Summary of Contents for Roxell CoMeo

- Page 1 001-1020 00107470 *00107470* CoMeo ® Use and Assembly Guide Original use and assembly guide ENGLISH...

-

Page 2: Table Of Contents

........II-7 COMEO PANS (CLEANING OPTION + POULTRY PERCH GUARD) .... - Page 3 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS LED LIGHT KIT F/ INTERM. CONTROL UNIT ........

- Page 4 Subsequent changes to any manual made by any third party have not been reviewed nor authenticated by Roxell. Such changes may include, but are not limited to, translation into languages other than English, and additions to or deletions from the original content. Roxell disclaims responsibility for any and all damages, injuries, warranty claims and/or any other claims associated with such changes, inasmuch as such changes result in content that is different from the authoritat- ive Roxell- -published English version of the manual.

-

Page 5: General Information

Roxell’s most current use and maintenance manuals; use of cleansing agents and disinfectants in violation with the instructions received from the suppliers; or use of the Products in an ATEX- surrounding. - Page 6 ROXELL - 0516 6. INFORMATION ABOUT THE RESIDUAL RISKS - USED SAFETY SIGNS There are three levels of danger, which you can recognize from the signal word * DANGER * WARNING * CAUTION The nature and source of the imminent danger and possible consequences of not obeying warnings is stated here! DANGER indicates a direct imminent danger that can result in a serious or even fatal accident if the safety measures are not respected.

- Page 7 1. In the European Union If you have used the product for commercial purposes and you want to dispose of it, contact Roxell who will give you information about the return of the product. It is possible that you will have to pay a disposal charge for the return and recycling.

-

Page 9: Part I : Instructions For The User

PART I INSTRUCTIONS FOR THE USER I- 1... - Page 10 ROXELL - 001 - 2415 COMEO - INSTRUCTIONS FOR THE USER I- 2...

-

Page 11: General Safety Rules

ROXELL - 001 - 4918 COMEO - INSTRUCTIONS FOR THE USER GENERAL SAFETY RULES Minimax/HaïKoo/Comeo Nr: 002.../009.../001 Automatisch pannen voedersysteem voor vleestkuikens Automatic pan feeding system for broilers Winching systeem Liersysteem voor voer- en drinklijnen Winching system for feed and drink lines... -

Page 12: Directions For Operating The System

In order to make the control pan more attractive for the 3. Warm up the house and the litter at least 24 hours birds, Roxell offers a LED light kit which fits on the CoMeo before placing the birds. both for intermediate and end control units. - Page 13 ROXELL - 001 - 2415 COMEO - INSTRUCTIONS FOR THE USER USING THE SYSTEM FOR OLDER BIRDS Clean the Comeo by using heigh pressure Suspend the lines at the correct height. You will obtain water on the inside of the cone and clean from optimum results when the birds can easily pick the feed top to bottom.

- Page 14 ROXELL - 001 - 2416 COMEO - INSTRUCTIONS FOR THE USER (**) P.S. Gaseous formaldehyde (formalin), liquid caustic HOW TO PROGRAMME : soda or solution of caustic soda, hypochlorite or chlorine There are many ways. water cresoles are very corrosive and they will quickly...

-

Page 15: Maintenance Instructions

ROXELL - 001 - 2415 COMEO - INSTRUCTIONS FOR THE USER MAINTENANCE INSTRUCTIONS Switch off the main switch first. Use personal protective equipment. DANGER ACTIONS IN GREY BACKGROUND MUST BE DONE BY A TECHNICALLY TRAINED PERSON. 1. Power unit - Make fan dust-free - Check possible damages to electrical wiring 2. -

Page 16: Troubleshooting Guide

ROXELL - 001 - 4215 COMEO - INSTRUCTIONS FOR THE USER TROUBLE SHOOTING GUIDE Switch off the main switch first. Use personal protective equipment. DANGER ACTIONS IN GREY BACKGROUND MUST BE DONE BY A TECHNICALLY TRAINED PERSON. PROBLEM CAUSE CORRECTIVE ACTION No current. - Page 17 ROXELL - 001 - 2415 COMEO - INSTRUCTIONS FOR THE USER PROBLEM CAUSE CORRECTIVE ACTION 8.Windows are open Some windows are actually closed. Adjust height of feeder line until all windows and feed level is completely open and close simultaneously.

-

Page 18: Operators Guide

OPERATOR’S GUIDE 00107550 2218 For floor feeding - from day-old chicks to broilers. AVOID FEED WASTAGE = ADJUST FEEDER HEIGHT EASY START Winch up Lower Age of 5-7 days 10-12 days Weeks birds open feed windows closed feed windows pans full automatic operation of control pan (FIXED/MOVABLE INTERMEDIATE) CONTROL PAN (for partial brooding) - Page 19 * Remove possible feed residues by turning the pans a couple of times 180 degrees around the tubes or by removing the pans from the 12 fin supports. * Protect electrical components against water. * Clean the whole system by means of a high- pressure cleaner (max. 100 Bar). * When using aggressive detergents or disinfectants consult your supplier. OPTION COMEO WITH CLEANING OPTION COMEO OPTION...

