Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Goulds Pumps 3498

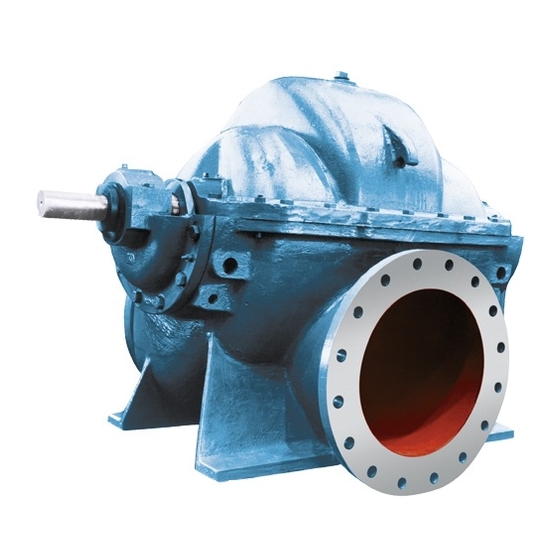

- Page 1 Installation, Operation, and Maintenance Manual Model 3498...

-

Page 3: Table Of Contents

Start the pump ........................ 36 Operational checklist ....................... 37 Shut down the pump ....................... 37 Freeze protection ......................38 Maintenance ........................39 Maintenance schedule ....................39 Flood-damaged pumps ....................40 Bearing maintenance ...................... 40 Model 3498 Installation, Operation, and Maintenance Manual... - Page 4 Troubleshooting ......................48 Troubleshooting ......................48 Parts Listings and Cross-Sectionals ................51 Parts List and Cross-Sectionals ..................51 Other Relevant Documentation or Manuals ..............54 Local ITT Contacts ......................55 Regional offices ......................55 Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 5: Introduction And Safety

ITT representative. Always specify the exact product type and identification code when requesting technical information or spare parts. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 6: Safety

Hazard level Indication A hazardous situation which, if not avoided, will result in death or serious injury DANGER: A hazardous situation which, if not avoided, WARNING: could result in death or serious injury Model 3498 Installation, Operation, and Maintenance Manual... -

Page 7: Environmental Safety

NOT send the product to ITT unless it has been properly decontaminated. Electrical installation For electrical installation recycling requirements, consult your local electric utility. Recycling guidelines Always follow local laws and regulations regarding recycling. User safety General safety rules These safety rules apply: Model 3498 Installation, Operation, and Maintenance Manual... -

Page 8: Ex-Approved Products

3. Seek medical attention, if necessary. Ex-approved products Follow these special handling instructions if you have an Ex-approved unit. Personnel requirements These are the personnel requirements for Ex-approved products in potentially explosive atmospheres: Model 3498 Installation, Operation, and Maintenance Manual... -

Page 9: Monitoring Equipment

• Level indicators • Motor load readings • Temperature detectors • Bearing monitors • Leak detectors • PumpSmart control system Product warranty Coverage ITT undertakes to remedy faults in products from ITT under these conditions: Model 3498 Installation, Operation, and Maintenance Manual... - Page 10 • Material damages • Economic losses Warranty claim ITT products are high-quality products with expected reliable operation and long life. However, should the need arise for a warranty claim, then contact your ITT representative. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 11: Transportation And Storage

The unit must be unloaded and handled by lifting equally at four or more points on the baseplate. The lugs on the upper half casing are designed for lifting the upper half of the casing only. Model 3498 Installation, Operation, and Maintenance Manual... - Page 12 Place a nylon sling chain or wire rope around both flanges. Use a latch hook or standard shackle and end loops. Be sure the lifting equipment is long enough to keep the lift angle less than 30° from the vertical. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 13: Storage Guidelines

These guidelines apply to horizontal and vertical pumps for storage of one month or less. If the equipment will not be installed and operated soon after arrival, then provide these conditions for storage: Model 3498 Installation, Operation, and Maintenance Manual... - Page 14 A seal box made of stainless material does not require this procedure. a) For a double-face seal, open uppermost flushing tap on the stuffing box and fill the cavity with a lightweight (#10-#20) rust preventative oil such as Mobilarma 500. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 15 • Tightly close the suction and discharge valves and remove all fluid from the pump and attached piping. • The interior of the pump and the piping must be thoroughly dried. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 16 • You can leave the corrosion inhibitor oil in the frame. • If the pump is started with the factory-supplied grease, then re-grease initially at half the recommended grease interval. 8. Remove the tape from the breather and seals. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 17: Product Description

