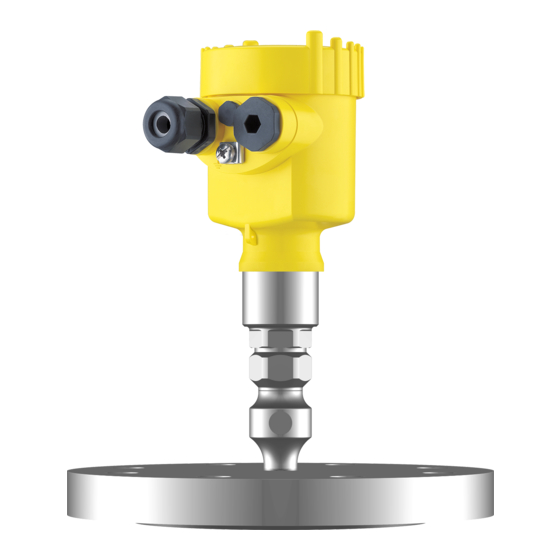

Vega VEGABAR 81 Operating Instructions Manual

Pressure transmitter with chemical seal

profibus pa

Hide thumbs

Also See for VEGABAR 81:

- Operating instructions manual (96 pages) ,

- Quick setup manual (20 pages) ,

- Product information (16 pages)

Summary of Contents for Vega VEGABAR 81

-

Page 1: Operating Instructions

Operating Instructions Pressure transmitter with chemical seal VEGABAR 81 Profibus PA Document ID: 45020... -

Page 2: Table Of Contents

Parameter adjustment - Quick setup ................33 Parameter adjustment - Extended adjustment..............34 Saving the parameter adjustment data ................47 Setup with PACTware Connect the PC ......................49 Parameter adjustment ....................49 Saving the parameter adjustment data ................50 VEGABAR 81 • Profibus PA... - Page 3 Safety instructions for Ex areas Please note the Ex-specific safety information for installation and op- eration in Ex areas. These safety instructions are part of the operating instructions manual and come with the Ex-approved instruments. Editing status:2014-07-01 VEGABAR 81 • Profibus PA...

-

Page 4: About This Document

Action This arrow indicates a single action. Sequence of actions Numbers set in front indicate successive steps in a procedure. Battery disposal This symbol indicates special information about the disposal of bat- teries and accumulators. VEGABAR 81 • Profibus PA... -

Page 5: For Your Safety

During work on and with the device the required personal protective equipment must always be worn. Appropriate use The VEGABAR 81 is a pressure transmitter for process pressure and hydrostatic level measurement. You can find detailed information about the area of application in chapter "Product description". -

Page 6: Namur Recommendations

The environment management system is certified according to DIN EN ISO 14001. Please help us fulfill this obligation by observing the environmental instructions in this manual: • Chapter "Packaging, transport and storage" • Chapter "Disposal" VEGABAR 81 • Profibus PA... -

Page 7: Product Description

Order-specific sensor data for an electronics exchange (XML) • Test certificate (PDF) - optional Go to www.vega.com, "VEGA Tools" and "Instrument search". Enter the serial number. Alternatively, you can access the data via your smartphone: VEGABAR 81 • Profibus PA... -

Page 8: Principle Of Operation

In the operating instructions manual, the optional instrument features are described. The respective scope of delivery results from the order specification. Principle of operation Measured variables The VEGABAR 81 is suitable for the measurement of the following process variables: • Process pressure •... - Page 9 3 Product description In combination with a slave sensor, VEGABAR 81 is also suitable for Electronic differential pressure electronic differential pressure measurement. You can find detailed information in the operating instructions of the respective slave sensor. Application area VEGABAR 81 is suitable for applications in virtually all industries. It is used for the measurement of the following pressure types.

-

Page 10: Supplementary Cleaning Procedures

Caution: The VEGABAR 81 in this version may not be used in oxygen ap- plications. For this purpose, instruments of VEGABAR series 80 are available in the special version "Oil and grease-free for oxygen applications". -

Page 11: Accessories And Replacement Parts

VEGABAR 81 an electronic differential pressure measurement. You can find further information in the operating instructions of the respective slave sensor. VEGADIS 81 The VEGADIS 81 is an external display and adjustment unit for VEGA plics sensors. ® For sensors with double chamber housing the interface adapter "DIS- ADAPT"... - Page 12 Supplementary electron- The supplementary electronics is a replacement part for sensors with ics Profibus PA Profibus PA and double chamber housing. You can find further information in the operating instructions "Supple- mentary electronics for Profibus PA" (Document-ID 42767). VEGABAR 81 • Profibus PA...

