Floating Condensing)

For the Installer Docking F2015 docked to the oil-fired/pellet boiler together with SMO 10 and water heater (floating con- densing) SMO 10 SÄV VXV1 FIGHTER 2020 SMO 10 controls F2015, oil-fired boiler, circulation pumps, shunts, etc. F2015 works with floating condensing against the heating system and prioritises hot water charging via the three way valve (VXV1). -

Page 11: Several F2015 Together With Smo 10 And Water Heater (Floating Condensing)

SÄV FIGHTER 2020 VP1 VXV1 SMO 10 controls up to nine F2015 (of which max one for hot water), immersion heater, circulation pump, shunt, etc. F2015 works with floating condensing against the heating system and prioritises hot water charging via three way valve VXV1. -

Page 12: F2015 Docked To An Electric/Oil Boiler (Floating Condensing)

Sƒ V FIGHTER 2020 RV LP F2015 is controlled by a room thermostat. F2015 works with floating condensing on the return from the heating system. If F2015 cannot meet the heating requirement the additional heat is shunted in using the existing control equipment. -

Page 13: F2015 Docked With Wood Fired Boiler And Hot Water Heater (Fixed Condensing)

For the Installer Docking F2015 docked with wood fired boiler and hot water heater (fixed condensing) Extern alt befintlig regler- utrustning. FIGHTER 2020 SÄV VVB / ACK Vedpanna F2015 charges the water heater/accumulator tank (VVB/ACK). When the firewood boiler is in use, the heat pump and im-... -

Page 14: Electrical Connections

NOTE The live external control must be taken into considera- tion when connecting. Incoming feed cable is supplied and factory connected to terminal block -X1. Approx. 1.8 m cable is accessible outside the heat pump. F2015... -

Page 15: General

“D” (compressor operation). For MCB size see "Technical Specifications". F2015 does not include an omnipolar circuit breaker on the incoming power supply. The heat pump’s supply cable must be connected to a circuit-breaker with at least a 3 mm breaking gap. -

Page 16: Charge Pump

When the charge pump is connected to the terminal block F2015 is equipped with a terminal block for the Condensation X11 (11) terminal 3 and 4 the pump is controlled by F2015. water trough KVT 10 accessory. Max load is 200 W. -

Page 17: Thermostat Control

Termostat 12 – 230V Additional heat / Downtime F2015 is equipped with a potential free contactor intended for additional heat. Max 250V 2A. The setting of the outdoor temperature (balance temperature) when the additional relay is activated is made on channel Hjälpkontaktor... -

Page 18: Commissioning And Adjusting Preparations

-15 °C the flow temperature is limited linearly from -7 °C / 55 °C to -15 °C / 45 °C. Soft-start relay F2015 is equipped with a soft-start relay (97) that limits the inrush current for the compressor. The compressor must not be forced to start with periods shorter than 1 start per 15 minutes. -

Page 19: Start-Up And Inspection

1. Communication cable (44) or thermostat, plinth (30) must not be connected. 2. Turn the isolator switch on. 3. Ensure that the F2015 is connected to the power source. 4. Check that the miniature circuit-breaker (2) is on. 5. The compressor heater (25) must have been operational for at least 6 –... -

Page 20: Adjustment, Charge Flow

ΔT will be 0.5 to 1 degrees lower (does This is easily done by using the temperatures measured in not apply to F2015-6 kW, which only has one fan speed). Channel T2 (flow temperature) less Channel T3 (return tem- 1 flow temperature. - Page 21 For the Installer Commissioning and adjusting F2015-11 Phase current, A ΔT Specified output, kW Phase current Rated output Outdoor temperature Outdoor temperature F2015...

-

Page 22: Control Explanation

Fan: F0 The fan has two speeds, high and low (does not apply to F2015-6 kW which only has one fan speed). The fan is con- Compressor off, circulation pump on trolled by the outdoor temperature. The lower speed is used when the outdoor temperature is too high to limit the output. -

Page 23: Channel Descriptions

STATUS, TEMP. or AD- JUST. are displayed. Status These channels show the status and statistics. Channel Shows the operating status of F2015. Value Normal operation. Defrosting is run. Cold outdoor air temperature. High return temperature. - Page 24 In the event of any defrosting problems, the When connecting to SMO 10 this must be selected so that value in channel A11 can be increased to relieve each F2015 in the system receives a unique address (1 – 9) the problem. for communication with SMO 10.

