Summary of Contents for Sumitomo Cyclo BBB5

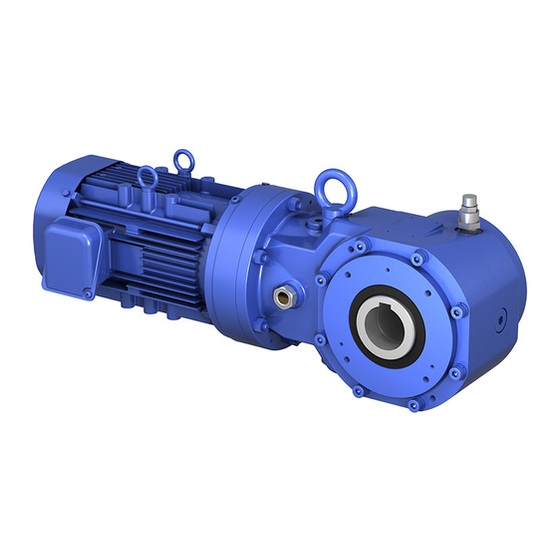

- Page 1 Cyclo® BBB5 Bevel Buddybox® Right Angle Spiral Bevel Speed Reducer with Cyclo® or Planetary Input Operation and Maintenance Manual 13.605.60.006 BBB5 O&M 2019...

-

Page 2: Table Of Contents

Cyclo® BBB5 Table of Contents Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Parts . -

Page 3: Important Notes

• rights to make a warranty claim. Read this manual and all accompanying documents thoroughly before use . Understand the machine, information on safety, and all precautions for correct operation . Sumitomo recommends that this manual is easily accessible for reference at the machine location . -

Page 4: Delivery

. Do not install or operate a damaged unit . • all bolts and nuts are fully tightened. Please consult a Sumitomo representative, distributor, or sales office if any defects are found or if there any questions . Nameplate Inspection When contacting Sumitomo’s agent, distributor, or sales office... -

Page 5: Nomenclature

Cyclo® BBB5 Nomenclature Nomenclature The nomenclature details specific information about Sumitomo products . Verify that the nomenclature of the unit delivered matches the order . Mounting Style Output Shaft Orientation Type Prefix Type Prefix Flange (Hollow Shaft) Horizontal Housing Mount (Hollow Shaft) - Page 6 Cyclo® BBB5 Nomenclature continued Nominal and Exact Ratio Gearmotor Specification Reducer Specification Type Suffix Specification Suffix BBB with Planetary Input BBB with Cyclo Input Standard Nominal Nominal Three-Phase Motor BBB Frame Exact BBB Frame Exact Input Overall Input Overall Shovel Base Single-Phase Motor Size Ratio...

-

Page 7: Storage Location

(and on motor if supplied) when moving Sumitomo . the unit . After securing the unit to the machine, • Consult Sumitomo when storing the unit for more than 3 remove the moving hooks/straps from the eyebolts . months . Rustproofing procedures are required . -

Page 8: Installation Notes

• Do not place combustible material on or around the Consult a local distributor, Original Equipment Manufacturer or Sumitomo directly if the mounting angle is to be other than unit; fire may occur . • Do not place any objects around the unit that will horizontal or vertical . -

Page 9: Installation Onto Driven Shaft

. If the fit is tight, use a jig such as the one shown in Table 1 to ease assembly . Sumitomo does not supply a mounting jig . This information is provided for reference only . - Page 10 Retaining Ring a Shrink Disc Type Mounting Introduction The keyless Shrink Disc provides a reliable commodity shaft attachment for Sumitomo speed reducers and gearmotors . This system allows bi-directional shaft rotation operation with a powerful, slip-free grip . To assure peak performance of equipment, please read, understand and follow these installation instructions .

-

Page 11: Shrink Disc Type Hollow Bore

If the fit is tight, use a jig such as the one shown in the Keyed Hollow Bore Installation section, to ease assembly . Sumitomo does not supply a mounting jig . This information is provided for reference only . -

Page 12: Torque Arm Installation

. Turnbuckle or tie-rod type shown below for reference: Figure 1 . Turnbuckle or Tie-Rod Type Schematics Sumitomo Supplied Components of Flange Mount (Banjo) Type Torque Arm Table 3 . Torque Arm Components... -

Page 13: Flange Mount (Banjo) Type Torque Arm

Cyclo® BBB5 Torque Arm Installation Flange Mount (Banjo) Torque Arm Place washer and rubber bushing on bolt . Torque Arm Bolt (Customer Rubber Insert torque arm bolt (supplied by customer) through mounting tab on Flange Supplied) Bushing When installed, Mount (Banjo) type torque arm . Washer bolt must be parallel to this... -

