Subscribe to Our Youtube Channel

Summary of Contents for Mindray DP-10

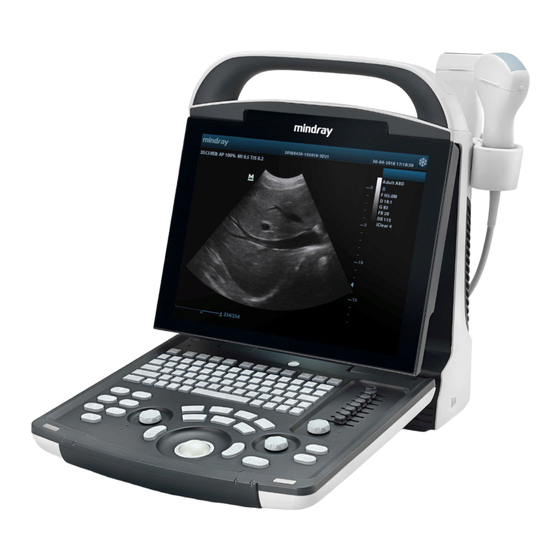

- Page 1 DP-10/DP-10T/DP-11/DP-15/DP-18 Digital Ultrasonic Diagnostic Imaging System Operator’s Manual [Basic Volume]...

-

Page 3: Table Of Contents

Contents Contents ......................i Intellectual Property Statement ....................I Responsibility on the Manufacturer Party ................II Warranty ..........................II Important Information ......................IV Preface ..........................V Safety Precautions ......................VIII System Basics ..................1-1 Structure ......................... 1-1 I/O Panel ........................ 1-3 Power Supply Panel .................... - Page 4 Image Control and Adjustment ............6-1 Adjusting Image Parameters .................. 6-1 Image Zoom ......................6-6 Image Reverse ....................... 6-7 Cine ......................7-1 Cine Indicator ......................7-1 Manual Cine and Auto Cine ................... 7-1 Measurements ..................8-1 Measurement Menu ....................8-1 General Procedure of Measurements ..............

- Page 5 12.1 Transducers ......................12-1 12.1.1 Name and Function of Each Part of the Transducer ........12-2 12.1.2 Orientation of the Ultrasound Image and the Transducer Head ....... 12-3 12.1.3 Procedures for Operating ................. 12-4 12.1.4 Wearing the Transducer Sheath ............... 12-7 12.1.5 Transducers Cleaning and Disinfection............

- Page 6 Appendix A System Configuration ............A-1 Appendix B Specifications ................ B-1 Appendix C Measurement Accuracy ............C-1 Appendix D Guidance and Manufacturer's Declaration ......D-1 Appendix E Maximum Surface Temperature of Transducers ....E-1 Appendix F Acoustic Output Reporting Table(61157-2007) ....F-1 Appendix G Safety Classification .............

-

Page 7: Intellectual Property Statement

Intellectual Property Statement SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray) owns the intellectual property rights to this Mindray product and this manual. This manual may refer to information protected by copyright or patents and does not convey any license under the patent rights or copyright of Mindray, or of others. -

Page 8: Responsibility On The Manufacturer Party

Contents of this manual are subject to change without prior notice. All information contained in this manual is believed to be correct. Mindray shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this manual. - Page 9 Exemptions Mindray's obligation or liability under this warranty does not include any transportation or other charges or liability for direct, indirect or consequential damages or delay resulting from the improper use or application of the product or the use of parts or accessories not approved by Mindray or repairs by people other than Mindray authorized personnel.

-

Page 10: Important Information

Important data must be backed up on external recording media such as clinical records, notebooks etc. Mindray shall not be liable for loss of data stored in the memory of this system caused by operator error or accidents. This manual contains Warnings regarding foreseeable potential dangers. Be alert at all times to dangers other than those indicated. -

Page 11: Preface

Preface To ensure safe and correct operation of the system, carefully read and understand this operator’s manual before operating the system. Structure of Operator’s Manual This manual mainly describes the structure, functions, installation, operation, maintenance of the system. This manual has two volumes. Basic volume –... - Page 12 Labels and Symbols on System The following table explains the labels and symbols attached on the system. Label or Symbol Signification General warning, caution, risk of danger. Before using the system, be sure to carefully read the relevant content of this operator’s manual. (a) General warning, caution, risk of danger.

- Page 13 Label or Symbol Signification Ethernet port Video output Equipotential terminal Remote control port VGA out USB port Transducer socket A Transducer socket B Reserved Reserved Brightness of the display Contrast of the display Authorized representative in the European Community. The device is fully in conformance with the Council Directive Concerning Medical Devices 93/42/EEC.

- Page 14 Conventions This manual uses the following way to mark keys on the control panel and words displayed on the screen. Keys on the control panel are marked with < >. For example, <Back> represents the “Back” key on the control panel. Words displayed on the screen are marked with [ ].

- Page 15 5. Do not connect the system to receptacles that control WARNING: current to devices such as life-support systems and are equipped with the same circuit breakers and fuses as those of the system. If the system malfunctions and generates overcurrent, when there instantaneous current at power ON, the circuit breakers...

- Page 16 17. Before moving the system, power it off, close the control WARNING: panel and then remove all connections (including connections to transducers). Then hold the system’s handle to move the system to a proper location carefully. 18. Before cleaning the system, power it off and remove the power plug from the receptacle to avoid electric shock.

