Vega VEGABAR 81 Operating Instructions Manual

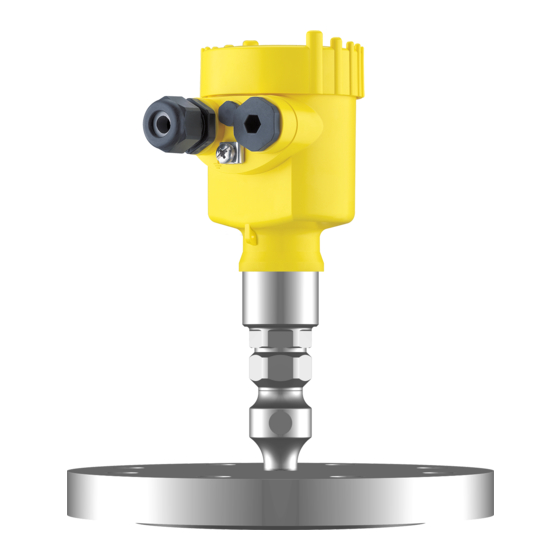

Pressure transmitter with chemical seal

Hide thumbs

Also See for VEGABAR 81:

- Operating instructions manual (96 pages) ,

- Quick setup manual (20 pages) ,

- Product information (16 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Vega VEGABAR 81

- Page 1 Operating Instructions Pressure transmitter with chemical seal VEGABAR 81 4 … 20 mA/HART With SIL qualification Document ID: 45019...

-

Page 2: Table Of Contents

Objective ........................34 6.2 SIL qualification ......................34 Application area ......................34 Safety concept of the parameterization ................35 Set up with the display and adjustment module ..............37 Insert display and adjustment module ................37 VEGABAR 81 • 4 … 20 mA/HART... - Page 3 12.4 Industrial property rights ....................93 12.5 Trademark ........................93 Safety instructions for Ex areas: Take note of the Ex specific safety instructions for Ex applications. These instructions are attached as documents to each instrument with Ex approval and are part of the operating instructions. Editing status: 2022-04-20 VEGABAR 81 • 4 … 20 mA/HART...

-

Page 4: About This Document

Symbols used Document ID This symbol on the front page of this instruction refers to the Docu- ment ID. By entering the Document ID on www.vega.com you will reach the document download. Information, note, tip: This symbol indicates helpful additional infor- mation and tips for successful work. -

Page 5: For Your Safety

During work on and with the device, the required personal protective equipment must always be worn. Appropriate use The VEGABAR 81 is a pressure transmitter for process pressure and hydrostatic level measurement. You can find detailed information about the area of application in chapter " Product description". Operational reliability is ensured only if the instrument is properly used according to the specifications in the operating instructions manual as well as possible supplementary instructions. -

Page 6: Sil Qualification According To Iec 61508

Protection of the environment is one of our most important duties. That is why we have introduced an environment management system Exception: Versions with measuring ranges from 250 bar. These are subject of the EU Pressure Device Directive. VEGABAR 81 • 4 … 20 mA/HART... - Page 7 2 For your safety with the goal of continuously improving company environmental pro- tection. The environment management system is certified according to DIN EN ISO 14001. Please help us fulfil this obligation by observing the environmental instructions in this manual: • Chapter " Packaging, transport and storage" • Chapter " Disposal" VEGABAR 81 • 4 … 20 mA/HART...

-

Page 8: Product Description

Hardware from 1.0.0 • Software version from 1.2.6 Note: You can find the hardware and software version of the instrument as follows: • On the type plate of the electronics module • In the adjustment menu under " Info" Type label The type label contains the most important data for identification and use of the instrument: VEGABAR 81 • 4 … 20 mA/HART... -

Page 9: Principle Of Operation

Alternatively, you can access the data via your smartphone: • Download the VEGA Tools app from the " Apple App Store" or the " Google Play Store" • Scan the DataMatrix code on the type label of the instrument or •... - Page 10 You can find detailed information in the operating instructions of the respective Secondary sensor. To reach the Safety Integrity Level (SIL) for the electronic differential pressure, both instruments must be SIL-qualified. The VEGABAR 81 is equipped with a chemical seal. It consists of a Chemical seal stainless steel diaphragm and an isolating liquid. A chemical seal has two tasks: • Separation of the sensor element from the medium...

