Table of Contents

Advertisement

Quick Links

Publication Part No. SK-2389

CAUTION

This manual contains important information for the correct installation, operation and maintenance of the

equipment described herein. All persons involved in such installation, operation, and maintenance should be

thoroughly familiar with the contents. To safeguard against the possibility of personal injury or property

damage, follow the recommendations and instructions of this manual and keep it for further reference.

®

WARNING

The equipment shown in this manual is intended for industrial use only and should not be used to lift, sup-

port, or otherwise transport people.

Advertisement

Table of Contents

Summary of Contents for Duff-Norton SK-2389

- Page 1 Publication Part No. SK-2389 CAUTION This manual contains important information for the correct installation, operation and maintenance of the equipment described herein. All persons involved in such installation, operation, and maintenance should be thoroughly familiar with the contents. To safeguard against the possibility of personal injury or property damage, follow the recommendations and instructions of this manual and keep it for further reference.

-

Page 2: Table Of Contents

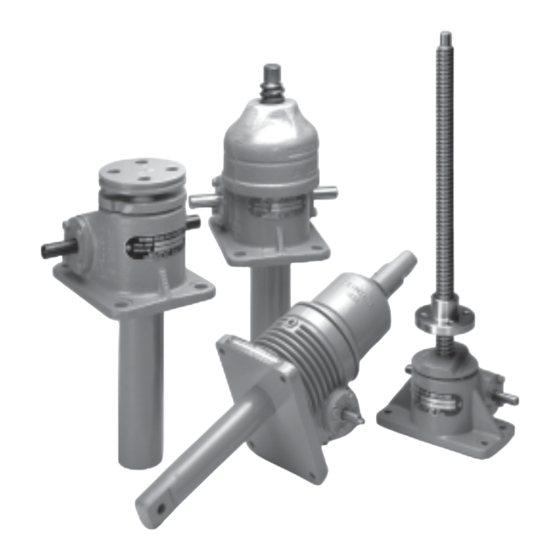

If your atmo- sphere is corrosive it is important to specify a non- 1-2. Applications corrosive material or finish. Duff-Norton can provide Industrial Use Only The actuators described stainless steel, nickel plated or epoxy coated actua- and illustrated in this manual are intended for tors. -

Page 3: Important Precautions

1-4 Important Precautions specified (catalog) closed height, or serious damage to internal mechanism may result. In order to ensure that Duff-Norton actuators Refer to table of specifications (par. 1-3) for provide good service over a period of years the closed heights of respective units. -

Page 4: Warranty And Warranty Repair

Duff-Norton will not repair or replace any have a clearance between their surfaces of 1/2 parts that become inoperative because of improper the thread thickness. -

Page 5: Cleaning

4. Remove gear (6A) or worm gear and nut assem- 2-6. Inspection (Refer to Figure 3-1) bly (6B) from shell (3). Inspect actuator parts as follows: 1. Make a visual inspection of shell (3) for broken, Note cracked or distorted areas. Check threads of all To facilitate removal of the gear from the shell bores for burrs or broken threads. -

Page 6: Anti-Backlash Nut Function

engage the threads of the lifting screw (1). Adjust- as required. ment of backlash is made by running down on the 7. Install top load bearing (7) or bearing cup on shell cap of the actuator. This forces the anti-back- worm gear (6A) or worm gear and nut assembly lash nut threads into closer contact, reducing clear- (6B). -

Page 7: Figure 3-1. Exploded Illustration

Figure 3-1. Exploded Illustration 1800 (2000), 9000 (10000), 4800 (5800) and 9400 (10400) Series Translating Machine Screw Actuators... - Page 8 ® P.O. Box 7010 Charlotte, NC 28241-7010 General Office (704) 588-0510 Customer Service (800) 477-5002 Customer Service (704) 588-4610 FAX (704) 588-1994 SK-2389 © 2000 Yale Industrial Products, Inc. Email: duffnorton@cmworks.com 2M/1002 www.duffnorton.com...

Need help?

Do you have a question about the SK-2389 and is the answer not in the manual?

Questions and answers