Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for CAMAG Derivatizer

- Page 1 INSTRUCTION MANUAl deRIvATIzeR...

-

Page 2: Table Of Contents

Content Introduction ............................ 1 Precaution ..........................1 Parts supplied with CAMAG Derivatizer ..................3 Spare parts for CAMAG Derivatizer ................... 4 Unpacking/Installation ........................4 Unpacking ..........................4 Installation environment ......................4 Installation ..........................5 Getting started ..........................5 Intended use ..........................5 Material compatibility ....................... - Page 3 Introduction User maintenance ........................20 Maintenance data sheet ......................21 Troubleshooting ........................22 Replacing the seal of the tray ......................22 Internal errors ..........................23 Technical data..........................23 Preparation of Derivatization reagents ..................24 Declaration of Decontamination (DoD) ..................27 Declaration of Conformity (DoC) Instruction Manual, Nov-17...

-

Page 4: Introduction

Introduction Introduction The CAMAG Derivatizer is an automated spraying device which sets a new standard of reproducibility in the reagent transfer onto TLC plates by employing a unique "micro droplet" spraying technology. The CAMAG Derivatizer ensures homogeneous and reproducible application of all common reagents. Moreover, the CAMAG Derivatizer offers further advantages compared to manual spraying: •... - Page 5 Only authorized personnel may open the instrument. Service and repair is only to be performed by trained specialists. Use spare parts and consumables supplied by CAMAG only. The warranty is voided if parts from other sources are used. Check the service manual before you start service to reduce product-specific risks •...

-

Page 6: Parts Supplied With Camag Derivatizer

• This equipment is intended to be used in an Industrial Electromagnetic Environment according IEC 61326-1 1.2 Parts supplied with CAMAG Derivatizer Part no Description 022.6050 Derivatization hood 20 x 20 cm or * 022.6055... -

Page 7: Spare Parts For Camag Derivatizer

The place for installation must meet the following requirements: • Grounded AC powerline Connections • The CAMAG Derivatizer has to be used under the fume hood, or with the output air pipe connected to it Bench space 300 x 500 x 500 mm (w x d x h) -

Page 8: Installation

Getting started 3.1 Intended use The primary use of the CAMAG Derivatizer is for derivatization of TLC plates. The following reagents have been tested and validated by CAMAG. The exact composition for the above reagents is specified in the chapter 6. -

Page 9: Material Compatibility

However, in the Derivatizer most parts are not in direct contact with the liquid phase of the reagents and might be unproblematic if sprayed. For some specific combinations of reagents, micro-cracks may appear in the transparent hood with continued use. -

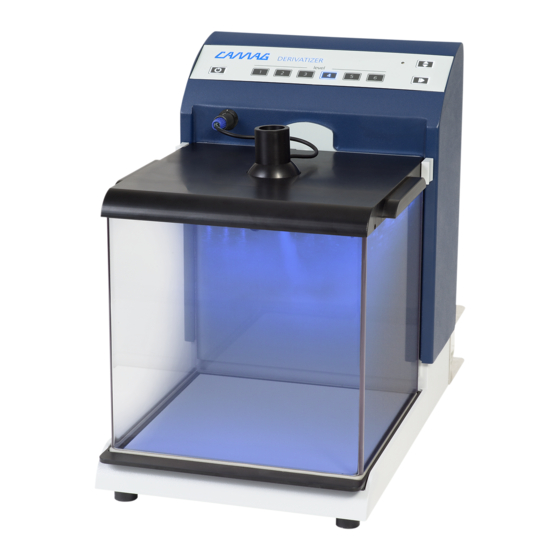

Page 10: Instrument

Hood (20 x 20 cm version shown) Tray with seal Nozzle Washing bottle Output air pipe Control panel The CAMAG Derivatizer has to be used under the fume hood, or with the output air pipe connected to a fume hood Instruction Manual, Nov-17... -

Page 11: Control Panel

Getting started 3.4 Control panel Power ON/OFF Spraying level (6 levels) Hood UP/DOWN START derivatization 3.5 State diagram Instruction Manual, Nov-17... -

Page 12: Nozzles

Getting started 3.6 Nozzles CAMAG provides 4 different types of nozzles. Each of them is coded by a different colour on the connector. The following types are available: 1. Green 2. Blue 3. Yellow 4. Red There are the standard type nozzles and the chemically more resistant Ultra nozzles. For potassium hydroxide containing reagents and for potentially aggressive reagents not listed in this manual we recommend the chemically resistant Ultra nozzles. -

Page 13: Insert/Remove Plate

Getting started If the derivatization reagent is one of the derivatization reagents described in this manual, refer to chapter 3.11. For other derivatization reagents refer to chapter 3.10: General remark: If two different nozzles spray well, it is always advisable to use a lower one (Green < Blue < Yellow <... -

Page 14: Derivatization Process

Getting started 3.9 Derivatization process CAMAG strongly recommends the following procedure: 3.9.1 Preparation of the reagents Choose the appropriate reagent and prepare it according chapter 6 Preparation of Derivatization reagents Be aware that some formulations used for immersion should not be used directly for spraying. -

Page 15: Preparation Of The Cleaning Solution

Setting the parameters Size of the hood: • CAMAG provides two different types of hoods (20 x 20 cm and 20 x 10 cm). The size of the hood is related to the size of the plate Spray nozzle and level: •... - Page 16 Getting started Nozzle: Empty nozzle, if necessary, and insert a filter paper instead of a TLC / HPTLC plate and perform a spraying procedure with 2 mL of cleaning solution (level 6). After spraying the settling time can be skipped by pressing the start button so that the process moves forward to the pumping step.