- Page 11 Measuring ranges up to 40 bar: piezoresistive sensor element with a transmission liquid, measuring ranges from 100 bar: a dry strain gauge (DMS) sensor element. Fig. 5: Configuration of a measuring system with piezoresistive sensor element Diaphragm Isolating liquid Base element Sensor element VEGABAR 81 • 4 … 20 mA/HART...

-

Page 12: Supplementary Cleaning Procedures

" Technical data", " Materials and weights". Supplementary cleaning procedures The VEGABAR 81 is also available in the version " Oil, grease and silicone-free". These instruments have passed through a special cleaning procedure to remove oil, grease and paint-wetting impair- ment substances (PWIS). -

Page 13: Packaging, Transport And Storage

Protected against solar radiation • Avoiding mechanical shock and vibration • Storage and transport Storage and transport temperature see chapter " Supplement - temperature Technical data - Ambient conditions" • Relative moisture 20 … 85 % VEGABAR 81 • 4 … 20 mA/HART... -

Page 14: Accessories

USB interface of a PC. Secondary sensors Secondary sensors of VEGABAR series 80 enable in conjunction with VEGABAR 81 an electronic differential pressure measurement. VEGADIS 81 The VEGADIS 81 is an external display and adjustment unit for VEGA plics sensors. ® VEGADIS adapter The VEGADIS adapter is an accessory part for sensors with double chamber housings. -

Page 15: Mounting

Depending on the device version, tightening can cause dam- age, e. g. to the rotation mechanism of the housing. Vibrations Avoid damages on the device by lateral forces, for example by vibra- tions. It is thus recommended to fix the devices with process fitting VEGABAR 81 • 4 … 20 mA/HART... -

Page 16: Instructions For Oxygen Applications

Process temperature Ambient temperature Instructions for oxygen applications Oxygen applications Oxygen and other gases can be explosive when brought into contact with oils, grease and plastics, so the following measures must also be taken: VEGABAR 81 • 4 … 20 mA/HART... -

Page 17: Ventilation And Pressure Compensation

5 s by up to 15 mbar. For an effective ventilation, the filter element must be always free from buildup. In case of horizontal mounting, turn the housing so that the filter element points downward after the instrument is installed. This provides better protection against buildup. Caution: Do not use a high-pressure cleaner. The filter element could be dam- aged, which would allow moisture into the housing. The following paragraphs describe how the filter element is arranged in the different instrument versions. VEGABAR 81 • 4 … 20 mA/HART... - Page 18 Filter element - Position Turn the metal ring in such a way that the filter element points Ex-d version downward after installation of the instrument. This provides better protection against buildup. Fig. 9: Position of the filter element - Ex-d version Rotatable metal ring Filter element Instruments with absolute pressure have a blind plug mounted instead of the filter element. VEGABAR 81 • 4 … 20 mA/HART...

-

Page 19: Process Pressure Measurement

Instruments with absolute pressure have a blind plug mounted instead of the filter element. Process pressure measurement Measurement setup in Keep the following in mind when setting up the measuring system: gases • Mount the instrument above the measuring point Possible condensation can then drain off into the process line. VEGABAR 81 • 4 … 20 mA/HART... - Page 20 Siphon in U or circular form Pipeline A protective accumulation of water is formed through condensation in the pipe bends. Even in applications with hot steam, a medium temperature < 100 °C on the transmitter is ensured. VEGABAR 81 • 4 … 20 mA/HART...