Page 14: Removal From Driven Shaft

If shaft removal is difficult, a jig such as the one shown in Table 6 may be used to ease the removal process . Sumitomo does not supply the removal jig . This information is supplied for reference only . -

Page 15: Removal Of Cyclo® Bbb5 With Shrink Disc

If shaft removal is difficult, a jig such as the one shown in the Keyed Hollow Bore section may be used to ease the removal process: Sumitomo does not supply the removal jig . This information is supplied for reference only . -

Page 16: Lubrication

Lubrication Introduction, Lubrication Nomenclature Lubrication Introduction Sumitomo Cyclo® BBB5s are shipped from the factory without lubricating oil, unless the customer specified otherwise when the unit was ordered . The unit must contain the correct type and amount of lubrication before operating . -

Page 17: Lubrication Method

Cyclo® BBB5 Lubrication, continued Lubrication Method Lubrication Method Using the model number and mounting configuration, refer to Tables 7 and 8 to determine the unit’s lubrication method . Table 7. Lubrication Method for Configurations Y1, Y2, Y3, Y5, Y6 Unit Size Mounting Configuration Lubrication Method Bevel... -

Page 18: Recommended Lubricants

/s) max. ® Buddybox • Consult local distributor, nearest authorized agent or Sumitomo directly when the unit will be operated in ambient temperatures other than 14° – 104°F (-10° – 40°C). Special unit modifications may be necessary. Cyclo® Portion Approved Greases Table 11, Cyclo®... -

Page 19: Oil Quantities

Cyclo® BBB5 Lubrication, continued Oil Quantities Oil Quantities Table 12 . Single Reduction Approximate Oil Quantity Units: U .S . liquid gallon (liter) Note: Output = Bevel Gear Portion Input = Cyclo® Mounting Configuration Bevel Gear Unit Size Output Input 5Z10 0 .21 (0.80) 0 .42 (1.58) - Page 20 N o t e : U n i t s s u p p l i e d w i t h M o b i l S H C G e a r H i - S h o c k 1 5 0 m a y d o u b l e t h e o i l c h a n g e i n t e r v a l s .

-

Page 21: Grease Quantities

Cyclo® BBB5 Lubrication, continued Grease Quantities Grease Quantities • Grease quantities listed in this section are for the Cyclo® portion of the reducer/gearmotor. • The Bevel Gear portion is always oil lubricated unless otherwise specified at time of order entry. •... -

Page 22: Grease Replenishment And Draining Procedures

Cyclo® BBB5 Lubrication, continued Grease Replenishment and Draining Procedures, Grease Replacement Grease Replenishment and Draining Procedure Procedure for adding grease to grease-lubrication models (excluding maintenance-free models) 1 . Remove the grease discharge plug from the outside cover . 2 . Add grease with a grease gun from the grease nipple in the inside cover section or motor connection cover . 3 . -

Page 23: Y2 Oil Fill & Drain Procedures

• Use the appropriate grade of lubricating oil based on ambient operating conditions of the application. • Refer to the Sumitomo product catalog and/or Operating & Maintenance manual for a list of Sumitomo approved lubricating oils. • Prior to beginning the fill process, ensure the Unit Drain Plug is in place and adequately tightened. - Page 24 Cyclo® BBB5 Y2 Oil Fill & Drain Procedures, continued Oil Fill Process Air breather Carefully remove the unit Air Breather assembly and put aside for reinsertion after oil fill process is complete . Slowly fill the Cyclo® (input) portion with the correct type and grade of oil as used in STEP #2 of this process .

- Page 25 Cyclo® BBB5 Y2 Oil Fill & Drain Procedures, continued Oil Drain Process Oil Drain Process CAUTIONARY NOTE: • Exercise extreme caution when draining the lubricating oil from the Cyclo® Bevel Buddybox® as it may be hot. • Follow all corporate, local, state and federal government regulations in disposing of the used lubricating oil. Identify the bevel portion oil drain plug on the bevel gear housing .

- Page 26 Cyclo® BBB5 Y2 Oil Fill & Drain Procedures, continued Oil Drain Process Table 20. BBB5 Y2 Single Reduction Oil Quantity* Y2 Configuration Oil Quantity Y2 Configuration Oil Quantity Bevel Gear Unit Size Bevel Gear Unit Size gallon liter gallon liter 5Z10 0 .42 1 .58...

