Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Goulds Pumps 3498

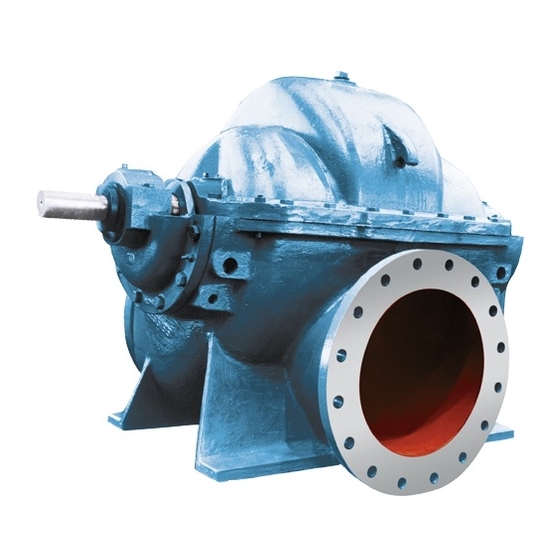

- Page 1 Installation, Operation, and Maintenance Manual Model 3498...

-

Page 3: Table Of Contents

4.6.3 Cartridge seals ..........................37 4.6.4 Controlled pressure system ......................37 4.6.5 Cyclone separator ......................... 38 4.7 Electrical requirements..........................38 5 Commissioning, Startup, Operation, and Shutdown ................... 39 5.1 Preparation for startup..........................39 Model 3498 Installation, Operation, and Maintenance Manual... - Page 4 8 Parts Listings and Cross-Sectionals ......................61 8.1 Parts List and Cross-Sectionals ......................61 9 Other Relevant Documentation or Manuals....................65 9.1 For additional documentation ........................65 10 Local ITT Contacts ............................66 10.1 Regional offices............................. 66 Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 5: Introduction And Safety

ITT. If there is any uncertainty regarding the appropriate use of the equipment, please contact an ITT representative before proceeding. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 6: Safety Terminology And Symbols

A practice not related to personal injury Hazard categories Hazard categories can either fall under hazard levels or let specific symbols replace the ordinary hazard level symbols. Electrical hazards are indicated by the following specific symbol: Model 3498 Installation, Operation, and Maintenance Manual... -

Page 7: Environmental Safety

Electrical installation For electrical installation recycling requirements, consult your local electric utility. 1.2.2.1 Recycling guidelines Always follow local laws and regulations regarding recycling. 1.2.3 User safety General safety rules These safety rules apply: Model 3498 Installation, Operation, and Maintenance Manual... - Page 8 Rinse the eyes with eyewash or running water for at least 15 minutes. Seek medical attention. Chemicals or hazardous fluids Remove contaminated clothing. on skin Wash the skin with soap and water for at least 1 minute. Seek medical attention, if necessary. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 9: Ex-Approved Products

The yield stress of fasteners must be in accordance with the approval drawing and the product specification. • Do not modify the equipment without approval from an authorized ITT representative. • Only use parts that are provided by an authorized ITT representative. Model 3498 Installation, Operation, and Maintenance Manual... - Page 10 • Rotate shaft by hand to ensure it rotates smoothly and there is no rubbing which could lead to excess heat generation, sparks and premature failure. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 11 The relevance of the ATEX re- quirements is not limited to Europe. You can apply these guidelines to equipment installed in any poten- tially explosive atmosphere. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 12: Monitoring Equipment

PumpSmart control system • Filter 1.3 Product warranty Coverage ITT undertakes to remedy faults in products from ITT under these conditions: • The faults are due to defects in design, materials, or workmanship. Model 3498 Installation, Operation, and Maintenance Manual... - Page 13 Material damages • Economic losses Warranty claim ITT products are high-quality products with expected reliable operation and long life. However, should the need arise for a warranty claim, then contact your ITT representative. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 14: Transportation And Storage

• Risk of serious personal injury or equipment damage. Proper lifting practices are critical to safe transport of heavy equipment. Ensure that practices used are in compliance with all applicable regulations and standards. Model 3498 Installation, Operation, and Maintenance Manual... - Page 15 Join the free ends of the slings together and place over the lifting hook. 45° max Figure 2: The proper lifting method for a horizontal pump on a base with lifting holes Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 16: Storage Guidelines