-

Page 21: Level Measurement

Keep the following in mind when setting up the measuring system: • Mount the instrument below the min. level • Do not mount the instrument close to the filling stream or emptying area • Mount the instrument so that it is protected against pressure shocks from the stirrer Fig. 15: Measurement setup for the level measurement VEGABAR 81 • 4 … 20 mA/HART... -

Page 22: External Housing

4 Mounting External housing Configuration Fig. 16: Configuration, process module, external housing Pipeline Process module Connection cable process assembly - External housing External housing Signal cable VEGABAR 81 • 4 … 20 mA/HART... -

Page 23: Connecting To Power Supply

The ground terminal on the outside of the housing must be connected to the ground potential (low impedance). In Ex systems, the grounding is carried out according to the installa- tion regulations. In electroplating plants as well as plants for cathodic corrosion protec- tion it must be taken into account that significant potential differences VEGABAR 81 • 4 … 20 mA/HART... -

Page 24: Connecting

1. Unscrew the housing lid 2. If a display and adjustment module is installed, remove it by turn- ing it slightly to the left 3. Loosen compression nut of the cable gland and remove blind plug VEGABAR 81 • 4 … 20 mA/HART... -

Page 25: Single Chamber Housing

10. Reinsert the display and adjustment module, if one was installed 11. Screw the housing lid back on The electrical connection is finished. Single chamber housing The following illustration applies to the non-Ex, Ex-ia and Ex-d ver- sion. VEGABAR 81 • 4 … 20 mA/HART... -

Page 26: Double Chamber Housing

The following illustrations apply to the non-Ex as well as to the Ex-ia version. Electronics compartment 4...20mA 6 7 8 Fig. 19: Electronics compartment - double chamber housing Internal connection to the connection compartment For display and adjustment module or interface adapter VEGABAR 81 • 4 … 20 mA/HART... - Page 27 Current output (I) - Voltage supply of the sensor and signal output (with HART) Additional current output (II) - Voltage supply and signal output (without HART) Ground terminal for connection of the cable screening VEGABAR 81 • 4 … 20 mA/HART...

-

Page 28: Ex-D-Ia Double Chamber Housing

For display and adjustment module or interface adapter Internal connection to the plug connector for external display and adjust- ment unit (optional) Note: HART multidrop mode is not possible when using an Ex-d-ia instru- ment. VEGABAR 81 • 4 … 20 mA/HART... -

Page 29: Double Chamber Housing With Vegadis-Adapter

Fig. 25: View to the electronics compartment with VEGADIS adapter for connec- tion of the external display and adjustment unit VEGADIS adapter Internal plug connection 3 M12 x 1 plug connector Assignment of the plug connector Fig. 26: Top view of the M12 x 1 plug connector Pin 1 Pin 2 Pin 3 Pin 4 VEGABAR 81 • 4 … 20 mA/HART... -

Page 30: Housing Ip66/Ip68 (1 Bar)

Blue (-): to voltage supply or to the processing system Shielding 4 Breather capillaries with filter element External housing with version IP68 (25 bar) Overview Fig. 28: VEGABAR 81 in IP68 version 25 bar with axial cable outlet, external housing Transmitter Connection cable External housing... - Page 31 Cable gland for voltage supply Cable gland for connection cable, transmitter Terminal compartment, housing socket 1 2 3 4 Fig. 30: Connection of the process component in the housing base Yellow White Black Shielding Breather capillaries VEGABAR 81 • 4 … 20 mA/HART...

-

Page 32: Connection Example

Ground terminal for connection of the cable screening Connection example Connection example, ad- ditional current output 4...20mA 4...20mA Fig. 32: Connection example VEGABAR 81 additional current output Supply and signal circuit, sensor Signal circuit, additional current output Input card PLC Sensor Circuit... -

Page 33: Switch-On Phase

The output signal jumps to the set fault current Then the actual measured value is output to the signal cable. The value takes into account settings that have already been carried out, e.g. default setting. VEGABAR 81 • 4 … 20 mA/HART... -

Page 34: Functional Safety (Sil)

SIL rating and can be also found on our homepage via the search. Application area The instrument can be used, for example, for process pressure and hydrostatic level measurement of liquids in safety-instrumented sys- VEGABAR 81 • 4 … 20 mA/HART... -

Page 35: Safety Concept Of The Parameterization

The DTM suitable for the device in conjunction with an adjustment software according to the FDT/DTM standard, e. g. PACTware Note: For operation of the VEGABAR 81 an actual DTM Collection is re- quired. The modification of safety-relevant parameters is only possible with active connection to the instrument (online mode). - Page 36 Warning: Instrument reset In case of a reset to basic settings, all safety-relevant parameters will also be reset to default. Therefore all safety-relevant parameters must be checked or readjusted. VEGABAR 81 • 4 … 20 mA/HART...