-

Page 25: Control Conditions, Cold Outdoor Air

The temperature on the flow sensor falls below 4°C. are deactivated. 6. The time counter has counted to 60 minutes. The com- pressor is permitted to start again. utelufttemp. Utelufttemperatur Tip: It is heat pump’s outdoor sensor that applies. F2015... -

Page 26: Sensor Placement

0.56 (BT17) 0.55 0.49 Temperature sensor, hot gas 0.47 0.43 (BT14) 0.41 0.38 Temperature sensor, return 0.36 0.33 (BT3) 0.31 0.29 0.27 0.26 0.24 0.23 0.21 0.20 0.19 0.18 0.17 0.16 0.15 0.15 0.13 0.13 0.12 0.12 0.11 0.11 F2015... -

Page 27: Miscellaneous

Miscellaneous Electrical circuit diagram Electrical circuit diagram 1x230V 6-11 kW F2015... - Page 28 Miscellaneous Electrical circuit diagram F2015...

- Page 29 Miscellaneous Electrical circuit diagram F2015...

- Page 30 Miscellaneous Electrical circuit diagram F2015...

-

Page 31: Technical Specifications Component Positions

Miscellaneous Technical specifications Technical specifications Component positions F2015... - Page 32 Terminal block, additional, downtime Non-return valve Temperature sensor, outdoor air Contactor, compressor Evaporator Connection, heating medium out of F2015, G1 (Ø28 mm) Condenser Connection, heating medium in to F2015, G1 (Ø28 mm) 4-way valve Temperature sensor, evaporator Drip tray heater...

-

Page 33: Sound Pressure Levels

The sound pressure levels are further affected by walls, bricks, differences in ground level, etc and should therefore only be F2015 is usually placed next to a house wall, which gives a seen as guide values. directed sound distribution that should be considered. Ac-... -

Page 34: Dimensions And Setting-Out Coordinates

Miscellaneous Technical specifications Dimensions and setting-out coordinates 1075 1175 1200 Fritt utrymme bakom Fritt utrymme Min. avstånd vid användning av flera F 2025 Fritt utrymme framför F2015... -

Page 35: Technical Specifications

Miscellaneous Technical specifications Technical specifications Type F2015-6 F2015-8 F2015-11 Delivered/supplied power* at 2/35 °C ** (kW) 5.4/1.4 7.1/1.8 9.4/2.6 Delivered/supplied power* at 7/35 °C ** (kW) 6.3/1.4 8.2/1.9 11.1/2.6 Delivered/supplied power* at -7/45 °C ** (kW) 3.7/1.6 5.0/2.1 7.1/2.9 Delivered/supplied power* at 0/45 °C ** (kW) 4.9/1.6... - Page 36 Miscellaneous Technical specifications Working area During shorter time it is allowed to have lower working temperatures on the water side, e.g. during start up. F2015...

-

Page 37: Enclosed Kit

Hot water control Heating thermostat Shuttle valve, Cu-pipe Ø28 Three way valve, DN 32 (11/4”) Part no. 418 801 Max recommended charge power, 15 kW Max recommended charge power, 40 kW Part no. 089 152 Part no. 089 388 F2015... -

Page 38: Dealing With Malfunctions

Miscellaneous Dealing with malfunctions Dealing with malfunctions Checking the status F2015 is not operational Scroll to channel S1 using the plus button to read off the Cause: External control equipment has not given the start signal. status and any alarms. See the section “Control” – “Channel description”. -

Page 39: Draining, Heat Medium Side

(See the section Pipe connections) NOTE As F2015 can be connected to a large number of ex- ternal units, these should also be checked. If the operating disturbance cannot be rectified by means of the above, an installation engineer should be called. - Page 40 F2015...

- Page 41 F2015...

- Page 42 F2015...

- Page 44 Tel: +43 (0)7662 8963-0 Fax: +43 (0)7662 8963-44 E-mail: mail@knv.at www.knv.at NIBE Wärmetechnik AG, Winterthurerstrasse 710, CH-8247 Flurlingen Tel: (52) 647 00 30 Fax: (52) 647 00 31 E-mail: info@nibe.ch www.nibe.ch Druzstevni zavody Drazice s.r.o, Drazice 69, CZ - 294 71 Benatky nad Jizerou Tel: +420 326 373 801 Fax: +420 326 373 803 E-mail: nibe@nibe.cz www.nibe.cz...

Need help?

Do you have a question about the F2015 and is the answer not in the manual?

Questions and answers