Table of Contents

Advertisement

R e f e r e n c e Ma n u a l

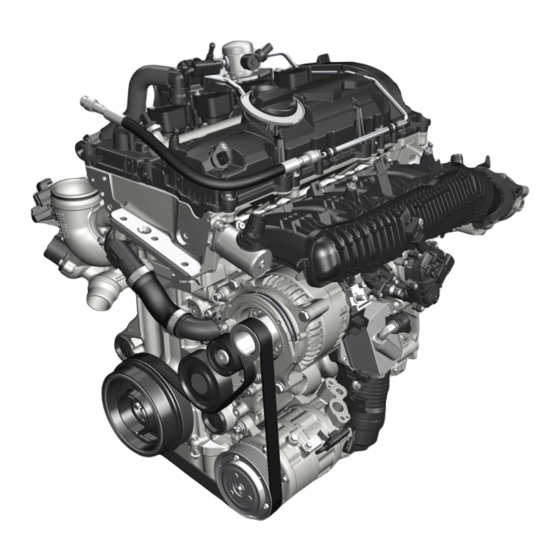

B 4 6 T U / B 4 8 T U

E N G I N E S

T e c h n i c a l T r a i n i n g

T h e i n f o r ma t i o n c o n t a i n e d i n t h i s ma n u a l i s n o t t o b e r e s o l d , b a r t e r e d , c o p i e d o r t r a n s f e r r e d

w i t h o u t t h e e x p r e s s w r i t t e n c o n s e n t o f B MW o f N o r t h A me r i c a , L L C ( " B MW N A " ) .

C o p y r i g h t © 2 0 1 8 B MW o f N o r t h A me r i c a , L L C

Advertisement

Table of Contents

Need help?

Do you have a question about the B46TU and is the answer not in the manual?

Questions and answers