• Arranged for field or factory conversion to mechanical seals without machine work Casing rings The casing rings have these characteristics: • Made of bronze, cast iron, or 316 stainless steel • Installed with an anti-rotation device Model 3498 Installation, Operation, and Maintenance Manual... - Page 18 The coupling guard used in an ATEX classified environment must be properly certified and constructed from a spark resistant material. Rotation The pump has a clockwise or counterclockwise rotation when viewed from the driver end. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 19: Nameplate Information

Identification No. A number which the end user of the pump requests to be put on the nameplate to identify the pump in his operation Year Year in which the pump was built Model 3498 Installation, Operation, and Maintenance Manual... - Page 20 Ensure that the code classifications on the pump are compatible with the specific environment in which the equipment is to be installed. If they are not compatible, do not operate the equipment and contact an ITT representative before proceeding. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 21: Installation

The installation must be evaluated to determine that the Net Positive Suction Head Available (NPSH ) meets or exceeds the Net Positive Suction Head Required (NPSH ), as stated by the pump performance curve. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 22: Foundation Requirements

• Allow enough bolt length for grout, shims, lower baseplate flange, nuts, and washers. Bolt installation diagram 1. Baseplate 2. Grout 3. Alternate bolt and washer 4. Concrete 5. Bolt sleeve Figure 8: Bolt installation Model 3498 Installation, Operation, and Maintenance Manual... -

Page 23: Piping Checklists

Make sure that all piping compo- — nents, valves and fittings, and pump branches are clean prior to assembly. Model 3498 Installation, Operation, and Maintenance Manual... - Page 24 Risk of excessive axial load or cavitation. Do not install an elbow directly before the suction of a double suction pump if the plane of the suction is parallel to the pump shaft. Alternatively, install an elbow with straightening vanes to help evenly distribute the flow. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 25 Figure 10: Suction pipe installed with a gradual rise to the pump – correct 1. Air pocket Figure 11: Suction pipe installed with a gradual rise to the pump – incorrect 1. Air pocket Figure 12: Suction pipe installed with a reducer – incorrect Model 3498 Installation, Operation, and Maintenance Manual...

- Page 26 • Make sure that the suction piping valves are placed right before the run of recommended straight pipe. • Never throttle the pump with the use of a valve on the suction side of the pump. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 27: Set The Baseplate

The pump and motor have been mounted and rough aligned at the factory. If the motor will be field mounted, consult the factory for recommendations. ITT cannot assume responsibility for final alignment. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 28: Grout The Baseplate

If necessary, temporarily use air relief tubing or drill vent holes in order to remove trapped air. 4. After the grout has completely hardened, tighten the foundation bolts. It will take approximately 24 hours for the grout to harden. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 29: Pump-To-Driver Alignment

This ensures that alignment can be accomplished. After you grout the baseplate This ensures that no changes have occurred during the grouting process. After you connect the piping This ensures that pipe strains have not altered the alignment. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 30: Align The Pump Using A Straight Edge

1. Fasten the indicator stand or magnetic base to the pump half of the coupling. 2. Adjust the assembly until the indicator button is resting on the periphery of the other coupling half. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 31: Pump Doweling

Stuffing box lubrication requirements The stuffing box must be supplied at all times with a source of clean, clear liquid in order to flush and lubricate the packing or seal. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 32: Packing

• Volume sufficient to create a definite direction of flow from the stuffing box into the pump casing: 1.9–3.8 lpm | 0.5–1.0 gpm. • Pressure high enough to keep the stuffing box free from foreign matter: 1.0–1.4 kg/cm | 15–20 psig above the suction pressure. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 33: Mechanical Seals

Pressure is based on the location of the pump with respect to the liquid source. A small pipe can be used for the connection to the stuffing box. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 34: Cyclone Separator

Check with an accurate temperature-measuring device to be sure. A motor operating outside its service factor will overheat and could possibly burn out. Motors are usually rated with normal temperature requirements stamped on the data plate. Model 3498 Installation, Operation, and Maintenance Manual... - Page 35 Motor controls must conform to all the electrical data stamped on the motor data plate. Complete instructions for installation, operation, and maintenance are included with the controlling device. External wiring Install wiring to the motor in conformance with the National Electrical Code and any local codes. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 36: Commissioning, Startup, Operation, And Shutdown

Initial grease lubrication CAUTION: Risk of explosive hazard and premature failure from sparks and heat generation. Ensure bearings are properly lubricated prior to startup. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 37: Pump Priming

This condition provides a positive suction head on the pump. It is also possible to prime the pump by pressurizing the suction vessel. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 38: Fill The System

The check valve must open five seconds or less after startup in order to prevent damage to the pump by operating at zero flow. 7. Adjust the liquid seal valves to produce the recommended pressure for either the mechanical seal or the packed stuffing box. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 39: Operational Checklist

Precautions must be taken to prevent physical injury. The pump may handle hazardous and/or toxic fluids. Proper personal protective equipment should be worn. Pumpage must be handled and disposed of in conformance with applicable environmental regulations. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 40: Freeze Protection

