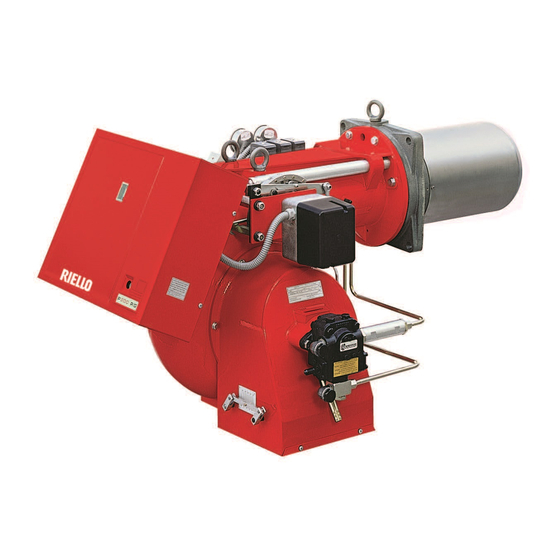

Riello P 300 P/G Installation, Use And Maintenance Instructions

Light oil burners

Hide thumbs

Also See for P 300 P/G:

- Installation, use and maintenance instructions (68 pages) ,

- Installation, use and maintenance instructions (96 pages)

Table of Contents

Advertisement

Quick Links

Installation, use and maintenance instructions

Light oil burners

GB

Progressive two-stage or modulating operation

CODE

20169224

20169232

20169233

20169234

20169235

20169236

MODEL

P 300 P/G

P 300 P/G

P 300 P/G

P 300 P/G

P 450 P/G

P 450 P/G

TYPE

483 M1

483 M1

483 M1

483 M1

484 M1

484 M1

20170350 (1) - 11/2019

Advertisement

Table of Contents

Summary of Contents for Riello P 300 P/G

- Page 1 Installation, use and maintenance instructions Light oil burners Progressive two-stage or modulating operation CODE MODEL TYPE 20169224 P 300 P/G 483 M1 20169232 P 300 P/G 483 M1 20169233 P 300 P/G 483 M1 20169234 P 300 P/G 483 M1...

- Page 2 Translation of the original instructions...

-

Page 3: Table Of Contents

Contents Declarations....................................2 Information and general warnings............................3 Information about the instruction manual ..............................3 Guarantee and responsibility ..................................4 Safety and prevention................................5 Introduction ........................................5 Personnel training ......................................5 Technical description of the burner ............................6 Burner designation ......................................6 Models available ......................................6 Technical description of the burner ............................ -

Page 4: Declarations

The quality is guaranteed by a quality and management system certified in accordance with ISO 9001:2015. Legnago, 21.04.2018 General Manager Research and Development Director RIELLO S.p.A. - Burners Department RIELLO S.p.A. - Burners Department Eng. U. Ferretti Eng. F. Comencini... -

Page 5: Information And General Warnings

Information and general warnings Information and general warnings Information about the instruction manual 2.1.1 Introduction WARNING: MOVING PARTS The instruction manual supplied with the burner: This symbol indicates that you must keep limbs is an integral and essential part of the product and must not away from moving mechanical parts;... -

Page 6: Guarantee And Responsibility

Information and general warnings 2.1.4 Delivery of the system and the instruction The system supplier must carefully inform the user about: – the use of the system; manual – any further tests that may be required before activating the When the system is delivered, it is important that: system;... -

Page 7: Safety And Prevention

Safety and prevention Safety and prevention Introduction The burners have been designed and built in compliance with the type and pressure of the fuel, the voltage and frequency of the current regulations and directives, applying the known technical electrical power supply, the minimum and maximum deliveries for safety rules and envisaging all the potential danger situations. -

Page 8: Technical Description Of The Burner

Technical description of the burner Technical description of the burner Burner designation Series: PRESS Size : 140... 450 Operation: Three-stage T/G Modulating P/G Emission: C01 or... Class 1 EN267 C02 or MZ Class 2 EN267 C03 or BLU Class 3 EN267 Head: Standard head Extended head... -