-

Page 17: Spraying Steps

The device will remain in this phase for 2 minutes. The duration of this phase can be shortened by pressing the “START” button. CAMAG recommends using the default settling time to ensure a homogeneous distribution of the reagent on the TLC plate. -

Page 18: Method To Transfer From Manual Spraying Or Immersion To Automated Spraying

If a rapid derivatization is preferred, a nozzle with a larger porosity should be selected A convenient transfer of methods involving manual spraying, immersion and automated spraying with the CAMAG Derivatizer is illustrated in the flowchart below: Instruction Manual, Nov-17... -

Page 19: Recommendations For Common Derivatization Reagents

6 Preparation of Derivatization reagents Tested and validated by CAMAG to obtain comparable results to manual spraying or to immersion. Recommendations to obtain optimal results with the freshly prepared reagents are a temperature of 20 °C – 25 °C and a relative humidity of 35 % - 45 %. See chapter 6 Preparation of Derivatization reagents for the composition of the reagents. - Page 20 Detection under white light. Ninhydrin reagent Spray, heat at 105 °C for 3 min on the CAMAG TLC Plate Heater, let cool to room temperature. Detection under white light. Copper(II) sulfate Spray, heat the plate at 110 °C for 10 min on the CAMAG TLC Plate Heater, reagent let cool to room temperature.

-

Page 21: Transfer From Manual Spraying To Automated Spraying (20 X 10 Cm Or 20 X 20 Cm Hood)

Getting started 3.11.1 Transfer from manual spraying to automated spraying (20 x 10 cm or 20 x 20 cm hood) The exact composition for the reagents is specified in the chapter 6. Spraying level Spraying level Reagent Nozzle for 20 x 10 cm for 20 x 20 cm 2 ml 4 ml... - Page 22 Getting started Spraying level Reagent Nozzle 20 x 10 cm 3 ml Copper (II) sulfate reagent blue Aniline – diphenylamine- phosphoric acid reagent yellow Vanillin – sulfuric acid reagent yellow Potassium hydroxide solution* green blue Enzymatic test: Tyrosinase (enzyme and substrate in aqueous yellow solutions) *) recommended to use with the chemically resistant Ultra nozzle...

-

Page 23: Maintenance And Service

Maintenance and Service Maintenance and Service 4.1 Cleaning Regular cleaning: • Clean the instrument with a lint free cloth • The hood and the tray can be cleaned in a dishwasher at a maximum temperature of 55 °C, with the nozzle and the tray seal removed Before and after each cycle follow the instruction under chapter Cleaning step in this manual 4.2 Decontamination... -

Page 24: Maintenance Data Sheet

Maintenance and Service 4.4 Maintenance data sheet The maintenance data sheet informs about maintenance interval of the respective instrument as well as the proposal for IQ/OQ interval if applicable. In addition, it identifies consumable parts with the respective replacement cycle. Maintenance interval Maintenance 12 months... -

Page 25: Troubleshooting

Replace the seal if it has gotten hard or is unevenly thick. • If the hood still does not sit properly on the seal when it is lowered, the height of the hood has to be adjusted: please contact support@camag.com Replacing the seal of the tray •... -

Page 26: Internal Errors

Technical data • Smooth the seal so that there are no wrinkles left (except at the corners) Internal errors In case of an error, the chamber will be illuminated in red, blinking at a frequency of 1 Hz. Additionally, the level buttons will be backlighted in red, the error code being displayed with the 6 levels. -

Page 27: Preparation Of Derivatization Reagents

Preparation of Derivatization reagents Be aware that the formulation of derivatization reagents should be adapted for the use in the CAMAG Derivatizer. Material compatibility and spray characteristics have to be considered. The reagent preparation can be followed to obtain comparable results to manual spraying or to immersion. - Page 28 Preparation of Derivatization reagents Reagent preparation Reagent to obtain comparable results to manual spraying or to immersion. Iodine solution Spraying: Place 0.5 g of iodine in a glass bottle and dissolve in 100 mL of ethanol. Store in a dark place. Natural products Spraying: reagent (NP reagent)

- Page 29 Preparation of Derivatization reagents Reagent preparation Reagent to obtain comparable results to manual spraying or to immersion. Enzymatic assay: Preparation of phosphate buffer 0.02 M, pH = 6.8 Tyrosinase (aqueous Solution A: Dissolve 0.35 g of potassium phosphate dibasic (K ) in 100 mL solution) of deionized water (in a volumetric flask).

-

Page 30: Declaration Of Decontamination (Dod)

Declaration of Decontamination (DoD) Declaration of Decontamination (DoD) In order to protect our employees and to fulfil the statutory regulations please fill out this form duly and completely. Attach it to any instrument or part that may be contaminated by hazardous substances Customer information (if not the same as the ones on the RMA form): Company Contact name... - Page 31 49 30 516 55 50 · Fax 49 30 795 70 73 · E-Mail: infoberlin@camag.com CAMAG Scientific Inc. (USA) · 515 Cornelius Harnett Drive · Wilmington, NC 28401 Telephone 800 334 3909 · Fax 910 343 1834 · E-Mail: tlc@camag.com www.camag.com...

- Page 33 Notes: __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________ __________________________________________________________________________________...

Need help?

Do you have a question about the Derivatizer and is the answer not in the manual?

Questions and answers