Figure 4: The proper lifting method for a vertical pump mounted on a half pedestal 30° max Nylon sling, chain, or wire rope Figure 5: The proper lifting method for a vertical pump mounted on a full pedestal 2.3 Storage guidelines Model 3498 Installation, Operation, and Maintenance Manual... -

Page 17: Pump Storage Requirements

Check the supplier’s technical data and the pump instruction book for this information. Seal all vents and apply a waterproof tape around the oil seals in the bearing frames. Prepare grease-lubricated bearing frames for storage: Model 3498 Installation, Operation, and Maintenance Manual... - Page 18 Cement the rubber diaphragm flange covers over the suction and discharge flanges. Protect these rubber diaphragm covers with hardboard material. Make sure all vents, drains, or plugs are tightly sealed. The pump is now ready to be placed in storage. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 19 When the oil used to protect the bearing frame is used to run the pump on startup, change this oil initially at half the recommended time for oil changes. Prepare the grease-lubricated bearing frame: Model 3498 Installation, Operation, and Maintenance Manual...

- Page 20 You can leave the corrosion inhibitor oil in the frame. • If the pump is started with the factory-supplied grease, then re-grease initially at half the rec- ommended grease interval. Remove the tape from the breather and seals. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 21: Product Description

At least six rings of die-formed, graphite, acrylic yarn packing • A split-type gland that permits removal and access to packing • Ample space for repacking the stuffing box • Arranged for field or factory conversion to mechanical seals without machine work Model 3498 Installation, Operation, and Maintenance Manual... - Page 22 Coupling guard The coupling guard is all metal. NOTICE: The coupling guard used in an ATEX classified environment must be properly certi- fied and constructed from a spark resistant material. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 23: Nameplate Information

The nameplate provides information about the ATEX specifica- tions of this pump. Nameplate on the pump casing Figure 6: Nameplate on the pump casing Nameplate field Explanation Size Size of the pump Type Type of pump Model 3498 Installation, Operation, and Maintenance Manual... - Page 24 Ensure the pump driver and all other auxiliary components meet the required area classifica- tion at the site. If they are not compatible, do not operate the equipment and contact an ITT representative before proceeding. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 25: Installation

When possible, locate the pump below the fluid lev- This facilitates priming, ensures a steady flow of liquid, and provides a positive suction head on the pump. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 26: Foundation Requirements

• Allow enough bolt length for grout, shims, lower baseplate flange, nuts, and washers. Bolt installation diagram 0.75–1.5 in. 8–12 in. 12–18 in. Baseplate Grout Alternate bolt and washer Concrete Bolt sleeve Model 3498 Installation, Operation, and Maintenance Manual... -

Page 27: Piping Checklists

Piping guidelines Guidelines for piping are given in the Hydraulic Institute Standards available from the Hydraulic Institute at 9 Sylvan Way, Parsippany, NJ 07054-3802. You must review this document before you install the pump. Model 3498 Installation, Operation, and Maintenance Manual... - Page 28 The sizing and installation of the suction piping is extremely important. It must be selected and installed so that pressure losses are minimized and sufficient liquid flows into the pump when it is started and op- erated. Many NPSH problems can be directly attributed to improper suction piping systems. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 29 Pump casing Impeller Pump suction flange Suction elbow Water velocity increases here and causes a greater flow to one side of the impeller. Figure 10: Unbalanced loading of double-suction impeller Model 3498 Installation, Operation, and Maintenance Manual...

- Page 30 Figure 12: Suction pipe installed with a gradual rise to the pump – incorrect Air pocket Figure 13: Suction pipe installed with a reducer – incorrect Air pocket Figure 14: Incorrect No air pockets Gradual rise Figure 15: Correct Model 3498 Installation, Operation, and Maintenance Manual...

