ABB DCS800 Service Manual

Hide thumbs

Also See for DCS800:

- Service manual (158 pages) ,

- Hardware manual (134 pages) ,

- Installation manual (70 pages)

Subscribe to Our Youtube Channel

Summary of Contents for ABB DCS800

- Page 1 DCS800 DCS800 Service manual Service manual DCS800 DCS800 Drives Drives 20 20 to to 5200 5200 A A...

- Page 2 DCS800 Drive Manuals Language Language Public. number Public. number 3ADW000191 3ADW000191 DCS800 Quick Guide DCS800 Quick Guide DCS800 Tools & Documentation CD DCS800 Tools & Documentation CD 3ADW000211 3ADW000211 DCS800 Converter module DCS800 Converter module Flyer Flyer DCS800 DCS800 3ADW000190...

- Page 3 Rev E E DCS800 Service Manual e e.doc DCS800 Service Manual e e.doc EFFECTIVE: EFFECTIVE: 03.2011 03.2011 SUPERSEDES: SUPERSEDES: Rev D D 09.2009 09.2009 2011 ABB Automation Products GmbH. All rights reserved. 2011 ABB Automation Products GmbH. All rights reserved. ...

-

Page 5: Safety Instructions

To which products this chapter applies The information is valid for the whole range of the product DCS800, the converter modules DCS800-S0x size D1 to D7, field exciter units DCF80x, etc. like the Rebuild Kit DCS800-R00-9xxx. -

Page 6: Installation And Maintenance Work

Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V) may be present on the relay outputs of the drive system (e.g. SDCS-IOB-2 and RDIO). • DCS800 with enclosure extension: Before working on the drive, isolate the whole drive system from the supply. -

Page 7: Table Of Contents

13 Table of contents Safety instructions 5 What this chapter contains......................5 To which products this chapter applies..................5 Usage of warnings and notes .....................5 Installation and maintenance work....................6 Grounding........................7 Mechanical installation........................9 Operation ..........................10 Table of contents 13 Introduction 16 How to use this manual......................16 Contents of this manual ......................16 Target group ..........................16 Associated publications ......................16... -

Page 8: Type Code

Remove faulty OnBoard bridge (V1) ................36 Install new OnBoard bridge (V1) .................. 36 OnBoard bridge (V1) and thyristor module location in DCS800-S01 (2-Q) units..37 OnBoard bridge (V1) and thyristor module location in DCS800-S02 (4-Q) units..38 OnBoard bridge and thyristor module terminals ............39 Exchange of Thyristors for Size D5 Installation of "Disc Type"... - Page 9 15 Preventive Maintenance 135 Recommended regular maintenance ..................136 Maintenance schedule ......................136 Annual preventive maintenance....................137 3 years preventive maintenance .....................140 6 years preventive maintenance .....................141 9 years preventive maintenance .....................143 Appendix A - Spare Parts List 145 ...

-

Page 10: Current And Voltage Ratings

Current and voltage ratings Unit Unit size size 2-Q rated rated current current 4-Q rated current 4-Q rated current Supply voltage [VAC] Supply voltage [VAC] DCS800-01 [ADC] DCS800-01 [ADC] DCS800-02 [ADC] DCS800-02 [ADC] 1200 1200 1000 1000 1200 1200 1200... - Page 11 20 20 ...

-

Page 12: Fault Tracing Thyristors

1000 V probes and test leads: 1000 V probes and test leads: An ESD-field service kit (ABB Service An ESD-field service kit (ABB Service Finland code 0001ESD / MS-Antistatic): Finland code 0001ESD / MS-Antistatic):... -

Page 13: Additionally For Service And Preventive Maintenance

Additionally for service and preventive maintenance Following additional tools are mandatory for cleaning: An ESD safe blower / ESD vacuum cleaner (ABB Service Finland code 0006ESD / MUNTZ 555-ESD-S-E): How to detect a faulty thyristor Thyristor problems can be noticed differently:... -