-

Page 13: Mounting

Higher process temperatures often mean also higher ambient Temperature limits temperatures. Make sure that the upper temperature limits stated in chapter "Technical data" for the environment of the electronics hous- ing and connection cable are not exceeded. VEGABAR 81 • Profibus PA... -

Page 14: Ventilation And Pressure Compensation

Ventilation of the electronics housing • Atmospheric pressure compensation (with relative pressure meas- uring ranges) → Turn the housing so that the filter element points downward after the instrument is installed. This provides better protection against buildup. VEGABAR 81 • Profibus PA... - Page 15 Single chamber housing, aluminium, stainless steel precision casting Double chamber housing, aluminium, stainless steel precision casting Rotatable metal ring Filter element Instruments with absolute pressure have a blind plug mounted instead of the filter element. VEGABAR 81 • Profibus PA...

-

Page 16: Process Pressure Measurement

Pipeline Measurement setup in Keep the following in mind when setting up the measuring system: vapours • Connect via a siphon • Do not insulate the siphon • Fill the siphon with water before setup VEGABAR 81 • Profibus PA... - Page 17 Keep the following in mind when setting up the measuring system: liquids • Mount the instrument below the measuring point The effective pressure line is always filled with liquid and gas bubbles can bubble up to the process line. VEGABAR 81 • Profibus PA...

-

Page 18: Level Measurement

Do not mount the instrument close to the filling stream or emptying area • Mount the instrument so that it is protected against pressure shocks from the stirrer Fig. 11: Measurement setup for level measurement VEGABAR 81 • Profibus PA... -

Page 19: External Housing

1. Mark the holes according to the following drilling template 2. Fasten wall mounting plate with 4 screws 90 mm (3.54") 70 mm (2.76") 8 mm (0.12") (0.32") Fig. 13: Drilling template - wall mounting plate VEGABAR 81 • Profibus PA... -

Page 20: Connecting To The Bus System

The screen in the sensor must be connected directly to the internal ground terminal. The ground terminal outside on the housing must be connected to the potential equalisation (low impedance). VEGABAR 81 • Profibus PA... -

Page 21: Connecting

1 cm (0.4 in) of insulation from the ends of the individual wires 5. Insert the cable into the sensor through the cable entry Fig. 14: Connection steps 5 and 6 - Single chamber housing VEGABAR 81 • Profibus PA... -

Page 22: Single Chamber Housing

10. Reinsert the display and adjustment module, if one was installed 11. Screw the housing cover back on The electrical connection is finished. Single chamber housing The following illustration applies to the non-Ex, Ex-ia and Ex-d ver- sion. VEGABAR 81 • Profibus PA... -

Page 23: Double Chamber Housing

Electronics compartment 6 7 8 Fig. 17: Electronics compartment, double chamber housing Internal connection to the terminal compartment Contact pins for the display and adjustment module or interface adapter Selection switch for bus address VEGABAR 81 • Profibus PA... -

Page 24: Double Chamber Housing Ex D

Double chamber housing Ex d Electronics compartment 6 7 8 Fig. 19: Electronics compartment, double chamber housing Internal connection to the terminal compartment Contact pins for the display and adjustment module or interface adapter Selection switch for bus address VEGABAR 81 • Profibus PA... -

Page 25: Double Chamber Housing With Dis-Adapt

Double chamber housing with DIS-ADAPT Electronics compartment Fig. 21: View to the electronics compartment with DISADAPT for connection of the external display and adjustment unit DIS-ADAPT Internal plug connection Plug connector M12 x 1 VEGABAR 81 • Profibus PA... -

Page 26: Housing Ip 66/Ip 68 (1 Bar)

Black Housing IP 66/IP 68 (1 bar) Wire assignment, con- nection cable Fig. 23: Wire assignment in permanently connected connection cable brown (+) and blue (-) to power supply or to the processing system Shielding VEGABAR 81 • Profibus PA... -

Page 27: External Housing With Version Ip 68 (25 Bar)

5 Connecting to the bus system External housing with version IP 68 (25 bar) Overview Fig. 24: VEGABAR 81 in IP 68 version 25 bar with axial cable outlet, external housing Transmitter Connection cable External housing Electronics and connec- tion compartment for power supply 4...20mA... -

Page 28: Switch-On Phase

10 s: • Internal check of the electronics • Indication of the instrument type, hardware and software version, measurement loop name on the display or PC VEGABAR 81 • Profibus PA... - Page 29 The output signal jumps to the set fault current Then the actual measured value is outputted to the signal cable. The value takes into account settings that have already been carried out, e.g. default setting. VEGABAR 81 • Profibus PA...