Page 9: Technical Description Of The Burner

Technical description of the burner Technical description of the burner Technical data MODEL PRESS 300 P/G PRESS 450 P/G Output 890 - 3560 1190 - 5340 Delivery kg/h 75 - 300 100 - 450 Fuel Light oil kWh/kg 11.8 - Net calorific value Mcal/kg 10,2 (10.200 kcal/kg) - Density... -

Page 10: Overall Dimensions

Technical description of the burner Overall dimensions The dimensions of the burner are given in (Fig. 1). Bear in mind that inspection of the combustion head requires the burner to be opened and the rear part drawn back on the slide bars. -

Page 11: Firing Rates

Technical description of the burner Firing rates During operation, burner output varies between: The FIRING RATE was obtained with an ambient MINIMUM FLOW RATE: can drop down to 75 kg/h temperature of 20°C and a barometric pressure of MAXIMUM OUTPUT: must be within the firing rate (Fig. 2 1000 mbar (approx. -

Page 12: Test Boiler

Technical description of the burner Test boiler The burner/boiler combination does not pose any problems if the In Fig. 4 you can see the diameter and length of the test boiler is EC approved and its combustion chamber dimensions combustion chamber. are similar to those indicated in the diagram (Fig. -

Page 13: Burner Description

Technical description of the burner Burner description 20172024 9 7 6 Fig. 5 Suction connection Pump pressure regulator Return connection Gauge connection (G 1/4) Vacuometer connection (G 1/4) Delivery pressure gauge Return pressure gauge Control box reset button with lockout signal Pressure switch 10 Head drive rod 11 Air adjustment cam... -

Page 14: Electrical Panel Description

Technical description of the burner Electrical panel description 20172025 Fig. 6 Fan motor thermal relay and contactor (for direct starter version only) Ignition transformer Filter to protect against radio disturbance Servomotor connector Control box base Cable grommets for external connections (to be carried out by the installer) Terminal board for electric connection Oil valve coils... -

Page 15: Control Box Rfgo-A23

Technical description of the burner Control box RFGO-A23 Important notes To avoid accidents, material or environmental damage, observe the following instructions! The control box is a safety device! Avoid opening ATTENTION or modifying it, or forcing its operation. The Manufacturer cannot assume any responsibility for damage resulting from unauthorised work! ... -

Page 16: 5.10 Servomotor Sqm40

Technical description of the burner 5.10 Servomotor SQM40 ... Important notes To avoid accidents, material or environmental damage, observe the following instructions! Avoid opening, modifying forcing ATTENTION servomotor. All interventions (assembly and installation operations, assistance, etc.) must be carried out by qualified personnel. ... -

Page 17: Installation

Installation Installation Notes on safety for the installation After carefully cleaning all around the area where the burner is to The installation of the burner must be carried out be installed, and arranging for the environment to be illuminated by qualified personnel, as indicated in this manual correctly, proceed with the installation operations. -

Page 18: Operating Position

Installation Operating position The burner is designed to work only in positions 1 and 4 (Fig. 10). Installation 1 is preferable, as it is the only one that allows the maintenance operations ATTENTION as described in this manual. ... -

Page 19: Securing The Burner To The Boiler

Installation Securing the burner to the boiler Provide an adequate lifting system. Be careful as some drops of fuel may leak out during this phase. D2590 To separate the burner from the cast iron blast tube, proceed as follows: Remove the cover 1), the split pin and pin 2), the nuts 3) and the screws 4). -

Page 20: Nozzle Installation

267 standard. In order to guarantee that emissions do not vary, If you want a delivery somewhere between the two values shown recommended and/or alternative nozzles specified by Riello in in the diagram (Fig. 16), select a nozzle with a higher flow rate. - Page 21 Installation To calibrate the delivery range of the nozzle, suitably adjust the 6.10.2 Indicative relation between: nozzle type and fuel maximum and minimum pressure on the nozzle return line, flow rate (in %) - return line pressure as shown in the diagram (Fig. 16). D3437 ...