Page 14: Dc-Current Pulses Measured By An Oscilloscope

23 DC-current pulses measured by an oscilloscope Connect an oscilloscope to the fixed AO I-act (X4:9/10 on the SDCS-CON-4 or X4:5/6 on the SDCS-IOB-3) and check for the proper amount of current pulses: Six current pulses in positive direction There should be six current pulses in positive direction. In case of a 4-Q converter also the six current pulses for the negative direction have to be checked. -

Page 15: How To Find A Faulty Thyristor

24 A fuse has disconnected one of the six thyristors. This is possible only for converters with 900 ... 5200 A (six internal branch fuses). A converter with three external fuses stops working completely at once when one of the three AC input fuses interrupts a phase input of the converter. - Page 16 4. Disconnect all I/O plugs (X3 to X7) at the SDCS-CON-4 and the plugs at the SDCS-DSL-4 board, if used (X51 to X54): Disconnect all plugs from SDCS- CON-4 and SDCS-DSL-4 boards Disconnect all plugs 5. Remove the grounding plug and the holding screw at the electronic tray: Remove the grounding plug and the holding screw Remove grounding and screws...

- Page 17 32 6. To unhinge the electronic tray including the SDCS-CON-4 pull it up and then out. Before remove tray completely unplug the flat cables (X12, X13, X37): Electronic tray with SDCS-CON-4 Remove flat cables Unhinge electronic tray 7. Remove all cables and plugs at the SDCS-PIN-4: Keep winding direction and T100 amount of windings for T100...

- Page 18 33 8. Remove the SDCS-PIN-4 board: OnBoard field exciter Snubber resistor bridge module Thyristor modules Current transformer Temperature sensor Remove SDCS-PIN-4 9. Remove the gate leads from the faulty thyristor module and mark the connectors clearly. 10. Remove the busbars necessary to get full access to the faulty thyristor module. 11.

-

Page 19: Install New Thyristor Modules

34 Install new thyristor modules 1. Ensure that the new thyristor module is of the correct type ( see appendix A of this manual). 2. Remove old heat conducting compound (grease) from the heat sink. Clean the mounting surfaces (heat sink and thyristor module) with an appropriate solvent (e.g. - Page 20 35 Nominal mounting torque bridge OnBoard and thyristor modules Size Type Electrical Thyristor module connections to heat sink 29 mm bridge block VVZF 70-16 5 Nm 20 mm block SKKT 27, 42, 57, 106 3 Nm 5 Nm 20 mm block MCC 26, 44, 56, 95 2.5 ...

-

Page 21: Remove Faulty Onboard Bridge (V1)

36 Remove faulty OnBoard bridge (V1) 1. Follow the instructions Remove faulty thyristor modules until step 8 is done. 2. Remove all connectors from the faulty OnBoard bridge and mark the connectors clearly. 3. Remove the faulty OnBoard bridge and mark it clearly as defective. Install new OnBoard bridge (V1) 1. -

Page 22: Remove Faulty Thyristor

46 46 Remove faulty thyristor Remove faulty thyristor 1. 1. Remove the screws of the DC – busbars and branch fuses preventing the Remove the screws of the DC – busbars and branch fuses preventing the stack to be prized open. stack to be prized open. -

Page 23: Install New Thyristor

47 47 Install new thyristor Install new thyristor 1. 1. Ensure that the new thyristor is of the correct type ( Ensure that the new thyristor is of the correct type ( see Appendix A see Appendix A . Keep the . - Page 24 48 48 7. 7. Tighten the nuts of the mounting clamp by hand so that the clamp is in parallel Tighten the nuts of the mounting clamp by hand so that the clamp is in parallel with the contact surface of the heat sinks. with the contact surface of the heat sinks.

- Page 25 49 left stack right stack rear front front rear View from the left Front view View from the right Location of thyristors in frame D5 (2-Q bridge)

- Page 26 50 D1 (-) C1 (+) Location of branch fuses frame D5...

