Subscribe to Our Youtube Channel

Summary of Contents for Baker Hughes Consolidated Generation II 2900 Series

- Page 1 Consolidated ™ 2900 Series Generation II Pilot-Operated Safey Relief Valves Instruction Manual (Rev. E) Baker Hughes Data Classification : Public...

- Page 2 REFERENCE INFORMATION IN ADDITION TO THE CUSTOMER/OPERATOR’S NORMAL OPERATION AND MAINTENANCE PROCEDURES. SINCE OPERATION AND MAINTENANCE PHILOSOPHIES VARY, BAKER HUGHES (AND ITS SUBSIDIARIES AND AFFILIATES) DOES NOT ATTEMPT TO DICTATE SPECIFIC PROCEDURES, BUT TO PROVIDE BASIC LIMITATIONS AND REQUIREMENTS CREATED BY THE TYPE OF EQUIPMENT PROVIDED.

- Page 3 Note: Multiply USCS unit with conversion factor to get metric value. NOTICE! For valve configurations not listed in this manual, please contact your local Green Tag™ Center (GTC) for assistance. © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 4: Table Of Contents

F. Freeze Protection ............. . .31 © 2021 Baker Hughes Company. All rights reserved. - Page 5 D. Assembly of 39MV22/72 ............73 © 2021 Baker Hughes Company. All rights reserved.

- Page 6 C. Maintenance Training ............110 © 2021 Baker Hughes Company. All rights reserved.

-

Page 7: Product Safety Sign And Label System

© 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 8: Safety Precautions

9. WARNING: These WARNINGS are as complete product damage. as possible but not all-inclusive. Baker Hughes cannot know all conceivable service methods nor evaluate all potential hazards. © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 9: Restoring Safety

Maintenance Manual, when correctly applied, will be effective. Wear necessary Always use protective equipment appropriate to prevent possible restoration injury. procedures. © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 10: Safety Notice

Nevertheless, Baker Hughes does offer certain Safety Precautions for customer information only. It is the responsibility of the purchaser or user of Baker Hughes's Consolidated valves/equipment to adequately train all personnel who will be working with the involved valves/equipment. For more information on training schedules, call your local Green Tag Center (GTC). -

Page 11: Warranty Information

Unauthorized Removal of Seals – All new valves and valves repaired in the field by Baker Hughes Field Service are sealed to assure the customer of our guarantee against defective workmanship. Unauthorized removal and/or breakage of this seal will negate our warranty. -

Page 12: Terminology For Pilot Operated Safety Relief Valves

Consequently, for that metal temperature, it is the highest pressure at which the primary pressure POSRV is set to open. 12 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 13: Handling And Storage

Never attempt to lift the valve by anything other than the eyebolts. | 13 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 14: Pre-Installation And Installation Instructions

On request, Baker Hughes will assist in the analysis to determine the appropriate length, size and maximum change in height for the sensing line and to determine the correct capacity of the pressure relief valve. - Page 15 25 psi (1-1.5 bar). For pressures exceeding this limit, a Nitrogen bottle (connected to the field test connector) precharged up to 97% of set pressure may be used. | 15 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 16: Introduction

Gas, Air, Steam or Liquid 3751 258.62 6250 430.92 -40.0 262.8 Note: With the installation of the heat exchanger, temperature range may be expanded to -450°F to 1200°F. (-267.8°C to 648.9°C) 16 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

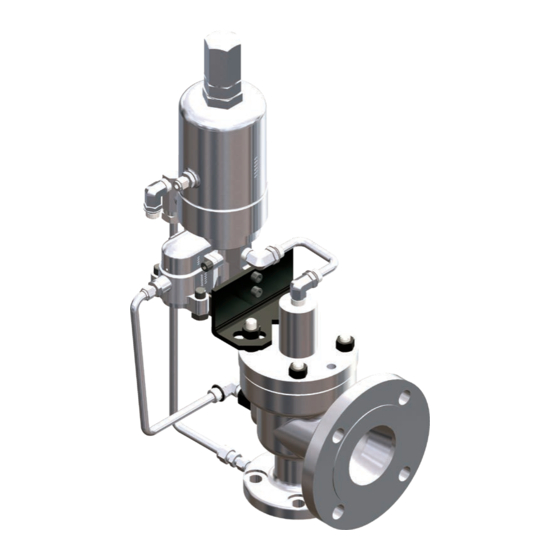

Page 17: 2900 Series Pilot Operated Safety Relief Valves

D Thru J Orifice K Thru U Orifice Figure 3: Main Valve Construction - Integral Sense Figure 2: Main Valve Construction - Soft Seat | 17 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 18: D-U Orifice (With Bellows)