-

Page 20: Declaration Of Incorporation Of Partly Completed Machinery

Roxell, Industrielaan 13, 9990 Maldegem Tel: +32 50 72 91 72 Fax: +32 50 71 67 21 “This part may only be filled out if all built-in subparts are delivered by Roxell” EG-verklaring van overeenstemming Verklaart geheel onder eigen verantwoordelijkheid dat het product: (Richtlijn 2006/42/EG, Bijlage II.1.A) -

Page 21: Ec-Declaration Of Conformity

EG-verklaring van overeenstemming (Richtlijn 2006/42/EG, Bijlage II.1.A) EC-declaration of conformity (Directive 2006/42/EC, Annex II.1.A) Fabrikant/Manufacturer: Roxell, Industrielaan 13, 9990 Maldegem Tel: +32 50 72 91 72 Fax: +32 50 71 67 21 Verklaart geheel onder eigen verantwoordelijkheid dat het product:... -

Page 23: Part Ii : Components

PART II COMPONENTS Environmentally-friendly design The motors comply with the Ecodesign legislation. Communication For all communication concerning parts/spare parts refer to the appropriate part number (not part name). -

Page 24: General Lay-Out

ROXELL - 009 - 2416 COMEO - COMPONENTS GENERAL LAY-OUT II- 2... -

Page 25: Component Numbers

ROXELL - 001 - 2119 COMEO - COMPONENTS COMPONENT NUMBERS Name Number CHAIN DIAM. 3.5 mm 00100750 HEAVY DUTY PULLEY 00100412 CABLE CLAMP NO. 5 00100545 CABLE DIAM. 5 mm 00100388 HAND OPERATED CENTR. WINCH 00102368 SUSPENSION CORD 00100610 SCREW HOOK 90 mm... -

Page 26: Adjuster Ring Regulator

ROXELL - 009 - 0717 COMEO - COMPONENTS ADJUSTER RING REGULATOR - 09717153 OPTION : AUGER INJECTOR KIT - 09701905 Key Nam e Part Nr. 1 AUGER INJECTOR INLET 19700673 2 AUGER INJECTOR Ø35.1X50.8 19700749 3 AUGER GUIDE 19700780 II- 4... -

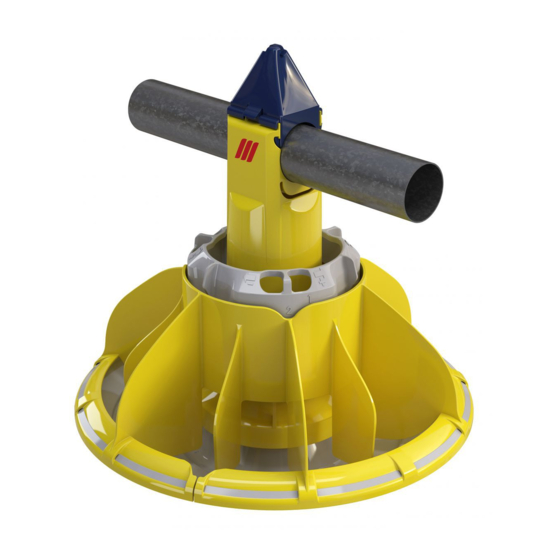

Page 27: Parts Comeo Pan

ROXELL - 001 - 4918 COMEO - COMPONENTS PARTS COMEO PAN Key Nam e Part Nr. 1 WIRE CONNECTOR 00107025 2 FLAT TOP SUPPORT 00901793 3 TOP SUPPORT 00900050 4 TOP HINGE 00107017 5 SHUT-OFF SHELL 00105262 6 ADJUSTER RING... -

Page 28: Parts For Broiler Cage

ROXELL - 001 - 4918 COMEO - COMPONENTS PARTS FOR BROILER CAGE COMEO Key Nam e Part Nr. FLAT TOP SUPPORT 00901793 ADJUSTER RING 00108872 12 FIN PAN SUPPORT 00108888 SHUT OFF SLIDE 00107053 SUPPORT CONE W/ RING 00107001 STEPPED ROUND FEEDER PAN... -

Page 29: Pan Parts For Comeo (Floor Feeding

ROXELL - 001 - 4918 COMEO - COMPONENTS PAN PARTS FOR COMEO (FLOOR FEEDING) Key Nam e Part Nr. TOP SUPPORT 00900050 ADJUSTER RING 00108872 12 FIN PAN SUPPORT 00108888 SHUT OFF SLIDE 00107053 SUPPORT CONE W/ RING 00107001 STEPPED ROUND FEEDER PAN... -

