Sumitomo Bevel BUDDYBOX 4 Series Maintenance Manual

Hide thumbs

Also See for Bevel BUDDYBOX 4 Series:

- Maintenance manual (48 pages) ,

- Operating manual (60 pages)

Table of Contents

Advertisement

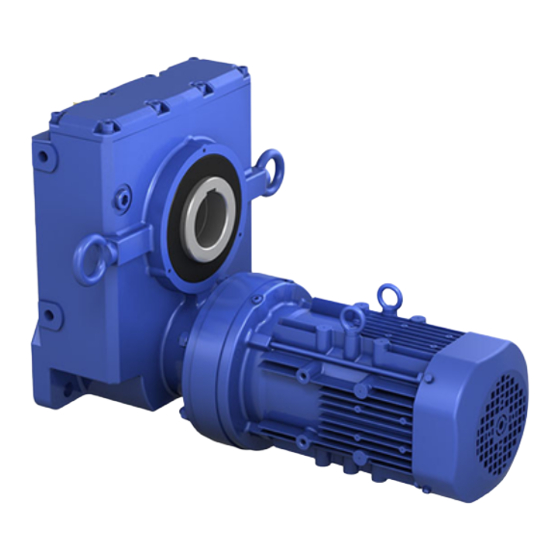

BUDDYBOX®

Bevel BUDDYBOX® 4 Series

Bevel BUDDYBOX® 5 Series

Helical BUDDYBOX®

Application Product

《CAUTION》

■ These Products should be handled, installed and maintained by trained technicians.

Carefully read the maintenance manual before use.

■ A copy of this maintenance manual should be sent to the actual user.

■ This maintenance manual should be kept by the user for future reference.

BUDDYBOX® with Torque Limiter

Maintenance Manual

No. CM2020E-3

Advertisement

Chapters

Table of Contents

Summary of Contents for Sumitomo Bevel BUDDYBOX 4 Series

- Page 1 BUDDYBOX® Bevel BUDDYBOX® 4 Series Bevel BUDDYBOX® 5 Series Helical BUDDYBOX® Application Product BUDDYBOX® with Torque Limiter 《CAUTION》 ■ These Products should be handled, installed and maintained by trained technicians. Carefully read the maintenance manual before use. ■ A copy of this maintenance manual should be sent to the actual user. ■...

-

Page 2: Introduction: Safety Precautions

Introduction: Safety Precautions - Carefully read this maintenance manual and all accompanying documents before use (installation, operation, maintenance, inspection, etc.). Thoroughly understand the machine, information about safety, and all precautions for correct operation. After reading, retain this manual for future reference. - Pay close attention to the "DANGER"... -

Page 3: Table Of Contents

Introduction: Reading the Maintenance Manual, Table of Contents This maintenance manual is common for “gearmotors”, “reducers” and “the application products BUDDYBOX with Torque Limiter”. The symbols shown below appear in the upper right or left corner of each page to indicate the classification. Please read the applicable pages. -

Page 4: Inspection Upon Delivery

1. Inspection upon Delivery Common CAUTION ● Make sure that the unit is positioned right side up before unpacking. Otherwise, injury may occur. ● Make sure that the unit agrees with your order. Injury or damage to the equipment may occur by using the incorrect product. ●... - Page 5 1. Inspection upon Delivery Common 1-3 Inspection of Nomenclature of Gearmotor or Reducer Nomenclature shows following information. Make sure it agrees with your order. Model Nominal reduction ratio Bevel Buddybox Brake Helical Buddybox With brake Blank Without brake Output shaft direction H Horizontal Mounting position Vertical...

- Page 6 1. Inspection upon Delivery Common Symbol of mounting position / Position of terminal-box / Position of oil filler and draiin / Rotation direction of output shaft (Bevel BUDDYBOX) Oil ller plug Oil level (Oli gauge) Oil drain plug Table 1-a LH□M-□-□1 LH□M-□-□2 LH□M-□-□3...