-

Page 30: Set Up With The Display And Adjustment Module

The display and adjustment module is powered by the sensor, an ad- ditional connection is not necessary. Fig. 28: Installing the display and adjustment module in the electronics compart- ment of the single chamber housing VEGABAR 81 • Profibus PA... -

Page 31: Adjustment System

Adjustment system Fig. 30: Display and adjustment elements LC display Adjustment keys • Key functions [OK] key: – Move to the menu overview VEGABAR 81 • Profibus PA... -

Page 32: Measured Value Indication

This menu item is used to select the national language for further Selection language parameter adjustment. A later change of the selection is possible via menu item "Setup - Display, Menu language". With the "OK" key you move to the main menu. VEGABAR 81 • Profibus PA... -

Page 33: Parameter Adjustment - Quick Setup

In this menu item you carry out the zero adjustment for the processs pressure. Enter the corresponding pressure value for 0 %. 7. Span adjustment In this menu item you carry out the span adjustment for the processs pressure Enter the corresponding pressure value for 100 %. VEGABAR 81 • Profibus PA... -

Page 34: Parameter Adjustment - Extended Adjustment

The quick setup is finished. Parameter adjustment - Extended adjustment For technically demanding measuring points, you can carry out extended settings in "Extended adjustment". Main menu The main menu is divided into five sections with the following func- tions: VEGABAR 81 • Profibus PA... - Page 35 Hardware addressing is effective if an address less than 126 is set with the address selection switches on the electronics module of VEGABAR 81. In such case, software addressing has no effect - only the set hardware address applies. Software addressing Software addressing is only effective if address 126 or higher is set on the instrument with the address selection switches.

- Page 36 In this menu item you activate/deactivate the slave sensor for elec- tronic differential pressure and select the application. VEGABAR 81 can be used for process pressure and level measure- ment. Default setting is process pressure measurement. The mode can be changed in this adjustment menu.

- Page 37 Setup - Adjustment VEGABAR 81 always measures pressure independently of the pro- cess variable selected in the menu item "Application". To output the selected process variable correctly, an allocation of the output signal to 0 % and 100 % must be carried out (adjustment).

- Page 38 Setup - span adjustment Proceed as follows: 1. Select with [->] the menu item "Span adjustment" and confirm with [OK]. 2. Edit the mbar value with [OK] and set the cursor to the requested position with [->]. VEGABAR 81 • Profibus PA...

- Page 39 [OK]. The cursor jumps now to the pressure value. 4. Enter the pressure value for the full vessel (e.g. 900 mbar) cor- responding to the percentage value. 5. Save settings with [OK] The max. adjustment is finished. VEGABAR 81 • Profibus PA...

- Page 40 In the menu item "Scaling", you assign the min. and max. values of Setup - AI FB1 - Scaling the input signal (Channel) to the respective values of the output (Out Scale). The units correspond to the previous selection. VEGABAR 81 • Profibus PA...

- Page 41 With active PIN, adjustment via PACTware/DTM as well as other systems is also blocked. You can change the PIN number under "Additional settings - PIN". Display - Language This menu item enables the setting of the requested national lan- guage. VEGABAR 81 • Profibus PA...

- Page 42 Polish • Czech • Turkish In the delivery status, the VEGABAR 81 is set to the ordered national language. Display - Displayed value In this menu item you can define the way measured values are indi- 1 and 2 cated on the display.

- Page 43 In this menu item, you adjust the internal clock of the sensor. There is Date Time no adjustment for summer/winter (daylight saving) time. Additional adjustments With a reset, certain parameter adjustments carried out by the user - Reset are reset. VEGABAR 81 • Profibus PA...

