Subscribe to Our Youtube Channel

Summary of Contents for SAMES KREMLIN REXSON 2B1000

- Page 1 2 BALL FLUID SECTION 1000 cm3 Pump REX2B1000 User Manual 582127110 2020-11-06 Index D Translation of the original instructions SAMES KREMLIN SAS 13 Chemin de Malacher 38240 Meylan www.sames-kremlin.com 33 (0)4 76 41 60 60...

- Page 2 Any communication or reproduction of this document, in any form whatsoever, and any exploitation or communication of its contents are prohibited, except with the express written consent of SAMES KREMLIN. The descriptions and features contained in this document are subject to change without notice.

-

Page 3: Table Of Contents

Contents Evolution table of the document ..........................5 Guarantee ..................................6 DECLARATION OF CONFORMITY ......................7 SAFETY INSTRUCTIONS ..........................8 ............................8 ERSONAL SAFETY Overview ..................................8 Meaning of the pictograms ............................9 Security devices ................................. 10 Danger of Pressure ..............................10 Injection hazards ................................ - Page 4 Wet Cup ..................................28 Tightening of the Wet Cup ............................28 Tightening procedure ..............................28 Adjustment of the suction valve ball cage screw ....................... 29 ..........................30 AFETY IN PRODUCTION ..............................30 TART UP ..........................31 HUTDOWN PROCEDURE Pump ..................................31 ....................

-

Page 5: Evolution Table Of The Document

Evolution table of the document Recording revisions Editor Object Revision Date Modified by SEGUIN 2 Ball fluid section 18/06/2020 1000 cm REX2B1000 SEGUIN 2 Ball fluid section 09/10/2020 1000 cm REX2B1000 SEGUIN 2 Ball fluid section 19/10/2020 1000 cm REX2B1000 SEGUIN 2 Ball fluid section 05/11/2020... -

Page 6: Guarantee

The warranty excludes wear parts, deterioration or wear resulting from abnormal or unscheduled use by SAMES KREMLIN, failure to observe instructions for proper operation or lack of maintenance. -

Page 7: Declaration Of Conformity

Declaration of Conformity 1 Declaration of Conformity Refer to the existing declaration delivered with the product. 582127110-2B1000-indD-EN.docx 06/11/2020... -

Page 8: Safety Instructions

It must be used only for the purpose for which it was intended. Do not modify or transform the material. Parts and accessories must only be supplied or approved by SAMES KREMLIN. The equipment must be checked periodically. Defective or worn parts must be replaced. -

Page 9: Meaning Of The Pictograms

Safety instructions Meaning of the pictograms Danger pinching, Danger : high Danger moving parts Risks of product crushin pressure emanation Danger : hot parts or Danger : flammability Risk of explosion Danger : electricity surfaces risks Danger (user) Gloves required Warning Danger Grounding Protective helmet... -

Page 10: Security Devices

Safety instructions Security devices Attention Guards (motor cover, coupling guard, housings, ...) are set up for safe use of the equipment. The manufacturer cannot be held responsible for any bodily injury as well as failures and / or damage to the equipment resulting from the destruction, the occultation or the total or partial removal of the protectors. -

Page 11: Injection Hazards

Safety instructions Injection hazards "HIGH PRESSURE" technology requires the utmost care. Operation can cause dangerous leaks. There is a risk of product injection into exposed parts of the body, which can lead to serious injury and the risk of amputation: ... -

Page 12: Hazards Of Toxic Products

Safety instructions Hazards of toxic products Toxic products or vapors can cause serious injury through contact with the body, in the eyes, under the skin, but also by ingestion or inhalation. It is imperative: To know the type of product used and the dangers it represents, ... -

Page 13: Integrity Of The Material

Safety instructions 2.2 Integrity of the material Material recommendations Protectors are put in place for safe use of the equipment. The manufacturer cannot be held responsible in case of: Bodily injury. As well as breakdowns and / or damage to the equipment resulting from the destruction, the misuse or the total or partial withdrawal of the protectors. -

