Summary of Contents for Baker Hughes Consolidated 2478 Series

- Page 1 Consolidated ™ 2478 Series Pressure Relief Valves Instruction Manual (Rev. C) Baker Hughes Data Classification : Public...

- Page 2 | © 2020 Baker Hughes Company. All rights reserved. Baker Hughes...

- Page 3 TO ASSIST IN THE INSTALLATION, TESTING, OPERATION, AND/OR MAINTENANCE OF THE EQUIPMENT DESCRIBED. THIS DOCUMENT SHALL NOT BE REPRODUCED IN WHOLE OR IN PART WITHOUT THE WRITTEN APPROVAL OF BAKER HUGHES. © 2020 Baker Hughes Company. All rights reserved. Consolidated 2478 Series Pressure Relief Valve Manual...

- Page 4 Note: Multiply USCS value with Conversion Factor to get Metric value. NOTICE! For valve configurations not listed in this manual, please contact your local Green Tag™ Center (GTC) for assistance. © 2020 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 5: Table Of Contents

Handling and Storage ......................9 VII. Pre-Installation and Installation Instructions ................9 VIII. Introduction ..........................9 Consolidated 2478 Series Relief Valve ................10 Operating Principle .......................11 Disassembly of 2478 Series Relief Valve ................11 XII. Inspection and Part Replacement ..................12 XIII. -

Page 6: Product Safety Sign And Label System

Handle valve carefully. to avoid possible this will result in severe prevent possible injury Do not drop or strike. severe personal injury personal injury or death. or death. © 2020 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 7: Safety Precautions

Striking a valve which is under pressure can cause premature actuation. Never tamper with the valve when system pressure is near the valve set pressure. • Before performing any machining on valve parts, consult Baker Hughes or its authorized representative. Deviation from critical dimensions can adversely affect valve performance. -

Page 8: Safety Notice

Baker Hughes product, or render it unsafe. It is also important to understand that these “safety messages” are not exhaustive. Baker Hughes can... -

Page 9: Warranty Information

Refer products of its manufacture. Therefore, customers to Baker Hughes’s Standard Terms of Sale, or specific contracting such repair services from unauthorized contract for complete details on warranty and limitation sources must do so at their own risk. - Page 10 Safety Valve fluid service. A safety valve is a pressure relief valve actuated by inlet static pressure and characterized by rapid • Warn opening or pop action. See “Simmer” (definition above). © 2020 Baker Hughes Company. All rights reserved. Baker Hughes...

-

Page 11: Handling And Storage

This manual therefore provides instructions for installation, maintenance and repair of Consolidated Bronze Safety Smokeless powder 1260 ft-Ib (1708 N-m) Valves. Nitroglycerin 2,000,000 ft-Ib (2,711,636 N-m) © 2020 Baker Hughes Company. All rights reserved. Consolidated 2478 Series Pressure Relief Valve Manual... -

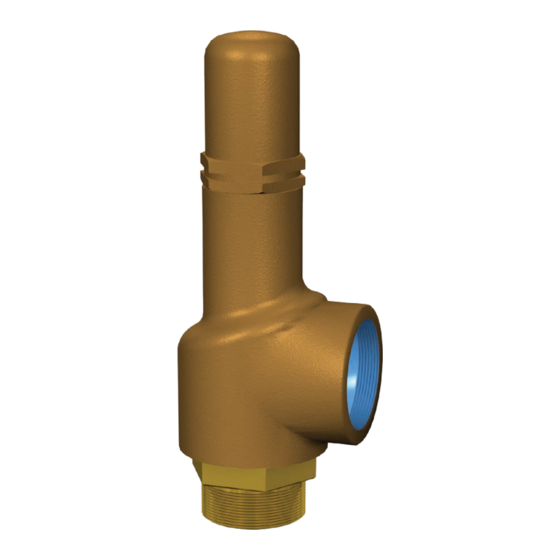

Page 12: Consolidated 2478 Series Relief Valve

Screwed Cap Lever Packed Cap Cam Shaft Bushing Figure 1: 2478 Standard Soft Seat Design Drive Screw O-Ring Release Nut Release Locknut O-Ring Gasket Figure 2: Packed Cap Assembly 10 | © 2020 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 13: Operating Principle

Ring by a sharp tool. Subsequently, remove Soft Seat using the same tool. will result in severe These two parts must not be used again. personal injury or death. | 11 © 2020 Baker Hughes Company. All rights reserved. Consolidated 2478 Series Pressure Relief Valve Manual... -

Page 14: Inspection And Part Replacement

When lapping the Base keep a firm grip on the lap or part to prevent the possibility of dropping it and damaging the seat. 12 | © 2020 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 15: Reassembly Of 2478 Series Relief Valve

7530163-5 Ring 2478G 2091158 7530163-7 Post 2478H 2091160 7530163-9 Disc 2478J 2091162 7530163-11 Metal Soft Seat Plate Figure 3: 2478 Soft Seat Assembly | 13 © 2020 Baker Hughes Company. All rights reserved. Consolidated 2478 Series Pressure Relief Valve Manual... -

Page 16: Setting And Testing

Hang-up occurs upon closing and is defined as leakage from the valve failing to shut-off tightly. Mechanical interference is the primary cause. Disc and disc guiding area in the bonnet should be examined. 14 | © 2020 Baker Hughes Company. All rights reserved. Baker Hughes... -

Page 17: Replacement Parts Planning

Green Tag Center (GTC) or Authorized Consolidated Sales Representatives • Baker Hughes guarantees the parts network. • Consolidated valve products have been in use since 1879 | 15 © 2020 Baker Hughes Company. All rights reserved. Consolidated 2478 Series Pressure Relief Valve Manual... -

Page 18: Recommended Spare Parts

XVIII. Recommended Spare Parts The recommended spare parts/tools are spring, disc, Refer to Consolidated 2478 Series Relief Valve catalog soft seat, retaining ring and retaining ring assembly for more detailed information on parts descriptions and tools. When ordering replacement or spare parts, state nomenclatures. -

Page 19: Manufacturer's Field Service & Repair Program

“Hands On” experience with It is highly recommended that the professional talents of Consolidated valves. The seminar also includes valve a Baker Hughes Field Service Engineer be employed to terminology and nomenclature, component inspection, make final field adjustments during the initial setting of trouble shooting, setting and testing, with emphasis on all Consolidated Safety Valves. - Page 20 Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation.

Need help?

Do you have a question about the Consolidated 2478 Series and is the answer not in the manual?

Questions and answers