-

Page 37: Set Up With The Display And Adjustment Module

The display and adjustment module is powered by the sensor, an ad- ditional connection is not necessary. Fig. 33: Installing the display and adjustment module in the electronics compart- ment of the single chamber housing VEGABAR 81 • 4 … 20 mA/HART... -

Page 38: Adjustment System

– Move to the menu overview – Confirm selected menu – Edit parameter – Save value • [->] key: – Change measured value presentation – Select list entry – Select menu items – Select editing position • [+] key: VEGABAR 81 • 4 … 20 mA/HART... -

Page 39: Measured Value Indication

[OK] will not be saved. Measured value indication Measured value indica- With the [->] key you can move between three different indication tion modes. In the first view, the selected measured value is displayed in large digits. In the second view, the selected measured value and a respective bargraph presentation are displayed. VEGABAR 81 • 4 … 20 mA/HART... -

Page 40: Parameter Adjustment

If possible, go through the items in the given sequence. The submenu points are described below. Operating sequence A parameter change with SIL qualified instruments must always be carried out as follows: • Unlock adjustment • Change parameters VEGABAR 81 • 4 … 20 mA/HART... - Page 41 In this menu item you activate/deactivate the Secondary Device for electronic differential pressure and select the application. VEGABAR 81 can be used for process pressure and level measure- ment. The setting in the delivery status is process pressure measure- ment. The mode can be changed in this adjustment menu.

- Page 42 With relative pressure measuring cells a manual offset can also be carried out. Note: If the current measured value is automatically accepted, it must not be falsified by medium coverage or static pressure. With the manual position correction, the offset value can be deter- mined by the user. Select for this purpose the function " Edit" and enter the requested value. VEGABAR 81 • 4 … 20 mA/HART...

- Page 43 Adjustment VEGABAR 81 always measures pressure independently of the pro- cess variable selected in the menu item " Application". To output the selected process variable correctly, an allocation of the output signal to 0 % and 100 % must be carried out (adjustment).

- Page 44 If the adjustment ranges are exceeded, the message " Outside parameter limits" appears. The editing procedure can be aborted with [ESC] or the displayed limit value can be accepted with [OK]. The span adjustment is finished. VEGABAR 81 • 4 … 20 mA/HART...

- Page 45 5. Save settings with [OK] The max. adjustment is finished. For an adjustment with filling, simply enter the actual measured value indicated at the bottom of the display. Damping To damp process-dependent measured value fluctuations, set an integration time of 0 … 999 s in this menu item. The increment is 0.1 s. The set damping is effective for level and process pressure measure- ment as well as for all applications of electronic differential pressure measurement. VEGABAR 81 • 4 … 20 mA/HART...

- Page 46 The default setting is output characteristics 4 … 20 mA, fault mode < 3.6 mA. The device assumes an approximately constant temperature and static pressure and converts the differential pressure into the flow rate via the characteristic curve extracted by root. VEGABAR 81 • 4 … 20 mA/HART...

- Page 47 3. Serial number acknowledgement Afterwards you confirm that the serial number of your instrument was carried over correctly. This is used to check device communication. 4. Verify parameters All safety-relevant parameters must be verified after a change: • SIL parameter 1: Zero adjustment • SIL parameter 2: Secondary on/off • Non-SIL parameter 1: Measured value presentation VEGABAR 81 • 4 … 20 mA/HART...

- Page 48 Otherwise the instrument remains in the released and hence unsafe condition. Information: As long as the VEGABAR 81 is powered, the display and adjustment module remains in the actually set adjustment menu. An automatic, time-controlled reset to the measured value indication is not carried out.

- Page 49 Peak value, temperature The respective min. and max. measured values of the measuring cell and the electronics temperature are stored in the sensor. In menu item " Peak value, temperature", both values are displayed. VEGABAR 81 • 4 … 20 mA/HART...

- Page 50 7.4.4 Additional adjustments Reset After a reset, certain parameter adjustments made by the user are reset. The following reset functions are available: Delivery status: Restores the parameter settings at the time of shipment from the factory, incl. the order-specific settings. Any user- defined linearisation curve as well as the measured value memory are deleted. VEGABAR 81 • 4 … 20 mA/HART...