- Page 7 1. Inspection upon Delivery Common Symbol of mounting position / Position of terminal-box / Position of oil filler and draiin / Rotation direction of output shaft (Helical BUDDYBOX) Oil ller plug Oil level (Oli gauge) Oil drain plug Table 2 EH□M-□-□1 EH□M-□-□2 A~...

- Page 8 1. Inspection upon Delivery 1-4 Motor Nomenclature Nomenclature shows following information. Make sure it agrees with your order. • Refer to related manual for units with servo motor or DC motor. Mounting method Standards • Regulations With Foot Premium efficiency motor Blank Flange type IEC Efficiency Standards Blank Other types of motors...

-

Page 9: Storage

2. Storage Common Note the following on storing gearmotor or reducer, when not using the unit right away. 2-1 Storage location Store the unit indoors in a clean dry place. • Avoid storage outdoors or in places with humidity, dust, sudden temperature changes or corrosive gas. 2-2 Storage period 1. -

Page 10: Installation

4. Installation Common DANGER ● Use explosion-protection type motor in explosive environment. Do not use the standard unit in explosive environment. Otherwise, it may cause explosion, ignition, electric shock, injury, fire, or damage to the equipment. explosion-protection motor ● Use the sufficient motor for matching the hazardous location (where explosive gas or steam exists). -

Page 11: Coupling With Other Machines

5. Coupling with Other Machines Common CAUTION ● Make sure of the rotation direction of the application machine before coupling. Difference in rotation direction may cause injury or damage to the equipment. ● Remove the temporary key on the output shaft when operating the gearmotor or reducer unit alone. Otherwise, it may cause injury. - Page 12 5. Coupling with Other Machines Common 5-2 Installation of coupling • Do not apply shock or excess axial load to the shaft when attaching the coupling. It may cause bearing damage or collar may fall off. • We recommend attachment by shrink fitting. (1) When Using Coupling Adjust the dimensions in Fig.

- Page 13 5. Coupling with Other Machines Common 5-3 Coupling hollow shaft type with other machines (1) Attachment and Removal of Hollow shaft and Driven Shaft (a) Attachment to Driven Shaft Apply molybdenum disulfide grease to the surface of driven shaft and inner diameter of hollow shaft. Insert the gearmotor or reducer to driven shaft.

- Page 14 5. Coupling with Other Machines Common (2) How to attach of torque arm (option) ● Attention of attachment 1 Attach torque arm to the application machine side of the reducer. 2 Attach retainer parts of torque arm (refer Fig.11) to release extra force between the reducer and the driven shaft. (Retainer is to be supplied by customer.) 3 Never lock the torque arm completely with locking bolts and such.

- Page 15 5. Coupling with Other Machines Common (3) Attachment of shock absorbing material (option) ● How to attach with spring washers • The spring washers that our supply are equivalent to DIN 2093 standardized. • Use the volts that have more than 10.9 for JIS strength class. •...

- Page 16 5. Coupling with Other Machines Common Fixing to Driven Shaft: Always engage the gearmotor with driven shaft when stopping the whirl by attachment method or tie- rod method. Fixing Example to Prevent Gearmotor Moving to the Machine side (Overhead view of EHYM3-A6105) Bearing Spacer Set screw...

- Page 17 5. Coupling with Other Machines Common 5-4 When Using Shrink Disk (Option) 5-4-1 Installing the Shrink Disk • With grease applied to the squeezing surface (before tightening of the boss), the shrink disk is shipped with the reducer, once you receive it, you can assemble it immediately.

- Page 18 5. Coupling with Other Machines Common 5-5 When Using Taper Grip for Hollow Shaft Type 5-5-1 Attachment Procedure of Taper Grip 1. Shaft Preparation Before Attaching the Machine 1-1) Remove all rusts and irregularity (especially protrusion) from the shaft. 1-2) Recommended tolerance of the shaft is "h8" 1-3) Wipe off all dusts and oil with a piece of cloth or alcohols solvent and such.

