Table of Contents

Advertisement

Quick Links

Published 09/10

OPERATOR'S MANUAL

This Operator's Manual is an integral part of the safe operation of this machine and must

be maintained with the unit at all times. READ, UNDERSTAND, and FOLLOW the Safety

and Operation Instructions contained in this manual before operating the equipment. C01-

Cover

®

BUSH HOG

2501 Griffin Ave.

Selma, AL 36703

334-874-2700

www.bushhog.com

300 Series

REAR MOUNTED BLADE

© 2010 Alamo Group Inc.

00786978C

Part No.

$0.00

Advertisement

Table of Contents

Summary of Contents for Bush Hog 300 Series

- Page 1 READ, UNDERSTAND, and FOLLOW the Safety and Operation Instructions contained in this manual before operating the equipment. C01- Cover ® BUSH HOG 2501 Griffin Ave. Selma, AL 36703 334-874-2700 www.bushhog.com 300 Series REAR MOUNTED BLADE © 2010 Alamo Group Inc. 00786978C Part No. $0.00...

- Page 2 To the Owner/Operator/Dealer All implements with moving parts are potentially hazardous. There is no substitute for a cautious, safe-minded operator who recognizes the potential hazards and follows reasonable safety practices. The manufacturer has designed this implement to be used with all its safety equipment properly attached to minimize the chance of accidents.

-

Page 3: Table Of Contents

TABLE OF CONTENTS SAFETY SECTION ... 1-1 Safety Messages ... 1-2 Decal Location ... 1-9 Decal Description... 1-11 Federal Laws and Regulations ... 1-15 INTRODUCTION SECTION ... 2-1 ASSEMBLY SECTION ... 3-1 Assembly of Moldboard to Mainframe ... 3-2 Gauge Wheel (Extra Equipment) ... 3-4 Skid Shoes &... -

Page 5: Safety Section

SAFETY SECTION Safety Section 1-1... -

Page 6: Safety Messages

Safety Messages. Always use good common sense to avoid hazards. Si no lee ingles, pida ayuda a alguien que si lo lea para que le traduzca las medidas de seguridad. 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY (SG-2) - Page 7 Operate the Tractor controls from the tractor seat only. Never allow children or other persons to ride on the Tractor or Implement. Falling off can result in serious injury or death. 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY...

- Page 8 The operator and all support personnel should wear hard hats, safety shoes, safety glasses, and proper hearing protection at all times for protection from injury including injury from items that may be thrown by the equipment. 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY (SG-11)

- Page 9 Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. Never attempt to lubricate, adjust, or remove material from the Implement while it is in motion or while tractor engine is running. 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY EXPOSURE...

- Page 10 Serious injury or death to the operator or others could result if the operator is under the influence of drugs or alcohol. 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY...

- Page 11 Lower Stand and pin in place, or put a secure support under the A-Frame. Lower Blade carefully to the ground. Do not put hands or feet under lifted components. 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY...

- Page 12 These parts are made and tested to Bush Hog specifications. Non-genuine "will fit" parts do not consistently meet these specifications. The use of “will fit” parts may reduce equipment performance, void warranties, and present a safety hazard. Use genuine Bush Hog parts for economy and safety.

-

Page 13: Decal Location

SAFETY Decal Location NOTE: Bush Hog supplies safety decals on this product to promote safe operation. Damage to the decals may occur while in shipping, use, or reconditioning. Bush Hog cares about the safety of its customers, operators, and bystanders, and will replace the safety decals on this product in the field, free of charge (Some shipping and handling charges may apply). - Page 14 00786980 999000 999200 03200347 000678 00763977 00786979 00786984 00786992 1458393 1458392 1458398 49722 00786978C *Furnished by Tractor Manufacturer 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY LEVEL PELIGRO WARNING IMPORTANT WARNING WARNING REFLECT INSTRUCT INSTRUCT LOGO NAME NAME SER PLT...