- Page 51 The following descriptions apply to both current outputs. The additional current output cannot be used as an output in the sense of a safety-instrumented application (SIL). VEGABAR 81 • 4 … 20 mA/HART...

- Page 52 Device name In this menu item, you can read out the instrument name and the instrument serial number: Instrument version In this menu item, the hardware and software version of the sensor is displayed. VEGABAR 81 • 4 … 20 mA/HART...

-

Page 53: Menu Overview

(with nominal measuring ranges ≥ 1 bar) Temperature unit (°C, °F) °C Position correction (SIL) 0.00 bar Adjustment (SIL) Zero/Min. adjustment 0.00 bar 0.00 % Span/Max. adjustment Nominal measuring range in bar 100.00 % Damping (SIL) Integration time VEGABAR 81 • 4 … 20 mA/HART... - Page 54 Copy instrument settings Read from sensor, write into sensor No reset Scaling Scaling size Volume in l Scaling format 0 % corresponds to 0 l 100 % corresponds to 0 l Without decimal positions VEGABAR 81 • 4 … 20 mA/HART...

-

Page 55: Save Parameter Adjustment Data

In the display and adjust- If the instrument is equipped with a display and adjustment module, ment module the parameter adjustment data can be saved therein. The procedure is described in menu item " Copy device settings". VEGABAR 81 • 4 … 20 mA/HART... -

Page 56: Setup With Pactware

Note: With power supply units with integrated HART resistance (internal resistance approx. 250 Ω), an additional external resistance is not necessary. This applies, e.g. to the VEGA instruments VEGATRENN 149A, VEGAMET 381, VEGAMET 391. Common Ex separators are also usually equipped with a sufficient current limiting resistance. In such cases, the interface adapter can be connected parallel to the 4 …... - Page 57 The standard version is available as a download under www.vega.com/downloads and " Software". The full version is avail- able on CD from the agency serving you. VEGABAR 81 • 4 … 20 mA/HART...

-

Page 58: Save Parameter Adjustment Data

8 Setup with PACTware Save parameter adjustment data We recommend documenting or saving the parameterisation data via PACTware. That way the data are available for multiple use or service purposes. VEGABAR 81 • 4 … 20 mA/HART... -

Page 59: Set Up With Other Systems

They can then be transferred to a Field Communicator. In the HART communication, the Universal Commands and a part of the Common Practice Commands are supported. VEGABAR 81 • 4 … 20 mA/HART... -

Page 60: Diagnosis, Asset Management And Service

10 s, with electronic differential pressure also the static pressure. The requested values and recording conditions are set via a PC with PACTware/DTM or the control system with EDD. Data are thus read out and also reset. VEGABAR 81 • 4 … 20 mA/HART... -

Page 61: Asset Management Function

The instrument is being worked on, the measured value is temporarily invalid (for example during simulation). This status message is active by default. It can be deactivated by the user via PACTware/DTM or EDD. Out of specification: The measured value is unreliable because an instrument specification was exceeded (e.g. electronics temperature). VEGABAR 81 • 4 … 20 mA/HART... - Page 62 Error in the calibration carried Exchanging the electronics Byte 4, Bit 0 of out in the factory Byte 0 … 5 Error in the calibration Send instrument for repair Error in the EEPROM VEGABAR 81 • 4 … 20 mA/HART...

- Page 63 S605 Measured process pressure be- Check nominal measuring range low or above the adjustment of the instrument Impermissible pressure range value If necessary, use an instrument with a higher measuring range VEGABAR 81 • 4 … 20 mA/HART...

