Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for ASIX AX58200

- Page 1 Motor Control User Guide Reference Design User Guide AX58200 Motor Control User Guide Revision 1.00 March 27 , 2020 rch 14 , 2020 rch 14 , 2020 rch 14 , 2020 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 2 AX58200 Motor Control User Guide Revision History Reference Design User Guide Revision Date Description 1.00 2020/03/27 Initial release Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 3: Table Of Contents

7-3 Link Reference ..................46 7-4 Execution PLC ..................46 8. Object Dictionary ......................49 8-1 Objects Description ................49 9. Performance Evaluation ....................51 9-1 Minimum DC Cycle Time ..............51 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 4 Figure 6 - 12 ..............................31 Figure 6 - 13 ..............................32 Figure 6 - 14 ..............................32 Figure 6 - 15 ..............................33 Figure 6 - 16 ..............................34 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 5 Figure 7 - 25 ..............................48 Figure 7 - 26 ..............................48 Figure 9 - 1 ................................ 51 Figure 9 - 2 ................................ 51 Figure 9 - 3 ................................ 52 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 6 Table 4 - 1 ................................16 Table 7 - 1 ................................46 Table 8 - 1 ................................49 Table 8 - 2 ................................50 Table 8 - 3 ................................50 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 7: Introduction

1. Introduction Reference Design User Guide This document introduces how to setup entire environment for motor control application on AX58200 evaluation platform (TSB + EXB-SMDB boards). The demo application of EtherCAT master side develops by PLC (Programmable Logic Controller) language through BECKHOFF TwinCAT engineering (XAE). The IDE rely Microsoft Visual Studio 2010 / 2013. -

Page 8: Requirements

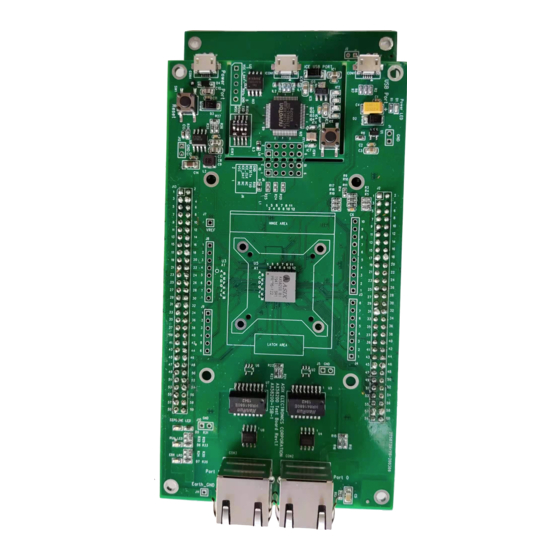

[Software at EtherCAT slave side] ⚫ ARM KEIL MDK micro-Vision 5 (for development only) Figure 2 - 2 ⚫ IAR Embedded Workbench for ARM 7.40 (for development only) Figure 2 - 3 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 9 AX58200 Motor Control User Guide [Hardware] ⚫ AX58200 Test Board (AX58200-TSB) x 1 Reference Design User Guide Figure 2 - 4 Figure 2 - 5 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 10 AX58200 Motor Control User Guide ⚫ AX58200-TSB to X-NUCLEO-IHM081 Adapter Board (AX58200-EXB-SMDB) x 1 Reference Design User Guide Figure 2 - 6 Figure 2 - 7 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 11 AX58200 Motor Control User Guide ⚫ X-NUCLEO-IHM08M1 3-Phase Inverter Board x 1 Reference Design User Guide Figure 2 - 8 Figure 2 - 9 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 12 ⚫ MOTION TECH BL60M24D8E00430080 Motor x 1 Please refer to MTM official website for more detail: http://www.motiontech.com.tw/ Reference Design User Guide Figure 2 - 10 Table 2 - 1 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 13 AX58200 Motor Control User Guide Reference Design User Guide Table 2 - 2 Table 2 - 3 ⚫ 24VDC/8A Power Supply x 1 Figure 2 - 11 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 14: Board Description

Reference Design User Guide 3-1 AX58200-TSB AX58200-TSB is a test / evaluation board for AX58200 IC and has below components: AX58200 – An ASIX IC that integrated an ESC (EtherCAT Slave Controller) + an ARM cortex-M4 ⚫ ⚫ ESC Port0 – Port0 of the ESC ⚫... -

Page 15: X-Nucleo-Ihm08M1

IHM08M1 board is ready by check these jumps and components status as below table. Component Status R74, R86 Removed JP1, JP2 Closed C3, C5 and C7 Removed J5, J6 Short 3sh side Table 3 - 1 Figure 3 - 2 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. -

Page 16: Hardware Setup

Please check the power USB port (CON4) is connected before you are ready to start up motor. The debug USB port (ICON1) is only used to upgrade firmware and debugging at development stage. Figure 4 - 1 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. -