-

Page 15: Decal Description

BODILY INJURY from SCALDING or FIRE with resulting BURN INJURY or DEATH. P/N 02965262 For safety and to guarantee optimum product reliability always genuine replacement parts. P/N 00786980 WARNING!-Multi-Hazard for blades P/N 999000 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY Bush Safety Section 1-11... - Page 16 Information that Grease Fitting is present and must apply grease P/N 000678 Operator's Manual (with repair parts) and warranty was attached to this implement during final inspection. P/N 00763977 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY Safety Section 1-12...

- Page 17 Logo Product Name: Bush Hog P/N 00786979 LOGO PRODUCT NAME: 300-12 P/N 00786984 LOGO PRODUCT NAME: 300-14 P/N 00786992 Red Reflector. Keep reflectors clean and visible. P/N 1458392 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY Safety Section 1-13...

- Page 18 Orange Reflector. Keep reflectors clean and visible. P/N 1458398 Read Operator’s Manual! The operator’s manual is located inside this canister. If the manual is missing order one from your dealer. P/N 00776031 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY Safety Section 1-14...

-

Page 19: Federal Laws And Regulations

Some regulations specify that no one under the age of 16 may operate power machinery. It is your responsibility to know what these regulations are in your own area or situation. (Refer to U.S. Dept. of Labor, Employment Standard Administration, Wage & Home Division, Child Labor Bulletin #102.) 300 Series 09/10 © 2010 Alamo Group Inc. SAFETY... -

Page 21: Introduction Section

INTRODUCTION SECTION Introduction Section 2-1... - Page 22 This 300 Series is designed with care and built with quality materials by skilled workers. Proper assembly, maintenance, and operating practices, as described in this manual, will help the owner/operator get years of satisfactory service from the machine. The purpose of this manual is to familiarize and instruct. The Assembly Section instructs the owner/operator in the correct assembly of the Blade using standard and optional equipment.

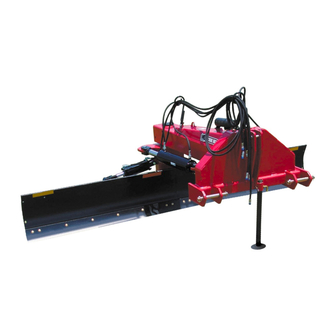

- Page 23 The 300 Series Blade is available in widths of 12' and 14' and features a massive CAT III-IV three-point hitch and quick-hitch. The 14' model is rated for up to 250 draw bar horsepower wheel-type tractors. Hydraulic adjustment of the mainframe swing, moldboard angle, and moldboard tilt is standard for easy and fast adjustments.

-

Page 24: Attention Owner/Operator

3. Record the Blade Model and Serial Numbers on the Warranty page at the front of the Operator’s Manual. Keep this as part of the permanent maintenance file for the implement. 300 Series 09/10 Introduction Section 2-4 © 2010 Alamo Group Inc. -

Page 25: Assembly Section

ASSEMBLY SECTION Assembly Section 3-1... -

Page 26: Assembly Of Moldboard To Mainframe

Assembly of Moldboard to Mainframe The Bush Hog 300 Series Blade is shipped in two bundles. The Mainframe, A-Frame and Moldboard Carrier are in one bundle; the Moldboard is in the second bundle. The assembly of the Moldboard to the Moldboard Carrier is made by inserting the Moldboard Pivot Pin and securing with Bolts. - Page 27 ASSEMBLY 1. Attach Moldboard Tilt Cylinder with the Rod End attached to the Moldboard. 2. Attach the Moldboard Pivot Cylinder. 3. Attach the Mainframe Swing Cylinder. 300 Series 09/10 Assembly Section 3-3 © 2010 Alamo Group Inc.