- Page 44 ≥1 bar) Temperature unit °C Position correc- 0.00 bar tion Adjustment Zero/Min. adjust- 0.00 bar ment 0.00 % Span/Max. adjust- Nominal measuring range in bar ment 100.00 % Damping Integration time 0.0 s Linearization Linear VEGABAR 81 • Profibus PA...

- Page 45 Additional adjustments - The instrument settings are copied with this function. The following Copy instrument settings functions are available: • Read from sensor: Read data from sensor and save in the display and adjustment module VEGABAR 81 • Profibus PA...

- Page 46 (2) and the scaling of the measured level value for 0 % and 100 %. In this menu item, you can read out the instrument name and the Info - Instrument name instrument serial number: VEGABAR 81 • Profibus PA...

-

Page 47: Saving The Parameter Adjustment Data

The data remain there permanently even if the sensor power supply fails. The following data or settings for adjustment of the display and ad- justment module are saved: • All data of the menu "Setup" and "Display" VEGABAR 81 • Profibus PA... - Page 48 If it is necessary to exchange a sensor, the display and adjustment module is inserted into the replacement instrument and the data are likewise written into the sensor via the menu item "Copy sensor data". VEGABAR 81 • Profibus PA...

-

Page 49: Setup With Pactware

Further setup steps are described in the operating instructions manu- al "DTM Collection/PACTware" attached to each DTM Collection and which can also be downloaded from the Internet. Detailed descrip- tions are available in the online help of PACTware and the DTMs. VEGABAR 81 • Profibus PA... -

Page 50: Saving The Parameter Adjustment Data

The standard version is available as a download under www.vega.com/downloads and "Software". The full version is avail- able on CD from the agency serving you. Saving the parameter adjustment data We recommend documenting or saving the parameter adjustment data via PACTware. -

Page 51: Set Up With Other Systems

Set up with other systems DD adjustment programs Device descriptions as Enhanced Device Description (EDD) are available for DD adjustment programs such as, for example, AMS™ and PDM. The files can be downloaded at www.vega.com/downloads under "Software". VEGABAR 81 • Profibus PA... -

Page 52: Diagnosis, Asset Management And Service

• Switch-on and switch-off times • Status messages (according to NE 107) • Error messages (according to NE 107) The data are read out via a PC with PACTware/DTM or the control system with EDD. VEGABAR 81 • Profibus PA... -

Page 53: Asset Management Function

PACTware/DTM or EDD. Failure The following table shows the error codes in the status message "Failure" and gives information on the reason and rectification. Keep in mind that some information is only valid with four-wire instruments. VEGABAR 81 • Profibus PA... - Page 54 – Send instrument for repair Error in the – Error in the EEPROM calibration F261 – Error during setup – Repeat setup – Error when carrying out a – Repeat reset Error in the reset configuration VEGABAR 81 • Profibus PA...

- Page 55 "Maintenance" and provides information on causes as well as corrective measures. Code Cause Rectification Text mes- sage M500 – Stored delivery status is – Send instrument for repair incorrect Error in the delivery sta- VEGABAR 81 • Profibus PA...

-

Page 56: Rectify Faults

24 hour service hotline Should these measures not be successful, please call in urgent cases the VEGA service hotline under the phone no. +49 1805 858550. The hotline is also available outside normal working hours, seven days a week around the clock. -

Page 57: Exchange Process Assembly With Version Ip 68 (25 Bar)

During exchange, protect the inner side of the parts against contami- nation and moisture. Proceed as follows when carrying out the exchange: 1. Losen the fixing screw with the hexagon key wrench 2. Carefully detach the cable assembly from the process assembly VEGABAR 81 • Profibus PA... -

Page 58: Software Update

9 Diagnosis, asset management and service Fig. 35: VEGABAR 81 in IP 68 version, 25 bar and lateral cable outlet, external housing Process assembly Plug connector Fixing screw Cable assembly Connection cable External housing 3. Loosen the plug connector 4. Mount the new process assembly on the measuring point 5. -

Page 59: How To Proceed If A Repair Is Needed

Instruments with approvals can be bound to certain software versions. Therefore make sure that the approval is still effective after a software update is carried out. You can find detailed information at www.vega.com/downloads and "Approvals". How to proceed if a repair is needed You can find a repair form as well as detailed information on how to proceed at www.vega.com/downloads and "Forms and certificates". -

