Table of Contents

Advertisement

Quick Links

Operation - Maintenance

Dispensit

1052

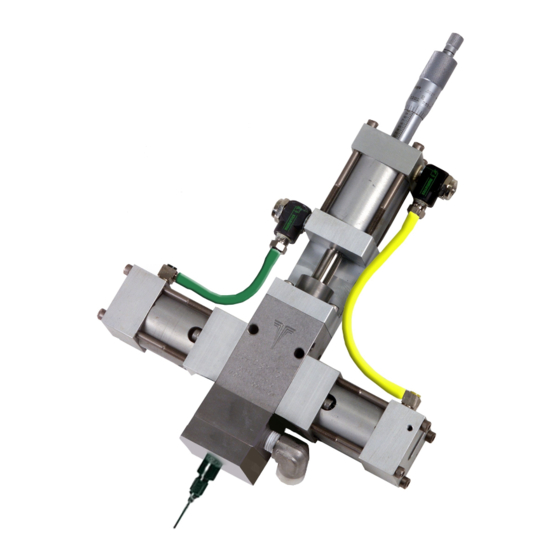

Patented meter and dispense system for precise one-component micro-dispensing. Not for

use in explosive atmospheres.

2000 psi (14 MPa, 138 bar) Maximum Outlet Fluid Working Pressure

Metal Sleeves: 1200 psi (8 MPa, 83 bar) Maximum Material Inlet Pressure

Plastic Sleeves: 400 psi (2.8 MPa, 28 bar) Maximum Material Inlet Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure

110°F (43°C) Maximum Ambient Temperature

150°F (65°C) Maximum Operating Temperature

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Cycle Detection and Luer Lock Outlet Shown

3A0231E

EN

Advertisement

Table of Contents

Summary of Contents for Graco Dispensit 1052

- Page 1 Operation - Maintenance Dispensit 1052 3A0231E Patented meter and dispense system for precise one-component micro-dispensing. Not for use in explosive atmospheres. 2000 psi (14 MPa, 138 bar) Maximum Outlet Fluid Working Pressure Metal Sleeves: 1200 psi (8 MPa, 83 bar) Maximum Material Inlet Pressure Plastic Sleeves: 400 psi (2.8 MPa, 28 bar) Maximum Material Inlet Pressure 100 psi (0.7 MPa, 7 bar) Maximum Air Working Pressure 110°F (43°C) Maximum Ambient Temperature...

-

Page 2: Table Of Contents

Graco Ohio Standard Warranty ....22 Graco Ohio Information ....22... -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama- tion point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable. - Page 4 Warnings WARNING ELECTRIC SHOCK HAZARD This equipment must be grounded. Improper grounding, setup, or usage of the system can cause elec- tric shock. • Turn off and disconnect power cord before servicing equipment. • Use only grounded electrical outlets. • Use only 3-wire extension cords.

-

Page 5: Isocyanate Conditions

Isocyanate Conditions Isocyanate Conditions • Keep the ISO lube pump reservoir (if installed) filled with Graco Throat Seal Liquid (TSL), Part 206995. The lubricant creates a barrier between the ISO and the atmosphere. Spraying or dispensing materials containing isocya- •... -

Page 6: Grounding

Grounding Grounding Optional Cycle Detection Spool Sensors The spool sensors are magnetic reed switches and must be connected to an electrical control. An LED on the switch illuminates to indicate the shifting of the spool. This product must be grounded. In the event of an elec- trical short circuit, grounding reduces the risk of electric shock by providing an escape wire for the electric cur- rent. -

Page 7: Component Identification

Component Identification Component Identification Typical System Configurations START HAND AUTO SW-2 PB-1 TR-1 SYSTEM AUXILIARY DISPENSE PRESSURE PRESSURE TIMER POWER REG-1 REG-2 SW-1/PL-1 Valve Liquid Control Top View of Controls Controls System shown with optional 4104A controls 3A0231E... -

Page 8: Typical Feed System Components

Component Identification Typical Feed System Components 5 Gallon Pail Cover 5 Gallon Pail Cover with Diaphragm with Diaphragm Pump Pump and Agitator 20 oz Cartridge Feed with Mounting Post 1 Gallon Ram and Pump WARNING DO NOT SERVICE WITHOUT REMOVING AIR PRESSURE AND WEARING SAFETY GLASSES. -

Page 9: Typical Feed System Components (Continued)

Component Identification Typical Feed System Components (continued) 5 Gallon Tank with Diaphragm Pump and Stand 5 Gallon Tank with 5:1 Pump and Stand 10 Gallon Tank with Diaphragm Pump, Agitator, 10 Gallon Tank with 5:1 Pump, Agitator, Vacuum, Vacuum, and Stand and Stand 3A0231E... -

