Table of Contents

Advertisement

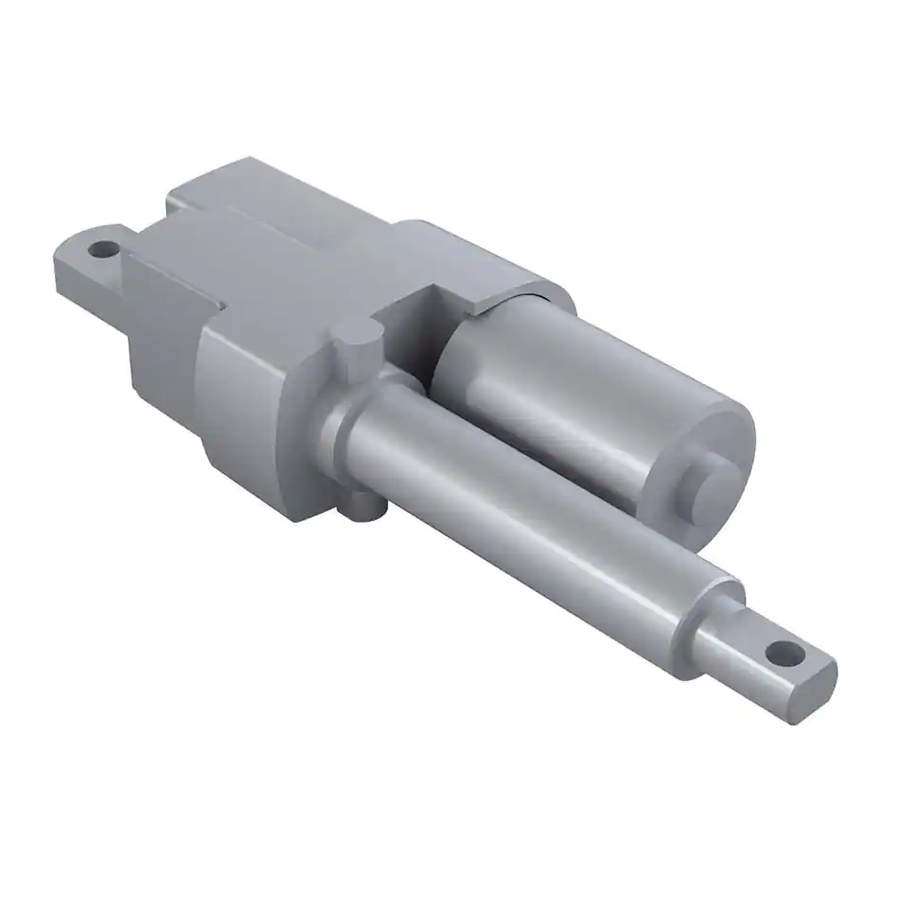

E

LECTROMECHANICAL

Linear Actuators

Installation, Operation &

Maintenance Instructions

6415 Series

7415 Series

(115 Volt A.C./220 Volt A.C.)

Publication Part No. SK-6415-200

This manual contains important information for the correct installation, operation and maintenance of the equipment

described herein. All persons involved in such installation, operation, and maintenance should be thoroughly familiar

with the contents. To safeguard against the possibility of personal injury or property damage, follow the recommenda-

tions and instructions of this manual and keep it for further reference.

The equipment shown in this manual is intended for industrial use only and should not be used to lift, support, or other-

wise transport people.

CAUTION

WARNING

Advertisement

Table of Contents

Summary of Contents for Duff-Norton 6415 Series

- Page 1 LECTROMECHANICAL Linear Actuators Installation, Operation & Maintenance Instructions 6415 Series 7415 Series (115 Volt A.C./220 Volt A.C.) Publication Part No. SK-6415-200 CAUTION This manual contains important information for the correct installation, operation and maintenance of the equipment described herein. All persons involved in such installation, operation, and maintenance should be thoroughly familiar with the contents.