Figure 4: Main Valve Construction - Bellows (D-U orifices) E. V & W Orifice (with Bellows) 1/2” NPT DRAIN Figure 5: Main Valve Construction - Bellows (V&W orifices) 18 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 19: Metal Seat Valve For Section I Liquid Service (La1)

Figure 6: Metal Seat Construction for Section I Liquid Spring Service (LA1) Integral Sensing Ring Integral Sensing Gasket Integral Sensing Tube Figure 7: Main Valve Construction - Integral Sense | 19 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 20: Soft Seat Valve For Section I Liquid Service (La1)

Figure 8: Soft Seat Construction for Section I Liquid Service (LA1) Part Nomenclature Nozzle Disc Disc Retainer Disc Holder Guide O-Ring Retainer Lock Screw O-Ring Retainer O-Ring Seat Seal 20 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 21: 39Pv07/37 Pilot Valves (Standard Service)

1. Standard material is a filter plug. For HIGH PRESSURE special materials, vent assembly is Figure 9: 39PV07/37 Pilot Valve Construction supplied. | 21 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 22: 39Mv07 Pilot Valve (Standard Service)

Figure 10: 39MV07 Pilot Valve Construction Bottom) Spring Seal (Piston Bottom) Spring Seal (Piston Top) 1: Standard material is a filter plug. For special materials, vent assembly is supplied. 22 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 23: J 39Mv22/72 Pilot Valve (Standard Service)

HIGH PRESSURE 1: Standard material is a filter plug. For Figure 11: 39MV22/72 Pilot Valve Construction special materials, vent assembly is supplied. | 23 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 24: Operating Principles

Since the area of the top of the piston is larger than the area of the seating surface, the differential area results in a net downward force keeping the main valve tightly closed. Figure 12: PV Valve Closed (Normal Position) 24 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 25 Figure 13: PV Valve OPEN (Relieving Position) | 25 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 26: B 2900 Series 39Mv07 (Modulating) Pilot - Operational Description

Since the area of the top of the piston is larger than the area of the seating surface, the differential area results in a net downward force keeping the main valve tightly closed. Dome Dome Shown out of Position Figure 14: MV07 Valve Closed (Normal Position) 26 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 27 Figure 15: MV07 Valve Modulating (Partial Relieving Position) closes the main valve. | 27 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 28: General Planning For Maintenance

For severe service applications, a 3 to 6 month inspection and test interim may be more appropriate. The specific plant's operating and service history will better determine this frequency. Baker Hughes encourages preventive maintenance. The 2900 series Pilot Operated Safety Relief Valve (POSRV) is easily maintained. -

Page 29: Inlet Piping

P.D. P.D. P.D. P.D. Stop From Protected Equipment Valve Vessel Vessel Vessel Figure 16: Pressure Drop on the Inlet Piping | 29 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 30: Outlet Piping

Long-Radius Long-Radius piping strains away from the Elbow Elbow pressure relief valve under all conditions of process Vessel Vessel Vessel operation and temperature. Figure 19: POSRV Parts Alignment 30 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 31: Remote Sensing

For remote sensing, .375” (9.53 mm) diameter tubing is adequate for distances up to 10 feet, (3.048 m). If distance is longer than Outside perimeter of Heat Exchanger 10 feet (3.048 m), please contact Baker Hughes may be insulated. Application Engineering. Pilot ATTENTION! - Page 32 Figures 20 and 21. Figure 20 shows a standard pilot operated relief valve. Figure 21 shows a pilot operated relief valve equipped with a heat exchanger. 32 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 33: Disassembly Of The 2900 Posrv

