Vega VEGABAR 81 Operating Instructions Manual

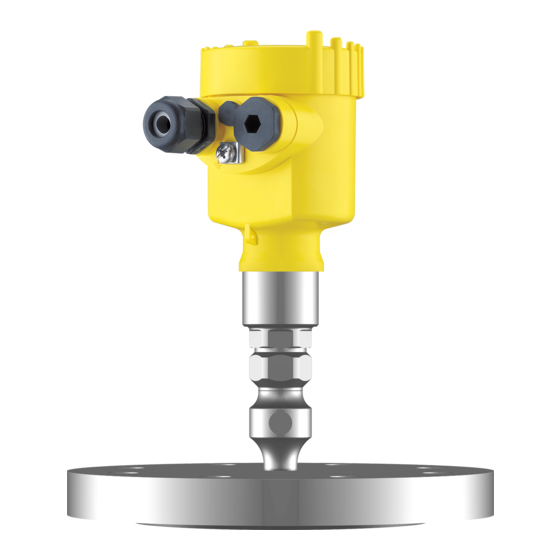

Slave sensor for electronic differential pressure, pressure transmitter with metallic measuring cell

Hide thumbs

Also See for VEGABAR 81:

- Operating instructions manual (96 pages) ,

- Quick setup manual (20 pages) ,

- Product information (16 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Vega VEGABAR 81

- Page 1 Operating Instructions Pressure transmitter with metallic measuring cell VEGABAR 81 Slave sensor for electronic differential pres- sure Document ID: 45049...

-

Page 2: Table Of Contents

Exchanging the electronics module ................42 Exchange process module on version IP68 (25 bar) ............43 How to proceed if a repair is necessary ................44 Dismount..........................45 Dismounting steps......................45 VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 3 Take note of the Ex specific safety instructions for Ex applications. These instructions are attached as documents to each instrument with Ex approval and are part of the operating instructions. Editing status: 2020-05-12 VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 4: About This Document

Symbols used Document ID This symbol on the front page of this instruction refers to the Docu- ment ID. By entering the Document ID on www.vega.com you will reach the document download. Information, note, tip: This symbol indicates helpful additional infor- mation and tips for successful work. -

Page 5: For Your Safety

During work on and with the device, the required personal protective equipment must always be worn. Appropriate use VEGABAR 81 is a slave sensor for electronic differential pressure measurement. You can find detailed information about the area of application in chapter "Product description". -

Page 6: Installation And Operation In The Usa And Canada

Please help us fulfil this obligation by observing the environmental instructions in this manual: • Chapter "Packaging, transport and storage" • Chapter "Disposal" Exception: Versions with measuring ranges from 250 bar. These are subject of the EU Pressure Device Directive. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 7: Product Description

Fig. 1: Layout of the type label (example) Product code Field for approvals Technical data Serial number of the instrument QR code Symbol of the device protection class ID numbers, instrument documentation VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 8: Principle Of Operation

Scan the DataMatrix code on the type label of the instrument or • Enter the serial number manually in the app Principle of operation Application area VEGABAR 81 is suitable for applications in virtually all industries. It is used for the measurement of the following pressure types. • Gauge pressure •... - Page 9 Relative pressure: the measuring cell is open to the atmosphere. Pressure types The ambient pressure is detected in the measuring cell and compen- sated. It thus has no influence on the measured value. VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 10: Supplementary Cleaning Procedures

Caution: The VEGABAR 81 in this version may not be used in oxygen ap- plications. For this purpose, instruments are available in the special version "Oil, grease and silicone-free for oxygen applications". -

Page 11: Accessories

Welded sockets and Welded sockets are used to connect the sensors to the process. adapters Threaded adapters enable simple adaptation of sensors with stand- ard threaded fittings, e.g. to process-side hygiene connections. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 12: Mounting

Devices with threaded fitting are screwed into the process fitting with Screwing in a suitable wrench via the hexagon. See chapter "Dimensions" for wrench size. VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 13 Make sure that the upper temperature limits stated in chapter "Technical data" for the environment of the electronics hous- ing and connection cable are not exceeded. Fig. 3: Temperature ranges Process temperature Ambient temperature VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 14: Instructions For Oxygen Applications