-

Page 28: Gauge Wheel (Extra Equipment)

Skid Shoes prevent gouging and scalping and increase Blade life. End Plates help move larger quantities of bulk material. Install as shown in Figure Asm-0006. Neither can be used while ditching. 300 Series 09/10 Assembly Section 3-4 © 2010 Alamo Group Inc. -

Page 29: Hydraulic System

Valve to one outlet to operate three Cylinders. Use the other remote outlet to operate the fourth Cylinder. If Closed Center Valve is used, Do Not Use the Adjustable Relief Assembly. Use the No- Relief Assembly. 300 Series 09/10 © 2010 Alamo Group Inc. ASSEMBLY... -

Page 30: Selector Valve (Accessory Equipment)

Selector Valve. When installing this Valve, observe all safety precautions as Hydraulic Lines are under high pressure (2500 PSI). If additional information is required concerning your Hydraulic System, contact your Bush Hog Dealer. 300 Series 09/10 Assembly Section 3-6 © 2010 Alamo Group Inc. -

Page 31: Operation Section

OPERATION SECTION Operation Section 4-1... - Page 32 Pictures contained in this section are intended to be used as a visual aid to assist in explaining the operation of a rear blade and are not necessarily of a 300 Series blade. Some pictures may show shields removed for purposes of clarity.

-

Page 33: Standard Equipment And Specifications

Pivot: Forward Angle Reverse Angle Tilt (Up and Down) No. of No-Wrench Adjustments Weight (Approx.): 12’ 14’ 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION 300 HP 250 HP 12’ or 14’ 1/2” x 20” 1/2” x 6” Std. -

Page 34: Operator Requirements

Serious injury or death to the operator or others could result if the operator is under the influence of drugs or alcohol. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION... -

Page 35: Tractor Requirements

The power required to operate a blade is determined by the tractor PTO horsepower. For most operating conditions, the 300 Series rear blade requires a tractor with at least 300 HP for 12’ and 250 HP for 14.’ Operating the blade with a tractor that does not have adequate power may damage the tractor engine. -

Page 36: Tractor 3-Point Hitch

The tractor 3-point hitch must be rated to lift at least 3463 lbs. for the 12’ and 3603 lbs. for the 14’. The 300 Series can attach to tractor’s with either a CAT III or IV hitch. Refer to the tractor operator’s manual for the category of the tractor used. -

Page 37: Boarding The Tractor

Never dismount a Tractor that is moving or while the engine is running. Operate the Tractor controls from the tractor seat only. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION... -

Page 38: Starting The Tractor

Start tractor only when properly seated in the Tractor seat. Starting a tractor in gear can result in injury or death. Read the Tractor operators manual for proper starting instructions. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION (SG-23) -

Page 39: Connecting The Rear Blade To The Tractor

Never work under the Implement, the framework, or any lifted component unless the Implement is securely supported or blocked up to prevent sudden or inadvertent falling which could cause serious injury or even death. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION OPS-0011_A... -

Page 40: Pre-Operation Inspection And Service

Power brake fluid level • Power steering fluid level • Fuel condition and level • Sufficient lubrication at all lube points • Air filter condition OPS-U-0030 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION (SG-21) The following Operation Section 4-10... -

Page 41: Blade Pre-Operation Inspection/Service

Ensure the manual canister is secured to the equipment with the operator’s manual inside. • Ensure all safety signs are in place and legible. Replace missing, damaged, and illegible decals. OPS-U- 0011 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Operation Section 4-11... - Page 42 The gauge wheel(s) are in good condition & lubricated. The scarifier shanks are properly retained. The scarifier points are in good condition and retained. Operator’s Signature:_____________________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Condition at Start of Shift...

- Page 43 The engine coolant fluid level is full The radiator is free of debris The air filter is in good condition Operator’s Signature:___________________________________________________ DO NOT OPERATE an UNSAFE TRACTOR or IMPLEMENT 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Condition at Start of Shift...