8. Remove the Main Valve Piston from the Cover Plate using a dowel pressed through the center hole in the top of the Cover Plate. | 33 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 34 XIII. Disassembly of the 2900 POSRV (Cont.) Figure 22: Conventional Metal Seat Valve Disassembly 34 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 35 XIII. Disassembly of the 2900 POSRV (Cont.) Figure 23: Bellows Metal Seat Valve Disassembly | 35 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 36 Top of Base Disc Retainer Disc O-Ring Seat Seal O-Ring Retainer Retainer Lockscrew Figure 28: Disc Holder Removal Tool (V & W) Figure 26: O-Ring Seat (K -W Orifices) 36 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 37: Nozzle Removal

Attach the lifting lug to the disc and lift out. 15. For O-Ring seat seal valves only, remove the | 37 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 38 4. The Main valve is ready for cleaning, inspection 2. Remove sensing ring and gasket from nozzle. and refurbishing. 5. Discard all O-Rings, guide rings, and seals. 38 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 39: Cleaning

5. Do not “sand blast” internal parts as it can reduce the dimensions of the parts. | 39 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 40: Maintenance Instructions

5° 45° Nozzle Nozzle Bore Bore Figure 34a: Metal Seat Nozzle Figure 34b: Soft Seat Nozzle Figure 34: Main Valve Nozzle Critical Dimensions 40 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 41 .353 ± .005 8.97 ± 0.13 30° .020 ± .005 0.51±0.13 .353 8.97 11.125 ± .005 282.58 ± 0.13 10.458 ± .005 265.63 ± 0.13 | 41 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 42: Lapping Nozzle Seats (Metal Seat, Non-O-Ring Styles)

0.005” (0.13 mm). Figure 36a and 36b illustrate the use of this tool in measuring the nozzle seat width. Measuring Magnifier Nozzle Figure 36a: Measuring Magnifier Figure 36b: Magnifier Details Figure 36: Measuring Magnifier 42 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 43 Not to exceed .070 ± .005” (1.78±0.13 mm). 4: 048” + .005” (1.22 + 0.13 mm) per 100 psig (6.89 barg). Not to exceed .070 ± .005” (1.78±0.13 mm). | 43 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 44: Lapping Disc Seats

ATTENTION! Before assembly, grind the contact surfaces of the nozzle and O-Ring retainer to provide metal-to- metal seat tightness in the event of O-Ring failure. 44 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 45: Re-Machining Nozzle Seats

Turn to the smoothest possible finish. Chuck Jaw Disc 90° Figure 39: Nozzle Positioned in a Jaw Figure 40: Standard Disc Seating Surface | 45 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 46 .068 1.73 .620 15.75 .068 1.73 .620 15.75 .068 1.73 .832 21.13 .068 1.73 .833 21.16 .068 1.73 1.230 31.24 .120 3.05 Type 3 1.855 47.12 .168 4.27 46 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 47: Inspection And Part Replacement

Figure 43c: V&W Orifice Figure 42b: V & W Orifice Figure 43: Guide Critical Dimensions Figure 42: Guide Critical Dimensions (Bellows) (Metal Seat) | 47 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 48 Figure 44b: J-U Orifices .014 0.36 .017 0.43 .015 0.38 .015 0.38 .025 0.64 .025 0.64 Figure 44c: V&W Orifices .035 0.89 Figure 44: Thermodisc Design .035 0.89 48 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 49 Holder is galled, pitted, or scratched. Solid Metal Gaskets: Solid Metal Gaskets can be reused unless they are corroded, pitted, or crimped. | 49 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 50 D-G Orifice H-W Orifice (Bellows), 7.360 186.94 6.997 177.72 (Bellows) D-W Orifice 8.110 205.99 7.747 196.77 (Conventional) 9.662 245.41 9.500 241.30 Figure 46: Main Valve Piston Contact Engineering Department. 50 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 51: Reassembly Of The 2900 Main Valve

1960 2657 2000 2712 Figure 47: Integral Sense Nozzle Assembly Note: DO NOT USE impact wrench on “D” through “K” orifice Nozzles. | 51 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 52: Integral Sensing Ring Assembly