Do not use a high-pressure cleaner. The filter element could be dam- aged, which would allow moisture into the housing. The following paragraphs describe how the filter element is arranged in the different instrument versions. VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 15 The process assembly of instruments with Second Line of Defense Instruments with Second Line of Defense (gastight leadthrough) is completely encapsulated. An absolute pres- sure measuring cell is used so that no ventilation is required. VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 16: Combination Master - Slave

Measurement result = Measured value of Master (total pres- sure) - measured value of Slave (static pressure) Depending on the application, individual combinations can result, see following examples: Example - large vessel Data Application: Level measurement Medium: Water VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 17: Level Measurement

Keep the following in mind when setting up the measuring system: • Mount the master sensor below the min. level • Do not mount the master sensor close to the filling stream or emptying area VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 18: 4.6 Differential Pressure Measurement

Take note of the following instructions for the measurement setup, for example in gases: • Mount the instruments above the measuring point Possible condensation can then drain off into the process line. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 19: Interface Measurement

The mounting distance h of the two sensors should be at least 10 %, better 20 %, of the final value of the sensor measuring range. A bigger distance increases the accuracy of the interface measurement. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 20: Density Measurement

The master/slave combination is suitable for density measurement. Requirements for a functioning measurement are: • Vessel with changing level • Distance between the measurement points as large as possible • Level always above the upper measuring point VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 21: Density-Compensated Level Measurement

Mount the master sensor below the min. level • Mount the slave sensor above the master sensor • Mount both sensors away from the filling stream and emptying and protected against pressure shocks from the stirrer VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 22 The density-compensated level measurement is only possible in open, i.e. unpressurized vessels. VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 23: 4.10 External Housing

4 Mounting 4.10 External housing Configuration Fig. 13: Configuration, process module, external housing Pipeline Process module Connection cable process assembly - External housing External housing Signal cable VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 24: Connecting To Power Supply

For this, use the supplied, confectioned cable. Solid cores as well as flexible cores with cable end sleeves are inserted directly into the terminal openings. VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 25 9. Unscrew the blind plug on the Master, screw in the supplied cable gland 10. Connection cable to Master, see steps 3 to 8 11. Screw the housing lid back on VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 26: Single Chamber Housing

To the Master sensor Ground terminal for connection of the cable screening External housing with version IP68 (25 bar) Overview Fig. 16: VEGABAR 81 in IP68 version 25 bar with axial cable outlet, external housing Transmitter Connection cable External housing Connect shielding here. - Page 27 Cable gland for connection cable, transmitter Terminal compartment, housing socket 1 2 3 4 Fig. 18: Connection of the process component in the housing base Yellow White Black Shielding Breather capillaries VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 28: Connection Example

Terminal 7 Terminal 7 Terminal 8 Terminal 8 Connect shielding here. Connect ground terminal on the outside of the hous- ing to ground as prescribed. The two terminals are galvanically connected. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 29: Set Up With The Display And Adjustment Module

6.1.1 Setup Application In this menu item you activate/deactivate the slave sensor for elec- tronic differential pressure and select the application. VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 30 6 Set up with the display and adjustment module The VEGABAR 81 in conjunction with a slave sensor can be used for flow, differential pressure, density and interface measurement. The default setting is differential pressure measurement. Switchover is carried out in the adjustment menu.

- Page 31 The position correction can be repeated any number of times. Adjustment VEGABAR 81 always measures pressure independently of the pro- cess variable selected in the menu item "Application". To output the selected process variable correctly, an allocation of the output signal to 0 % and 100 % must be carried out (adjustment).