- Page 17 4. Always keep the system dry. Do not move the system quickly from a cold place to a warm one. Condensation or water drops formed may cause short circuit. 5. If the circuit breaker is tripped or the fuse is blown, it indicates that the system or peripherals have problems.

- Page 18 9. Only engineers of our company or authorized by our company can replace the fuses. 10. Only perform operations described in this manual. 11. Do not modify system parameters. If it is necessary to change system parameters, contact our company’s Customer Service Department or your local distributor.

- Page 19 8. Please use the disinfection or sterilization solution that recommended in this operator’s manual, otherwise Mindray will not be liable for damage caused by other solutions. If you have any questions, please contact Mindray Customer Service Department or sales representative.

- Page 20 dust excessive vibration heat generators Use the probes under the specified ambient conditions. 3. Repeated disinfection will eventually damage the probe, please check the probe’s performance periodically.

-

Page 21: System Basics

System Basics The system is intended for diagnosis of human liver, gallbladder, spleen, kidney, pancreas, bladder, ureter, uterus, uterine appendages, small parts and pregnant women in hospitals and clinics. This chapter introduces the system structure, control panel, basic elements of software interface and general operations of the elements. - Page 22 System Basics Part Description Power supply panel Panel of electrical interfaces Winding rack Used to wind the power cable. I/O Panel Refer to 1.2 I/O Panel Gel holder Used to place the ultrasound gel temporarily. Part Description USB port Used to connect USB devices...

-

Page 23: I/O Panel

System Basics I/O Panel The I/O panel locates at the back of the system. <4> <1> <2> <5> <3> <6> Name Function Network port To connect the network cable Separate video output, connecting video printer or S-Video output monitor Video output (coaxial-cable) Video output, connecting video printer or monitor USB ports Used to connect USB devices. -

Page 24: Control Panel

System Basics Name Function Power inlet AC power inlet Used for equipotential connection, that balances the Equipotential protective earth potentials between the system and other terminal electrical equipment. Control Panel <1> <2> <3> <4> <5> <6> <7> <8> <9> <14> <10>... - Page 25 System Basics Name Description Function Direction key To adjust monitor brightness or contrast when pressing with <Fn> key. F1~F4 User-defined key You can assign a function to the key. File File To enter/exit file system (iStation) Setup Setting To open/close the Setup menu. Press to delete the comment, etc.

-

Page 26: Interface Elements And Operations

System Basics Name Description Function Caliper Press to enter/exit Measurement Depth Press: to switch between Depth and Zoom; Zoom Rotate: to adjust corresponding parameter Back Press to decrease parameter value or undo last step during measurement Roll the trackball to change the cursor Trackball position. - Page 27 System Basics Introduction Hospital name, patient name and ID Some of the current image parameters, including BG (B gain), MG (M gain), AP (acoustic power), IP (image process), FR (frame rate) Transducer model Current frequency of the transducer Frozen symbol (when the image is frozen, the symbol appears) Current date of the system (the date displayed on a frozen image is the date when the image is frozen) Current time of the system (the time displayed on a frozen image is the time when...

-

Page 28: Menu

System Basics Introduction The direction where the arrow indicates shows the initial scan position of the transducer (“ ” means the first scan line from the left is the initial scan position of the transducer; “ ” means the first scan line from the right is the initial scan position of the transducer). - Page 29 System Basics 1.5.2.2 Number Menu Items A number menu item adjusts the value of a parameter. The parameter name is on the left of the menu item and the value is on the right. To operate a number menu item, turn the trackball to move the cursor onto the menu item and then press <Set>...

-

Page 30: Dialog Box

System Basics To operate a submenu menu item, turn the trackball to move the cursor onto the menu item and its submenu pops up. Then, turn the trackball to move the cursor onto one item of the submenu and press <Set>. 1.5.3 Dialog Box The following figure is an example of dialog box. - Page 31 System Basics Page labels To enter a page, turn the trackball to move the cursor onto the corresponding page label and then press <Set>. Button A button is used for some operation. To click a button, turn the trackball to move the cursor onto the button and then press <Set>. Scroll bar When not all of contents can be displayed in the current area, the scroll bar appears.

- Page 32 System Basics Pulldown list To select an option from a pull-down list, turn the trackball to move the cursor onto the pull-down list or and then press <Set> to pop up the options. Then turn the trackball to move the cursor onto the option you want and then press <Set>. Edit box You can enter characters into an edit box.

- Page 33 System Basics A list displays multiple contents in a line. To select an item in a list, turn the trackball to move the cursor onto the item you want and then press <Set>. 1-13...