- Page 19 5. Coupling with Other Machines Common 4. Additional tightening after operation. Check the tightening torque 20-30 hours after operation. Tighten again with designated tightening torque when they seem to be loose. Make sure to check the tightening torque in regularly, such as once every half year. Table 4-1 Bevel BUDDYBOX Tighten Bolt Tighten Torque...

-

Page 20: Wiring

6. Wiring standard three-phase motor made by Sumitomo Drive Technologies • Directions on this manual are for use with motor with brake motor made by other companies Use the related motor manual when using DANGER ● Do not work on the unit with live wire. Always turn off the power before working on the unit. Otherwise, electric shock may occur. - Page 21 6. Wiring 6-2 Measurement of insulation resistance • Always cut off the connection with control board when measuring the insulation resistance for motor. Motor resistance must be measured independently. Measure the insulation resistance before wiring. Insulation resistance (R) varies by the effect of: Motor output, voltage, type of insulation, coil temperature, humidity, dirt, period of operation, loading duration during test, etc.

- Page 22 6. Wiring 6-4 Motor connection Fig.25 shows the motor connection and the standard specification for terminal codes. Fig.25 Motor connection and terminal code 3 lead wires 6 lead wires (direct on-line starting) Motor Motor ‒Δ 6 lead wires ( starting) 4/8P two speed, single wound rotor (constant torque) When at low At start...

-

Page 23: Operation

7. Operation Common DANGER ● Do not go close to or touch the rotating parts (such as output shaft). It may cause injury by getting caught and may result in serious injury or death. ● Turn off the power switch when blackout occurs. Unexpected start may cause electric shock, injury, or damage to the equipment. ●... -

Page 24: Daily Inspection And Maintenance

8. Daily inspection and Maintenance Common DANGER ● Do not handle the unit when cables are live. Be sure to turn off the power; otherwise, electric shock may result. ● Do not touch the rotating parts (such as output shaft) on inspection while operating the machine. It may cause injury by getting caught in the rotating part. - Page 25 8. Daily inspection and Maintenance Common 8-2 Lubrication Method • Always conduct maintenance following related instructions. Incorrect maintenance may cause troubles. (1) Refer to Table 8 for method of gear lubrication for you model. (2) Table 9 shows location of information for maintenance method for each lubrication type in this manual. (3) Bevel BUDDYBOX with Torque Limiter may be unable be referred to below table, so please refer to Page 47.

- Page 26 8. Daily inspection and Maintenance Common Gear Part with Oil Lubrication 8-3 Oil Supply and Change for (1) Interval Oil Change Table 10 Oil Change Interval Task Change interval Conditions of use Supply of oil At purchase common First Change 500 hrs operation or 6 months, whichever comes first.

- Page 27 8. Daily inspection and Maintenance Common (3) Amount of Oil Supply • Table 13 and 14 shows approximate amount of oil. • Always check the level of oil surface through oil gauge for Bevel BUDDYBOX or overflow plug for helical BUDDYBOX. •...

- Page 28 8. Daily inspection and Maintenance Common Table 13-b Approximate Amount of Oil Supply for Bevel BUDDYBOX (4 series) [L] Single Stage Type Output side: Bevel-gear, Input side: CYCLO Drive G: Grease lubrication (Refer to table 20 on page 30 for amount of grease when refilling.) Attachment direction Frame size Y4,F4,G4,K4,W4...

- Page 29 8. Daily inspection and Maintenance Common Table 14 Approximate Amount of Oil Supply for Helical BUDDYBOX [L] Single Stage Type Output side: Helical-gear, Input side: CYCLO Drive G: Grease lubrication (Refer to Table 21 on page 31 for amount of grease when refilling.) Output side Z609 □...

- Page 30 8. Daily inspection and Maintenance Common (4) Oil supply and discharge Bevel BUDDYBOX 5 & 4 Series (Except Y2, F2, G2, K2, V2, W2) ● Oil supply 1 Remove the air-vent plug on oil supply port. 2 Supply oil on the oil supply port while checking the level of oil surface through the oil level gauge. 3 Make sure that the level of oil surface is at the middle of oil level gauge after it has settled.