Page 14: Products Implemented

It will determine the risks of immediate reactions or due to repeated exposures to the staff. SAMES KREMLIN declines any responsibility, in case of: Bodily or psychic injuries. Direct or indirect material damage due to the use of chemical substances. -

Page 15: Environment

Environment 3 Environment The equipment must be installed on a horizontal, stable and flat ground (eg concrete slab). Non-moving equipment must be fixed to the ground by suitable fasteners (spit, screws, bolts, ...) to ensure their stability during use. To avoid risks due to static electricity, the equipment and its components must be grounded. - Page 16 Environment Material marking Each device is equipped with a identification plate with the name of the manufacturer, the reference of the device, important information for the use of the device (pressure, power, ...) and sometimes against the pictogram shown below. The equipment is designed and manufactured with high quality materials and components that can be recycled and reused.

-

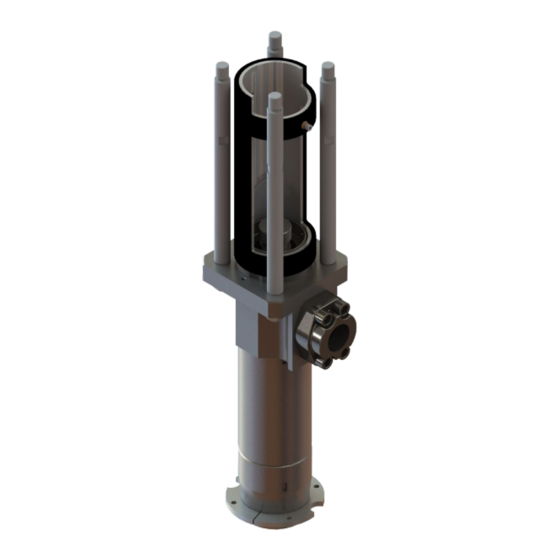

Page 17: Available Configurations

Available Configurations 4 Available Configurations Codification of High Viscosity Pumps Presentation of the pompe REX2B1000 A very versatile pump, the REX2B1000 hydraulic is used for airless applications as well as for the extrusion of thick products (<50000 cP*). Different configurations are available. * 1 cP = 1 mPa.s Significant designation R E X... - Page 18 Available Configurations 4.1 Table 1 Fluid Section-Air Motor Selection Available Motors (MO) Pressure Ratio Maximum Air Inlet Maximum Outlet Pressure Fluid Pressure NONE MOTOR 9200-2 60 : 1 5200 4.2 Table 2 Fluid Section – Pump Foot Selection Available foot pump (FO) Available material (MA) SC : stainless steel + carbide valves Follower plate...

-

Page 19: Identification

Identification 5 Identification 5.1 Description of the marking of the plate Principles This equipment complies with the following provisions: Machinery Directive (2006/42 / EC), Low Voltage Directive 2006/95 EEC EMV Directive 2004/108 EEC Safety machinery Basic terms, general implementation guidelines DIN EN ISO 12100 T1/T2... - Page 20 Identification Description SAMES KREMLIN Manufacturer's mark STAINS FRANCE POMPE / PUMP Pump reference and serial number. The first two digits indicate the year of manufacture. REF / SERIE PROD Maximum product pressure (Bar/Psi) MAX. PRES. (Bar/Psi) Maximum air pressure (Bar/Psi)

-

Page 21: Technical Characteristics And Performance

Technical characteristics and performance 6 Technical characteristics and performance 6.1 General characteristics Technical characteristics Volume per 1005 cm cycle 33,98 oz Stroke 205 mm / 8,07 in Fluid outlet 1"1/2 connections F BSPP Weight 43 kg / 94.8 lb Maximum fluid 80°C / 176°F temperature Wetted parts... - Page 22 Technical characteristics and performance (General characteristics - continued) Pump Foot (FO) Technical characteristic Follower Plate Ø 105 mm Materials of construction (MA) stainless steel + carbide valves Pump body Wet Cup Stainless steel Upper body Stainless steel Cylinder Stainless steel chromed Piston Piston rod Stainless steel chromed...