-

Page 34: System Connection

System Connection This chapter introduces how to connect the power supply, equipotential terminal, transducers and peripherals to the system. NOTE: Before connecting the system, put the system in a proper place and ensure at least 20cm of clearance at the back and sides of the system. The transportation, storage and operating environments of the system must meet requirements listed in the appendix. -

Page 35: Connecting Transducer

System Connection When the system is connected with other equipments, be WARNING: sure to connect their equipotential terminals before inserting any of their power plugs into a receptacle, and also, be sure to remove the power plugs from receptacles before disconnecting the equipotential terminals. -

Page 36: Connecting A Footswitch

System Connection Turn off the system or freeze the image. Turn the lock handle 90° counterclockwise. Remove the transducer connector from the transducer socket on the system. Connecting a Footswitch Plug the connector of the footswitch to the socket with the bulge of the footswitch connector aligning with the groove of the socket. - Page 37 System Connection NOTE: If you remove the USB connector from the USB port directly without performing the steps above, the USB storage device and the system may be damaged. To connect a video printer Turn off the system and the printer. Use the data cable of printer to connect the “VIDEO IN”...

-

Page 38: Startup/Shutdown

Startup/Shutdown This chapter introduces procedures of startup and shutdown of the system. Startup Before the startup, complete the following checks: The ambient temperature, humidity and atmospheric pressure meet requirements listed in the appendix. The system is placed in a clean location where there is no direct sunlight, no sudden changes in temperature, no condensation, few dust, no vibration, and far from heat generators. -

Page 39: Shutdown

Startup/Shutdown After the startup, check the system as follows. If you find any abnormality, turn off the system and WARNING: refer to “13.3 Troubleshooting” to see if the section lists any solution for the problem. If not, contact our company’s Customer Service Department or your local distributor. -

Page 40: Preset

Preset This chapter briefly describes how to preset the system. Refer to the Advanced Volume for details. The preset function is used to set the operating status, configuration parameters of each exam mode, post process and others. The system runs automatically with the preset parameters after each startup. -

Page 41: Beginning Exam

Beginning Exam This chapter describes the general procedure before scanning a patient. Before examining a patient, press <Patient> to update the patient CAUTION: information. Otherwise, the patient information does not correspond to the patient data and misdiagnosis may occur. Inputting Patient Information Although you can scan a patient without inputting the patient CAUTION: information, it is recommended to input patient information... -

Page 42: Selecting Exam Mode

Beginning Exam Selecting Exam Mode If the system is not in the exam mode you want, press <EXAM> to enter the [Exam Select] menu and then select the exam mode. The system supports the following exam modes: Abdomen Gynecology Obstetric Small parts Selecting Transducer For the system connecting two transducers, if the current transducer is not the one you... -

Page 43: Image Control And Adjustment

Image Control and Adjustment This chapter describes how to control and adjust the image. Adjusting Image Parameters To obtain a better image, it is recommended to rotate the brightness knob and contrast knob to make the marks on them in the top position. Parameter Description B/M gain... - Page 44 Image Control and Adjustment Parameter Description TGC (time gain control) means using the gain compensation curve separated to several segments by depth to optimize the image. Four groups of TGC keys adjusts the current image by segments. The TGC curve appears on the left of screen when it is being adjusted and changes as a TGC key is pressed, which is shown in the figure below.

- Page 45 Image Control and Adjustment Parameter Description Edge The edge enhancement increases image profile to distinguish image enhancement boundary. You can only adjust the parameter on real-time images. To adjust the parameter of B image, enter the [B MODE MENU] menu and then set [Edge] in the menu; to adjust the parameter of M image, enter the [M MODE MENU] menu and then set [Edge] in the menu.

- Page 46 Image Control and Adjustment Parameter Description IP is an image process effect, which is a group of image process parameters including the dynamic range, edge enhancement and frame average. You can preset IP in the [PRESET] menu (see the “Preset” chapter in the Advance Volume for details).

- Page 47 Image Control and Adjustment For real-time B images, enter the [B MODE MENU] menu. For real-time M images, enter the [M MODE MENU] menu. For frozen or cine images, or opened FRM/CIN files, enter the [FREEZE MENU] menu. Select [Curve] in [Post Proc] or [B Post Proc] or [M Post Proc]. The [Gray Trans Curve] dialog box pops up.

-

Page 48: Image Zoom

Image Control and Adjustment Select [Rejection] in [Post Proc] or [B Post Proc] or [M Post Proc]. The [Gray Rejection] dialog box pops up. Move the cursor to “▲” and the cursor changes to “ ”. Press <Set>. Move the trackball and “▲” moves with it. Move “▲” to the position you want. If you want to place “... -

Page 49: Image Reverse

Image Control and Adjustment In the B, B/B or M/B mode, press <Zoom/Depth> knob to light the Zoom indicator, and a frame appears on the center of image. Note that in the B/B mode, only the active window can be zoomed. Frame 400% Move the trackball to move the frame to select the zoom center. -

Page 50: Cine

Cine This chapter introduces the cine and its operation method. Before examining a patient, press <Patient> to update the patient CAUTION: information and clear the cine memory. Otherwise, the patient information does not correspond to the patient data and misdiagnosis may occur. The system supports only the cine of B images. - Page 51 Cine In the B, B/B or M/B mode, press <Freeze> to enter the manual cine. The [FREEZE MENU] menu is displayed (if no menu is displayed, press <Menu>). Note that in the B/B mode, only the window that is active when <Freeze> is pressed has the cine.