Page 17: Basic Operation Of Twincat

Reference Design User Guide Before starting up the AX58200-TSB first time, you MUST download available contents into AX58200 EEPROM first. If there are no available contents in AX58200 EEPROM, the MCU will be reset forcibly by ESC. Assume you already installed the BECKHOFF TwinCAT XAE in your environment. - Page 18 Step 2: Specify “Name” and “Location” and click “OK”. Reference Design User Guide Figure 5 - 3 Step 3: Click the “TWINCAT -> Show Realtime Ethernet Compatible Devices…” ⚫ Figure 5 - 4 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 19 BSP directory: “YOUR_BSP_FOLDER\SampleCode\SampleCode\Ethercat_MotorControl_Reference_D esign\For_TwinCAT\ESI” ⚫ Step 6: Copy the file to TwinCAT directory: “C:\TwinCAT\3.1\Config\Io\EtherCAT\” ⚫ Step 7: Click “TWINCAT -> EtherCAT Devices -> Reload Device Descriptions”. Figure 5 - 6 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 20 Step 8: Plug USB power and connect ESC port0 to TwinCAT master port. Reference Design User Guide Figure 5 - 7 ⚫ Step 9: Right-click on “IO / Devices” and select “Scan”. Figure 5 - 8 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 21 Step 10: Choose main network adapter. Reference Design User Guide Figure 5 - 9 ⚫ Step 11: Click “Yes”. Figure 5 - 10 ⚫ Step 12: Click “Yes”. Figure 5 - 11 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 22 Step 13: Double click “Device N (EtherCAT)” and you will see the TwinCAT master scanned out the EtherCAT slave Reference Design User Guide Figure 5 - 12 ⚫ Step 14: Select the slave, right-click and choose “EEPROM Update…” Figure 5 - 13 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 23 Step 16: Wait for progress bar at lower right corner of the TwinCAT screen. Figure 5 - 15 ⚫ Step 17: Select “Device N (EtherCAT)”, right-click and choose “Remove”. Figure 5 - 16 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 24 So the state field “INIT INIT_ERR” is properly / reasonable. Figure 5 - 18 If there is an available firmware with Slave Stack Code in AX58200, you should see below screen. The “State” field is “OP” mode. Figure 5 - 19 Note: Please refer to Chapter 6 for download firmware.

-

Page 25: Download Firmware To Ax58200

Motor Control User Guide 6. Download Firmware to AX58200 Reference Design User Guide If you want to download firmware to AX58200, you have 4 methods basically: (1) Mass Storage Method (MSG mode in ICE) (2) NUVOTON ICP Tool Method (3) ARM KEIL MDK Method (4) IAR EWARM Method If you do not have any requirements for development in further, just reference the item (1) and (2). -

Page 26: Mass Storage Method

After finish copy, the AX58200 will auto-restart. Note: If you want to check out the firmware status for judge if the download is success, please refer to Chapter 6.5. Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. -

Page 27: Nuvoton Icp Tool Method

Make sure to take off the USB power cable and modify the “DIP of ICE” to below state: Figure 6 - 4 And let “Debug Port” to connect your host as following: Figure 6 - 5 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 28 AX58200 Motor Control User Guide Execute the ICP Programming Tool. Click “Continue>>”. Reference Design User Guide Figure 6 - 6 Click “Connect” button. Figure 6 - 7 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 29 AX58200 Motor Control User Guide If the green text appears, that means the ICP tool finds out the ICE and AX58200 successfully. Reference Design User Guide Figure 6 - 8 Click “APROM” button and select the firmware file “AX58200_MotorControl_vX.X.X.bin” from the BSP directory “YOUR_BSP_FOLDER\SampleCode\Ethercat_MotorControl_Reference_Design\Binary\”...

- Page 30 AX58200 Motor Control User Guide Click “Options”. Reference Design User Guide Figure 6 - 10 Check the items “Erase”, “Program” and “Verify”. Figure 6 - 11 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 31 Reference Design User Guide Figure 6 - 12 Note: If you want to check out the firmware status for judge if the download is success, please refer to Chapter 6.5. Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 32: Arm Keil Mdk Method

⚫ Licensed ARM KEIL MDK ⚫ BECKHOFF SSC (Slave Stack Code) or SSC Tool Note: Please refer to the “AX58200 SSC Tool Configuration Import User Guide” for generate related source files. We don’t overtalk the ARM KEIL MDK installation here. We assume it is ready in your environment. Before opening the KEIL project file you must generate related source files through BECKHOFF SSC Tool. - Page 33 If everything is fine, you should see Build Output window without errors after click “Rebuild” button. The output binary file “AX58200_MotorControl.bin” in the directory “YOUR_BSP_FOLDER\SampleCode\Ethercat_MotorControl_Reference_Design\Keil\Objects” Now you can download the firmware by click “LOAD” button. If the progress complete, the AX58200 will auto- restart. Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 34: Iar Ewarm Method