-

Page 27: Motor Wiring

Wiring Guidelines Wiring Guidelines This section details wiring for standard Sumitomo three-phase motors and brakemotors . If using a motor manufactured by a company other than Sumitomo, please refer to that manufacturer’s instruction manual for wiring, operating and maintenance details . -

Page 28: Motor Protection

Cyclo® BBB5 Motor Wiring, continued Motor Protection, Motor Wiring Method Motor Protection • Use a molded case circuit breaker for protection against short circuit. • Use an overload protection device that protects the unit against voltage surges. Table 23. Typical 230/460V, Three-Phase Wiring U .S . -

Page 29: Brake Wiring

Brake Wiring Varistor Selection For wiring of Fast Brake Action, Sumitomo recommends the use of a Varistor (VR) . Refer to Table 40 to assist in the selection of the appropriately sized Varistor . Table 25 . Varistor Specifications Table... -

Page 30: U .S . Standard And Csa Approved Motor Brake Wiring

Cyclo® BBB5 Motor Wiring, continued U .S . Standard and CSA Approved Motor Brake Wiring U .S . Standard and CSA Approved Motor Brake Wiring The brake portion (if supplied) of the motor may be wired using one of the following these methods: Models FB-01A through FB-15B/FB-15E Figure 10. - Page 31 Cyclo® BBB5 Motor Wiring, continued U .S . Standard and CSA Approved Motor Brake Wiring U .S . Standard and CSA Approved Motor Brake Wiring The brake portion (if supplied) of the motor may be wired using one of the following these methods: Models FB-01A through FB-15B/FB-15E with Inverter Figure 14.

-

Page 32: Ce Motor Brake Wiring

Cyclo® BBB5 Motor Wiring, continued CE Motor Brake Wiring CE Motor Brake Wiring Models FB-01A through FB-5B/FB-5E, 220/380V, 50Hz Figure 20. Normal Brake Action, 220V Motor 220V Brake Figure 21. Fast Brake Action, 220V Motor 220V Brake Figure 23. Fast Brake Action, 380V Motor, 220V Brake, Tapped Figure 22. - Page 33 Cyclo® BBB5 Motor Wiring, continued CE Motor Brake Wiring Models FB-8B/FB-8E through FB-15B/FB-5E Figure 26. Normal Brake Action, 380V Motor, 380V Brake Figure 27. Fast Brake Action, 380V Motor, 380V Brake CE Motors Models FB-01A through FB-15B/FB-15E with Inverter Figure 28 . Normal Brake Action Figure 29 .

-

Page 34: Brake Rectifiers And Power Modules

Cyclo® BBB5 Motor Wiring, continued Brake Rectifiers and Power Modules Table 27 . Standard Brake Rectifiers 230V/460V Rectifier 575V Rectifier Motor Brake Type HP (kW) x P Model Number Part Number Model Number Part Number FB-01A 1/8 (0.1) x 4 1/4 (0.2) x 4 FB-02A 1/3 (0.25) x 4... -

Page 35: Parts

Cyclo® BBB5 Parts Cyclo® BBB5 Reducer Figure 31 . Cyclo® BBB5 Reducer Parts Table 30. Cyclo® BBB5 Reducer Parts Number Description Number Description BBB5 Gear Assembly Cyclo® High-Speed End Shield Cyclo® Ring Gear Housing Pins Eccentric Key Cyclo® Ring Gear Housing Rollers High Speed Shaft Oil Seal Collar Cyclo®... -

Page 36: Cyclo® Planetary Reduction Component Parts

Cyclo® BBB5 Parts, continued Cyclo® Planetary Reduction Component Parts Cyclo® Planetary Reduction Component Parts (Cyclo® Ratios 11 - 18:1) Figure 32 . Cyclo® Planetary Reduction Component Ring Gear (x1) Bevel Shaft Pin Carrier (x1) Washer (x6) Input Carrier Sun Gear (x1) Needles Planet Gear... - Page 37 Cyclo® BBB5 Parts, continued Cyclo® Reduction Component Parts Cyclo® BBB5 Reduction Component Part Numbers (Ratios≥ 19:1) Figure 33. Cyclo® BBB5 Reduction Components - 5Z100 thru 5C175 Bevel Pin Carrier Reduction Kit Input Kit Table 32. Cyclo® Reduction Component Part Numbers (Ratios ≥ 19:1) Reduction Ratio Part Numbers Reduction Ratio...

- Page 38 Cyclo® BBB5 Parts, continued Cyclo® Reduction Component Parts Table 33. Cyclo® Reduction Component Part Numbers (Ratios ≥ 19:1), continued Reduction Ratio Part Numbers Reduction Ratio Part Numbers Unit Size Input Reduction Bevel Pin 5A14 5B14 5C14 Unit Overall Cyclo® Input Reduction Carrier Size...