- Page 31 Make sure this valve is of the flapper type, rather than the multiple spring type, and that it is sized to avoid excessive friction in the suction line. • Size the foot valve and pipe in order to maximize NPSH to the pump by minimizing suction line losses. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 32: Set The Baseplate

The studs must extend through the holes in the baseplate. Add or remove shims under the base in order to level and plumb the pump shaft and flanges. The baseplate does not need to be level. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 33: Grout The Baseplate

Approximately fourteen days after the grout has been poured and the grout has completely dried, apply an oil-based paint to the exposed edges of the grout in order to prevent air and moisture from coming in contact with the grout. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 34: Pump-To-Driver Alignment

This ensures that alignment can be accomplished. After you grout the baseplate This ensures that no changes have occurred during the grouting process. After you connect the piping This ensures that pipe strains have not altered the alignment. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 35: Align The Pump Using A Straight Edge

Figure 21: Incorrect parallel alignment Straight edge Feeler gauge Figure 22: Correct alignment 4.4.3 Align the pump using a dial indicator Before you begin, you must have a dial indicator with a mounting magnet and extension bars. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 36: Pump Doweling

Pump units can be doweled on diagonally opposite feet. Do not do this until the unit has run for a suffi- cient length of time and alignment is within the required alignment tolerance. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 37: Stuffing Box Lubrication Requirements

The temperature is above 0°C | 32°F and below 71°C | 160°F. • The suction pressure is below 5.27 kg/cm | 75 psig. • The pumped fluid has lubricating qualities. • The pumped fluid is non-toxic and non-volatile. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 38: Mechanical Seals

Volume sufficient to create a definite direction of flow from the stuffing box into the pump casing: 0.5–1.0 gpm (1.9–3.8 lpm). • Pressure high enough to keep the stuffing box free from foreign matter: 15–20 psig (1.0–1.4 kg/ ) above the suction pressure. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 39: Cartridge Seals

Excess pressure from an external source can be very destructive to packing. However, more pressure is required for abrasive slurries than for clear fluids. Examine the leakage in order to determine whether to increase or decrease external pressure. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 40: Cyclone Separator

Motor controls must conform to all the electrical data stamped on the motor data plate. Complete instruc- tions for installation, operation, and maintenance are included with the controlling device. External wiring Install wiring to the motor in conformance with the National Electrical Code and any local codes. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 41: Commissioning, Startup, Operation, And Shutdown

NOTICE: Sealing systems that are not self-purging or self-venting, such as plan 23, require manual venting prior to operation. Failure to do so will result in excess heat generation and seal failure. Model 3498 Installation, Operation, and Maintenance Manual... - Page 42 Check that the pump is full of liquid and that all valves are properly set and operational, with the discharge valve closed and the suction valve fully open. Purge all air from the top of the casing. • Check the direction of the rotation. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 43 Risk of premature failure. Casing deformation can result in misalignment and contact with rotating parts, causing excess heat generation and sparks. Flange loads from the piping system, including those from the thermal expansion of the piping, must not exceed the limits of the pump. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 44 You may need to sandblast the surfaces of a baseplate that come in contact with grout, and then coat those surfaces with a primer that is grout-compatible. Make sure to remove all equipment be- fore sandblasting. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 45: Pump Priming

Suction lift Priming must be done by other methods such as foot valves, ejec- tors, or by manually filling the casing and suction line. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 46: Fill The System

The check valve must open five seconds or less after startup in order to prevent damage to the pump by operating at zero flow. Adjust the liquid seal valves to produce the recommended pressure for either the mechanical seal or the packed stuffing box. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 47: Operational Checklist

Hydraulic Institute Standards. 5.6 Shut down the pump WARNING: Always disconnect and lock out power before servicing to prevent unexpected startup. Failure to do so could result in death or serious injury. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 48: Freeze Protection

Keep fluid moving in the pump and insulate or heat the pump to prevent freezing. NOTICE: If heat is used to prevent the pump from freezing, then the temperature should not rise above 66°C | 150°F. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 49: Maintenance

• Check the wear ring clearances. Replace the wear rings when clearances become three times their normal clearance or when you observe a significant decrease in discharge pressure for the same flow rate. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 50: Flood-Damaged Pumps

30 ml | 1 oz. of clean grease every 3–6 months. It is always best to stop the unit while grease is added in order to avoid overloading. Excess grease is the most common cause of overheating. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 51: Lubricate The Oil-Lubricated Bearings

Maintain an exact oil level. If the oil level is too high, the bearing temperature can increase. If the oil level is too low, the bearing will not be properly lubricated and could cause operational problems. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 52: Shaft-Seal Maintenance

This will burn the packing, score slightly loose without causing an air leak. As the shaft sleeve, and prevent circulation of the liquid that cools the the pump runs in, gradually tighten the gland packing. bolts evenly. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 53: Mechanical Seal Maintenance

