Vega VEGABAR 81 Product Information

Pressure transmitter

Hide thumbs

Also See for VEGABAR 81:

- Operating instructions manual (96 pages) ,

- Quick setup manual (20 pages) ,

- Operating instructions manual (96 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Vega VEGABAR 81

-

Page 1: Product Information

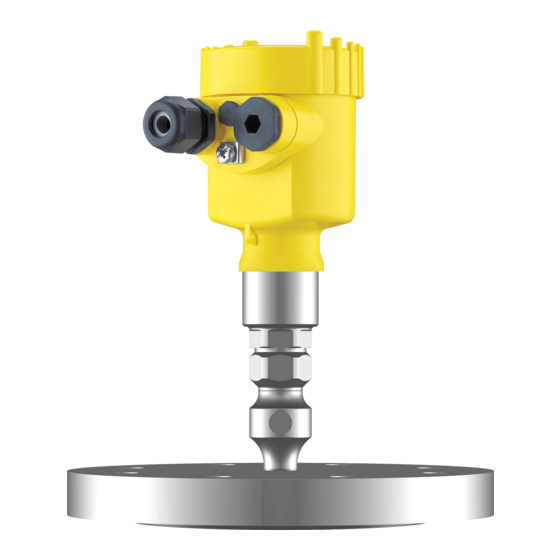

Product Information Process pressure Pressure transmitter VEGABAR 81, 82, 83... -

Page 2: Table Of Contents

Take note of safety instructions for Ex applications Please note the Ex specific safety information which you can find on our homepage www.vega.com/downloads under "Approvals" and which comes with every instrument. In hazardous areas you should take note of the corresponding regulations, conformity and type approval certificates of the sensors and power supply units. -

Page 3: Measuring Principle

Overview The process pressure acts via the process diaphragm to the sensor ele- The VEGABAR 81, 82 and 83 can be used universally for the measure- ment. The process pressure causes a resistance change which is con- ment of gases, vapours and liquids. The instrument series is designed for verted into a corresponding output signal and outputted as measured all applications in industrial measurement engineering. -

Page 4: Type Overview

Type overview Type overview VEGABAR 81 VEGABAR 82 VEGABAR 83 ® ® Measuring cell Piezoresistive/DMS CERTEC Piezoresistive/strain gauge, METEC Diaphragm Metal Ceramic Metal Media gases, vapours and liquids, also gases, vapours and liquids, also with gas, vapours and liquids, also vis-... -

Page 5: Instrument Selection

Instrument selection Application area VEGABAR 81 The VEGABAR 81 is a pressure transmitter with chemical seal for pres- sure and level measurement. The process-adapted chemical seal system of VEGABAR 81 ensures reliable measurement even in highly corrosive and hot media. -

Page 6: Selection Criteria

Selection criteria Selection criteria VEGABAR VEGABAR VEGABAR Wear through process Aggressive products – ● ● Abrasive products – ● – 150 °C (302 °F) Process temperature up to ● ● ● 200 °C (302 °F) ● ● ● 400 °C (752 °F) ●... -

Page 7: Housing Overview

Housing overview Housing overview Plastic PBT IP 66/IP 67 IP 66/IP 67 Protection rating Version Single chamber Double chamber Application area Industrial environment Industrial environment Aluminium IP 66/IP 67, IP 66/IP 68 (1 bar) IP 66/IP 67, IP 66/IP 68 (1 bar) Protection rating Version Single chamber... -

Page 8: Mounting

Mounting Mounting Installation position The instruments function in any installation position. But the installation position can influence the measurement, depending on the measuring system. This can be compensated by a position correction. It is useful to select an installation position you can easily reach for mount- ing and connecting as well as later retrofitting of an display and adjustment module. -

Page 9: Electronics - 4

Electronics - 4 … 20 mA - two-wire Electronics - 4 … 20 mA - two-wire Connection Configuration of the electronics The pluggable electronics is mounted in the electronics compartment of Single chamber housing the instrument and can be exchanged by the user when servicing is re- quired. -

Page 10: Electronics - 4

Electronics - 4 … 20 mA/HART - two-wire Electronics - 4 … 20 mA/HART - two-wire Connection Configuration of the electronics The pluggable electronics is mounted in the electronics compartment of Single chamber housing the instrument and can be exchanged by the user when servicing is re- quired. -

Page 11: Electronics - Profibus Pa

Electronics - Profibus PA Electronics - Profibus PA Double chamber housing Configuration of the electronics The pluggable electronics is mounted in the electronics compartment of the instrument and can be exchanged by the user when servicing is re- quired. The electronics is completely encapsulated to protect against vibration and moisture. -

Page 12: Electronics - Foundation Fieldbus

Electronics - Foundation Fieldbus 10 Electronics - Foundation Fieldbus Double chamber housing Configuration of the electronics The pluggable electronics is mounted in the electronics compartment of the instrument and can be exchanged by the user when servicing is re- quired. The electronics is completely encapsulated to protect against vibration and moisture. -

Page 13: Electronics - Slave Sensor For Electronic Differential Pressure

Electronics - Slave sensor for electronic differential pressure 11 Electronics - Slave sensor for electronic differential pressure Configuration of the electronics The pluggable electronics is mounted in the electronics compartment of the instrument and can be exchanged by the user when servicing is re- quired. -

Page 14: Operation

Operation 12 Operation echo curves. In addition, there is a tank calculation program as well as a 12.1 Overview multiviewer for display and analysis of the saved measured value and echo curves. The sensors can be adjusted with the following adjustment media: With the display and adjustment module Connection of the PC via VEGACONNECT With external display and adjustment unit... -

Page 15: Dimensions

Threaded version G1½ A, 200 °C Tri-Clamp version 2" The listed drawings are only an excerpt of the available process fittings. Stainless steel housing You can find more drawings at www.vega.com/downloads under "Draw- ~ 69 mm ~ 87 mm ~ 59 mm ings". - Page 16 VEGA Grieshaber KG You can find at www.vega.com Am Hohenstein 113 operating instructions manuals 77761 Schiltach specification sheet Germany Software Phone +49 7836 50-0 drawings Fax +49 7836 50-201 certificates E-Mail: info.de@vega.com www.vega.com approvals and much, much more Subject to change without prior notice...

Need help?

Do you have a question about the VEGABAR 81 and is the answer not in the manual?

Questions and answers