Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for pronovost PGS-1020TRC

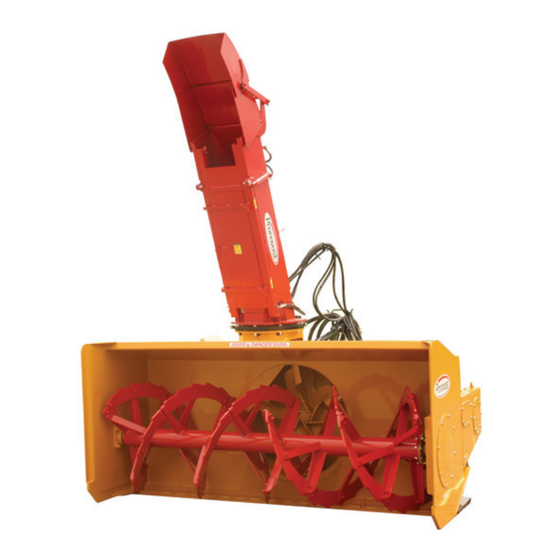

- Page 1 OPERATOR'S / PARTS MANUAL Snowblowers Model PGS-1020TRC No. C2806 12/2011...

- Page 2 Copyright © Les Machineries Pronovost Inc., 2011 All rights reserved. Printed in Canada.

-

Page 3: Table Of Contents

General maintenance ....................17 Storage ........................18 Trouble Shooting ...................... 19 Specifications......................20 Parts List ........................22 Snowblower PGS-1020TRC ................22 Semi-industrial Chute PSIG-92104 ..............25 Industrial Chute PCG-92104 ................27 Hydraulic telescopic chute PCT-92104 ............29 Hydraulic telescopic chute PCTC-INDR ............31 Options ...................... -

Page 5: Introduction

INTRODUCTION CONGRATULATIONS! Thank you for choosing PRONOVOST. We are NOW take a moment to enter the model, serial confident this equipment will meet your requirements number and the date of purchase of your Snowblower in terms of quality, performance and reliability. -

Page 6: Safety

SAFETY GENERAL SAFETY WHEN YOU SEE THIS SYMBOL 8) Prolonged exposure to noise may hamper hearing. Protect yourself by wearing adequate protection devices. 9) Hydraulic fluids under pressure can damage your skin. Do not use your hands to locate a leak. 10) Before the beginning of the snow season, inspect all areas where the Snowblower will be used and remove any object which may cause an accident and/or damage... -

Page 7: Safety With Maintenance

SAFETY (cont'd) 2) Stop engine and relieve all hydraulic pressures before 10) Before unplugging the chute, always disengage the doing inspection, maintenance or repairs. P.T.O., stop the engine and relieve all hydraulic pressu- res. 3) Never perform any work under the Snowblower while it is supported only by the tractor's hydraulic system. -

Page 8: Decals

DECALS SAFETY DECALS The safety decals are affixed wherever special safety precautions are indicated. Locate them on the machine and read them carefully. If a decal is damaged, lost or illegible, install a new one. The following photos indicate where each one must be installed. Figure 3 Figure 4 Decal B... - Page 9 DECALS (cont'd) Figure 6 Figure 7 Decal C Part no.: 190-11641 If your snowblower is equipped with a reduction gear box, the decal C will be the one shown below. Figure 8 Decal C Pièce no.: 190-11651 Decal E in Fig. 9 is located directly on the P.T.O. shaft.

- Page 10 DECALS (cont'd) Figure 13 Figure 10 Decal F Part no.: A 109 Figure 14 Decal G Part no.: 190-10991 Figure 11 Figure 12 Decal D Part no.: A103 Figure 15 - 10 -...

- Page 11 DECALS (cont'd) Figure 18 Decal J Part no.: 190-07611 Figure 16 Decal H Part no.: 190-06651 Figure 19 Figure 17 - 11 -...