Page 30: Comeo Pans (Cleaning Option + Poultry Perch Guard

ROXELL - 001 - 4918 COMEO - COMPONENTS COMEO PANS (CLEANING OPTION + POULTRY PERCH GUARD) Key Nam e Part Nr. WIRE CONNECTOR 00107025 TOP HINGE 00107017 ADJUSTER RING 00108872 12 FIN PAN SUPPORT 00108888 SUPPORT CONE W/HINGE AND RING 00106977... -

Page 31: Feeder Line Components

ROXELL - 009 - 4018 COMEO - COMPONENTS FEEDER LINE COMPONENTS Key Nam e Part Nr. Key Nam e Part Nr. 2 ANCHOR BRACKET - LOW 00102681 TUBE 2.74M W/1 RECTANG'R HOLE 00104182 3 SPRING 00400077 TUBE 2.74M W/2 RECT. HOLES 00104174 4 DUPLEX CABLE CLAMP ST.ST. -

Page 32: 100Kg Hopper

ROXELL - 009 - 4016 COMEO - COMPONENTS 100KG HOPPER - 00100602 Key Nam e Part Nr. Qt. Key Nam e Part Nr. 1 HOPPER SIDE 10102259 9 PATENT DECAL COM-ATF-MINIMAX 10103893 2 PVC TUBE DIAM. 90 - L = 700 MM 10102382 *10 SCREW M4x10-DIN 84 - 4.8... -

Page 33: Thumper Assembly (Option

ROXELL - 009 - 4016 COMEO - COMPONENTS THUMPER ASSEMBLY (OPTION) - 00103036 Key Nam e Part Nr. 1 THUMPER BODY POULTRY 10107548 2 THUMPER STOP 13107982 3 THUMPER HOLDER 13107974 4 LOCKNUT M6 - DIN 985 20100400 5 BOLT M6 X 16 - DIN 933 - 8.8... -

Page 34: Poultry Intake Boot With Sensor - 230 V Ac / 24 V Dc

ROXELL - 001 - 2119 COMEO - COMPONENTS * POULTRY INTAKE BOOT WITH SENSOR - 230 V AC - 00108952 ** POULTRY INTAKE BOOT WITH SENSOR - 24 V DC - 00108950 Key Nam e Part Nr. 1 ANCHOR & BEARING ASS'Y... -

Page 35: Option : Double Feed Intake Boot

ROXELL - 001 - 2119 COMEO - COMPONENTS OPTION: DOUBLE FEED INTAKE BOOT - 00106518 Key Nam e Part Nr. 1 DOUBLE BOOT WELDMENT 10106029 2 ANCHOR & BEARING ASS'Y 10111441 3 DECAL - HANDS WARNING 13106596 OPTION: THUMPER KIT FOR DOUBLE INTAKE BOOT- 00106765 Key Nam e Part Nr. - Page 36 ROXELL - 001 - 2119 COMEO - COMPONENTS * OPTION: EXTENSION WITH SENSOR - 230 V AC - 03000901 ** OPTION: EXTENSION WITH SENSOR - 24 V DC - 03000899 Key Nam e Part Nr. *1 SENSOR VC12RT230106821 S3 D1...

-

Page 37: Control Unit Comeo With Switch

ROXELL - 001 - 1020 COMEO - COMPONENTS CONTROL UNIT COMEO WITH SWITCH - 00107326 00109136: CONNECTION BOX KIT CONTR. PAN Key Nam e Part Nr. For US only; to be ordered separately STEPPED ROUND FEEDER PAN 00106953 SUPPORT CONE F/ CONTROL PAN... -

Page 38: Control Unit Comeo With Sensor

ROXELL - 001 - 1020 COMEO - COMPONENTS CONTROL UNIT COMEO WITH SENSOR - 00107334 00109136: CONNECTION BOX KIT CONTR. PAN Key Nam e Part Nr. For US only; to be ordered separately STEPPED ROUND FEEDER PAN 00106953 SUPPORT CONE F/ CONTROL PAN... -

Page 39: Fixed Intermediate Control Unit Comeo With Switch

ROXELL - 001 - 1020 COMEO - COMPONENTS FIXED INTERMEDIATE CONTROL UNIT COMEO - WITH SWITCH - 00107342 00109136: CONNECTION BOX KIT CONTR. PAN Key Nam e Part Nr. 1 STEPPED ROUND FEEDER PAN 00106953 For US only; to be ordered separately... -

Page 40: Fixed Intermediate Control Unit Comeo With Sensor

ROXELL - 001 - 1020 COMEO - COMPONENTS FIXED INTERMEDIATE CONTROL UNIT COMEO - WITH SENSOR - 00107350 00109136: CONNECTION BOX KIT CONTR. PAN Key Nam e Part Nr. For US only; to be ordered separately 1 STEPPED ROUND FEEDER PAN... - Page 41 ROXELL - 001 - 1020 COMEO - COMPONENTS MOVABLE INTERMEDIATE CONTROL UNIT COMEO - WITH SWITCH - 00107390 00109136: CONNECTION BOX KIT CONTR. PAN Key Nam e Part Nr. For US only; to be ordered separately 1 STEPPED ROUND FEEDER PAN...