Prior to assembly of the Disc into the Disc Holder, remove the Disc Retainer from the back of the Disc. Use 1000 grit grinding compound on the bearing 52 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 53 Make note of the the disc holder ensuring that guide rings remain length of the studs. The two longer ones will © 2021 Baker Hughes Company. All rights reserved. | 53 Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 54 20. The Main Valve is ready to receive the pilot and finished assembly. Main Valve Piston Main Valve Piston O-Ring Guide Ring Figure 49: Main Valve Piston 54 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 55 — — — — — — — — — — — — — — — — — — — — — — | 55 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 56 XVI. Reassembly of the 2900 Main Valve (Cont.) Table 13: Torque Required for Each Round of Pattern Round Percentage of Required Torque Wrench Tight Holes Holes Holes Holes Holes Figure 50: Bolt Tightening Patterns 56 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 57: Disassembly Of Pilot Valve

Field Test Connection and discard the Spring Seal (Main Piston) and O-Ring (Top Plate). 15. Remove Main Piston from Pilot Base. | 57 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 58 XVII. Disassembly of Pilot Valve (Cont.) 39PV37 Figure 51: 39PV07/37 Disassembly 58 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 59 55c Drive Pin 1: Standard material is a filter plug. For special Figure 52: Lifting Lever Disassembly materials, vent assembly is supplied. | 59 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 60: 39Mv07 Disassembly

Top Plate to the Pilot Base. Remove Preventer Option (Section XXII.A) for and discard the Spring Seal (Main Piston) and disassembly of Field Test Connection. O-Ring (Top Plate). 60 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 61 XVII. Disassembly of Pilot Valve (Cont.) Figure 53: 39MV07 Disassembly | 61 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 62 O-Ring (Modulator Seat) O-Ring (Modulator Piston Bottom) Spring Seal (Piston Bottom) Spring Seal (Piston Top) 1: Standard material is a filter plug. For special materials, vent assembly is supplied. 62 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 63: 39Mv22/72 Disassembly

Spring Seal (Main Piston), O-Ring (Top number of flats for reassembly. Plate) and back-up rings (if applicable). 15. Remove Main Piston Assembly from Pilot Base. | 63 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 64 Adjuster Bottom by turning Adjuster Top counterclockwise. Remove the Vent Seal Adaptor from the Adjuster Top. Remove and discard the Spring Seal (Adjuster Top) and Spring Seal (Adjuster Bottom). Figure 54: 39MV22 Disassembly 64 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 65 XVII. Disassembly of Pilot Valve (Cont.) Figure 55: 39MV72 Disassembly | 65 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 66: Cleaning

Vent Seal (Adaptor) Spring Seal (Vent Seal Adaptor) Back-up Ring (39MV72 Only) Top Plate 1: Standard material is a filter plug. For special materials, vent assembly is supplied. 66 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 67: Part Inspection Of Pilot Valve

Also, check for galling of threads. 11. Spring: Check for any corrosion or pitting. 11. Spring: Check for any corrosion or pitting. | 67 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 68: 39Mv22/72

Adjuster Top: Galling or excessive wear on the inside diameter that guides the Main Piston. Check for any corrosion or pitting. Also, check for galling of threads. 68 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 69: Reassembly Of Pilot Valve

Spring Seal (Insert) Adjuster Top Adjuster Bottom Spring Seal Funnel Tube (Main Piston) Figure 56: Funnel Tube Figure 58: Adjuster Top Assembly | 69 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 70 #4995401 Figure 93). Tighten wrench tight. Make sure milled slot is facing up. g. Lubricate Main Piston stem and cycle Main Piston through Spring Seal (Insert) five Figure 60: Top Plate (39PV07) times. 70 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 71: Assembly Of 39Mv07

Lubricate Main Piston stem and cycle Main 15. Install Pipe Plug (Pilot Valve) in port above vent Piston through Spring Seal (Adjuster Top) five hole (if removed). times. | 71 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 72 Place Spring over Lifting Stem and place on inserted into Pilot Base. Bottom Spring Washer. Place O-Ring (Insert) into groove. Final Insert Assembly is shown in Figure 59. 72 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 73: Assembly Of 39Mv22/72