Relapping is practical only for seals that are 5.1 cm | 2 in. or larger. For optimum seal life, always follow these precautions: • Keep the seal faces as clean as possible. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 54: Disassembly

Slide the gland plates (107) away in order to release the mechanical seal faces. Remove all casing main joint nuts and dowels. Use jacking screws in two tapped holes to break the joint. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 55: Remove The Rotating Element

To remove the impeller and the inboard sleeves, hold the shaft vertically and allow it to drop on a block of wood a few times. The weight of the impeller will force it and the shaft sleeves off the shaft. If this does not work, then apply a light press. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 56: Preassembly Inspections

Position the impeller according to dimension A, which you recorded when you disassembled the unit. Install the spacer sleeves, O-rings, stuffing-box sleeves, and shaft sleeve nuts. Install the mechanical seals on the shaft. Install the casing rings. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 57: Install The Bearings

Set the motor on its magnetic center. Insert a phenolic disc, or equivalent, between the pump shaft and the motor shaft. The phenolic disc must be of a specified thickness to accomplish the proper limited end float. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 58: Torque Table

0.7633 19235 1.125-8 0.7904 19918 1.25-7 0.9691 24421 1.25-8 1.000 25200 1.375-6 1.155 29106 1.375-8 1.234 31097 1.5-6 1.405 35406 1.5-8 1.492 37598 1.5-12 1.581 39841 1.625-8 1.775 44730 1.75-5 1.899 47855 1047 Model 3498 Installation, Operation, and Maintenance Manual... - Page 59 3.987 100472 2983 2.5-4 3.999 100775 3149 2.5-8 4.442 111938 3498 2.625-8 4.921 124009 4069 2.75-4 4.934 124337 4274 2.75-8 5.425 136710 4699 2.875-8 5.953 150016 5391 5.967 150368 5639 6.506 163951 6148 Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 60: Troubleshooting

The condition can be corrected with larger piping. The suction lift is too high. Check for obstructions at the inlet and make sure the suction valves are open. Check for pipe friction Model 3498 Installation, Operation, and Maintenance Manual... - Page 61 Make sure to not over- load the driver. The system head or discharge head is Check for pipe friction losses and that the valves too high. are wide open. The condition can be corrected with larger piping. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 62 The casing is distorted due to exces- Check the alignment. Examine the pump for rub- sive strains from the suction and dis- bing between the impeller and the casing. Replace charge piping. damaged parts and redo the piping. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 63: Parts Listings And Cross-Sectionals

8 Parts Listings and Cross-Sectionals 8 Parts Listings and Cross-Sectionals 8.1 Parts List and Cross-Sectionals Drawings - exploded view Model 3498 Installation, Operation, and Maintenance Manual... - Page 64 8.1 Parts List and Cross-Sectionals Model 3498 Installation, Operation, and Maintenance Manual...

- Page 65 Stud - gland Washer - gland Hex nut - gland stud Hex cap screw - housing (casing) Bearing lock washer Mechanical seal Key - coupling Key sleeve 412A O-ring - impeller 443U Slinger, thrust Model 3498 Installation, Operation, and Maintenance Manual...

- Page 66 Pin - case ring 467A Bushing - breather 467B Nipple - breather 467C Coupling - breather 496L O-ring - bearing end cap 496Q O-ring - Imp sleeve (SB sleeve) O-ring - sleeve nut Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 67: Other Relevant Documentation Or Manuals

9 Other Relevant Documentation or Manuals 9 Other Relevant Documentation or Manuals 9.1 For additional documentation For any other relevant documentation or manuals, contact your ITT representative. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 68: Local Itt Contacts

Camino La Colina # 1448 Condominio Industrial El Rosal Huechuraba Santiago 8580000 Chile Middle East and Africa ITT - Goulds Pumps +30 210-677-0770 +30 210-677-5642 Achileos Kyrou 4 Neo Psychiko 115 25 Athens Greece Model 3498 Installation, Operation, and Maintenance Manual... - Page 69 Visit our website for the latest version of this document and more information: http://www.gouldspumps.com ITT Goulds Pumps, Inc. 240 Fall Street Seneca Falls, NY 13148 Form IOM.3498Goulds.en-US.2021-04 ©2021 ITT Inc. The original instruction is in English. All non-English instructions are translations of the original instruction.

Need help?

Do you have a question about the 3498 and is the answer not in the manual?

Questions and answers