-

Page 22: Light Oil Supply

Installation 6.11 Light oil supply Explosion danger due to fuel leaks in the presence of a flammable source. Precautions: avoid knocking, attrition, sparks and heat. Make sure the fuel shut-off valve is closed before D2584 performing any operation on the burner. The fuel supply line must be installed by qualified personnel, in compliance with current standards and laws. - Page 23 Installation 6.11.1 Hydraulic connections 6.11.2 Hydraulic circuit diagram D2583 Make sure that the hoses to the pump supply and return line are installed correctly. CAUTION The pumps are equipped with a by-pass that connects return line with suction line. They are installed on the burner with the by- pass closed by screw 6)(Fig.

-

Page 24: Pump

Installation 6.12 Pump 6.12.1 Technical data Pump TA4C4010-7 TA5C3010-7 Burner PRESS 300 P/G PRESS 450 P/G Min. delivery rate at 40 bar pressure kg/h 1000 Delivery pressure range 7 - 40 7-30 Max. suction depression cm Hg Viscosity range 4 - 75 4-75 Maximum light oil temperature °C... -

Page 25: Electrical Connections

Installation 6.13 Electrical connections Notes on safety for the electrical wiring The electrical wiring must be carried out with the electrical supply disconnected. Electrical wiring must be made in accordance with the regulations currently in force in the country of destination and by qualified personnel. -

Page 26: Calibration Of The Thermal Relay

Installation 6.14 Calibration of the thermal relay The thermal relay (Fig. 20) serves to avoid damage to the motor due to an excessive absorption increase or if a phase is missing. D8685 For calibration 2), refer to the table indicated in the electrical layout (electrical wiring by the installer). -

Page 27: Start-Up, Calibration And Operation Of The Burner

Start-up, calibration and operation of the burner Start-up, calibration and operation of the burner Notes on safety for the first start-up The first start-up of the burner must be carried out Check the correct working of the adjustment, by qualified personnel, as indicated in this manual command and safety devices. -

Page 28: Pressure Variator Adjustment

Start-up, calibration and operation of the burner Pressure variator adjustment The pressure variation on the return line (pressure gauge, 3) D2001 Fig. 22 on page 26) changes the flow rate of the fuel coming out of the nozzle. 7.4.1 Pressure variator To calibrate the eccentric 8), proceed as follow: remove the cover 9), loosen the screws 7), turn the screw 4) until the desired eccentricity is obtained. -

Page 29: Combustion Head Adjustment

Start-up, calibration and operation of the burner Combustion head adjustment The combustion head moves at the same time of the eccentric 8), No. notches PRESS 300 P/G (Fig. 22) and variable profile cam 1) (Fig. 26). D2706 The head positioning can be seen on cylinder 2) (Fig. 23). The control levers of the head are set at the factory to the maximum stroke of 45 mm. -

Page 30: Air Damper Setting

Start-up, calibration and operation of the burner Air damper setting The setting of the air damper is carried out by acting on the D1998 variable profile cam 1). This operation must be performed after regulating the pressure variator and the combustion head. With burner on, disconnect the servomotor from the power supply and release it manually by pressing the release button placed on the lower side. -

Page 31: Servomotor Adjustment

Start-up, calibration and operation of the burner Servomotor adjustment The servomotor adjusts simultaneously, through driving gears, the output and pressure of the air and the delivery of the fuel in use. It performs a 135° rotation in 45s. After the adjustment made in the factory to its 6 cams to allow an initial ignition. -

Page 32: Operation Sequence Of The Burner

Start-up, calibration and operation of the burner Operation sequence of the burner 7.9.1 Burner start-up program Standard Lock-out because of no ignition 20171919 Remote control Motor Transformer F-R-S valves Flame Lockout 2 . 5 2 . 5 Fig. 30 7.10 Final checks ... -

Page 33: Maintenance

Maintenance Maintenance Notes on safety for the maintenance The periodic maintenance is essential for the good operation, Before carrying out any maintenance, cleaning or checking safety, yield and duration of the burner. operations: It allows you to reduce consumption and polluting emissions and to keep the product in a reliable state over time. -

Page 34: Opening The Burner

Maintenance Flame presence check 8.2.3 Safety components Check the level of the flame detection signal with the “Check The safety components should be replaced at the end of their life mode” function from the flame control: LEDs from 2 to 6 indicate cycle indicated in the following table. -