Final Modulator Piston Assembly is shown in c. Install the Set Screw into the threaded hole Figure 62. of the Piston Nut and hand tighten. | 73 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 74 Place O-Ring (Insert) into groove. bottom and torque to 27±2 ft-lbs (37± 2.7 N-m). Final Insert Assembly is shown in Figure 59. Lubricate Main Piston stem and cycle Main 74 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 75 Piston through Insert Assembly. Note: For Dirty Service Option, install Main Piston /Top Plate Assembly into Dirty Service Insert instead of Pilot Base. | 75 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 76: Setting And Testing

Swagelok Gap Inspection Gauge (Swagelok P/N MS-IG-468) will go. Continue to torque down fitting until Swagelok Gap Inspection Gauge will not go. Figure 64: 39PV07/37 Figure 63: Tubing Dimensions 76 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 77: Integral Sensing Ring

Note: No need to pop the valve on elevated temperature air. Figure 67: 39MV72 Figure 66: 39MV22 Figure 65: 39MV07 | 77 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 78: Troubleshooting Leakage

1.20 0.60 2500 172.37 1.50 0.75 3000 206.84 1.50 0.90 4000 275.79 1.50 1.20 5000 344.74 1.50 1.50 Figure 68: with Optional Line Filter 6000 413.69 1.50 1.50 78 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 79 Possible point of leakage on the pilot 39PV model (gas/steam): less than valve. or equal to 5% or 3 psig (0.20 barg), whichever is greater. | 79 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 80: Conversions Between Conventional And Bellows Type

Ori- 2 Pipe Plug bellows valve fices Disc holder for bellows valve 4 Cover Plate 1. Conventional Cover Plate may be modified to work on a bellows valve. 80 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 81: Field Testing Of Posrv Assembly

Figure 69: Typical Field Test Arrangement the pilot dome. 81 | | 81 © 2021 Baker Hughes Company. All rights reserved. © 2020 Baker Hughes Company. All rights reserved. Baker Hughes Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 82 Vent Valve Aux Source Inlet Supply Field Test (Integral or Remote) Connection 82 | | 82 © 2020 Baker Hughes Company. All rights reserved. © 2021 Baker Hughes Company. All rights reserved. Baker Hughes Consolidated 2900 Series POSRV Instruction Manual...

- Page 83 Continue to drop pressure until 80% of set pressure. 9. Close Nitrogen Bottle Valve. 83 | | 83 © 2021 Baker Hughes Company. All rights reserved. © 2020 Baker Hughes Company. All rights reserved. Baker Hughes Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 84 Figure 73: Typical Installation Arrangement with Auxilary Supply for Artificial Actuation of Pilot Only 84 | | 84 © 2020 Baker Hughes Company. All rights reserved. © 2021 Baker Hughes Company. All rights reserved. Baker Hughes Consolidated 2900 Series POSRV Instruction Manual...

-

Page 85: Troubleshooting

Discharging into a closed contain- sure vessel er or not enough capacity in the Install Backflow Preventer. discharge system. | 85 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 86: 2900 Series Posrv Options

2. Cleaning agents used shall be such that effective cleaning is assured without injuring the surface finishes or material properties of the part. 86 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 87: Dirty Service Option

1/4” - 18 NPT Dirty Media Source SHOWN 90° OUT OF POSITION Figure 76: 39MV07 Dirty Service Figure 77: 39MV22/72 Dirty service | 87 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 88 1. Insert Top: Galling or excessive wear on the inside diameter that guides the Main Piston. Check for any corrosion or pitting. Also, check for galling of threads. 88 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 89: Dual Pilots

Note: See Tables 27 to 30 for replacement filter parts information. | 89 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 90: Single, Dual And High Capacity Filters (Optional)

Figure 80: Sensing Line Figure 81: High Capacity Figure 82: Dual Filter Filter Filter 90 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 91: Gag

(Figures 84 and 85). Figure 83: Gag Figure 84: Heat Exchanger - Hot Service Figure 85: Heat Exchanger - Cold Service | 91 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 92: Lifting Lever