-

Page 52: Measurements

Measurements This chapter briefly introduces measurements on B and M images. Refer to the Advanced Volume for details. Ensure proper measurement targets and images and WARNING: measurements are performed in valid image area. Incorrect measurement results may cause misdiagnosis. For a measurement in frozen status, unfreezing the image will CAUTION: clear measurement calipers and general measurement data. - Page 53 Measurements Press <Measure> to enter the measurement status. The corresponding measurement menu will be displayed (if no menu is displayed, press <Menu>). Select items to perform measurements and calculations. To switch to another measurement menu, you can Press <EXAM> to select the exam mode you want; for the system connecting two transducers, select the proper transducer;...

-

Page 54: Comment

Comment This chapter introduces how to add, modify and delete comments. Be sure to add correct comments. Otherwise, misdiagnosis WARNING: may occur. Entering Comment Status Press <Comment> to enter the comment status. The cursor is displayed as a “|”. Adding Comments You can add comments on real-time, frozen and cine images, on opened FRM/CIN files, and on their zoomed images. - Page 55 Comment Press <Update>. The [Comment Library] dialog box pops up and the page corresponding to the current exam mode is displayed. If none of the comments in the [Comment Library] dialog box is what you need, click [Close] or press <Update> or press <Esc> to close the [Comment Library] dialog box.

-

Page 56: Moving Comments

Comment Moving Comments To move a comment (excluding arrow) Enter the comment status. Move the cursor onto the comment to be moved. The cursor changes to “ ”. Press <Set>. The selected comment has a gray background. Turn the trackball and a frame whose size is the same as that of the comment moves with it. -

Page 57: Deleting Comments

Comment Deleting Comments 9.5.1 Deleting All Comments First method to delete all comment (including arrows) Press <Clear> to clear all comments (including arrows), body mark, measurement caliper s and general measurement data on the screen. Second method to delete all comments (including arrows) Enter the comment status. -

Page 58: Body Mark

Body Mark This chapter introduces how to add, move and clear the body mark. Be sure to add correct body mark. Otherwise, misdiagnosis WARNING: may occur. The body mark indicates the body position on which the scan is performed and the transducer orientation to interpret the image. -

Page 59: Moving Body Mark

Body Mark If you do not want to add any body mark, click [Close] or press <BodyMark> or press <Esc> to close the dialog box. No body mark appears on the image. The operation is over. If the body mark you want is not in the current page, enter other pages to find it and then go to the next step. -

Page 60: File System

File System This chapter introduces the file system and its operation. The file system saves image data to files in a storage device after the image is frozen and manages the files. The system supports the following file formats. Screen file (BMP) Screen file (JPG) Cine file (CIN) Frame file (FRM) -

Page 61: Opening Files

File System Freeze the image. If necessary, review images until the image to be saved is displayed on the screen. Press <File> and the [FILE MENU] menu is displayed (if no menu is displayed, press <Menu>). In the [FILE MENU] menu, click [Save BMP]. The [Save As] dialog box pops up. In the dialog box, the default directory to save the file and the default file name are displayed. - Page 62 File System The following procedure describes the opening of a BMP file. The saving of files with other formats is similar to it and not described in this manual (note that the opening of DCM files is only available in the system configuring DICOM). Enter the [FILE MENU] menu.

-

Page 63: File/Directory Management

File System Note that during the steps above, you can click [Cancel] in the [Load File] dialog box or press <Esc> to close the dialog box and open none of files. 11.4 File/Directory Management You can manage directories and files in the Flash memory and USB storage device. Enter the [FILE MENU] menu. - Page 64 File System Move the cursor onto the item you want in the directory list and then press <Set> twice successively to enter the directory. If you want to return to the parent directory, move the cursor onto [..] and then press <Set> twice successively.

-

Page 65: File Management

File System Select the directory to be deleted in the directory list. Click [Del] in the left part of dialog box and the following dialog box pops up. If you want to delete the selected directory, click [OK]; if you want to delete nothing, click [Cancel] or press <Exit>. - Page 66 File System Select the driver in [Driver:]. The Flash memory in the system is the driver C, and the remaining driver(s) belong(s) to the USB storage device if a USB storage device is connected. If the USB storage device is selected in the previous step, move the cursor onto the item you want in the directory list and then press <Set>...

-

Page 67: Ivision

File System If you want to delete the selected file, click [OK]; if you want to delete nothing, click [Cancel] or press <Exit>. To delete all files in a directory If the files to be deleted are not in the current directory, perform the following steps in the [File/Disk Manager] dialog box. - Page 68 File System If demo files are not in the current directory, click [Browse]. The [Dir Select] dialog box pops up. Select the driver in [Driver:]. The Flash memory in the system is the driver C, and the remaining driver(s) belong(s) to the USB storage device if a USB storage device is connected.