- Page 42 ROXELL - 001 - 1020 COMEO - COMPONENTS MOVABLE INTERMEDIATE CONTROL UNIT COMEO - WITH SENSOR - 00107398 00109136: CONNECTION BOX KIT CONTR. PAN Key Nam e Part Nr. For US only; to be ordered separately 1 STEPPED ROUND FEEDER PAN...

-

Page 43: Power Unit

ROXELL - 001 - 1020 COMEO - COMPONENTS POWER UNIT Nam e Part Nr. On Demand SERVICE PARTS FAN COVER On Demand CONNECTION BOX On Demand CAPACITOR 1-PHASE MOTOR See table CABLE RING On Demand Ke y Nam e Part Nr. -

Page 44: Power Units (For Us Only

ROXELL - 001 - 1020 COMEO - COMPONENTS POWER UNITS (FOR US ONLY) Key Nam e Part Nr. POWER UNIT - ROXELL, US 0… (See Table) GEARBOX WITH ELASTIC COUPLER 1… (See Table) MOTOR - IEC FLANGE TYPE 1… (See Table) COUPLER SET PKG, KG5.014/1... -

Page 45: Suspension Components

ROXELL - 001 - 1020 COMEO - COMPONENTS SUSPENSION COMPONENTS Key Nam e Part Nr. Key Nam e Part Nr. *1 ADJUSTMENT LEVELER 00602060 15 CADDY CLIPS TYPE 4H58 20104220 2 NEEDLE TO FIX SUSPENSION CORD 00100792 16 CHAIN DIA. 3.5 MM... -

Page 46: Single Eye Pulley

ROXELL - 001 - 1020 COMEO - COMPONENTS SINGLE EYE PULLEY - 00100420 Key Nam e Part Nr. 1 LOCKNUT M10-DIN 985 20100426 2 CABLE GUIDE WHEEL 10111417 3 PULLEY SIDE PLATE (SE) 10111391 4 BOLT M10X35-DIN 933 20102190 5 CLEVIS PIN... -

Page 47: Mounting Plate F/Hand Operated Central Winch

ROXELL - 001 - 1020 COMEO - COMPONENTS HAND OPERATED CENTRAL WINCH - 00102368 MOUNTING PLATE F/HAND OPERATED CENTRAL WINCH - 02001188 TELESCOPICAL WINCH DRIVE ASSEMBLY - 00102962 II- 25... -

Page 48: Motor

ROXELL - 001 - 1020 COMEO - COMPONENTS MOTOR Capacitor 1 phase motor System WINCH 10106136 09802330 RUN CAPACITOR 10 µF Gearbox With Key Motor Shaft Ø14 09802338 RUN CAPACITOR 12,5 µF Ratio FOR CENTRAL 09802346 RUN CAPACITOR 18 µF... -

Page 49: Winch W/Switch - Motor Operated

ROXELL - 001 - 1020 COMEO - COMPONENTS WINCH W/SWITCH - MOTOR OPERATED - 00107190 Key Nam e Part Nr. FLANGE BEARING DIAMETER 25 11006756 GEARBOX FRA60 PC1 - 1/320 10106136 LIMIT SWITCH WINCH 10111845 OPTION : CONTROL PANEL FOR CENTRAL WINCH Do not use the winch control panel to directly switch motor currents. -

Page 50: Motor Starter

ROXELL - 001 - 1020 COMEO - COMPONENTS MOTOR STARTER STOP START STOP START Key Nam e Part Nr. 1 ENCLOSURE MOTOR STARTER 15011934 THERMAL MAGNETIC PROTECTION: See: Where used 3 MOUNT SOCLE GV2-AF01 15010291 4 CONTACTOR 3P+1NO 230VAC 15011926... -

Page 51: Control Panel With Time Clock

ROXELL - 001 - 1020 COMEO - COMPONENTS CONTROL PANEL WITH TIME CLOCK - 00100685 BOX W/COUNTER - 00102905 OPTION : CONTROL PANEL INTERMEDIATE CONTROL UNIT - 05000922 II- 29... -

Page 52: End Unit

ROXELL - 001 - 1020 COMEO - COMPONENTS END UNIT - 00901827 Key Nam e Part Nr. 1 OVERFLOW BOX 10204998 2 TUBE BRACKET ASS'Y 10205771 3 BOTTOM PLATE 10204980 4 PROTECTION PLATE 10110237 5 BOLT M6X10 - DIN 933-8.8... -

Page 53: Minimum Switch

ROXELL - 001 - 1020 COMEO - COMPONENTS MINIMUM SWITCH - 00201145 Key Nam e Part Nr. 1 MINIMUM SWITCH COMPLETE 10206043 1.1 MINIMUM SWITCH ASS'Y 10203073 1.2 SWITCH COVER 10206035 1.3 SWITCH SUPPORT 10203107 1.4 PARCKER SCREW 4.2x9.5 DIN 7981 20102745 1.5 MINIMUM SWITCH SHIELD... -