-

Page 27: Exchange Of Thyristors For Size D6

Exchange of Thyristors for Size D6 Installation of "Disc Type" thyristor in converters size D6 (1900...3000 A) All DCS800 converters sizes D5/D6/D7 are equipped with disk type thyristors. The structure of the "Disc type" semiconductor component is such that it requires a certain compression force to operate. -

Page 28: Disk Type Thyristors

Converter with original Converter with second thyristor type T 1329Nxxx thyristor type T 1xxx-24 Id code: 3ADC340081P0001 Id code: 3ADC340098P0001 DCS800-S01-1900-08 3 ~ 800 VAC DCS800-S01-1900-08 a DCS800-S02-1900-08 3 ~ 800 VAC DCS800-S02-1900-08 a DCS800-S01-2050-05 3 ~ 525 VAC DCS800-S01-2050-05 a DCS800-S02-2050-05... -

Page 29: Bct Thyristors

53 Gate (4): Faston 2.8 x 0.8 mm Cathode (5): Faston 4.8 x 0.8 mm Conductive plate: Diameter 48 mm Second thyristor type Thyristor T 1xxx-24 with Id code 3ADC340098P0001 Second thyristor type Gate (y): Round terminal D = 1.5 mm Cathode (K Faston 4.8 x 0.5 mm Conductive plate:... - Page 30 84 Removing the converter fans 1. Remove the DCS Control Panel, the design cover and the fan connection plug X2 on the top of the converter housing: Remove DCS Control Panel Design cover...

- Page 31 85 2. Remove the two fan arrangement screws: Fan arrangement 3. Move the fan arrangement forward: Move fan arrangement...

- Page 32 86 4. Remove the fan holding screws: Fan holding screws 5. Remove Faston plugs and fans: Faston plugs 6. Reassemble everything and check for correct blow direction of each fan. The air should be sucked out of the module.

- Page 33 87 How to remove the converter fans in a frame D3 (four fans) Converters types DCS800-S01-0405-0x to DCS800-S02-0520-0x using four 115 VAC fans. Depending on the supply voltage they are either connected in series, for 230 VAC. or in parallel, for 115 VAC: Fan configuration D3 In case a fan fails there are different approaches due to the incoming voltage.

- Page 34 88 Removing the converter fans 1. Remove the DCS Control Panel, the design cover and the fan connection plug X2 on the top of the converter housing: Remove DCS Control Panel Design cover...

- Page 35 98 Select the workspace in directory: C:\ABB\DCS800\Firmware\CON-4\Ver x.x Confirm with Open Activate firmware download: Select Firmware with a right mouse click and choose Set as Active Project from the pop up menu...

- Page 36 99 Choose COM Port and communication speed: Select Firmware with a right mouse click and choose Properties from the pop up menu Select the Communications tap, choose the desired COM Port, un-tick the box Use default baud from the pop up menu and set the Target Baud Rate to 38400 .

- Page 37 100 Download firmware file to device: Select desired firmware with a right mouse click and choose Download File to Device from the pop up menu...

- Page 38 Disconnect tool: After the download is complete the FDT2.2 has to be disconnected. Select Firmware with a right mouse click and choose Disconnect from the pop up menu...

- Page 39 Set jumper S5 on SCDS-CON-4 from position 1-2 to position 3-4 Energize the DCS800 electronics. In case the 7-segment display shows a the firmware’s corresponding text file has to be downloaded from the workspace. If the 7-segment display shows something else, it is not necessary to download the text file and the download is complete.

-

Page 40: General

In case the Hitachi Flash Development Toolkit 2.2 is not installed at its default location (e.g. using Windows in an different language than English): C:\Program Files\Hitachi\FDT2.2 it is not possible to use the standard ABB workspace called DCS800.fdt . Thus the user has to create a new workspace. Start download tool: Start the Hitachi Flash Development Toolkit 2.2 by means of... - Page 41 115 Name new workspace: Name the new workspace, choose its location and confirm with OK Choose Yes ...

- Page 42 116 Create the project for the firmware file: Name the new project and confirm with Next ...

- Page 43 117 Choose Device And Kernel: Select Device: H8S/2633F and confirm with Next ...