Figure 88: Pressure Differential Switch L. Pressure Spike Snubber Baker Hughes recommends the use of a pressure spike snubber (Figure 89) for all applications which Figure 86: Manual Blowdown Valve may have high frequency pressure spikes. The... -

Page 93: Remote Pilot Mounting

Sensing Tube Plug Filter Sensing Ring Figure 91: Sensing Ring 93 | | 93 © 2021 Baker Hughes Company. All rights reserved. © 2021 Baker Hughes Company. All rights reserved. Baker Hughes Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 94: Maintenance Tools And Supplies

1.063” (26.99 mm) Figure 92: Adjuster Top Seal Insertion Tool 94 | | 94 © 2021 Baker Hughes Company. All rights reserved. © 2021 Baker Hughes Company. All rights reserved. Baker Hughes Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 95: Insert Installation Tool

.125” (3.18 mm) (TYP) ITEM 2 ITEM 3 .750” (19.05mm) ø.250” 2.9375” (6.35mm) (74.61mm) .313” (794mm) SQ Figure 93: Insert Installation Tool | 95 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 96: Lapping Tools

None None 4875201 1: Ring Laps: One set of three (3) ring laps is recommended for each orifice to assure ample flat laps are available at all times. 96 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 97: Disc Holder And Guide Removal And Assembly Tool

M THREADS Ø L HOLE Ø M HOLE DET. 5 DET. 3 Figure 95: Disc Holder and Guide Removal and Assembly Tool | 97 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 98: 2900 Is Torquing Tool Insert

Nozzle 2910 12/14/16J 2905/06/10/12/14/16K 2905/06L Integral 1.964 2.750 Sense 2.428 3.438 Nozzle 2910 12/14/16L/2905/06/10/12/14M/N/P Integral Sense 3.300 4.375 Nozzle 2905/06/10/12Q/R Integral Sense 4.526 5.312 Nozzle 2905/06/10/12T/U Integral Sense 98 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 99: Replacement Parts Planning

How to verify Materials of O-Rings and Seals: Kit coding indicates O-Ring and seals material. Examples: M0RK-70T006 Teflon Buna N PSGK - 31B Ethylene / Propylene Viton Kalrez | 99 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... -

Page 100: Positive Identification Of Main Valve And Pilot Valve Combinations

• Baker Hughes guarantees the parts • Consolidated valve products have been in use since 1879 • Baker Hughes has worldwide service • Baker Hughes has fast response availability for parts 100 | © 2021 Baker Hughes Company. All rights reserved. -