Page 54: Extension Feed Intake Boot

ROXELL - 001 - 1020 COMEO - COMPONENTS EXTENSION FEED INTAKE BOOT - 00901470 Key Nam e Part Nr. 1 SIDE PLATE EXTENSION BOX 10900397 2 FRONT&BACK PLATE EXTENSION BOX 10900389 3 TOP PLATE EXTENSION BOX 10900405 4 NUT M6 - DIN 934... -

Page 55: Led Light Kit For Control Unit

ROXELL - 001 - 1020 COMEO - COMPONENTS LED LIGHT KIT FOR CONTROL UNIT - 00108158 Key Nam e Part Nr. 1 POWER SUPPLY 12VDC - 6W 10112245 2 LEDBAR - 100LUMEN - LG 550MM 10112237 LED LIGHT KIT F/ INTERM. CONTROL UNIT - 00108166 Key Nam e Part Nr. -

Page 56: Spares Set Bear.cap Hold - Ø44.5

ROXELL - 001 - 1020 COMEO - COMPONENTS SPARES SET BEAR. CAP HOLD - Ø44.5 (SET 10 PCS) - 00106929 Nam e Part Nr. BEAR.CAP HOLDER-Ø44.5 (SET 10PCS) 00106929 10 Used in : 00106500 FEED INTAKE BOOT POULTRY 00108950 POULTRY INTAKE BOOT WITH SENSOR... -

Page 57: Part Iii : Installation Instructions

PART III INSTALLATION INSTRUCTIONS... - Page 58 HAIKOO - INSTALLATION INSTRUCTIONS ROXELL - 009 - 2313...

-

Page 59: General Safety Rules

ROXELL - 009 - 2416 COMEO - INSTALLATION INSTRUCTIONS GENERAL SAFETY RULES LINE SYSTEMS IMPORTANT Carefull read the following instructions before you DANGER INSTALL the system 1. Be CAREFUL when handling the ROLLS OF AUGER. When you release the BINDING WIRE, it is possible that the auger UNROLLS. This can cause injuries. -

Page 60: General Lay-Out

ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS GENERAL LAY-OUT III- 4... -

Page 61: Component Numbers

ROXELL - 001 - 2119 COMEO - INSTALLATION INSTRUCTIONS COMPONENT NUMBERS Name Number CHAIN DIAM. 3.5 mm 00100750 HEAVY DUTY PULLEY 00100412 CABLE CLAMP NO. 5 00100545 CABLE DIAM. 5 mm 00100388 HAND OPERATED CENTR. WINCH 00102368 SUSPENSION CORD 00100610... -

Page 62: Tools

ROXELL - 009 - 2218 COMEO - INSTALLATION INSTRUCTIONS TOOLS Ø32 (SENSOR) - 09701699 - Ø40 - 09700022 (MOD. 55), - Ø51 - 09700030 (MOD. 75), - Ø70 - 09700048 (MOD. 90), - Ø108 - 09700055 (MOD. 125) - Ø130MM (Holes in wall) 09700071 Ø9, Ø7 &... -

Page 63: Electricity

- Motor protections are set at minimum by the manufacturer. - If you do not use a Roxell control panel, make sure to provide the necessary motor protections. - Compare motor label plate and motor connection with local voltage :... -

Page 64: The Suspension

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS THE SUSPENSION The suspension of the system is very important: it must be done carefully and accurately! Closely study the instructions before starting the suspension. - IMPORTANT: If there is a layer of insulation, first install the necessary reinforcements! - Each suspension point (small pulley) should be able to hold a 100 kg burden. -

Page 65: Drawings Of Suspension System With Central Winch

ROXELL - 009 - 4018 COMEO - INSTALLATION INSTRUCTIONS DRAWINGS OF SUSPENSION SYSTEM WITH CENTRAL WINCH FOR YOUR SAFETY: NEVER MAKE THE INSTALLATIONS LONGER THAN THE RECOMMENDED LENGTH. DANGER 31 - 85,9 M (MAX. 300 KG) 05000872 00100545 00102368 00100412... - Page 66 ROXELL - 009 - 2416 COMEO - INSTALLATION INSTRUCTIONS CHOOSE BETWEEN 2 FOLLOWING POSSIBILITIES (SO THE CABLE CLAMPS WILL NOT TOUCH THE PULLEYS WHEN YOU WINCH UP THE LINE). Feeder line. 15cm 15cm 25cm 25cm 25cm 25cm 15cm 15cm Cable install the central winch somewhat out of line.