- Page 44 118 Communication Port: Select the proper COM port, Select Baud Rate: 38400 , un-tick Use Default Baud Rate and confirm with Next ...

- Page 45 119 Device Settings: Enter the CPU crystal frequency for the selected device: 6.25 MHz , Select the multiplier for the main clock frequency (CKM): 4 and confirm with Next ...

- Page 46 120 Connection Type: Select connection: BOOT Mode , Select Interface: Direct Connection, un-tick Kernel already resident and confirm with Next ...

- Page 47 125 125 Device Settings: Device Settings: Enter the CPU crystal frequency for the selected device: 6.25 MHz Enter the CPU crystal frequency for the selected device: 6.25 MHz , , Select the multiplier for the Select the multiplier for the main clock frequency (CKM): 4 main clock frequency (CKM): 4 and ...

- Page 48 126 126 Connection Type: Connection Type: Select connection: BOOT Mode Select connection: BOOT Mode , , Select Interface: Direct Select Interface: Direct Connection, Connection, tick tick Kernel already resident Kernel already resident and confirm with confirm with Next ...

- Page 49 127 127 Programming Options: Programming Options: Protection: Automatic Protection: Automatic and and Messaging: Advanced, Messaging: Advanced, confirm with confirm with Finish Finish Now the project for the text file Now the project for the text file is finished: is finished:...

- Page 50 128 Close download tool: When closing the FDT2.2 confirm with Yes Creating of projects is complete now.

- Page 51 129 Download SDCS-COM-8 firmware Requirements: In case the PCMCIA adapter NDPA-02 with NDPC-12 is used the NtNisa drivers have to be installed (see NtNisa5x.zip or NtNisa5x.exe) before downloading the firmware. In case the USB adapter RUSB-02 is used together with DriveWindow 2.22 ...

- Page 52 130 Connect the DCS800 directly with the PC, fiber optic cable from SDCS-COM-8 channel 3 to: 1. PCMCIA adapter NDPA-02 with NDPC-12 or 2. USB adapter RUSB-02 Switch on the DCS800 Set Ch3 HW Config (70.21) = Ring ...

- Page 53 139 Check the door air filters. Door filters Clocked up filters prevent proper cooling of the drive. Wash dirty filters with water (60°C) and detergent. Check for dust, corrosion and temperature inside the module / cabinet. The DCS will run into overtemperature faults if the heatsinks are not clean. Heatsink Use compressed air to remove the dust from the heatsinks (the air flow must be from bottom to top).

-

Page 54: How To Remove The Converter Fan In A Frame D6

140 Ground components Check the quality of the supply voltage. 3 years preventive maintenance Following additional actions have to take place: Replace the cooling fans of units D6 and D7. How to remove the converter fan in a frame D6 ... - Page 55 Where used: DCS800-S0x-1900-y4/5/8… GR31M DCS800-S0x-3000-y/5/8 400 … 500 V DCS800-S0x-1900-y6/7 GR31M DCS800-S0x-3000-y6/7 500 … 690 V DCS800-S0x-3300-y1… GR35C DCS800-S0x-5200-y1 400 V / 690 V Aging of the components result in: 1. Increased vibration due to the imbalance of the cooling fan (can last for several months) 2.

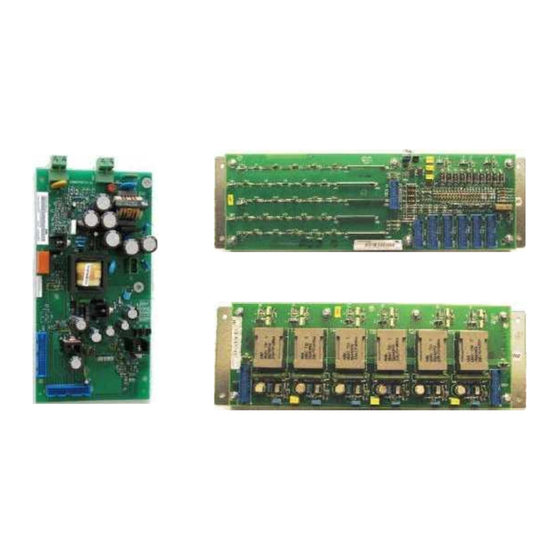

- Page 56 SDCS-POW-4 also is equipped with several capacitors which are sensitive to high ambient temperature. Where used: DCS800-S0x-1000, …, DCS800-S0x-5200 D5 to D7 and DCS800-R Aging of the electronic card result in: 1. Damage other devices 2. Trip the drive and cause break-down time Check the flat cables and their connections.