- Page 32 Now select with [->] the menu item "Adjustment", then "Min. adjustment" and confirm with [OK]. 2. Edit the percentage value with [OK] and set the cursor to the requested position with [->]. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 33 The maximum negative pressure must then be entered for the min. adjustment. For linearization, select "bidirectional" or "bidirectional-extracted by root" accordingly, see menu item "Liner- arization". The min. adjustment is finished. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 34 1. Select with [->] the menu item Span adjustment and confirm with [OK]. 2. Edit the mbar value with [OK] and set the cursor to the requested position with [->]. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 35 2. Edit the percentage value with [OK] and set the cursor to the requested position with [->]. 3. Set the requested percentage value with [+] and save with [OK]. The cursor jumps now to the density value. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 36 2. Edit the percentage value with [OK] and set the cursor to the requested position with [->]. 3. Set the requested percentage value with [+] and save with [OK]. The cursor jumps now to the height value. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 37 2. Edit the percentage value with [OK] and set the cursor to the requested position with [->]. 3. Set the requested percentage value (e.g. 100 %) with [+] and save with [OK]. The cursor jumps now to the pressure value. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 38 As input signals, the output values of Transducer Block (TB) can be selected. The device assumes an approximately constant temperature and static pressure and calculates the flow rate from the measured differential pressure using the characteristic curve extracted by root. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 39 In menu item "Peak value, pressure", both values are displayed. In another window you can carry out a reset of the peak values separately. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 40 During simulation, the simulated value is output as digital signal. The status message along with the Asset Management function is "Maintenance". Note: Without manual deactivation, the sensor terminates the simulation automatically after 60 minutes. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 41 Furthermore the adjustment for the volume or mass flow at 0 % or 100 % is carried out. The device automatically adds the flow in the selected unit. With appropriate adjustment and bidirectional linearization, the flow rate is counted both positively and negatively. VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 42: Diagnosis, Asset Management And Service

Should these measures not be successful, please call in urgent cases 24 hour service hotline the VEGA service hotline under the phone no. +49 1805 858550. The hotline is also available outside normal working hours, seven days a week around the clock. -

Page 43: Exchange Process Module On Version Ip68 (25 Bar)

Proceed as follows when carrying out the exchange: 1. Losen the fixing screw with the hexagon key wrench 2. Carefully detach the cable assembly from the process module Fig. 22: VEGABAR 81 in IP68 version, 25 bar and lateral cable outlet, external housing Process module... -

Page 44: How To Proceed If A Repair Is Necessary

Attach the completed form and, if need be, also a safety data sheet outside on the packaging • Ask the agency serving you to get the address for the return ship- ment. You can find the agency on our homepage. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 45: Dismount

Pass the instrument directly on to a specialised recycling company and do not use the municipal collecting points. If you have no way to dispose of the old instrument properly, please contact us concerning return and disposal. VEGABAR 81 • Slave sensor for electronic differential pressure... -

Page 46: Supplement

Ʋ Seal between base and wall mounting EPDM (fixed connected) plate Inspection window housing cover Polycarbonate (UL-746-C listed), glass Seal, housing lid Silicone SI 850 R, NBR silicone-free Glass with Aluminium and stainless steel precision casting housing VEGABAR 81 • Slave sensor for electronic differential pressure... - Page 47 -1 … +5 bar/-100 … +500 kPa +15 bar/+1500 kPa -1 bar/-100 kPa -1 … +10 bar/-100 … +1000 kPa +30 bar/+3000 kPa -1 bar/-100 kPa Data on overload capability apply for reference temperature. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 48 -10 … 100 % Ʋ Level value according to the measuring ranges in m Max. permissible Turn Down Unlimited (recommended 20 : 1) Dynamic behaviour output Dynamic characteristics depending on medium and temperature VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 49 Influence of the installation position depending on the chemical seal version Deviation in the current output due to < ±150 µA strong, high-frequency electromagnetic fields acc. to EN 61326-1 VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 50 (TD) is the ratio nominal measuring range/set span. Long-term stability zero signal and output < (0.1 % x TD)/year span Depending on which chemical seal is used, the values can also be higher. VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 51 (266 °F) (-104 °F) -40 °C (-104 °F) Fig. 24: Temperature derating VEGABAR 81, version up to +130 °C (+266 °F) Process temperature Ambient temperature With process fitting PVDF, process temperature max. 100 °C (212 °F). Measuring cell ø 28 mm...