-

Page 23: Principle Of Operation

Technical characteristics and performance 6.2 Principle of operation Expected use These pumps coupled to air or hydraulic motors are intended for transferring, transferring or spraying different liquid or pasty products with a desired flow rate and output pressure. Functional description When the piston (1) rises, the Upper (2) closes or Lower Ball check (3) opens. - Page 24 Technical characteristics and performance ATTENTION! The friction generated by the movement of the product inside the pump and its accessories, as well as that caused by the seals, creates static electricity that can cause fire or explosion. Therefore, the fluid section system must be earthed via the motor ground cable (see the motor instruction manual for its ground connection).

-

Page 25: Installation

(pneumatic or hydraulic) compatible race. It is imperative to comply with an air motor / hydraulic combination provided by SAMES KREMLIN Make sure that all connections of the pump and fluid section components - cables, hoses and pipes - are installed in such a way that they do not cause people to fall. -

Page 26: Air Supply Connection

Installation 7.2.2 Air supply connection Ensure that in bound air supply and hose are of correct size to reduce pressure fluctuations and pressure drops. 7.3 Storage Pump Place the equipment away from moisture after closing the various air inlets and various openings (plugs). Storage before installation: ... -

Page 27: Commissioning

Commissioning 8 Commissioning The fluid sections are integrated in a system, if necessary refer to any additional instructions for further information on commissioning. Pump The Pumps are tested for operation at the factory using a light weight oil lubricant. Before commissioning, this lubricant must be removed by flushing with a suitable solvent. -

Page 28: Use Of The Product

Use of the product 9 Use of the product 9.1 User settings Wet Cup Before commissioning, fill the wet cup halfway with lubricant "T". The wetting cup nut must be tightened moderately. Overtightening quickly damages the gland packing. A wrench is supplied to allow proper tightening. -

Page 29: Adjustment Of The Suction Valve Ball Cage Screw

Use of the product Adjustment of the suction valve ball cage screw Depending upon the fluid viscosity to be pumped, adjust the height of the screw (32) to increase the ball up motion. Lock the screw on the lock nut (33). (For a full description of spare parts, see Part 12 - Spare Parts) 582127110-2B1000-indD-EN.docx 06/11/2020... -

Page 30: Safety In Production

Use of the product 9.2 Safety in production Guards (motor cover, coupling guard, housings, ...) are set up for safe use of the equipment. The manufacturer can not be held responsible in case of bodily injury as well as breakdowns and / or damage of material resulting from... -

Page 31: Shutdown Procedure

Use of the product 9.4 Shutdown procedure Pump To avoid the risk of personal injury, material injections, injuries caused by moving parts or electric arcs, it is imperative that the following procedure be followed before any work is carried out when shutting down the system, assembling, cleaning or changing the nozzle. -

Page 32: Diagnostic Help / Troubleshooting Guide

Use of the product 9.5 Diagnostic help / Troubleshooting guide Possible symptoms of faults / Causes of faults / Remedy to be applied Defaults Possible causes Remedies Leakage at the cup seals Insufficient tightening of the Tighten the cup. packing nut Incorrect assembly of seals Check the assembly. - Page 33 Use of the product Defaults Possible causes Remedies Pump strokes quickly Bad feeding of the pump. Check parameters downward (simple effect accessories (pressure follower working) plate or suction rod,…). Accessories can be not adapted or clogged. Product is too viscous. Bad definition of the pump.