Page 35: Led Indicator And Special Function

LED indicator and special function LED indicator and special function Description of LED lamps It turns on when the fan motor is powered (T6) and blinks when RUN/CHECK switch is set to “CHECK” during damper movement phases, PTFI AND MTFI. S9740 It blinks when the air damper is moving towards the maximum opening position until the Damper... -

Page 36: Led Lamps: Burner Operating Status

LED indicator and special function LED lamps: burner operating status OPERATING STATUSES INDICATED BY LEDS DURING NORMAL OPERATION AND CHECK MODE Operation Damper Damper Modulation Ignition Flame Status LED ● = ON open closed Icon S9740 S9741 S9742 S9743 S9744 S9745 S9746 Power OFF/ON... -

Page 37: Problems - Causes - Remedies Signalled By Led Indicators

Problems - Causes - Remedies signalled by LED indicators Problems - Causes - Remedies signalled by LED indicators When an emergency stop occurs, the control device LEDs Thermal unit’s operation, maintenance and indicate the cause of the stop. troubleshooting interventions must be carried out The terminal T3 is not powered. - Page 38 Problems - Causes - Remedies signalled by LED indicators Error / RFGO LED lock-out codes Faults LED 1 LED 2 LED 3 LED 4 LED 5 LED 6 LED 7 Operation Open Closed Auto Ignition Flame Status LED ● = ON damper damper Icon...

- Page 39 Problems - Causes - Remedies signalled by LED indicators Faults LED 1 LED 2 LED 3 LED 4 LED 5 LED 6 LED 7 Off-specification mains voltage ● ● ● ● ● UV: Internal fault ● ● Supervisor processor fault ●...

- Page 40 Problems - Causes - Remedies signalled by LED indicators Faults Cause Solution UV: no flame at the end of the Inspect the system, check the gas pressure, No flame at the end of the 2 safety time check the UV scanner, check the wiring, safety time (MTFI) etc.

- Page 41 Problems - Causes - Remedies signalled by LED indicators Faults Cause Solution Internal processor fault Internal fault Replace the control device UV: false flame during operation False flame detected before ignition Check the scanner FR: false flame during operation False flame detected before ignition Check the wiring Check the scanner Make sure that earthing is appropriate...

- Page 42 Potentiometer kit Burner Code PRESS 300 P/G 20096322 PRESS 450 P/G Spacer kit Burner Code P 300 P/G 3000723 P 450 P/G 3000751 230 V conversion kit Burner Code PRESS 300 P/G 20163347 The installer is responsible for the addition of any safety device not foreseen in this manual.

- Page 43 Appendix - Electrical panel layout Appendix - Electrical panel layout Index of layouts Reference indication Functional layout STAR/TRIANGLE START-UP Functional layout RFGO-A23 Functional layout RFGO-A23 Electrical wiring that is the responsibility of the installer Functional layout RWF Reference indication / 1 . A 1 Sheet no.

- Page 44 Appendix - Electrical panel layout 20170350...

- Page 45 Appendix - Electrical panel layout 20170350...

- Page 46 Appendix - Electrical panel layout 20170350...

- Page 47 Appendix - Electrical panel layout 20170350...

- Page 48 Appendix - Electrical panel layout 20170350...

- Page 49 Appendix - Electrical panel layout 20170350...

- Page 50 Appendix - Electrical panel layout 20170350...

- Page 51 Appendix - Electrical panel layout 20170350...

- Page 52 Appendix - Electrical panel layout 20170350...

- Page 53 Appendix - Electrical panel layout 20170350...

- Page 54 Appendix - Electrical panel layout WIRING DIAGRAM KEY Electrical control box Filter to protect against radio disturbance RWF50 output power regulator Burner terminal strip Starter terminal strip Fan motor Three-phase line fuses, fan motor thermal relay Three-phase line fuses Three-phase line fuses Single-phase line fuses Fan motor thermal relay Servomotor...

- Page 56 RIELLO S.p.A. I-37045 Legnago (VR) Tel.: +39.0442.630111 http:// www.riello.it http:// www.riello.com Subject to modifications...

Need help?

Do you have a question about the P 300 P/G and is the answer not in the manual?

Questions and answers