-

Page 12: Maintenance Decals

DECALS (cont'd) MAINTENANCE DECALS The maintenance decals indicate the points requiring lubrication. Refer to maintenance section for more details. A 105 A 106 Figure 20 Figure 23 Decal L Part no.: 190-11581 Figure 21 Figure 24 Decal K Part no.: 190-11591 Figure 25 Figure 22 - 12 -... -

Page 13: Assembly

ASSEMBLY ASSEMBLY 1) The Snowblower is shipped partly assembled. 2) Install 3-point system according to the model of your Snowblower. (See section 10 for parts numbers). Use the holes most convenient to the type of tractor used (Fig. 26). 3) If your snowblower is equipped with the optional 1000 to 540 RPM reducer, install it on the gear box with the plate included (Fig. -

Page 14: Motor On The Rotary Drum

ASSEMBLY (cont'd) MOTOR ON THE ROTARY DRUM 1) Install the mounting plate tightening the bolts lightly. 2) Bolt hydraulic motor in place pointing the oil outlets to the exterior and install sprocket (Fig. 29). 3) Using the take-up screws, adjust gear to mesh without bottoming. -

Page 15: Hydraulic Chute Kit: Motor

ASSEMBLY (cont'd) HYDRAULIC CHUTE ROTATION Motor 1) Install U-shaped UHMW piece , place chute on Snowblower and secure with retaining bracket and bolts provided. 2) Install the mounting plate; put the required spacers between mounting plate and base of chute (see p. 26 to 31 for chute model). -

Page 16: Start-Up

STARTING-UP START-UP PROCEDURES 1) Check oil level in gearbox and in speed reducer if so equipped. Use SAE 80W90 gear box oil. 2) Check oil level in auger drive chain box. Fill to Use SAE 80W90 oil (Fig. 33). level plug. 3) Lubricate all points with a good quality Oil level ... -

Page 17: Maintenance

MAINTENANCE GENERAL MAINTENANCE 1) Wipe off all grease fittings with a clean cloth 11) Check all nuts and bolts once a year. If necessary before adding grease in order to avoid injecting use torque chart on page 47. dirt and sand. 12) Standard scraper blades are reversible. -

Page 18: Storage

STORAGE 1) Store the Snowblower in a cool, dry place. 5) Thoroughly inspect all parts of the Snowblower. Replace or repair worn or defective parts. 2) Support the Snowblower with wooden blocks. 6) Touch-up or repaint if necessary. 3) Keep all piston rods in the retracted position. This will assure better protection against the elements. -

Page 19: Troubleshooting

TROUBLESHOOTING P.T.O. SHAFT PROBLEM POSSIBLE CAUSE CORRECTION - Premature wear of U-joints and/ - Insufficient lubrication. - Follow lubrication or bluish color of cross journals. recommendations. - Replace defective U-joints. - Excessive working angle. - Make sure the Snowblower inlet face is perpendicular to the ground and if possible readjust 3-point hitch in order to position... - Page 20 TROUBLESHOOTING (cont'd) SNOWBLOWER PROBLEM POSSIBLE CAUSE CORRECTION - Raise P.T.O. speed to a minimum - The snow is not being thrown as - Tractor RPM too low. of 540 RPM. far as usual. - Adjust impeller blades closer to - Gap too wide between impeller drum outlet (1/8"...

-

Page 21: Specifications

SPECIFICATIONS Model PGS-1020TRC Horse power required 100 to 150 HP Approximate performance 950 tons imp./hour (tractor 150 HP) Height including telescopic chute PCT 119" retracted (approximately) in working position 149" extended (approximately) Height - chute base 50" Chute rotation On UHMW, for hydraulic motor Frame height 47 1/2"... -

Page 22: Parts List

SNOWBLOWER PGS-1020TRC 170-05343 - 22 -... - Page 23 SNOWBLOWER PGS-1020TRC (cont'd) REF. PART # DESCRIPTION 140-15152 Reversible scraper blade 1/2" x 4" x 93 3/4" lg ............319-38325 Plow bolt 7/16" NC x 1 1/2" lg + nut & lock washer ..........120-07472 Frame ........................323-36160 Hexagonal socket set screw 3/8" NC x 3/8" lg ............

- Page 24 SNOWBLOWER PGS-1020TRC (cont'd) REF. PART # DESCRIPTION 150-05961 Pin category 2 (top link) ................... 190-11541 Non skid tape ......................190-11551 Non skid tape ......................130-61323 Access panel for auger drive shaft ................110-39191 Threaded rod for idler adjustment ................9687 Compression spring ....................

-

Page 25: Semi-Industrial Chute Psig-92104

SEMI-INDUSTRIAL CHUTE PSIG-92104 170-03455 - 25 -... - Page 26 SEMI-INDUSTRIAL CHUTE PSIG-92104 REF. PART # DESCRIPTION 110-22555 Chute base ....................110-22934 Access panel ..................... 110-22232 Lower chute deflector ................Std. Goupille fendue 1/8" x 1" lg ................ 346-36000 Nylon locknut 3/8" NC ................140-13931 Connecting rod ..................110-22242 Upper chute deflector ................. 300-40400 Bolt 1/2"...