Page 60: Dismount

Pass the instrument directly on to a spe- cialised recycling company and do not use the municipal collecting points. These may be used only for privately used products according to the WEEE directive. VEGABAR 81 • Profibus PA... -

Page 61: Supplement

Connection cable, master and slave PE, PUR sensor Weights Total weight VEGABAR 81 approx. 0.8 … 8 kg (1.764 … 17.64 lbs), depending on process fitting and housing Torques Max. torque for NPT cable glands and Conduit tubes Ʋ Plastic housing 10 Nm (7.376 lbf ft) - Page 62 The specifications on the nameplate apply. Nominal range Overload capacity, max. Overload capacity, min. pres- pressure sure Gauge pressure 0 … +5 psig +25 psig -14.5 psig 0 … +15 psig +75 psig -14.5 psig VEGABAR 81 • Profibus PA...

- Page 63 20 : 1 (no limitation) Output variable Output signal digital output signal, format according to IEEE-754 Sensor address 126 (default setting) Damping (63 % of the input variable) 0 … 999 s, adjustable Profibus PA profile 3.02 VEGABAR 81 • Profibus PA...

- Page 64 Ʋ VEGABAR 81 ≤ 80 ms (ti: 0 s, 10 … 90 %) Ʋ VEGABAR 81 - IP 68 (25 bar) ≤ 200 ms (ti: 0 s, 10 … 90 %) To this amounts the reaction time of the isolatng system. This time varies from values < 1 s with compact chemical seals to several seconds with capillary systems.

- Page 65 Ʋ Flange 2" 150 lbs RF, ANSI B16.5 1.2 mbar/10 K Ʋ Flange 3" 150 lbs RF, ANSI B16.5 0.25 mbar/10 K Ʋ Flange 3" 150 lbs RF, ANSI B16.5 with 1.34 mbar/10 K extension 2 " VEGABAR 81 • Profibus PA...

-

Page 66: Ambient Conditions

5 m Halocarbon oil KN21 -40 … +150 °C (- -40 … +80 °C (- 40 … +302 °F) 40 … +176 °F) Depending on which chemical seal is used, the values can also be higher. VEGABAR 81 • Profibus PA... - Page 67 180 m (590.6 ft) Ʋ Min. bending radius 25 mm (0.984 in) with 25 °C (77 °F) Ʋ Diameter approx. 8 mm (0.315 in) Ʋ Colour - Non-Ex version Black Ʋ Colour - Ex-version Blue VEGABAR 81 • Profibus PA...

- Page 68 4 … 20 mA, 4 … 20 mA/HART Ʋ Sensors with signal output Profibus 25 m PA, Foundation Fieldbus Interface to the slave sensor Data transmission digital (I²C-Bus) Configuration, connection cable 4-wire, screened Cable length max. 25 m VEGABAR 81 • Profibus PA...

- Page 69 NEMA 6P Aluminium Single chamber IP 66/IP 67 NEMA 6P IP 68 (1 bar) Double chamber IP 66/IP 67 NEMA 6P Stainless steel, electro- Single chamber IP 66/IP 67 NEMA 6P polished Single chamber IP 69K VEGABAR 81 • Profibus PA...

-

Page 70: Communication Profibus Pa

Instruments with approvals can have different technical specifications depending on the version. For that reason the associated approval documents of these instruments have to be carefully noted. They are part of the delivery or can be downloaded under www.vega.com, "VEGA Tools" and "Instrument search" as well as under www.vega.com/downloads and "Approvals". - Page 71 11 Supplement Fig. 37: VEGABAR 81: Block diagram with AI FB 1 … AI FB 3 OUT values TB Transducer Block FB Function Block Analogue Input Module of the PA sensors For the cyclic data traffic, VEGABAR 81 provides the following modules: •...

- Page 72 Fig. 39: Data format of the measured value Coding of the status byte associated with the PA output value You can find further information for the coding of the status byte in the Device Description 3.02 on www.profibus.com. VEGABAR 81 • Profibus PA...