-

Page 67: Central Winch

ROOF CONSTRUCTION. REINFORCE WHEN NECESSARY. DANGER = HAND OPERATED CENTRAL WINCH. Roxell supplies the hand operated winch without mounting plate and bolts/ nuts. Fix the winch directly to a SOLID CEILING. You can install plate & winch in any direction. -

Page 68: Suspension For Feeder Line

ROXELL - 009 - 2416 COMEO - INSTALLATION INSTRUCTIONS SUSPENSION FOR FEEDER LINE SUSPEND THE CONTROL UNIT AT LEAST 3M FROM THE HOUSE END WALL ! MAKE SURE THAT THE MAIN CABLE 5mm DOES NOT HANG IN, BUT BESIDE THE SCREW HOOKS AND PULLEYS ! FIGURE 14. - Page 69 ROXELL - 009 - 2416 COMEO - INSTALLATION INSTRUCTIONS CONSIDER THE DOUBLE DIVERSION !! ONLY THEN INSTALL THE CABLE. YOU CAN HANG THE MAIN CABLE IN THE SCREW HOOKS FOR THE TIME BEING. - Measure the distance from the wall to the first feeder line.

-

Page 70: To Install The Main Cable

ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE MAIN CABLE FIGURE 20. III- 14... - Page 71 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS FEEDER LINE > 85,9M : SEE PAGE III-9 FIGURE 9. : SINGLE DIVERSION Required cable length : 4 x height. FIGURE 21. FIGURE 23. Required cable length : 4 x height.

- Page 72 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS FIGURE 24. 00102699 FIGURE 25. III- 16...

- Page 73 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS CENTRAL WINCH W/GEARBOX FIGURE 26. FIGURE 27. FIGURE 28. FIGURE 29. FIGURE 30. III- 17...

- Page 74 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS FIGURE 31. FIGURE 32. OVERVIEW 00107198 00100412 00100545 FIGURE 33. III- 18...

-

Page 75: Tighten Main Cable

ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS TIGHTEN MAIN CABLE ¦15 kg FIGURE 34. L= H+55+2+3+15 15cm 15cm +55cm CUT BY MEANS OF A SOLDERING IRON OR AN ELECTRICALLY HEATED KNIFE. FIGURE 35. III- 19... -

Page 76: To Install The Line

ROXELL - 001 - 4918 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE LINE POSSIBLE FEEDER PAN COMBINATIONS COMEO FLOOR FEEDING (PERCH GUARD) 00107025 00900050 00107017 00108872 00108872 00108888 00108888 00107053 00106977 00107001 00106953 00106953 FIGURE 36. FIGURE 37. III- 20... -

Page 77: Possible Feeder Pan Combinations

ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS POSSIBLE FEEDER PAN COMBINATIONS COMEO - BROILER CAGE 00901793 00107017 00107009 00107009 00106961 00106961 00106977 00107001 00106953 00106953 FIGURE 38. FIGURE 39. III- 21... -

Page 78: To Install The Feeder Pans

ROXELL - 001 - 4918 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE FEEDER PANS 09717145 00108872 (3x) FIGURE 40. FIGURE 41. CLICK FIGURE 42. III- 22... - Page 79 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS FIGURE 43. FIGURE 44. OPTION ∅2mm ⇒ ∅3mm FIGURE 45. FIGURE 46. III- 23...

- Page 80 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS CLICK FIGURE 47. OPTION 00101105 FIGURE 48. FIGURE 49. FIGURE 50. FIGURE 51. III- 24...

- Page 81 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS Welding seam FIGURE 53. FIGURE 54. FIGURE 52. FIGURE 53. III- 25...

- Page 82 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS FIGURE 54. CLICK CLICK FIGURE 55. III- 26...

- Page 83 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS CLICK CLICK 90° FIGURE 56. CLICK CLICK FIGURE 57. III- 27...

- Page 84 ROXELL - 009 - 2415 COMEO - INSTALLATION INSTRUCTIONS COMEO FLOOR FEEDING (PERCH GUARD) 00107053 00900050 00107009 00106961 00107001 00107053 00900050 00107001 00106953 FIGURE 58. FIGURE 59. III- 28...

- Page 85 ROXELL - 001 - 4918 COMEO - INSTALLATION INSTRUCTIONS COMEO FLOOR FEEDING (PERCH GUARD) 00107025 00107017 00108872 00108888 00106977 00106953 FIGURE 60. FIGURE 61. III- 29...

- Page 86 ROXELL - 001 - 4918 COMEO - INSTALLATION INSTRUCTIONS COMEO - BROILER CAGE 00901793 00108872 00108888 00107001 00106953 FIGURE 62. FIGURE 63. III- 30...

-

Page 87: Chick Starter Outlet Ass'y Kit (Option)

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS CHICK STARTER OUTLET ASS'Y KIT (OPTION) FIGURE 64. Sandpaper CLICK Right CLICK Left CLOSED OPEN OPTION FIGURE 65. III- 31... -

Page 88: To Install The Shut Off Slide

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE SHUT OFF SLIDE FOR PARTIAL STARTING - REAR Partial starting area Running direction of the feed 00104133 FIGURE 66. FIGURE 67. FOR PARTIAL STARTING - FRONT Intermediate control pan... -

Page 89: To Install The Feeder Line

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS TOTAL HOUSE BROODING Running direction of the feed 00108264 00108264 FIGURE 70. TO INSTALL THE FEEDER LINE 10Nm 00102921 100kg hopper. 10mm INSTALL AN ANCHOR BRACKET : FIGURE 71. III- 33... - Page 90 ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS Start suspending from the central winch. Proceed to both ends until the whole feeder line is suspended. 00100792 REMARK : AFTER INSTALLATION OF THE PANS, WHEN THE LINE HANGS LEVEL, YOU CAN INSERT THE CORD END BACK INTO THE CORD.