• Keep fluid moving in the pump and insulate or heat the pump to prevent freezing. NOTICE: If heat is used to prevent the pump from freezing, then the temperature should not rise above 66°C | 150°F. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 41: Maintenance

Record the figures and compare them with the figures of the last test. This is especially important where the pumped liquid tends to form a deposit on internal surfaces. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 42: Flood-Damaged Pumps

82°C | 180°F, then shut down the pump and determine the cause. Grease-lubricated bearings must not be used where the temperature of the pumped fluid exceeds 177°C | 350°F. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 43: Lubricate The Oil-Lubricated Bearings

Oil change periods can be increased up to 2,000–4,000 hours based on an 8,000-hour year. Check the oil frequently for moisture, dirt, or signs of breakdown. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 44: Shaft-Seal Maintenance

• Mechanical seals are precision products that must be treated with care. Use special care when handling seals. Make sure that oil and parts are clean in order to prevent Model 3498 Installation, Operation, and Maintenance Manual... -

Page 45: Disassembly

4. Slide the gland plates (107) away in order to release the mechanical seal faces. 5. Remove all casing main joint nuts and dowels. 6. Use jacking screws in two tapped holes to break the joint. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 46: Remove The Rotating Element

The weight of the impeller will force it and the shaft sleeves off the shaft. If this does not work, then apply a light press. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 47: Preassembly Inspections

4. Install the mechanical seals on the shaft. 5. Install the casing rings. 1. Casing ring 2. Impeller ring 3. Spacer sleeve Install the bearings 1. Install the bearing seals (333A and 332A) and bearing endplates onto the shaft. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 48: Install The Rotating Element

4. Push the pump and motor shafts against the phenolic disc. The thrust bearing of the pump limits the end float toward the pump. The coupling covers limit the end float toward the motor. Model 3498 Installation, Operation, and Maintenance Manual... - Page 49 The thrust bearing is large enough to carry any magnetic thrust that is developed by the motor, if the pump and motor are aligned properly. When this procedure is completed, follow the procedures in Pump-to-driver alignment (page 27). Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 50: Troubleshooting

Do not overload the driver. The system head or discharge head is Check for pipe friction losses and that the valves are too high. wide open. The condition can be corrected with larger piping. Model 3498 Installation, Operation, and Maintenance Manual... - Page 51 The pump and driver are not aligned Realign the pump and driver. properly. The bearings are worn out or improperly Inspect the bearings and replace them if necessary. lubricated. Model 3498 Installation, Operation, and Maintenance Manual...

- Page 52 The casing is distorted due to excessive Check the alignment. Examine the pump for rubbing strains from the suction and discharge between the impeller and the casing. Replace dam- piping. aged parts and redo the piping. Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 53: Parts Listings And Cross-Sectionals

Parts Listings and Cross-Sectionals Parts Listings and Cross-Sectionals Parts List and Cross-Sectionals Drawings - exploded view Model 3498 Installation, Operation, and Maintenance Manual... - Page 54 Parts Listings and Cross-Sectionals Parts List Item Name Qty. Casing Impeller Lantern Ring 105A Packing base ring Stuffing box packing 1 set Packing gland 109A Bearing end cover 112A Ball bearing - thrust 113A Breather Model 3498 Installation, Operation, and Maintenance Manual...

- Page 55 Pin - case ring 467A Bushing - breather 467B Nipple - breather 467C Coupling - breather 496L O-ring - bearing end cap 496Q O-ring - Imp sleeve (SB sleeve) O-ring - sleeve nut Model 3498 Installation, Operation, and Maintenance Manual...

-

Page 56: Other Relevant Documentation Or Manuals

Other Relevant Documentation or Manuals Other Relevant Documentation or Manuals For additional documentation For any other relevant documentation or manuals, contact your ITT representative. Model 3498 Installation, Operation, and Maintenance Manual... -

Page 57: Local Itt Contacts

Camino La Colina # 1448 Condominio Industrial El Rosal Huechuraba Santiago 8580000 Chile Middle East and Africa ITT - Goulds Pumps +30 210-677-0770 +30 210-677-5642 Achileos Kyrou 4 Neo Psychiko 115 25 Athens Greece Model 3498 Installation, Operation, and Maintenance Manual... - Page 58 Visit our website for the latest version of this document and more information: http://www.gouldspumps.com ITT - Goulds Pumps 240 Fall Street Seneca Falls, NY 13148 Form IOM.3498Goulds.en-US.2017-05 © 2017 ITT Corporation The original instruction is in English. All non-English instructions are...

Need help?

Do you have a question about the 3498 and is the answer not in the manual?

Questions and answers