- Page 31 8. Daily inspection and Maintenance Common Helical BUDDYBOX ● Oil supply 1 Remove the air-vent plug on oil supply port. (Suppling oil on 2 ports will need by some models.) 2 Supply oil on the oil supply port while checking the level of oil surface through the oil level gauge. 3 Make sure that the level of oil surface is at the middle of oil level gauge after it has settled.

- Page 32 8. Daily inspection and Maintenance Common (5) Long-term stoppage Table 15 Long-term stoppage Approx. 1 month Change the oil and operate the unit for several minutes before stopping the unit. Stoppage Flush the unit, supply rust-preventive oil, and operate the unit without a load for several minutes before period More than 1 month stopping the unit.

- Page 33 8. Daily inspection and Maintenance Common (2) Recommended grease Table 19 Recommended grease Ambient Model Mounting position Frame size Type Manufacturer Description temperature 4A10 □ , 4A11 □ , 4A12 □ Long-life Grease NIPPECO BEN10-No.2 4B12 □ 4A14 □ Bevel 4B14 □...

- Page 34 8. Daily inspection and Maintenance Common Table 21 Approximate Amount of Grease Supply for Helical BUDDYBOX [g] Single Stage Type Double Stage Type Mounting Direction Mounting Direction Size Y1,Y2,Y3,Y4 Y5,Y6 Size All of Direction Input Side Input Side Input Side Z609 Z609DA □...

-

Page 35: Troubleshooting

9. Troubleshooting Common Whenever abnormality occurs in gearmotors or reducers, take sufficient measure immediately referring to Table 22 and 23. Consult our nearest distributor or sales office when the unit does not recover after taking the measure. Table 22 Troubleshooting Problem Possible cause Measure... - Page 36 9. Troubleshooting Common Table 23 Troubleshooting Problem Possible cause Correction Sudden acceleration/deceleration Make the acceleration/deceleration time longer. Shut-off due to overcurrent Sudden change in load Decrease the load change. Grounding overcurrent Grounding on the output side Make correction to eliminate grounding. Make correction to eliminatge short-circuiting.

- Page 37 10. Construction Drawing Common 10-1 Construction Drawing of Gear part Fig.28 LHYM1-5Z115-Y1 (5 Series) Fig.29 LHY-5Z115-Y1 (5 Series) Table 24 Main parts of Bevel Buddybox gears (5 Series) Part name Part name Part name Casing End plate Pin carrier pin Gear Hexagon socket head bolt Ring gear housing...

- Page 38 10. Construction Drawing Common Fig. 30 LHYM3-4C145 (4 series) Fig. 31 LHY-4C145 (4 series) Table 24 Main parts of Bevel Buddybox gears Part name Part name Part name Part name Casing Hexagon socket head plug (brimmed) Pin carrier pin High speed shaft Gear Hexagon socket head bolt Ring gear housing...

- Page 39 10. Construction Drawing Common Fig. 32 EHYM3-C6145 Fig. 33 EHY-C6145 Table 26 Main parts of Helical Buddybox gears Part name Part name Part name Part name Casing Hexagon socket head plug Pin carrier pin High speed shaft B bearing Bush Pinion shaft B bearing Ring gear housing Oil seal...

- Page 40 10. Construction Drawing Common 10-2 Construction Drawing of Motor part (for direct coupling with CYCLO drive) Fig. 34 Construction Example of Frame Size 80-112M Fig. 35 Construction Example of Frame Size 180 and Longer Table 27 Main parts of motor Part name Part name Part name...