-

Page 91: To Install The Intermediate Control

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE INTERMEDIATE CONTROL The intermediate control replaces a standard pan of the feeder line. MOVABLE INTERMEDIATE CONTROL FIXED INTERMEDIATE CONTROL UNIT UNIT FOR PARTIAL STARTING FOR PARTIAL STARTING 5 ...3 Partial starting area FIGURE 74. -

Page 92: Control Panel Intermediate Control Unit (With Sensor)

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS Cable FIGURE 77. CONTROL PANEL INTERMEDIATE CONTROL UNIT (WITH SENSOR) For an “easy use”, and/or switching over from a partial area to full use of the house, you can make advant- age of a control panel intermediate control unit ( (optional). -

Page 93: Feed Intake Boot

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS FEED INTAKE BOOT FIGURE 79. OPTION: SUPPORT FOR HOPPER IN LINE FIGURE 80. III- 37... -

Page 94: To Install And Suspend The 100Kg Hopper

ROXELL - 001 - 2119 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL AND SUSPEND THE 100KG HOPPER Install as shown on page II-10. FIGURE 81. HEIGHT ADJUSTMENT OF THE 100KG HOPPER Hopper hook. Chain 3,5mm. FIGURE 83. III- 38... -

Page 95: To Install The Control Unit

ROXELL - 009 - 4016 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE CONTROL UNIT FIGURE 83. POWER UNIT SUSPENSION 05000013 00100545 10203156 10107449 FIGURE 84. III- 39... -

Page 96: Connection Box Kit For Control Pan (For Us Only)

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS CONNECTION BOX KIT FOR CONTROL PAN (FOR US ONLY) FIGURE 85. FIGURE 86. III- 40... - Page 97 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS 20100244 10112548 FIGURE 87. FIGURE 88. III- 41...

-

Page 98: To Install The Auger

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE AUGER TAKE CARE THAT AUGER DOES NOT UNROLL ! FIGURE 89. FIGURE 90. FIGURE 91. OPTION 09701905 ¦ 4 m FIGURE 92. FIGURE 93. 20100483 10100782 20102158 FIGURE 94. - Page 99 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS FIGURE 95. FIGURE 96. III- 43...

- Page 100 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS FIGURE 97. FIGURE 98. III- 44...

- Page 101 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS OPTION (for cages) Overflow box 00901827 FIGURE 99. FIGURE 100. 1,7cm per 3m tube. FIGURE 101. III- 45...

- Page 102 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS FIGURE 102. FIGURE 103. FIGURE 104. III- 46...

- Page 103 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS AUGER BRAZING Always use hard solder. We recommend a bronze, flux-coated rod. The joint must be well filled. Avoid sharp edges or rough corners : these wear out the tubes. Braze at low temperature.

-

Page 104: To Install The Thumper (Option)

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE THUMPER (OPTION) Perforate the prepunched holes ! FIGURE 108. SECTION FIGURE 109. FIGURE 110. III- 48... -

Page 105: Adjustment

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS ADJUSTMENT 1 = Max 2 = Min FIGURE 111. ADJUSTMENT 1 = Max 2 = Min Left Right Right Left FIGURE 112. III- 49... -

Page 106: Adjustment Limit Switch

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS ADJUSTMENT LIMIT SWITCH 1 = Max FIGURE 113. 2 = Min CONNECTION DIAGRAM : SEE CP CENTRAL WINCH FIGURE 114. III- 50... -

Page 107: To Install The Poultry Perch Guard

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE POULTRY PERCH GUARD FIGURE 115. 00102681 00102921 00106945 Make a double loop around the central notch of the 00900050 anchor bracket. FIGURE 116. III- 51... - Page 108 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS Comeo with cleaning option 00107025 20 20 FIGURE 117. EVERY 3 FEEDER TUBES FIGURE 118. FIGURE 119. 10107472 FIGURE 120. III- 52...

- Page 109 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS 00400077 To stretch min. 50mm / max. 65mm. FIGURE 121. After all cables for poultry perch have been installed, connect the poultry perch guard to the ” cable. Poultry perch guard...