-

Page 44: Driving The Tractor And Implement

When operating in traffic always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION... -

Page 45: Starting The Tractor

When operating in traffic, always use the Tractor’s flashing warning lights and reduce your speed. Be aware of traffic around you and watch out for the other guy. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION... -

Page 46: Driving The Tractor And Blade

Special attention should be paid to foreign debris, rough terrain, steep slopes, and passersby and animals in the area. OPS-U- 0015 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION... -

Page 47: Operating The Blade

It is also very easy to operate the Blade at too high a speed, with resulting damage. NOTE: The warranty shall not apply to damage caused by misuse, abuse, or contact with obstructions. 300 Series 09/10 Operation Section 4-17... -

Page 48: Shutting Down The Implement

When the pin is loose and easy to rotate, remove the pin from the blade. Next remove both lower hitch pins. OPS- 0052_C 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION (S3PT-15) Operation Section 4-18... -

Page 49: Blade Storage

Never allow children or other persons to ride on the Tractor or Implement. Falling off can result in serious injury or death. When transporting, only raise the blade enough to clear ground obstacles to prevent tipping, especially when traveling through rough terrain. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION replacements... -

Page 50: Transporting On Public Roadways

Make certain that the “Slow Moving Vehicle” (SMV) sign is installed in such a way as to be clearly visible and legible. When transporting the Equipment use the Tractor flashing warning lights and follow all local traffic regulations. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Locking the... - Page 51 Always stay alert when transporting the tractor and implement on public roads. Use caution and reduce speed if other vehicles or pedestrians are in the area. OPS- B- 0022 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION roads, have...

-

Page 52: Hauling The Tractor And Implement

OPS-U- 0025 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Operation Section 4-22... - Page 53 If during transport a hard braking, sharp turning, or swerving action was performed, stop at the next safe location to inspect the security of the load. OPS-U- 0026 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION against...

-

Page 54: Troubleshooting Guide

Hydraulic Cylinder(s) Not enough pressure will not operate Valve not connected properly Quick Coupler not completely connected 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Remedy Lubricate Pivot Pin Tighten Bolt to proper torque Can be removed but will not... - Page 55 Connection not tight connection Did not use sealant Connection cracked from over-tightening Mismatched Connection threads or types. 300 Series 09/10 © 2010 Alamo Group Inc. OPERATION Remedy Replace Valve or Conversion Plug and Main Relief Replace with Closed Center Plug...

-

Page 57: Maintenance Section

MAINTENANCE SECTION Maintenance Section 5-1... -

Page 58: Maintenance

MAINTENANCE Lubrication The Bush Hog 300 Series is a rugged, dependable Blade that should perform satisfactorily with the following preventive maintenance: Lubricate the Moldboard Pivot Pin (Figure Asm- 0001), the Moldboard Tilt Pin (Figure Asm-0002), and Mainframe Swing Pin on the A-Frame after every 10 hours of operation. -

Page 59: Proper Torque For Fasteners

NOTE: These values apply to fasteners as received from supplier, dry or when lubricated with normal engine oil. They do not apply if special graphited or molydisulphide greases or other extreme pressure lubricants are used. This applies to both UNF fine and UNC coarse threads. 300 Series 09/10 Maintenance Section 5-3 © 2010 Alamo Group Inc. -

Page 60: Limited Warranty

2. If the unit has been subjected to misapplication, abuse, misuse, negligence, fire or other accident. 3. If parts not made or supplied by Bush Hog have been used in connection with the unit, if, in the sole judgement of Bush Hog such use affects its performance, stability or reliability. - Page 61 To keep your implement running efficiently and safely, read your manual thoroughly and follow these directions and the Safety Messages in this Manual. The Table of Contents clearly identifies each section where you can easily find the information you need. The OCCUPATIONAL SAFETY AND HEALTH ACT requirements of tractor operators: REQUIRED OF THE OWNER:...

- Page 62 300 Series Rear Mounted Blade 300 Series - SOM - 09/10 P/N 00786978C Printed U.S.A...

Need help?

Do you have a question about the 300 Series and is the answer not in the manual?

Questions and answers