-

Page 27: Industrial Chute Pcg-92104

INDUSTRIAL CHUTE PCG-92104 170-03485 - 27 -... - Page 28 INDUSTRIAL CHUTE PCG-92104 REF. PART # DESCRIPTION 110-00681 Chute adaptor with quick attach ..............Std. Hitch pin clip 5/32" ..................9414 Pin for quick attach (adaptor & extension) ............. 4 PR-92104P-2 Extension 24" ................... opt. PR-92104P Extension 48" ................... opt. 110-22942 Access panel for extension 24"...

-

Page 29: Hydraulic Telescopic Chute Pct-92104

HYDRAULIC TELESCOPIC CHUTE PCT-92104 170-04071R4 - 29 -... - Page 30 HYDRAULIC TELESCOPIC CHUTE PCT-92104 REF. PART # DESCRIPTION 110-29112 Upper chute deflector ....................110-29121 Lower chute deflector ....................346-36000 Nylon locknut 3/8" ....................378-36500 Flat washer 3/8" i.d. x 1 1/2" o.d................Std. Grease fitting 1/4"-28 straight .................. 140-13931 Connecting rod .......................

-

Page 31: Hydraulic Telescopic Chute Pctc-Indr

HYDRAULIC TELESCOPIC CHUTE PCTC-INDR 170-05401 - 31 -... - Page 32 HYDRAULIC TELESCOPIC CHUTE PCTC-INDR (cont'd) REF. PART # DESCRIPTION 110-43233 Stationary deflector ....................110-43203 Intermediate deflector ....................346-36000 Nylon locknut 3/8" ....................378-36500 Flat washer 3/8" i.d. x 1 1/2" o.d................Std. Grease fitting 1/4"-28 straight .................. 130-84931 Lever for terminal deflector ..................376-43000 Flat washer 5/8"...

- Page 33 HYDRAULIC TELESCOPIC CHUTE PCTC-INDR (cont'd) REF. PART # DESCRIPTION Std. Retaining ring - external 1" ..................376-46310 Flat washer 3/4" d.i. x 1 1/2" d.e................110-45661 Threaded rod 5/8"-11 NC x 20 1/4" lg + nut 5/8" (welded) ......... 150-14921 Spacer 14 29/32"...

-

Page 34: Options

OPTIONS 170-05473 10 10 - 34 -... - Page 35 OPTIONS (cont'd) REF. PART # DESCRIPTION SIT1 140-21632 1/2" x 4" x 93 3/4" ..........Scraper blade (hardened steel, not sharpened, reversible) Std. Plow bolt 7/16" NC x 1 3/4" lg + nut & lockwasher ................. 10 Std. Plow bolt 7/16" NC x 1 3/4" lg + nut & lockwasher ................. 10 140-21642 1/2"...

- Page 36 OPTIONS (cont'd) REF. PART # DESCRIPTION PR3G200-2 130-76201 Mounting plate for speed reducer 1000 @ 555, with gears 200 HP ........... 9721 Speed reducer 1000 @ 555 with gears 200 HP ................9475-1 P.T.O. T90, QD 1 3/8"-21, SBI 1 3/4"-20 ................your choice 9475-2 P.T.O.

-

Page 37: Shaft T90 # 9475

P.T.O. SHAFT # 9475, 9475-1 & 9475-2 (T90) REF. PART # DESCRIPTION 9476 Safety shear yoke (2 bolts) 1 3/4" - 20 splines ..........9477 U-joint + 4 retaining rings + 1 grease fitting ..........9478 Retaining ring ..................... 8110 Grease fitting ..................... -

Page 38: Shaft V90 # 9598, 9599 & 9604

P.T.O. SHAFT # 9598, 9599 & 9604 (V90) REF. PART # DESCRIPTION 9481 Yoke with hole 1 3/8" - 6 splines with lock yoke (540 RPM) ......9482 Yoke with hole 1 3/8" - 21 splines with lock yoke (1000 RPM) ......9483 Yoke with hole 1 3/4"... -