Then open the IAR project by double-click the project file “MotorControl.eww” in the directory “YOUR_BSP_FOLDER\SampleCode\Ethercat_MotorControl_Reference_Design\IAR”: You will see below screen and items: (1) BECKHOFF SSC files and related source files of AX58200 (2) Motor control stack code (3) Main program file of Motor Control Reference Design (4) Click on menu “Project/Rebuild All”... -

Page 35: Check Firmware Status By Debug Port

Make sure to take off the USB power cable and modify the “DIP of ICE” to below state: Figure 6 - 17 And let “Debug Port” to connect your host: Figure 6 - 18 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 36 AX58200 Motor Control User Guide The default setting of UART port of AX58200 as following: Baud rate: 115200 Data: 8 bit Reference Design User Guide Parity: none Stop: 1 bit Flow control: none Figure 6 - 19 Open the COM port. If no any characters appear in COM port, you can press “Reset” button to confirm again.

-

Page 37: Plc Application

PLC entry of TwinCAT project. Please refer to below steps: ⚫ Step 1: Right-click on “PLC” entry and select “Add Existing Item…” Figure 7 - 2 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 38 And you will see below screen, the demo application be inserted into PLC entry. Figure 7 - 3 ⚫ Step 3: Right-click on “SYSTEM -> Tasks” and select “Add New Item…” Figure 7 - 4 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 39 Step 4: Type “Plc Task” on “Name” field and click “OK”. Reference Design User Guide Figure 7 - 5 ⚫ Step 5: Click “AX58200_MotorControl Project -> Add -> Referenced Task…” Figure 7 - 6 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 40 Step 6: Select the “Plc Task” and click “Open”. Reference Design User Guide Figure 7 - 7 ⚫ Step 7: Right-click on “AX58200_MotorControl Project -> Plc_Task -> Add” and select “Existing Item…” Figure 7 - 8 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 41 Yellow color indicates the software variables are used for read PD (Process Data) input value from slave. Red color indicates the software variables are used for write PD (Process Data) output value to slave. Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 42: Pd Link

We illustrate procedure of PD link here. If you want to create a PD link, please follow below procedure: ⚫ Please follow steps below then press “OK” to complete PD link of “MAIN.arrECMaster_NetId” variable. Figure 7 - 12 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 43 Figure 7 - 13 ⚫ Next, you need to complete remaining PD link in the same way. Link “MAIN.nIOStatusWord” variable. Figure 7 - 14 Link “MAIN.nIOPositionValue” variable. Figure 7 - 15 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 44 AX58200 Motor Control User Guide Link “MAIN.fbStatusChange.nIOCtrlWD” variable. Reference Design User Guide Figure 7 - 16 Link “MAIN.nIOTargetVelocity” variable. Figure 7 - 17 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 45 Reference Design User Guide Figure 7 - 18 If you want to clear the link, just right click on the software or PD and select “Clear Link(s)”. Figure 7 - 19 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 46: Link Reference

Note: You MUST setup PD link so that TwinCAT master can let the slave enter OP mode. Figure 7 - 20 Please follow below steps for execute PLC application: ⚫ Step 1: Confirm the AX58200 in “OP” state Figure 7 - 21 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 47 Step 2: Click “Login” Reference Design User Guide Figure 7 - 22 ⚫ Step 3: Click “Yes” Figure 7 - 23 ⚫ Step 4: Click ”Start” icon Figure 7 - 24 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 48 Run lamp indicates CiA402 state in operation and motor is running. Error lamp indicates fault occurred and CiA402 state entered fault state. Highlight 11: Error status lamps indicates which error happen. Figure 7 - 26 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 49: Object Dictionary

RECORD Tx pdo mapping of csp/csv actual position actual velocity mode of operation display 0x1A01 PDO Mapping Mapped objects: RECORD Tx pdo mapping of csp status word actual position Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 50 INTEGER32 (Only CSV mode is 0x6502 Supported drive modes UNSIGNED32 supported in this FW verson) 0xF000 RECORD Modular device profile 0xF010 Module profile list UNSIGNED32 Table 8 - 3 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

-

Page 51: Performance Evaluation

8bytes input and 8bytes output, under this setting, the minimum DC cycle time can down to 200us. Figure 9 - 1 Without frame lost and Tx/Rx error at Master side. Figure 9 - 2 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved. - Page 52 AX58200 Motor Control User Guide Also, without detected SM-Event Missed, Cycle Time Too Small and Sync Error at Slave side. Reference Design User Guide Figure 9 - 3 Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

- Page 53 No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of ASIX. ASIX may make changes to the product specifications and descriptions in this document at any time, without notice.

- Page 54 AX58200 Motor Control User Guide Reference Design User Guide 4F, No.8, Hsin Ann Rd., Hsinchu Science Park, Hsinchu, Taiwan, R.O.C. TEL: +886-3-5799500 FAX: +886-3-5799558 Email: support@asix.com.tw Web: http://www.asix.com.tw Copyright (C) 2020 Reserved by ASIX Electronics Corporation, All Rights Reserved.

Need help?

Do you have a question about the AX58200 and is the answer not in the manual?

Questions and answers