-

Page 2: Table Of Contents

Warranty and Warranty Repair .......................3 1-5. Specifications ..........................3 Table 1-1. 6415 Series DC Actuator Specifications ..................3 Table 1-2. 6415 Series DC Super Pac Actuator Duty Cycle ................3 1-6. Dimensions and Specifications .....................4 Figure 1-1. SPA-6415 and SPA-7415 Technical Illustration ................4 Figure 1-2. Limit Switch Wire Color Diagram ....................4... -

Page 3: Introduction

6.20 2.00 will lift its rated load. The brake is preset at the factory and no further Table 1-2. 6415 Series DC Super Pac Actuator adjustment is required. With proper maintenance, this Duty Cycle brake prevents the actuator from self-lowering. -

Page 4: Dimensions And Specifications

1-6. Dimensions and Specifications equal. Equipped with thermal overload which opens and resets automatically. Standard motor requires capacitor AC Motor is enclosed, permanent split capacitor for applies loads up to 1500 pounds. induction type. Load/no0load speeds are approximately Figure 1-1. SPA-6415 and SPA-7415 Technical Illustration Figure 1-2. -

Page 5: Installation

Section II Installation 2-1. Installation Procedures the housing clevis hole centerline and the translating tube clevis hole centerline equals Use Figure 1-2 as a guide to properly attach the the desired extended height. This centerline to SPA 6415 & 7415 AC actuator to your power source. centerline dimension is not to exceed the 2-2. -

Page 6: Digital Position Indicator

To aid in rebuilding, a repair kit with step by step instructions is available through Duff-Norton Company under repair kit part number SK-6415-41. -

Page 7: Maintenance

Section IV Maintenance 4-1. Lubrication CAUTION Duff-Norton recommends the use of the following Take care not to damage potentiometer when removing lubricant in conjunction with proper maintenance gear. procedures of this unit: Exxon Ronnex Extra Duty #1. 4. Remove screws (1) from capacitor box cover (2) and 4-2. -

Page 8: Assembly

17. Remove bearing (28), bushing (34) and flange 31. Remove the lifting screw (62) from the lifting bearing (25) from cover (9). nut (64). 32. Remove the four pins (65) by pressing each one the NOTE rest of the way through the lifting nut wall. Bushing (34) and flange bearing (25) should not be removed unless they are damaged. - Page 9 13. Press guide bushing (59) and wiper scraper seal (60) designates DC unit. If your replacement spring is into outer tube (55). (Scraper part of scraper seal red, contact your local distributor or the Duff-Norton should be facing outward away from guide Factory for immediate replacement.

- Page 10 and one pin drops into hole. (Note: spacer nut should NOTE not be rotated more than 221/2 before pin drops into Before turning motor shaft, make sure pinion shaft hole in gear.) It is preferable to tighten spacer nut has not been pushed out. It may be necessary to down instead of loosening.

- Page 11 a. Feed motor (53) lead wires into capacitor box cover (9). Care should be taken not to damage lead wires. Assemble cover on housing (42), aligning dowel pins (27) with bore in cover and flats of limit switch shaft (22) with bore and slot in end of screw (62). NOTE Limit switch shaft should be able to spring up when a light pressure with finger is applied downward on limit...

-

Page 12: Parts List And Technical Illustration Table 5-1. Parts List For 6415 And 7416 Ac Actuator

Section V Parts List and Technical Illustration Table 5-1. Parts List for 6415 and 7416 AC Actuator Index Qty. Part Index Qty. Part Part Name Part Name Req. Number Req. Number Screw H-2979 Spacer Nut SK-6415-17 Cover SK6415-142 Set Screw H-2594 Gasket SK-6415-37... - Page 13 WARNING Use only replacement parts supplied by or approved by Duff-Norton. Non-authorized parts may be inadequate, resulting in serious injury or death in event of failure. Figure 5-1. Exploded Parts Illustration 6415 & 7415 Series AC Actuator...

-

Page 14: Technical Illustrations

Section VI Technical Illustrations 6-1. Brake Alignment Figure 6-1A. Brake, Spring, Motor and Figure 6-1B. Brake Spring, Motor and Pinion Coupling Alignment Pinion Coupling Alignment 6-2. Limit Switch Wiring Diagram Figure 6-2. Limit Switch Wiring Diagram, 6415 & 7415 Series AC Actuator 6-3. - Page 15 Notes...

- Page 16 Duff-Norton also Manufactures Mechanical Actuators Electromagnetic Actuators Rotary Unions Mechanical Jacks 2020 © Duff-Norton - A Columbus McKinnon Company. ® All rights reserved. 9415 Pioneer Avenue, Suite 100, Charlotte NC 28273 800-477-5002 • www.duffnorton.com • duffnorton@cmworks.com ECO 9-8865 SK-6415-200 01/17...

Need help?

Do you have a question about the 6415 Series and is the answer not in the manual?

Questions and answers