-

Page 41: Application Product Buddybox With Torque Limiter

BUDDYBOX with Torque Limiter Application Product Application Product BUDDYBOX® with Torque Limiter This manual covers the torque limiter unit. For information on handling the reducer unit and the motor unit see P1 – 39. Contents 11. Wiring ……………………………………………………………………………………………………………… 42 12. Adjusting Preset Torque …………………………………………………………………………………………... -

Page 42: Wiring

11. Wiring Application BUDDYBOX with Torque Limiter Product DANGER ● Do not handle the unit when cables are live. Be sure to turn off the power when performing operations on the unit; otherwise, electric shock may result. ● Connect a power cable to the unit in accordance with the maintenance manual; otherwise, electric shock or fire may result. ●... - Page 43 11. Wiring Application BUDDYBOX with Torque Limiter Product (3) Limit Switch Specifications Table 28 Model Products of OMRON Corporation. Rotation Direction Right or Left Reversible Direction Signal Main motor OFF Z−15GQ22−B (1 piece) Submotor or alarm ON Z−15GQ−B (1 piece) Z−15GQ−B (2 pieces) Auxiliary signal Z−15GQ−B (1 piece) Please consult with us.

-

Page 44: Adjusting Preset Torque

12. Adjusting Preset Torque Application BUDDYBOX with Torque Limiter Product CAUTION ● Increasing the preset torque will cause the torque limiter to function at a torque value that exceeds the initial setpoint. Damage to the machine may occur. 12-1 Adjusting Preset Torque for the Spring-Loaded Limit Switch Model •... -

Page 45: Daily Inspection And Maintenance

13. Daily Inspection and Maintenance Application BUDDYBOX with Torque Limiter Product 13-1 Torque Limiter, Daily Check Open the switch box and check every time that oil is replenished or changed. (1) Limit Switch • Use a tester to see if the limit switch activates normally. •... - Page 46 40~60 5C16DA 5C16DA 20~30 5C16DB 5C16DB 40~60 Table 32 Bevel BUDDYBOX 4 Series with Torque Limiter Approximate amount of oil Supply Approximate amount of grease supply Mounting position Mounting position Frame size Y2, F2, G2, K2, V2, W2 Y4, F4, G4, K4, W4...

-

Page 47: Torque Indicator

14. Torque Indicator Application BUDDYBOX with Torque Limiter Product 14-1 Torque Indicator (1) Checking the Torque Indicator • The torque indicator is zero adjusted, and the preset torque is adjusted before shipment. After the reducer has been connected to equipment, if zero is not indicated when the reducer is at rest, it is possible that a small load is already being applied to the output shaft. -

Page 48: Construction Drawings

15. Construction Drawings Application BUDDYBOX with Torque Limiter Product 15-1 Construction Drawings Cross-section B-B Output side Input side Fig.43 Single stage type bevel-gear or helical-gear + Double stage type CYCLO Drive... - Page 49 15. Construction Drawings Application BUDDYBOX with Torque Limiter Product Table 33 Torque Limiter Principal Parts PRESET Part Name Fixed ring gear housing Ring gear housing N·m Intermediate cover Internal cover Intermediate cover Motor flange bracket Viewed from C Dog bar Bushing Spring 23 26 40...

- Page 50 15. Construction Drawings Application BUDDYBOX with Torque Limiter Product 15-2 Torque Indicator Construction Drawings For type B torque indicator For type A torque indicator 9 10 11 12 1 0 0 1 0 0 Viewed from B 33 34 35 36 37 41 38 67 68 Input side Output side Viewed from C...

- Page 51 16. Warranty Common The scope of our product warranty is limited to our manufacturing range. Warranty (period and contents) Warranty The product warranty period is 18 months after delivery, 18 months after shipment of the product from the seller, or 12 months from product commissioning, whichever is first. Period In the event that any problem or damage to the product arises during the “Warranty Period”...

- Page 52 SM-Cyclo Italy Srl (SMIT) Sumitomo Industrias Pesadas do Brasil Ltda. (SHIB) Via dell' Artigianato 23, 20010 Cornaredo (MI), Italy Sumitomo (SHI) Cyclo Drive Asia Paci c Pte. Ltd. Philippines Branch O ce (SMPH) Rodovia do Acucar (SP-075) Km 26 TEL (39)293-481101...

Need help?

Do you have a question about the Bevel BUDDYBOX 4 Series and is the answer not in the manual?

Questions and answers