-

Page 34: Maintenance

If the information given here does not solve the problem you are experiencing, please contact your local SAMES KREMLIN representative for assistance. During prolonged shutdown, stop the pump when the piston is in the low position. -

Page 35: Preventive Maintenance Plan

Maintenance 10.1 Preventive Maintenance Plan ATTENTION Before any intervention, it is imperative to follow the decompression procedure and the safety instructions. Systematic maintenance after a certain number of operating hours is recommended. This is defined by the service department of the user and depends on the product, the working cycle and the usual pressure. -

Page 36: General Preconisation Maintenance

Maintenance 10.2 General preconisation maintenance ATTENTION Before pump maintenance service work performed imperative follow depressurization procedure and the safety instructions. Before each reassembly Clean the parts with the appropriate cleaning solvent. Fit new seals if necessary, after greasing them. ... -

Page 37: Disassembly / Reassembly Operation

Disassembly / Reassembly Operation 11 Disassembly / Reassembly Operation ATTENTION Before pump maintenance service work performed imperative follow depressurization procedure and the safety instructions. ATTENTION The equipment is subject to the ATEX directive and must not be modified under any circumstances. Failure to comply with this recommendation does not engage our responsibility. - Page 38 Disassembly / Reassembly Operation (For a full description of spare parts, see Part 12 - Spare Parts) 06/11/2020 582127110-2B1000-indD-EN.docx...

-

Page 39: Disassembly Of The Pump

Disassembly / Reassembly Operation Disassembly of the pump Unscrew the tie rods (46) and the protection (45), Clamp the pump horizontally through the fluid flange (2) with a vice, Unscrew the foot-valve body assembly (38), the flange (40) and the O-Rings (39), ... -

Page 40: Cup Seals

Disassembly / Reassembly Operation Cup seals Nota: the fluid flange (2) consists of a cartridge (4) to make easier the changing of the seals. Ind.2 Unscrew the cup (13), Take off the 10 srews (5) that tighten the cartridge (4) in the fluid flange (2), ... -

Page 41: Iso Flansh Flange Seal

Disassembly / Reassembly Operation ISO FLANSH flange seal Unscrew the 4 screws (11), Take off the ISO FLANSH flange (10) and the seal (12) Clean all the parts, check them; if there are damaged or worn, change them, ... -

Page 42: Spare Parts

Spare parts 12 Spare parts Use only genuine SAMES KREMLIN accessories and spare parts designed to withstand the pump's operating pressures. 06/11/2020 582127110-2B1000-indD-EN.docx... - Page 43 Spare parts Parts REX2B1000---FP- Spare Ind. Description # Ref. part level** Fluid section 144 251 006 Upper flange Fluid flange 144 250 001 Cartridge assembly 144 250 096 Cartridge N.S (211 562) Screw, CHc M 8x20 930 151 279 ...

- Page 44 Spare parts REX2B1000---FP- Spare Ind. Description # Ref. part level** Piston seat assembly 144 250 025 Carbide seat N.S (044 250 027) Ball Ø 32, carbide 87 532 Screw, Hc M 5x16 N.S (934 171 194) Ball guide kit 107 161 ...

-

Page 45: Lower Adapter Flange

Spare parts Lower adapter flange Spare Ind. Description # Ref. part level** Lower adapter flange for motor 9200-2 144 245 495 **45 Protective housing N.S. (051 150 110) **46 N.S. (051 150 101) Tie-rod * Recommended maintenance parts. N S: Denotes parts are not serviceable. **Level 1 : Preventive maintenance Level 2 : Corrective Level 3 : Exceptional... -

Page 46: Seal Kits Composition - Pump Rex2B1000----06

Spare parts Seal Kits composition – Pump REX2B1000----06 # FLUID SECTION REX2B1000----06 Kit : 106 591 Ind. Description Material Seal 909 420 265 Cup block 210 724 ST STEEL 84 395 Cup packing 210 722 Seal 84 456 210 726 Piston packing 211 318 PTFEV...

Need help?

Do you have a question about the REXSON 2B1000 and is the answer not in the manual?

Questions and answers