Page 10: Metering Valve

Component Identification Metering Valve Key: Material Inlet Reload Air Inlet Grounding Lug Extend Air Flow Adjustment Spool Knob Metering Rod Retract Air Flow Adjustment Oil Cup Retaining Block Knob Extend Air Inlet Shot Size Locking Ring Retract Air Inlet Shot Size Adjuster Dispense Air Inlet Needle 3A0231E... -

Page 11: Setup

Setup Setup NOTE: See Typical Installation diagram. 3. Connect each 1/4 in. outside diameter supplied air line to the corresponding control solenoid. See 1. Perform Setup procedure for feed system compo- Component Identification starting on page 7. nents. See feed system manual(s). 4. -

Page 12: Valve Mounting Diagram

Setup Valve Mounting Diagram As desired, use the following diagram to mount the metering valve. 1.250 .937 .625 .377 .313 Ø.312 C-BORE FOR 95/0503/00 O-RING (2) PLACES 1.250 1.062 OUT IN .625 Ø.126/.128 X .25 DP .188 FOR 1/8 DOWEL PINS (2) PLACES 8-32 X .38 DP - OPTIONAL... -

Page 13: Startup

Startup Startup 1. Lubricate the metering rod port in the oil cup retain- ing block and fill the spool valve ports with compati- ble lubricant such as mesamoll or silicone oil. Metering Rod Port Spool Valve Ports . 7: Top View of Metering Valve with Top Section Removed 2. -

Page 14: Adjusting The Shot Size

Adjusting the Shot Size Adjusting the Shot Size 1. Rotate the shot size locking ring counterclockwise to loosen. 2. Rotate the shot size adjuster to adjust shot size. 3. Rotate the shot size locking ring clockwise to tighten. 4. Dispense into waste container to test shot size. 5. -

Page 15: Operation

Operation Operation Step 2: Shift The operation of the 1052 metering valve is controlled by an external source. If a 4104A Control Box was pur- chased, see the 4104A Control Box manual for opera- tion instructions. Sequence of Operation Step 1: Reload •... -

Page 16: Pressure Relief Procedure

4. Dispense 5 shots. Shots should be at least 75% of the full stroke. Air Dryer 5. Extend the metering rod into the tubes. If Graco Check the condition of the desiccant air dryer. Replace controls are provided with the system, see the as necessary. -

Page 17: Troubleshooting

Troubleshooting Troubleshooting Perform Pressure Relief Procedure before perform- ing any troubleshooting procedure. Problem Cause Solution Metering valve stalling and no mate- Blocked needle Check needle for cured material, rial being dispensed despite ade- replace as required quate input pressure Flow control valve closed Open needle Metering valve not discharging nor- Low material level in reservoirs... -

Page 18: Rebuild

Rebuild Rebuild Cutaway Front View SCREW,CAP,#6-32 x 3 DRIVE cylinder end cap assembly DISPENSE piston u-cup seal O-Ring RETAINING ring WASHER u-cup seal FLOW control DIVORCED section METERING rod SEAL cup posipak SEAL dispense sleeve O-Ring SCREW,shc,#6-32 x 5/8 Tee Fitting SCREW,CAP,#6-32 x 2 END cap screw,rhm,#6-32 x 1... -

Page 19: Assembly

Rebuild 8. Remove the Screws (36), that hold the Needle Block 23. Remove the Screws (20) that hold the Seal Plate Assembly (29) to the Inlet Block (34). The Needle Cups (26) to each side of the Main Body (27). The Block Assembly (29) may look different than the Seal Retainer Washers (22), and the Posipak Seals illustration as it may have multiple needles. - Page 20 Rebuild Build the Divorced Section and Mount to the Main 16. Install two lubricated U-cup Seals (4) onto the Dis- Body pense Piston (3) with the upper seal lip up and the lower seal lip down as shown. 5. Place lubricated U-cup Seal (8) lip side up into the Divorced Section (10).

-

Page 21: Technical Data

Wetted Parts........Metering Valve: Hardened steel, 303/304, 404, UHM- WPE, Tungsten, carbide, fluoroelastomer, EPDM, PTFE, Acetal Graco-supplied Feed System Hoses and Fittings: Mild steel, 303/304, PTFE, buna, polyethylene, polypropyl- Graco-supplied Tanks: Polyethylene, 303/304, mild steel... -

Page 22: Graco Ohio Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the Dispensit 1052 and is the answer not in the manual?

Questions and answers