Table of Contents

Advertisement

Quick Links

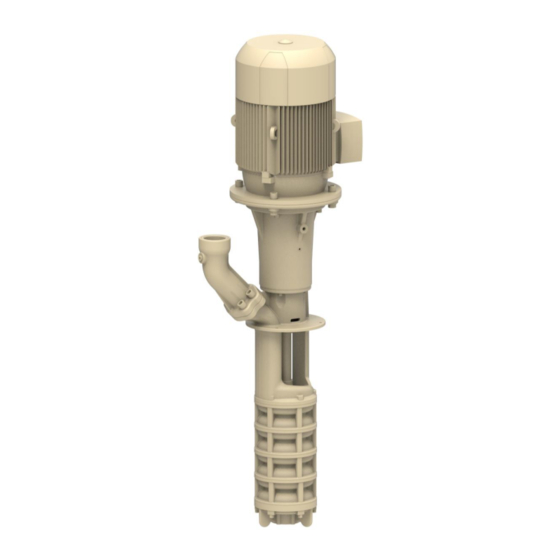

BAS6502

BRINKMANN Immersion Pumps

BRINKMANN PUMPS, Inc.

47060 Cartier Drive

Wixom, MI 48393

USA

Phone: +1 248 926 9400

Fax.:

+1 248 926 9405

Subject to change without prior notice.

© Brinkmann Pumps, Inc.

Operating Instructions

Edition

STA/SAL1005...1006

www.brinkmannpumps.com

sales@brinkmannpumps.com

Order - No.: BAS6502 ENGLISH

04/2020

Page 1 of 11

Advertisement

Table of Contents

Summary of Contents for Brinkmann STA1005

- Page 1 BRINKMANN PUMPS, Inc. 47060 Cartier Drive Wixom, MI 48393 Phone: +1 248 926 9400 www.brinkmannpumps.com Fax.: +1 248 926 9405 sales@brinkmannpumps.com Subject to change without prior notice. Order - No.: BAS6502 ENGLISH © Brinkmann Pumps, Inc. 04/2020 Page 1 of 11 Edition...

-

Page 2: Table Of Contents

Brinkmann Immersions Pumps of the Series STA/SAL1005 ... 1006 Contents Indication to the manual ........2 8 Servicing and Maintenance ....... 7 Description of the Product ......2-3 9 Troubleshooting Guide ........7 Safety instructions .......... 3-4 10 Spare Parts ............8 Transportation and Storage ....... -

Page 3: Safety Instructions

Height Depth of Weight Power Noise level pressure del. volume immersion spec. weight 1 Inches dBA / 60 Type Type l/min Inches STA1005/ 530 10.8 1450 36.0 20.87 23.0 24.80 17.3 29.92 34.65 STA1006S 610 SAL1006S 630 12.5 1450 38.3 24.02... -

Page 4: Transportation And Storage

Safety instructions relevant for operation 4 Transportation and Storage • If hot or cold machine components involve hazards, Protect the pump against damage when transporting. The pumps may only be transported in a horizontal po- they must be guarded against accidental contact. sition and hooks or straps must be attached on the mo- •... -

Page 5: Installation And Connection

5 Installation and Connection Mechanical installation During any assembly or disassembly process the pumps must be secured against tipping trough ropes The pump must be mounted in that way that rotat- for example at all times. ing parts under the cover of the coolant tank can Pumps must be mounted securely. -

Page 6: Start-Up / Shut-Down

Circuit on request the mounting flange, also ensure that the minimal liquid level for the STA pump is 2.36 Inches (60 mm) before ∆ (Star connection) (Delta connection) starting up the motor, for the SAL pump the suction up to 7.4 HP 8, 8.7, 10.1, 12.1, 14.7, 17.4 HP hole of the pump body must be covered with liquid. -

Page 7: Servicing And Maintenance

8 Servicing and Maintenance ATTENTION bearing play) and does not require any special mainte- The surface of the motor must be kept free of dirt. nance. The motor shaft is spinning in permanently greased ball bearings (with special grease and increased 9 Troubleshooting Guide Fault Cause... -

Page 8: Spare Parts

10 Spare Parts 10.1 Spare Part List for the Immersion umps of the Series STA/SAL1005 ... 1006 Item Description Motor Bearing housing Woodruff key DIN 6888 Bearing shaft Ball bearing DIN 628 Socket head cap screw DIN 912 Bearing cover Coupling 10 Nilos-ring 11 Threaded pin... -

Page 9: Repair

1. Pumptype – Set the pump down on the bearing housing. e.g. STA1005/630 – Position the shaft clamp (1) (use a new shaft clamp) 2. Pump No. in the centre of the cranked clamping diameter (2) e.g. -

Page 10: Terms And Conditions

Brinkmann to inspect, at any rea- of any such occurrence of malfunction. At pacity, and capability of products, all of sonable time, said part and the machine in Brinkmann‘s request made at any time,... - Page 11 Brinkmann shall be kept ment. Any specifications contained therein in confidence and shall be listed and main-...

Need help?

Do you have a question about the STA1005 and is the answer not in the manual?

Questions and answers