Page 39: Gear Box # 9307

GEAR BOX # 9307 (T279) 170-05031.tif Oil volume required: 1.64 liters Use SAE 80W90 oil or equivalent. Oil filler plug Oil level plug Oil drain plug REF. PART # DESCRIPTION 6314 Oil seal 52 x 85 x 10 ....................30209-A Bearing: cone &... -

Page 40: Reduction Gear Box Prh-25M-2

SPEED REDUCER # 9792 PRH-25M-2 Oil volume required: 1.6 liters Use XLEP-68/220 oil or equivalent. REF. PART # DESCRIPTION 9793 Half casing ......................9794 Half casing ......................9795 Hollow cover ......................9796 Seal ........................9797 Protective guard ..................... 9798 Middle gear shaft 1 3/4"-20 splines 1.84:1 ..............9799 Shims ...................... -

Page 41: Reduction Gear Box Prh-30M-2

REDUCTION GEAR BOX # 9769 PRH-30M-2 Oil volume required: 1.2 liters Use XLEP-68/220 oil or equivalent. Oil level Drain plug REF. #PART DESCRIPTION 9770 Half casing ......................9771 Gear ........................9772 Splined adaptor 1 3/4" - 20 ..................9773 Input shaft with gear ....................9774 Gear ........................ -

Page 42: Reduction Gear Box Pr3G200-2 # 9721 200 Hp

SPEED REDUCER # 9721 - 200 HP PR3G-200-2 Oil volume required: 0.9 liters Use XLEP-68/220 oil or equivalent. Oil level REF. PART # DESCRIPTION 9752 Half casing ......................8753 Half casing ......................9754 Helical gear with the teeth inclined to the right (28 teeth) ..........9756 Adaptor ......................... -

Page 43: Cylinder 25Tr08

CYLINDER 25TR08 15050 REF. PART # DESCRIPTION 1 See #RK25TR O-ring 1/8" x 2¼" x 2½" ................2 See #RK25TR Back-up 2½" o.d. x 3/16 ø ................. 3 See #RK25TR O-ring 3/16" x 2 1/8" x 2½" ............... 4 See #RK25TR O-ring 1/16"... -

Page 44: Cylinder 15Pc32

CYLINDER 15PC32 170-04361 REF. PART # DESCRIPTION 150-06561 Head 1 1/2" dia................150-06571 Piston 1 1/2" dia................110-26561 Piston rod 1" dia................110-29631 Cylinder body 1 1/2" dia. (15PC32D) ..........110-29632 Cylinder body 1 1/2" dia. (15PC32G) ..........5 DRTU-18-1.00-31 «U»... -

Page 45: Cylinder 15Pl12

DEFLECTOR CYLINDER 15L12 170-05801 CLOSED REF. PART # DESCRIPTION 150-06561 Head 1 1/2" dia................... 150-06571 Piston 1 1/2" dia.................. 110-43122 Piston rod 1" dia.................. 110-43101 Cylinder body 1 1/2" dia............... 5 DRTU-18-1.00-31 «U» seal 3/16" x 1" x 1 3/8" ..............ST-100 Wiper 3/16"... -

Page 46: Hydraulic Motor Mlh-315

HYDRAULIC MOTOR # MLH-250 & MLH-315 CUSHION VALVE H110 MOTOR REF. PART # DESCRIPTION 8368 Set of seals ....................8369 Key for "Orbit" motor ................. - 46 -... -

Page 47: Torque Chart

TORQUE CHART TORQUE SPECIFICATION TABLE Thread UNC and UNF Grade 2 Grade 5 Grade 8* Bolt size Torque Torque Torque Pound feet Newton meters Pound feet Newton meters Pound feet Newton meters Inches min. max. min. max. min. max. min. max. -

Page 48: Warranty

WARRANTY PRONOVOST warrants this product to the initial All PRONOVOST spare parts purchased are covered purchaser for the period of one year from the date of by a three (3) month warranty. purchase against defects in materials and workmanship. This warranty becomes void and nul if the equipment... - Page 52 Ce manuel est aussi disponible en français. Veuillez téléphoner. LES MACHINERIES PRONOVOST INC. 260, Haut du Lac Sud (route 159), Saint-Tite, Quebec, Canada, G0X 3H0 Tel.: (418) 365-7551, Fax: (418) 365-7954 www.pronovost.qc.ca...

Need help?

Do you have a question about the PGS-1020TRC and is the answer not in the manual?

Questions and answers