- Page 52 (302 °F) (-104 °F) -40 °C (-104 °F) Fig. 25: Temperature derating VEGABAR 81, version up to +150 °C (+302 °F) Process temperature Ambient temperature SIP process temperature (SIP = Sterilization in place) Applies to instruments configurations suitable for vapour, i.e. material measuring cell seal EPDM or FFKM (Perlast G75S).

- Page 53 Ʋ Colour Black Connection cable Slave - Master, electrical data Ʋ Wire cross-section 0.34 mm² (AWG 22) Ʋ Wire resistance < 0.05 Ω/m (0.015 Ω/ft) Breather capillaries not with Ex-d version. VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 54: Dimensions

Protection rating (IEC 61010-1) Dimensions The following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded at www.vega.com under "Downloads" and "Drawings". Galvanic separation between electronics and metal housing parts When used with fulfilled housing protection. - Page 55 9 mm/0.35 in or 18 mm/0.71 in higher) Plastic single chamber (IP66/IP67) Aluminium - single chamber Stainless steel single chamber (electropolished) Stainless steel single chamber (precision casting) Stainless steel single chamber (electropolished) IP69K VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 56 8 mm (0.12") (0.32") 110 mm x 90 mm (4.33" x 3.54") Fig. 27: VEGABAR 81, IP68 version with external housing Lateral cable outlet Axial cable outlet Plastic single chamber Stainless steel single chamber Seal 2 mm (0.079 in), (only with 3A approval)

- Page 57 GE G½ A outside PN 160, ISO 228-1; diaphragm: inside; > 105 °C with temperature adapter GK G¾ A outside PN 600, DIN 3852-E; diaphragm: front-flush GL G1 A outside PN 600, ISO 228-1; diaphragm: front-flush GN G1½ PN 600, DIN 3852-A; diaphragm: front-flush VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 58 " 4.09" 0.79" Fig. 29: VEGABAR 81, tube isolating diaphragm Tube isolating diaphragm for mounting between flanges Tube isolating diaphragm according to DIN 11851 Tube isolating diaphragm according to DIN 11864-1 VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 59 48,3 4 x ø19 24,3 152,4 3" Fig. 30: VEGABAR 81, flange connection, dimensions in mm Flange connection according to DIN 2501 Flange connection according to ASME B16.5 Order-specific Diaphragm diameter VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 60 4 x ø0.75" 3" 7.48" 0.96" 6" 5" 0.08" Fig. 31: VEGABAR 81, flange connection, dimensions in inch Flange connection according to DIN 2501 Flange connection according to ASME B16.5 Order-specific Diaphragm diameter VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 61 6.3" 0.71" 3.5" 16..100 0.79" 5.43" 3.5" Fig. 32: VEGABAR 81, flange and cell isolating diaphragm with capillary line Flange isolating diaphragm with capillary line Cell isolating diaphragm with capillary line VEGABAR 81 • Slave sensor for electronic differential pressure...

-

Page 62: Industrial Property Rights

Les lignes de produits VEGA sont globalement protégées par des droits de propriété intellec- tuelle. Pour plus d'informations, on pourra se référer au site www.vega.com. VEGA lineas de productos están protegidas por los derechos en el campo de la propiedad indus- trial. Para mayor información revise la pagina web www.vega.com. - Page 63 – Level measurement 17, 21 Oxygen applications 14 Parameterization example 31 Peak value indicator 39 Position correction 30 Pressure compensation 16 – Ex d 15 – Second Line of Defense 15 – Standard 15 VEGABAR 81 • Slave sensor for electronic differential pressure...

- Page 64 Subject to change without prior notice © VEGA Grieshaber KG, Schiltach/Germany 2020 VEGA Grieshaber KG Phone +49 7836 50-0 Am Hohenstein 113 Fax +49 7836 50-201 E-mail: info.de@vega.com...

Need help?

Do you have a question about the VEGABAR 81 and is the answer not in the manual?

Questions and answers