-

Page 110: To Install The Flex Auger Feed Supply System

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE FLEX AUGER FEED SUPPLY SYSTEM INSTALLATION INSTRUCTIONS : SEE OUR FLEXAUGER OPERATOR'S MANUAL. ATTENTIVELY READ THESE INSTRUCTIONS. ATTENTION : USE AS LITTLE ELBOWS AS POSSIBLE. MAKE SURE THAT THERE ARE NO TUBE CONNECTIONS AT LOCATIONS WHERE YOU NEED... -

Page 111: To Install The Telescopical Tube

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS TO INSTALL THE TELESCOPICAL TUBE S-hook Chain dia 3,5. Tube clamp w/S-hook Cut a hole in the cover at any desired loca- tion. Screw link 100Kg Hopper Hook for 100kg hopper FIGURE 125. -

Page 112: Electrical Symbols

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS ELECTRICAL SYMBOLS 2/T1 4/T2 6/T3 Automatic fuse - Si1 - Fu2 Main Switch 1/L1 3/L2 5/L3 - Q1 1/L1 3/L2 5/L3 - M1 Motor I> I> I> 1.1kW Thermal-magnetic motor pro-... - Page 113 MAXIMUM CABLE LENGTHS TO THE MOTORS: SEE PAGE III-138 Junction box Junction box 1x230V AC (IEC38) Connection of start/stop conditions From motor starter 1/L1 3/L2 5/L3 2-wire 5-wire L2 PE First start/stop condition 1 L1 3 L2 5 L3 1 L1 3 L2 5 L3 2/T1...

- Page 114 MAXIMUM CABLE LENGTHS TO THE MOTORS: SEE PAGE III-138 Junction box Junction box 3x230V AC (IEC38) Connection of start/stop conditions From motor starter 1/L1 3/L2 5/L3 2-wire 5-wire First start/stop condition 1 L1 3 L2 5 L3 1 L1 3 L2 5 L3 2/T1 4/T2...

- Page 115 MAXIMUM CABLE LENGTHS TO THE MOTORS: SEE PAGE III-138 Junction box Junction box 3x400V AC+N (IEC38) Connection of start/stop conditions From motor starter 1/L1 3/L2 5/L3 2-wire 5-wire First start/stop condition 1 L1 3 L2 5 L3 1 L1 3 L2 5 L3 2/T1 4/T2...

-

Page 116: Led Light Kit For Control Unit

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS LED LIGHT KIT FOR CONTROL UNIT CONNECT THE POWER SUPPLY TO 100-240 VAC, 50/60HZ. ; 0,22A/CU. 20101614 00108158 30° FIGURE 128. FIGURE 129. 20103149 20100160 20100400 FIGURE 130. FIGURE 131. III- 60... -

Page 117: Led Light Kit For Intermediate Control Unit

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS LED LIGHT KIT FOR INTERMEDIATE CONTROL UNIT CONNECT THE POWER SUPPLY TO 100-240 VAC, 50/60HZ. ; 0,22A/CU. CONNECT THE POWER SUPPLY TO 100-240 VAC, 50/60HZ. ; 0,22A/CU. 20101812 30° 00108166 FIGURE 132. -

Page 118: Motor Protection

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS MOTOR PROTECTION STOP START III- 62... -

Page 119: Maximum Cable Lengths To The Motors

ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS MAXIMUM CABLE LENGTHS TO THE MOTORS Calculation method: IECHD 603645 Cable type: PVC – XLPE – Silicon Placing: Open cable trough Materials used: Schneider Electric GV2 motor protections Please be aware that you have to follow the local regulations for your country! - Page 120 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS Motor Power (kW) Net voltage Protection Max. cable length (m) Wire gauge (mm²) 0 - 107 3x220V 60Hz 108 - 178 GV2ME07 3x230V 60Hz 179 - 285 0.45 0 - 294...

- Page 121 ROXELL - 001 - 1020 COMEO - INSTALLATION INSTRUCTIONS Motor Power (kW) Net voltage Protection Max. cable length (m) Wire gauge (mm²) 0 - 27 28 - 46 1x230V 50Hz GV2ME14 47 - 74 0 - 44 45 - 73...

- Page 122 ROXELL bvba ‐ Industrielaan 13, 9990 Maldegem (Belgium) Tel. +32 50 72 91 72 ‐ info@roxell.com ‐ www.roxell.com ROXELL USA Inc. ‐ 720 Industrial Park Road, Anderson MO 64831 (USA) Tel. +1 417 845 6065 ‐ info.usa@roxell.com ‐ www.roxell.com ROXELL Malaysia ‐ No. 49, Jalan Permata 2/KS9, Taman Perindustrian Air Hitam, 41200 Klang, Selangor (Malaysia) Tel. +60 3 3123 1767 ‐ info.malaysia@roxell.com ‐ www.roxell.com ROXELL Россия ‐ ООО «Рокселл» ОГРН 1157746055026 125167, Россия, город Москва, Ленинградский проспект, дом 37, корпус 9, помещение 653 Телефон: +7 495 983 30 15 ‐ Адрес электронной почты: info.russia@roxell.com ‐ www.roxell.com ...

Need help?

Do you have a question about the CoMeo and is the answer not in the manual?

Questions and answers