Page 101: Recommended Spare Parts

1 set of Nuts and Studs Tube Fittings (2) 1: A combination of Class I and II parts will satisfy maintenance requirements 85% of the time. | 101 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual... - Page 102 M0RK29052B008 2905,06,10,12,20,22 M0RK29006B008 M0RK29032B008 2914,16,24,26 M0RK29024B008 M0RK29050B008 2905,06,10,12,14,20,22,24 M0RK29007B008 M0RK29033B008 2905,06,10,12,14,20,22,24 M0RK29008B008 M0RK29034B008 2905,06,10,20 M0RK29009B008 M0RK29035B008 2912,14 M0RK29019B008 M0RK29045B008 2905,06,10,12,20,22 M0RK29010B008 M0RK29036B008 2905,06,10,12,20,22 M0RK29011B008 M0RK29037B008 2905,06,10,12,20,22 M0RK29012B008 M0RK29038B008 102 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 103 M0RK29050B018 2905,06,10,12,14,20,22,24 M0RK29007B018 M0RK29033B018 2905,06,10,12,14,20,22,24 M0RK29008B018 M0RK29034B018 2905,06,10,20 M0RK29009B018 M0RK29035B018 2912,14 M0RK29019B018 M0RK29045B018 2905,06,10,12,20,22 M0RK29010B018 M0RK29036B018 2905,06,10,12,20,22 M0RK29011B018 M0RK29037B018 2905,06,10,12,20,22 M0RK29012B018 M0RK29038B018 | 103 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 104 M0RK29052T006 2905,06,10,12,20,22 M0RK29006T006 M0RK29032T006 2914,16,24,26 M0RK29024T006 M0RK29050T006 2905,06,10,12,14,20,22,24 M0RK29007T006 M0RK29033T006 2905,06,10,12,14,20,22,24 M0RK29008T006 M0RK29034T006 2905,06,10,20 M0RK29009T006 M0RK29035T006 2912,14 M0RK29019T006 M0RK29045T006 2905,06,10,12,20,22 M0RK29010T006 M0RK29036T006 2905,06,10,12,20,22 M0RK29011T006 M0RK29037T006 2905,06,10,12,20,22 M0RK29012T006 M0RK29038T006 104 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 105 M0RK29050E002 2905,06,10,12,14,20,22,24 M0RK29007E002 M0RK29033E002 2905,06,10,12,14,20,22,24 M0RK29008E002 M0RK29034E002 2905,06,10,20 M0RK29009E002 M0RK29035E002 2912,14 M0RK29019E002 M0RK29045E002 2905,06,10,12,20,22 M0RK29010E002 M0RK29036E002 2905,06,10,12,20,22 M0RK29011E002 M0RK29037E002 2905,06,10,12,20,22 M0RK29012E002 M0RK29038E002 | 105 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 106 M0RK29052E019 2905,06,10,12,20,22 M0RK29006E019 M0RK29032E019 2914,16,24,26 M0RK29024E019 M0RK29050E019 2905,06,10,12,14,20,22,24 M0RK29007E019 M0RK29033E019 2905,06,10,12,14,20,22,24 M0RK29008E019 M0RK29034E019 2905,06,10,20 M0RK29009E019 M0RK29035E019 2912,14 M0RK29019E019 M0RK29045E019 2905,06,10,12,20,22 M0RK29010E019 M0RK29036E019 2905,06,10,12,20,22 M0RK29011E019 M0RK29037E019 2905,06,10,12,20,22 M0RK29012E019 M0RK29038E019 106 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 107 M0RK29050V005 2905,06,10,12,14,20,22,24 M0RK29007V005 M0RK29033V005 2905,06,10,12,14,20,22,24 M0RK29008V005 M0RK29034V005 2905,06,10,20 M0RK29009V005 M0RK29035V005 2912,14 M0RK29019V005 M0RK29045V005 2905,06,10,12,20,22 M0RK29010V005 M0RK29036V005 2905,06,10,12,20,22 M0RK29011V005 M0RK29037V005 2905,06,10,12,20,22 M0RK29012V005 M0RK29038V005 | 107 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 108 M0RK29052V022 2905,06,10,12,20,22 M0RK29006V022 M0RK29032V022 2914,16,24,26 M0RK29024V022 M0RK29050V022 2905,06,10,12,14,20,22,24 M0RK29007V022 M0RK29033V022 2905,06,10,12,14,20,22,24 M0RK29008V022 M0RK29034V022 2905,06,10,20 M0RK29009V022 M0RK29035V022 2912,14 M0RK29019V022 M0RK29045V022 2905,06,10,12,20,22 M0RK29010V022 M0RK29036V022 2905,06,10,12,20,22 M0RK29011V022 M0RK29037V022 2905,06,10,12,20,22 M0RK29012V022 M0RK29038V022 108 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 109 Note: The sensing tube filter element cannot High Capacity Filter/S4 be cleaned and must be replaced when Seal Material Part No. clogged. Teflon ® 9465-18191 | 109 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

-

Page 110: Field Service, Repair And Training Program

Green Tag Center (GTC). modifications, e.g. butt-weld, bushing replacements, code welding, pilot replacement, etc. For further information, please contact your local Green Tag Center (GTC). 110 | © 2021 Baker Hughes Company. All rights reserved. Baker Hughes... - Page 111 Notes: | 111 © 2021 Baker Hughes Company. All rights reserved. Consolidated 2900 Series Generation II POSRV Instruction Manual...

- Page 112 Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation.

Need help?

Do you have a question about the Consolidated Generation II 2900 Series and is the answer not in the manual?

Questions and answers