-

Page 73: Dimensions

- low limited 0 x 8e good (non-cascade) - ac- Hi-Hi-Alarm tive critical alarm - high limited 11.3 Dimensions The following dimensional drawings represent only an extract of the possible versions. Detailed VEGABAR 81 • Profibus PA... - Page 74 11 Supplement dimensional drawings can be downloaded at www.vega.com under "Downloads" and "Drawings". Plastic housing ~ 69 mm ~ 84 mm (2.72") (3.31") ø 79 mm ø 79 mm (3.11") (3.11") M16x1,5 M20x1,5/ ½ NPT M20x1,5/ ½ NPT Fig. 40: Housing versions in protection IP 66/IP 68 (0.2 bar) - with integrated display and adjustment module the housing is 9 mm/0.35 in higher...

- Page 75 Fig. 43: Housing versions in protection IP 66/IP 68 (0.2 bar) - with integrated display and adjustment module the housing is 9 mm/0.35 in higher Single chamber version, electropolished Single chamber version, precision casting Double chamber version, precision casting VEGABAR 81 • Profibus PA...

- Page 76 (2.3") ø 80 mm (3.15") M20x1,5/ ½ NPT Fig. 45: Housing version with protection rating IP 69K - with integrated display and adjustment module the housing is 9 mm/0.35 in higher Single chamber version, electropolished VEGABAR 81 • Profibus PA...

- Page 77 (4.33" x 3.54") 41,6 mm (1.64") ~ 66 mm (2.60") 110 mm x 90 mm (4.33" x 3.54") Fig. 46: IP 68 version with external housing - plastic version Lateral cable outlet Axial cable outlet VEGABAR 81 • Profibus PA...

- Page 78 G1 1/2 ø 39 mm ø 60 mm (1.54") (2.36") Fig. 47: VEGABAR 81, threaded fitting GE G½ (ISO 228-1), >105 °C with temperature adapter GK G¾ (DIN 3852-E) GL G1 A (DIN 3852-E) GN G1½ (DIN 3852-A) VEGABAR 81 • Profibus PA...

- Page 79 " 4.09" 0.39" RD44x " 4.09" 0.79" Fig. 48: VEGABAR 81, tube isolating diaphragm Tube isolating diaphragm for mounting between flanges Tube isolating diaphragm according to DIN 11851 Tube isolating diaphragm according to DIN 11864-1 VEGABAR 81 • Profibus PA...

- Page 80 4 x ø19 3" 24,3 152,4 4 x ø19 152,5 3" 24,3 152,4 Fig. 49: VEGABAR 81, flange connection, dimensions in mm Flange connection according to DIN 2501 Flange connection according to ANSI B16.5 Diaphragm diameter VEGABAR 81 • Profibus PA...

- Page 81 4 x ø0.75" 6" 2.99" 2.84" 3" 7.48" 0.96" 6" 5" 0.08" Fig. 50: VEGABAR 81, flange connection, dimensions in inch Flange connection according to DIN 2501 Flange connection according to ANSI B16.5 Diaphragm diameter VEGABAR 81 • Profibus PA...

- Page 82 4.02" 7.87" 0.79" 5.43" 0.71" 3.5" 16..100 6.3" 0.79" 5.43" 3.5" Fig. 51: VEGABAR 81, flange and cell isolating diaphragm with capillary line Flange isolating diaphragm with capillary line Cell isolating diaphragm with capillary line VEGABAR 81 • Profibus PA...

- Page 83 Les lignes de produits VEGA sont globalement protégées par des droits de propriété intellec- tuelle. Pour plus d'informations, on pourra se référer au site www.vega.com. VEGA lineas de productos están protegidas por los derechos en el campo de la propiedad indus- trial. Para mayor información revise la pagina web www.vega.com.

- Page 84 Service hotline 56 Instrument address 35 Setup Instrument master file 70 – Quick setup 33 Simulation 43 Software addressing 35 Linearization 40 Status bytes PA output value 72 Status messages - NAMUR NE 107 53 VEGABAR 81 • Profibus PA...

- Page 85 INDEX Telegram configuration 72 VEGABAR 81 • Profibus PA...

- Page 86 Notes VEGABAR 81 • Profibus PA...

- Page 87 Notes VEGABAR 81 • Profibus PA...

- Page 88 Subject to change without prior notice © VEGA Grieshaber KG, Schiltach/Germany 2014 VEGA Grieshaber KG Phone +49 7836 50-0 Am Hohenstein 113...

Need help?

Do you have a question about the VEGABAR 81 and is the answer not in the manual?

Questions and answers