- Page 57 Control Panels and plug-in options D1 - D7 8.04 - 8.05 Field exciters FEX-425-Int, DCF803-0035 and DCF503/4B 8.06 Overvoltage protection DCF506-... for fieldexciter DCS800-S0x-0020, …, 0520, 20 A - 520 A 8.07 Common parts for DCS800-A0 Enclosed Converters 8.08 Parts for DCS800-R0 Rebuild Kit 8.09...

- Page 58 Fan for DCF50xB0060 GHSN700002P0001 AC220V 8556V Fan M55/M56 for DCF50xB0060 Item 8.06 Overvoltage protection DCF506-... for fieldexciter DCS800-S0x-0020, …, 0520, 20 A - 520 A 8.06 Overvoltage protection DCF506-... for fieldexciter DCS800-S0x-0020, …, 0520, 20 A - 520 A DESCRIPTION CODE...

- Page 59 31.00a 31.00a DCS800-S01-0900-06 DCS800-S01-0900-06a/07a & DCS800-S02-0900-06a/07a (600 V - 690 V a/07a & DCS800-S02-0900-06a/07a (600 V - 690 V ) ) DESCRIPTION DESCRIPTION 2 2 - - Q Q 4 4 - - Q Q C C O O D D E E...

- Page 61 T T 5 5 1 1 / / T T 5 5 2 2 f f o o r r D D 5 5 a a n n d d D D 6 6 Module Module contai contains: 41.00 41.00 DCS800-S01-1900-08 & DCS800-S02-1900-08 (800 V) DCS800-S01-1900-08 & DCS800-S02-1900-08 (800 V) DESCRIPTION DESCRIPTION 2 2 - - Q Q 4 4 - - Q Q...

- Page 62 43.00a 43.00a DCS800-S01-2050-06 DCS800-S01-2050-06a/07a & DCS800-S02-2050-06a/07a (600 V - 690 V a/07a & DCS800-S02-2050-06a/07a (600 V - 690 V ) ) DESCRIPTION DESCRIPTION 2 2 - - Q Q 4 4 - - Q Q C C O O D D E E...

- Page 64 154 Module contains: 47.00 DCS800-S01-3000-04/05 & DCS800-S02-3000-04/05 (400 V - 500 V) DESCRIPTION CODE TYPE/DATA NOTES Thyristor for DCS800-S01, 2-Q 3ADC340088P0001 T 989-3300xxx Bidirectional-Controlled-Thyristor (BCT) Thyristor for DCS800-S02, 4-Q 3ADC340079P0001 5 STB 24-Qxxx Puls transformer board 3ADT220090R 0043 SDCS-PIN -48...

- Page 66 S DCS-PIN-5x-11 90 me as . P re pa red fo r ga lva nic iso latio n (A92 ) Semiconductor fuses 3ADC770025P0001 UR 1700 A / 1500 V Flush-end contact fuse Module contains: 54.00 DCS800-S01-3300-04/05 & DCS800-S02-3300-04/05 (400 V - 500 V) DESCRIPTION CODE TYPE/DATA NOTES Thyristor 3ADC340089P0001...

- Page 67 E v e R 1 0 5 0 R 5 9 1 0 0 0 W D A 3 . : o 1 N 1 t . 0 2 n e 2 d I 0 *195R0401A9370000* *195R0401A9370000*...

Need help?

Do you have a question about the DCS800 and is the answer not in the manual?

Questions and answers