Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK WSG 25

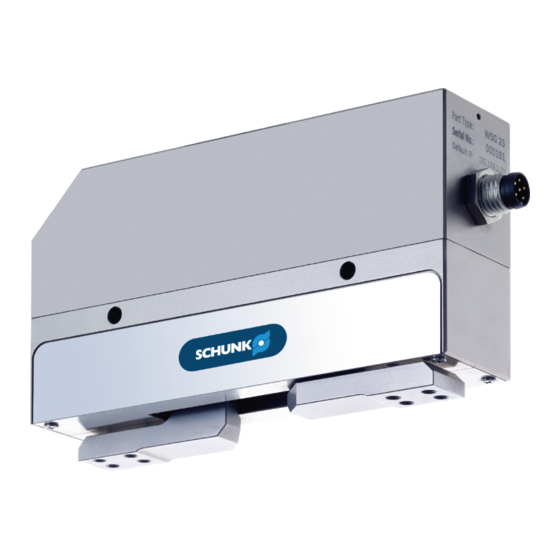

- Page 1 Translation of the original manual Assembly and Operating Manual WSG 25 Servo-electric 2-finger parallel gripper...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

3.3.1 Fuse ...................... 18 Interfaces and connections ................ 19 3.4.1 Power supply and Ethernet .............. 19 Name plate ...................... 20 Design and description.................... 21 Design ......................... 21 Description ...................... 21 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 4 The gripper jaws don't move................ 51 Gripper stops abruptly.................. 51 No connection to the web interface.............. 52 10 Translation of original declaration of incorporation .......... 53 10.1 Annex to Declaration of Incorporation............... 54 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 5: General

Dangers for persons! Non-observance can lead to irreversible injury and even death. CAUTION Dangers for persons! Non-observance can cause minor injuries. NOTICE Material damage! Information about avoiding material damage. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 6: Applicable Documents

The following accessories, which must be ordered separately, are required for the product: • 5 m data and supply cable, M8 socket, 6-pin, straight to RJ-45 and free cable end power supply, for WSG 25 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 7: Basic Safety Notes

• Structural changes should only be made with the written approval of SCHUNK. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 8: Special Standards

• Observe Maintenance intervals, Maintenance and cleaning 50]. • Make sure that the environment is clean and the ambient temperature corresponds to the specifications per the catalog. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 9: Personnel Qualification

• Wear protective gloves and safety goggles when handling hazardous substances. • Wear close-fitting protective clothing and also wear long hair in a hairnet when dealing with moving components. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 10: Notes On Safe Operation

• Do not recommission the product until the malfunction has been rectified. • Test the product after a malfunction to establish whether it still functions properly and no increased risks have arisen. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 11: Disposal

• If the energy supply is connected, do not move any parts by hand. • Do not reach into the open mechanism or movement area of the product during operation. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 12: Notes On Particular Risks

Before starting any work on the product: Switch off the power • supply and secure against restarting. Make sure, that no residual energy remains in the system. • 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 13: Technical Data

Technical data 3 Technical data 3.1 Outer dimensions Base jaws opened Finger side Flange side Outer dimensions 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 14: Nominal Mechanical Data

Ambient temperature [°C] Min. Max. Air humidity [%] non condensing Min. Max. Repeatability [mm] ±0.03 3σ-deviation Gripping speed [mm/s] Min. Max. Finger acceleration [mm/s Min. Max. 5000 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 15 Technical data Determining the clamping height Acceleration 5,000 mm/s² Finger position [mm] Acceleration performance at gripping force 20 N and finger mass 2x22g 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 16: Permitted Finger Load

Depending on stroke and speed of the gripping procedure, the maximum permitted gripping force may exceed the force which is actually achievable. Gripping force [N] Recommended gripping speed (steel on steel, finger length: 40 mm) 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 17 NOTICE Damage to the product is possible! For high gripping forces or long holding cycles, make sure that heat is well dissipated via the screw contact surface. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 18: Nominal Electrical Data

3.3.1 Fuse The product has an integrated fuse to protect against short circuits and incorrect polarity. To have the fuse changed, please contact SCHUNK (Tel. +49 7133-103-2333). 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 19: Interfaces And Connections

Malfunction of the gripper if the cable is manipulated! Changes to the cable may cause malfunction or failure of the gripper. No changes may be made to the cable! • 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 20: Name Plate

3.5 Name plate The name plate is on the narrow side of the product above the connector. It shows the type and the serial number of the product. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 21: Design And Description

TCP/IP. Previous figure shows the connectors and components of the product. The configuration of the product is done via a Web- Interface supporting almost every common web browser. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 22: Assembly

For all work in the vicinity of hot surfaces, wear safety gloves. • Before carrying out any work, make sure that all surfaces have • cooled down to the ambient temperature. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 23: Mechanical Connection

NOTE To ensure fault-free operation and to minimize the radiation of electromagnetic interference (EMC) the product’s housing must be properly earthed. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 24 Assembly closed: 0 open: 64 Finger side Flange side: NOTICE Material damage due to inadmissible tightening torque! Observe the maximum tightening torque: – Screw M3: 0.8 Nm 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 25: Installation Of The Fingers

Pin Ø2 mm Base jaws Installation of the fingers NOTICE Material damage due to inadmissible tightening torque! Observe the maximum tightening torque: – Screw M3: 1.0 Nm 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 26: Start-Up