-

Page 39: Bearings And Oil Seals

Cyclo® BBB5 Parts, continued Bearings and Oil Seals Bearing and Oil Seals Figure 34 . Cyclo® BBB5 Bearings and Oil Seals B1-1 B1-2 Table 34 . Cyclo® BBB5 Reducer Bearings and Oil Seals Bearings Oil Seals Unit Size B1-1 B1-2 5Z100 5Z105 20 x 35 x 7... -

Page 40: Bevel Gearing Parts Tooth Count

Cyclo® BBB5 Parts, continued Bevel Gearing Parts and Tooth Count Bevel Gearing Parts and Tooth Count Bevel gear and pinions are sold in sets only . Individual components are not available for purchase . The information below regarding tooth count of the bevel gearset is provided for vibration analysis purposes . Figure 35 . -

Page 41: Cyclo® Portion Disassembly/Assembly

The Bevel Gear portion is designed for lower speeds and therefore has lower operating cycles when compared to the Cyclo® input assembly, therefore in most cases, does not require rebuilding . Contact Sumitomo repair centers for replacement information . The Cyclo® portion has significantly higher operating cycles than the Bevel Gear portion, rebuild and repair is a convenient way to extend the useful life of your gearbox . - Page 42 Cyclo® BBB5 Cyclo® Portion Disassembly/Assembly, continued Disassembly Procedure Remove all bolts While continuing to externally support the entire Cyclo® BBB5 unit, remove each of the bolts from the Cyclo® ring gear housing (shown in horizontal position for clarity) . Cyclo® Reduction Components Carefully separate the bevel gear housing assembly from the Cyclo®...

- Page 43 Cyclo® BBB5 Cyclo® Portion Disassembly/Assembly, continued Disassembly Procedure Using both hands, carefully remove the top Cycloid disc . Cycloid Disc Cycloid Disc Spacer For Cyclo® units supplied with a spacer, remove the Cycloidal disc spacer . Eccentric Bearing Remove the eccentric bearing from the high speed shaft . Using both hands, carefully remove the remaining Cycloid disc .

- Page 44 Cyclo® BBB5 Cyclo® Portion Disassembly/Assembly, continued Disassembly Procedure Ring Gear Housing Remove the ring gear housing . Snap Ring Remove the spacer and the snap ring from the high speed end shield . Spacer High Speed Shaft Bearing Remove the high speed shaft, along with its associated bearing, from the high speed end shield .

-

Page 45: Cyclo® Portion - General Reassembly

Cyclo® BBB5 Cyclo® Portion Disassembly/Assembly, continued Reassembly Procedure Cyclo® Portion – General Reassembly The Cyclo® portion of the speed reducer may be reassembled by reversing the disassembly procedure . All parts must be returned to the original order from which they were removed during disassembly . Take care to keep the moving reduction components free of dust or foreign material, and properly align all gaskets in order to keep the assembly oil tight/leak free . - Page 46 Cyclo® BBB5 Cyclo® Portion Disassembly/Assembly, continued Reassembly Procedure Code on upper disc Insert the top Cycloid disc so that the code engraved on its surface is 180° opposed to the corresponding etched code on the lower Cycloid disc. 180 º Code on lower disc If the Cyclo®...

-

Page 47: Troubleshooting

Cyclo® BBB5 Troubleshooting Reducer Troubleshooting Reducer Troubleshooting This troubleshooting guide provides assistance in identifying and overcoming common problems in reducers and motors . If a problem with the reducer and/or the motor is not listed below, please consult the factory for assistance . Problem with the Reducer Possible Causes Suggested Remedy... -

Page 48: Motor Troubleshooting

Cyclo® BBB5 Troubleshooting, continued Motor Troubleshooting Motor Troubleshooting This troubleshooting guide provides assistance in identifying and overcoming common problems in reducers and motors . If a problem with the reducer and/or the motor is not listed below, please consult the factory for assistance . Problem with the Motor Possible Causes Suggested Remedy... - Page 49 CYCLO® 6000 Gearmotors Cyclo® BBB5 Notes Notes Cyclo® BBB5 Operation & Maintenance Manual 5.26 Cyclo® 6000 Series Technical Information...

- Page 50 Sumitomo Heavy Industries, Ltd. Power Transmission & Controls Group For worldwide locations, please visit ThinkPark Tower, 1-1, Osaki 2-chome, Shinagawa-ku, Tokyo 141-6025 Japan www.sumitomodrive.com/worldwide Tel: +81-36-737-2511 • Fax: +81-36-866-5160 Manual 04.601.60.006; Supersedes Manual 04.601.60.005 ©2019 Sumitomo Machinery Corporation of America Printed in USA...

Need help?

Do you have a question about the Cyclo BBB5 and is the answer not in the manual?

Questions and answers