-

Page 69: Sending Dcm Files

File System If you want to start the demo, click [Start] and the demo starts or if the files to be played include CIN or FRM files, the following dialog box pops up; if you do not want to start the demo, click [Exit] or press <Exit>. If you want to start the demo, click [OK] in the dialog box and the system deletes the current patient information and starts the demo;... -

Page 70: Exiting File System

File System In the [FILE MENU] menu, click [Send DCM Image]. The system starts to send the current image to the server. “Transmitting…” is displayed at the lower part of screen. After the image is sent, the system will prompt the successful transmitting. 11.8 Exiting File System After all operations to the file system are completed, press <File>... -

Page 71: Transducers And Biopsy

Transducers and Biopsy Note: For details of storage time and condition for disinfected probes or sterilized probes and brackets, please refer to Technical standard for Disinfection of Medical and Health Structures 12.1 Transducers The system supports the following transducers: Probe Type Illustration 35C20EA... -

Page 72: Name And Function Of Each Part Of The Transducer

Transducers and Biopsy Some of the transducers have matched needle-guided brackets for biopsy, the available transducers and the corresponding needle-guided brackets are listed as follows: Transducer Needle-guided Biopsy Type Applicable Biopsy Needle Model Bracket Model Angle/Depth Metal/needle 14G, 16G, 18G, 20G, 22G un-detachable 35C20EA NGB-003... - Page 73 Transducers and Biopsy Name Function It converts the electrical signal into ultrasound signal, making the sound beams focus in the given direction; meanwhile, it will receive the ultrasound signal and then <1> Transducer head convert the received signal into electrical signal. The lens on the surface is the acoustic lens.

-

Page 74: Procedures For Operating

Transducers and Biopsy O Mark Pointed to marked side Method 2 Mark Orientation Mark 12.1.3 Procedures for Operating This section describes general procedures for operating the transducer. The proper clinical technique to be used for operating the transducer should be selected on the basis of specialized training and clinical experience. - Page 75 Transducers and Biopsy Procedures for operating (with biopsy function): Inspection before examination Connection to the ultrasonic diagnostic system Examinations Biopsy procedure Disconnection to the ultrasonic Sterilization of the needle guided Wiping off the ultrasound gel Inspection after use Washing the transducer with water Storage Draining/drying Immersion into disinfectant...

- Page 76 Transducers and Biopsy Procedures for operating (with no biopsy function): Inspection before examination Connection to the ultrasonic Examinations Disconnection to the ultrasonic Wiping off the ultrasound gel Washing the transducer with water Draining/drying Disinfection Immersion into disinfectant Removing the transducer from Rinsing the transducer into sterile Draining/drying Inspection after use...

-

Page 77: Wearing The Transducer Sheath

Transducers and Biopsy 12.1.4 Wearing the Transducer Sheath A legally marketed transducer sheath must be installed over the transducer before performing intra-cavitary and intra-operative examination. Protective barriers may be required to minimize disease transmission. Transducer sheaths are available for use with all clinical situations where infection is a concern. -

Page 78: Transducers Cleaning And Disinfection

Chemical residues on the transducer may be harmful to the human body. 3. The efficacy of disinfectants and sterilizing solutions is not guaranteed by MINDRAY. Contact the manufacturers for information on the activity of the products. NOTE: 1. - Page 79 Transducers and Biopsy Cleaning Please follow the instructions in the manual for cleaning. 1. Wear sterile gloves to prevent infection. 2. Wash the transducer with water and remove all foreign matter. Soapy water may be used. A soft urethane sponge can be used to wash the transducer. Avoid using a brush, because it may damage the transducer.

- Page 80 Transducers and Biopsy Quaternary Ammoniums based disinfectant: Chemical Name Manufacturer Trade Procedures Name Quaternary Ecolab Inc. Ster-Bac Please refer instructions Ammoniums provided by the manufacturer of the solution for details. Hydrogen Peroxide and Peroxyacetic Acid -based disinfectant: Trade Name Chemical Name Procedures ®...

-

Page 81: Storage And Transportation

2. Store and transport the transducer under the specified ambient conditions. 3. When the transducer is sent to MINDRAY Customer Service Department or sales representative for repair, be sure to disinfect it and keep it in the carrying case to prevent infection. - Page 82 If an abnormality is found on the needle-guided bracket, immediately stop using it and contact MINDRAY Customer Service Department or sales representative. 4. DO NOT use a needle-guided bracket when scanning is performed.

-

Page 83: Needle-Guided Brackets

A needle-guided bracket is available for purchase as an optional accessory; it is used in combination with the transducer. Some of the transducers have matched needle-guided bracket and needles. To order needle-guided brackets, contact MINDRAY Customer Service Department or sales representative. -

Page 84: Names Of Parts

Transducers and Biopsy 12.2.2 Names of Parts This section describes the parts and corresponding functions of each needle-guided bracket. Here, we take a matched transducer as an example. NGB-001, NGB-002, NGB-003, and NGB-005 (Metal/needle un-detachable) The structure of metal/needle un-detachable needle-guided bracket NGB-001, NGB-002, NGB-003 and NGB-005 are similar to each other. - Page 85 Transducers and Biopsy NGB-001 (Metal/needle detachable) Name Description Groove needle-guided Matches with the tab of the transducer bracket Clamp Used for installing the needle-guided bracket on the needle-guided transducer bracket Adjusting base The size of the guiding hole: 5 types of needles can be needle type adjusted Guiding...

- Page 86 Transducers and Biopsy Name Description Determines the guiding hole together with the V-shaped V-shaped cover guiding block. It can be opened and closed. Determines the angle of the biopsy; different specifications Angle block of blocks can be used Angle shift sign Matches with the biopsy angle (25°, 35°, 45°)

- Page 87 Transducers and Biopsy Name Description Used for determining the angle of the biopsy; different <6> Angle block specifications of blocks can be used Used installing biopsy needle; there five <7> Guiding block specifications of guiding blocks for different biopsy needles Specification <8>...