• To directly operate the product on your computer’s network connection, you may have to alter your computer’s network configuration. If in doubt, contact your system administrator. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 27 The starting page of the web-based interface From the menu, select the Motion -> Manual Control option and Ø click on the “Home“ button The product will now zero itself. ✓ 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

- Page 28 On the Settings -> System page, create a user with Ø corresponding rights and activate the web interface’s security function, to prevent changes to your setting by unauthorized persons. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 29: Changing The Ip Address And Using Dhcp

This is why the DHCP server should be config-ured so that the product is issued with an IP address which is known in advance For further information, please contact your network administrator. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 30: Operation

If there is an error, the indicator will light up red for 5 seconds. After that the boot loader will automatically be restarted. This will continue until firmware can be loaded correctly. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 31: Display Of Operating State

The product is ready for operation and waiting for a command. Busy White, quickly pulsating The product is in the initialization phase or is executing a command. Not available Green, quickly pulsating 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 32 A serious exception error has occurred and the execution of the software in the device has been stopped. The product starts again after a short period of time. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 33: Status Word And Gripper State

The documentation for the status word can be found in the manual "WSG command set reference". Gripping state Fast-Stop System state Web interface: side bar with system status 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 34: Gripper State

An error occurred carrying out the last command. For errors which require acknowledgment, the SF_FAST_STOP flag is also set in the system status word. After any acknowledgment required, the movement can be restarted. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 35 Transitions between the gripping states Stop command: Issuing a Stop command in any state (except ERROR) will abort the current action and immediately return to IDLE state. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 36: Homing The Product

• To automatically reference the product on startup, activate the "Homing on Startup" option via the web interface (menu item Settings -> Motion Configuration). 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 37: Gripping, Detecting Parts To Be Gripped And Monitoring The Gripping

"NO PART FOUND". If a contact is detected outside of the defined range, this will be detected as an axis block and the gripper's state will change to "ERROR". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 38 • Setting the part width tolerance to the full range of movement of the product (maximum settings) will deactivate the detection of axis blocking when gripping. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 39: Software Limit Switch

MINUS software limit switch PLUS Software limit switch 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 40 • Further information on this topic can be found in the manual "WSG command set reference". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 41: Fast Stops Requiring Acknowledgment

• A fast stop can also be triggered via the command interface or manually via the web interface. • Further information on this topic can be found in the manual "WSG command set reference". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 42: Log Memory

• The command to read out the current housing temperature and the command to acknowledge the Fast Stop via the command interface are documented in the "WSG Command Set Reference Manual". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 43: Monitoring The Motor Current

• This error can only be acknowledged if there is no longer a current error. • For the documentation of the command to acknowledge the "Fast Stop" via the command inter-face, see the "WSG Command Set Reference Manual". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 44: Monitoring The Supply Voltage

• Futher information of the system status word and of the command to acknowledge the "Fast Stop" via the command interface, see the "WSG Command Set Reference Manual". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 45: Configuration And Diagnosis Via The Web Interface

• Mobile Safari (iOS 4.3 and above) • Internet Explorer 8 and above NOTE To display the web user interface, JavaScript must be enabled in your browser. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 46 Via integrated help texts, the product’s web interface is intuitive to use. In the upper area you will find a menu bar via which the individual pages can be called up. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 47: Access Restrictions For The Web User Interface

Administrator: Can adjust all of the product’s settings without restriction. NOTE If access restrictions have been activated, then the product will record which user logs in and when. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 48: Command Interface

The gripper state changes to "GRIPPING". Wait until the gripper state is "HOLDING". Deal with errors if gripper state is "NO PART FOUND" or "ERROR". 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 49 In the case of long-term short travel, it is possible to dry the product. Every 1000 movements or at least once per day the product • should be moved through its full range of travel. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

-

Page 50: Maintenance And Cleaning

In the case of long-term short travel, it is possible to dry the product. Every 1000 movements or at least once per day the product • should be moved through its full range of travel. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 51: Troubleshooting

Acknowledge the fast stop, Fast stops requiring acknowledgment Error message in the system Check operating state of the product. (the operating state indicators of the product illuminate yellow or red) 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 52: No Connection To The Web Interface

Supply voltage is not Check the power supply. connected. Communication not possible. Check the connections and communications cables. Check network settings on the product. Check network settings on the computer. 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 53: Translation Of Original Declaration Of Incorporation

Person authorized to compile the technical documentation: Robert Leuthner, Address: see manufacturer's address Lauffen/Neckar, June 2019 p.p. Ralf Winkler, Manager for development of gripping system components 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... -

Page 54: Annex To Declaration Of Incorporation

Risks due to falling or ejected objects 1.3.4 Risks due to surfaces, edges or angles 1.3.5 Risks related to combined machinery 1.3.6 Risks related to variations in operating conditions 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684... - Page 55 1.5.16 Lightning Maintenance 1.6.1 Machinery maintenance 1.6.2 Access to operating positions and servicing points 1.6.3 Isolation of energy sources 1.6.4 Operator intervention 1.6.5 Cleaning of internal parts 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

- Page 56 Supplementary essential health and safety requirements for machinery intended for underground work Supplementary essential health and safety requirements for machinery presenting particular hazards due to the lifting of persons 05.00 | WSG 25 | Assembly and Operating Manual | en | 389684...

Need help?

Do you have a question about the WSG 25 and is the answer not in the manual?

Questions and answers