- Page 88 Transducers and Biopsy Name Description Support of Used for installing the needle-guided bracket on the needle-guided transducer bracket Groove and tab of Respectively matched with the tab and groove of the needle-guided transducer bracket Angle adjusting base There are 3 types of angles available to be adjusted Angle shift Matched with the biopsy angle (40°,50°,60°) sign(40°,50°,60°)

-

Page 89: Inspection Of The Needle-Guided Bracket

Be sure to perform inspections before and after use of the needle-guided bracket. If an abnormality is found on the needle-guided bracket, immediately stop using it and contact MINDRAY Customer Service Department or sales representative. 1. Sterilize the needle-guided bracket before and after use. - Page 90 Transducers and Biopsy 3) Screw the pinch nut of the needle-guided bracket to confirm that the needle-guided bracket is properly installed on the transducer. 4) Adjust the adjusting nut of needle type to a desired shift and screw the nut to fix the guiding block.

- Page 91 Transducers and Biopsy NGB-001, NGB-002, NGB-003 and NGB-005 metal/needle un-detachable needle-guided bracket (taking NGB-001 as example) 1) Inosculate the locating groove on the clamp with the two raised edges on the transducer head and aligning the locating pit of the clamp to the convex point on the transducer head.

- Page 92 Transducers and Biopsy 2) Hold the transducer by one hand, select the proper needle-guided bracket, and hold it with the other hand. Match the groove and tab with the tab and groove of the transducer respectively. Amount the bracket onto the transducer. 3) Screw the pinch nut of the needle-guided bracket to confirm that the needle-guided bracket is properly installed on the transducer.

-

Page 93: Entering Status Of Guide Line Adjustment

Transducers and Biopsy 5) Insert a biopsy needle with the same specification as that of the guiding block into the hole of the guiding block. Ensure that all guide parts are seated properly prior to performing CAUTION: a biopsy. 12.2.5 Entering Status of Guide Line Adjustment When the B image is real-time, select [Puncture] in the [B MODE MENU] menu. -

Page 94: Selecting Guide Line

Transducers and Biopsy 12.2.6 Selecting Guide Line Enter the status of guide line adjustment. In the [NEEDLE GUIDE] menu, select the guide line you want in [GuideLine]. In it, ”All” represents all guide lines. 12.2.7 Adjusting Guide Line NOTE: Guide lines can only be adjusted on real-time B images. To move a guide line horizontally Enter the status of needle guide adjustment. -

Page 95: Exiting Status Of Guide Line Adjustment

Transducers and Biopsy 12.2.9 Exiting Status of Guide Line Adjustment You can exit the status of guide line adjustment by: Clicking [Return] in the [NEEDLE GUIDE] menu or pressing <Esc>. Or, directly pressing another key such as <Measure>, <Comment>, <BodyMark> or <File>. - Page 96 Transducers and Biopsy 2) Separate the residual part of the needle-guide bracket and the transducer from the needle. 3) Screw the pinch nut of the bracket, and remove the needle-guided bracket from the transducer. Metal/needle un-detachable needle-guided bracket: While holding the transducer and the needle-guided bracket, open the Grip knob of the needle-guided bracket.

-

Page 97: Clean And Sterilize The Needle-Guided Bracket

Please follow the instructions in the manual for cleaning. Sterilization 1. Wear sterile gloves to prevent infection. 2. Clean the needle-guided bracket before sterilizing it. MINDRAY recommends the following solution or sterilizing system to sterilize the needle-guided bracket. 3. Follow local regulations when selecting and using the disinfectant. -

Page 98: Storage And Transportation

2. Between examinations, keep the needle-guided bracket in a sterile environment. 3. When the needle-guided bracket is sent to your MINDRAY representative for repair, be sure to disinfect or sterilize it and keep it in the carrying case to prevent infection. -

Page 99: Disposal

Transducers and Biopsy 12.2.13 Disposal Be sure to dispose the needle-guided bracket only after sterilizing it. Contact your MINDRAY representative when disposing of this device. 12-29... -

Page 100: System Maintenance

System Maintenance This chapter introduces the system maintenance and simple troubleshooting. The system maintenance is completed by the user and the WARNING: service engineer. After the system is delivered to the user, the user assumes all the responsibilities in maintenance and operation. -

Page 101: Maintenance Performed By Service Engineers

System Maintenance proper external storage media. See “To copy a file” in “11.4 File/Directory Management” for details. Note that only the system supporting the USB port can backup data. To clean the transducer Refer to the transducer’s manual to clean and disinfect the transducer. To clean the screen Use soft cloth dipped with glass detergent to clean the screen and then air dry it. -

Page 102: Troubleshooting

System Maintenance 13.3 Troubleshooting The following troubleshooting can be performed by users. If any failure listed in the table below occurs, follow the measure in the table to troubleshoot it. If you cannot restore the system from the failure after performing the measure, contact our company’s Customer Service Department or your local distributor. -

Page 103: Acoustic Power Principle

Acoustic Power Principle 14.1 Concerns with Bioeffects Diagnostic ultrasound is recognized as being safe. In fact, there have been no reports of injuries to patients caused by diagnostic ultrasound. It cannot be stated categorically that ultrasound is 100% safe. Studies have revealed that ultrasound with extremely high intensity is harmful to body tissues. -

Page 104: Derated Ultrasonic Output Parameters

Acoustic Power Principle Users must take responsibility for the safety of patients and utilize ultrasound deliberately. Deliberate use of ultrasound means that output power of ultrasound must be selected based on ALARA. It was verified that the MI and TI values didn’t exceed 1.0 in each exam mode. 14.4 Derated Ultrasonic Output Parameters In order to determine the relevant Ultrasonic Output Parameters, a method is used which allows for the comparison of ultrasound systems which operate at different frequencies and... -

Page 105: Parameters Affecting Acoustic Power

Acoustic Power Principle 14.6 Parameters Affecting Acoustic Power Acoustic Power is affected by transmission conditions (focus, drive frequency, voltage applied to piezoelectric elements, etc.), scan conditions, settings, etc. 14.7 Imaging Functions Changing Acoustic Output Power Changes of imaging mode and adjustments to controls also affect the acoustic output power. Specific information is provided in the following table. -

Page 106: References For Acoustic Power And Safety

Acoustic Power Principle Operation Effect on the acoustic output power Reset or Power Resetting or turning on/off the system causes the system to return to Off/On the default status thus may change the acoustic output power. 14.8 References for Acoustic Power and Safety “Bioeffects and Safety of Diagnostic Ultrasound”... -

Page 107: Appendix A System Configuration

Appendix A System Configuration A.1 Basic Configuration Main unit Accessories Operator’s manual Power cord of the main unit Probe holder Gel holder Remote cable of printer A.2 Options DICOM software: DICOM3.0 Mobile trolley: UMT-110 Portable package Foot switch: 971-SWNOM Keyboard dust-proof cover Dual-transducer socket Needle-guided bracket Dust-proof cover... - Page 108 Sterilization A.4 Peripherals USB storage device Footswitch Video printer Graph/text printer The system supports the USB storage devices using FAT16 or FAT 32 file format and SCSI instructions. The system supports the following video printers: SONY UP-895MD SONY UP-897MD MITSUBISHI P93W The system supports the following graph/text printers (local print): HP DeskJet 5652/5650/3820/1280 (USB port) Business Inkjet 1200 (USB port)

-

Page 109: Appendix B Specifications

Appendix B Specifications B.1 Image Mode The system supports the following image modes: B.2 Power Supply Voltage: 100-240V~ Frequency: 50/60 Hz Input current: 1.0-0.5A Fuse: 250V~ T3.15AH B.3 Environment Conditions B.3.1 Operating Environment Ambient temperature: 0°C-40°C Relative humidity: 30%-85% (no condensation) Atmospheric pressure: 700hPa-1060hPa B.3.2 Storage and Transportation Environment Ambient temperature: -20°C-55°C... -

Page 110: Appendix C Measurement Accuracy

Appendix C Measurement Accuracy Within the selected field range, the measurement accuracy is ensured within the range mentioned above. The accuracy specifications are performance in the worst conditions, or based on the real test for the system. Depth and time Item Error range Range: full screen... -

Page 111: Appendix D Guidance And Manufacturer's Declaration

Appendix D Guidance and Manufacturer's Declaration The system complies with the EMC standard IEC60601-1-2: 2007. The use of unapproved accessories may diminish system WARNING: performance. NOTE: Use of accessories, transducers, and cables other than those specified may result in increased emission or decreased immunity of system. The system should not be used adjacent to or stacked with other equipment. - Page 112 Guidance and Manufacturer's Declaration TABLE 1 GUIDANCE AND MINDRAY DECLARATION—ELECTROMAGNETIC EMISSIONS The system is intended for use in the electromagnetic environment specified below. The customer or the user of system should assure that it is used in such an environment.

- Page 113 Guidance and Manufacturer's Declaration TABLE 2 GUIDANCE AND MINDRAY DECLARATION—ELECTROMAGNETIC IMMUNITY The system is intended for use in the electromagnetic environment specified below. The customer or the user of system should assure that it is used in such an environment.

- Page 114 Guidance and Manufacturer's Declaration TABLE 3 GUIDANCE AND MINDRAY DECLARATION—ELECTROMAGNETIC IMMUNITY The system is intended for use in the electromagnetic environment specified below. The customer or the user of system should assure that it is used in such an environment.

- Page 115 Guidance and Manufacturer's Declaration Over the frequency ranges 150kHz to 80MHz, field strengths should be less than 1V/m. TABLE 4 RECOMMENDED SEPARATION DISTANCES BETWEEN PORTABLE AND MOBILE RF COMMUNICATION AND system The system is intended for use in an electromagnetic environment in which radiated RF disturbance are controlled.

-

Page 116: Appendix E Maximum Surface Temperature Of Transducers

Expression of uncertainty in measurement. Three transducer samples have been tested and the confidence coefficient is at 95%, the value of t.975 is 4.30. The measurement data were obtained under the test conditions employed at Mindray. Transducer model Maximum surface temperature Maximum surface temperature (°C) -

Page 117: Appendix F Acoustic Output Reporting Table(61157-2007

Appendix F Acoustic Output Reporting Table(61157-2007) F.1 35C20EA Mode Parameter System settings Display depth10.8cm Display depth10.8cm Display depth10.8cm focus 8cm AP100% focus 8cm AP100% focus 8cm AP100% Standard used: IEC 61157 Ed2 (MPa) 0.75±0.12 0.75±0.12 0.75±0.12 (mW/cm 0.38±0.12 9.81±3.24 10.19±3.37 spta (mW/cm 0.53±0.18... - Page 118 Acoustic Output Reporting Table(61157-2007) F.2 65C15EA Mode Parameter System settings Display depth4.31cm Display depth4.31cm Display depth4.31cm focus 2.5cm AP100% focus 2.5cm AP100% focus 2.5cm AP100% Standard used: IEC 61157 Ed2 (MPa) 2.27±0.37 2.27±0.37 2.27±0.37 (mW/cm 2.31±0.76 56.18±18.53 58.47±19.29 spta (mW/cm 13.89±4.57 2.41±0.79 13.40±4.42...

- Page 119 Acoustic Output Reporting Table(61157-2007) F.3 75L60EA Mode Parameter System settings Display depth2.16cm Display depth2.16cm Display depth2.16cm focus 2cm AP100% focus 2cm AP100% focus 2cm AP100% Standard used: IEC 61157 Ed2 (MPa) 2.21±0.36 2.21±0.36 2.21±0.36 (mW/cm 7.56±2.49 87.07±28.71 94.63±31.20 spta (mW/cm 3.95±1.30 1.93±0.64 6.22±2.05...

- Page 120 Acoustic Output Reporting Table(61157-2007) F.4 35C50EB Mode Parameter System settings Display depth8.62cm Display depth8.62cm Display depth8.62cm focus 7cm AP100% focus 7cm AP100% focus 7cm AP100% Standard used: IEC 61157 Ed2 (MPa) 1.23±0.20 1.23±0.20 1.23±0.20 (mW/cm 2.10±0.69 47.54±15.72 49.60±16.40 spta (mW/cm 1.73±0.57 1.61±0.53 1.63±0.54...

- Page 121 Acoustic Output Reporting Table(61157-2007) F.5 65EC10EB Mode Parameter System settings Display depth2.16cm Display depth2.16cm Display depth2.16cm focus 2cm AP100% focus 2cm AP100% focus 2cm AP100% Standard used: IEC 61157 Ed2 (MPa) 2.18±0.36 2.18±0.36 2.18±0.36 (mW/cm 2.43±0.80 57.21±18.87 59.61±19.66 spta (mW/cm 2.76±0.91 0.40±0.13 3.93±1.30...

- Page 122 Acoustic Output Reporting Table(61157-2007) F.6 75L38EB Mode Parameter System settings Display depth6.47cm Display depth6.47cm Display depth6.47cm focus 3cm AP100% focus 3cm AP100% focus 3cm AP100% Standard used: IEC 61157 Ed2 (MPa) 2.55±0.42 2.55±0.42 2.55±0.42 (mW/cm 9.00±2.97 84.88±27.99 93.88±30.96 spta (mW/cm 11.89±3.92 1.81±0.60 16.67±5.49...

-

Page 123: Appendix G Safety Classification

Appendix G Safety Classification Standard of Classification Type of Product According to the type of protection CLASS I EQUIPMENT or EQUIPMENT against electric shock WITH INTERNAL POWER SUPPLY According to the degree of protection EQUIPMENT WITH TYPE-BF APPLIED against electric shock PARTS Degree of protection against harmful Enclosure: IPX0, transducers: IPX7,... -

Page 124: Appendix H Input Of Characters

Appendix H Input of Characters This appendix describes how to input characters from the keyboard. To input characters Press keys on the keyboard to input characters. Pressing <Caps Lock> can switch between the uppercase and lowercase. For example, if the current letters are lowercase, press <Caps Lock>... -

Page 125: Appendix I Electrical Safety Inspection

Appendix I Electrical Safety Inspection The following electrical safety tests are recommended as part of a comprehensive preventive maintenance program. They are a proven means of detecting abnormalities that, if undetected, could prove dangerous to either the patient or the operator. Additional tests may be required according to local regulations. - Page 126 Electrical Safety Inspection I.1.2 Device Enclosure and Accessories I.2 Visual Inspection Test Item Acceptance Criteria No physical damage to the enclosure and accessories. No physical damage to meters, switches, connectors, etc. The enclosure and accessories No residue of fluid spillage (e.g., water, coffee, chemicals, etc.).

- Page 127 Electrical Safety Inspection The following outlet conditions apply when performing the Earth Leakage test. normal polarity( Normal Condition); reverse polarity( Normal Condition); normal polarity with open neutral(Single Fault Condition); reverse polarity with open neutral(Single Fault Condition). LIMITS For UL60601-1, 300 μA in Normal Condition. 1000 μA in Single Fault Condition.

- Page 128 Electrical Safety Inspection LIMITS For BF applied parts, 100μA in Normal Condition. 500μA in Single Fault Condition. I.8 Mains on Applied Part Leakage The Mains on Applied Part test applies a test voltage, which is 110% of the mains voltage, through a limiting resistance, to selected applied part terminals.

- Page 129 P/N: 046-002342-00 (V2.0)

Need help?

Do you have a question about the DP-10 and is the answer not in the manual?

Questions and answers

Dp10 ultrasound machine can't transfer images to printer