-

Page 64: Rectify Faults

Operating voltage too low, load resist- Check, adapt if necessary ance too high Current signal greater than Sensor electronics defective Replace device or send in for repair de- 22 mA, less than 3.6 mA pending on device version VEGABAR 81 • 4 … 20 mA/HART... -

Page 65: Exchanging The Electronics Module

24 hour service hotline Should these measures not be successful, please call in urgent cases the VEGA service hotline under the phone no. +49 1805 858550. The hotline is also available outside normal working hours, seven days a week around the clock. -

Page 66: Software Update

10 Diagnosis, asset management and service Fig. 42: VEGABAR 81 in IP68 version, 25 bar and lateral cable outlet, external housing Process module Plug connector Fixing screw Cable assembly Connection cable External housing 3. Loosen the plug connector 4. Mount the new process module on the measuring point 5. -

Page 67: How To Proceed If A Repair Is Necessary

• Attach the completed form and, if need be, also a safety data sheet outside on the packaging • Ask the agency serving you to get the address for the return ship- ment. You can find the agency on our homepage. VEGABAR 81 • 4 … 20 mA/HART... -

Page 68: Dismount

If personal data is stored on the old device to be disposed of, delete it before disposal. If you have no way to dispose of the old instrument properly, please contact us concerning return and disposal. VEGABAR 81 • 4 … 20 mA/HART... -

Page 69: Supplement

Glass with Aluminium and stainless steel precision casting and Ex d housing Only for 316L with 3A approval Glass with Aluminium and stainless steel precision casting housing Between transmitter and external electronics housing. VEGABAR 81 • 4 … 20 mA/HART... - Page 70 -1 … 0 bar/-100 … 0 kPa +3 bar/+300 kPa -1 bar/-100 kPa -1 … +1.5 bar/-100 … +150 kPa +7.5 bar/+750 kPa -1 bar/-100 kPa Fix connected to the sensor. Data on overload capability apply for reference temperature. VEGABAR 81 • 4 … 20 mA/HART...

- Page 71 Starting current (for run-up time) ≤ 3.6 mA Output variable For details on the operating voltage see chapter "Voltage supply" Output signal 4 … 20 mA/HART Range of the output signal 3.8 … 20.5 mA/HART (default setting) VEGABAR 81 • 4 … 20 mA/HART...

- Page 72 Damping (63 % of the input variable), 0 … 999 s adjustable Dynamic behaviour output Dynamic characteristics depending on medium and temperature Last measured value not possible with SIL. The output values can be assigned individually. VEGABAR 81 • 4 … 20 mA/HART...

- Page 73 860 … 1060 mbar/86 … 106 kPa (12.5 … 15.4 psi) Determination of characteristics Limit point adjustment according to IEC 61298-2 Characteristic curve Linear Reference installation position upright, diaphragm points downward Influence of the installation position depending on the chemical seal version VEGABAR 81 • 4 … 20 mA/HART...

- Page 74 The actual values depend on the diameter, material and strength of the diaphragm as well as the isolating liquid. They are available on request. Temperature coefficient of the chemical seal in mbar/10 K with Ʋ Flange DN 50 PN 40, Form C, 1.2 mbar/10 K DIN 2501 VEGABAR 81 • 4 … 20 mA/HART...

- Page 75 -40 … +250 °C (-40 … +482 °F) with capillaries Silicone oil KN 17 with cooling element -90 … +200 °C (-130 … +392 °F with capillaries Depending on which chemical seal is used, the values can also be higher. VEGABAR 81 • 4 … 20 mA/HART...

- Page 76 0.5 g at 5 … 200 Hz according to EN 60068-2-6 (vibra- metal housing tion with resonance) Shock resistance Ʋ Standard versions 50 g, 2.3 ms according to EN 60068-2-27 (mechanical shock) no vacuum Depending on the instrument version. VEGABAR 81 • 4 … 20 mA/HART...

- Page 77 180 m (590.5 ft) Ʋ Min. bending radius at 25 °C/77 °F 25 mm (0.985 in) Ʋ Diameter approx. 8 mm (0.315 in) IP66/IP68 (0.2 bar), only with absolute pressure. Breather capillaries not with Ex-d version. VEGABAR 81 • 4 … 20 mA/HART...

- Page 78 12 V DC (9.6 V < U < 14 V) ≤ 0.7 V (16 … 400 Hz) Ʋ for U 24 V DC (18 V < U < 35 V) ≤ 1.0 V (16 … 400 Hz) VEGABAR 81 • 4 … 20 mA/HART...

-

Page 79: Chemical Seal With Vacuum Applications

A chemical seal is closed to the medium with a metallic diaphragm. The inner space between the diaphragm and the sensor element is completely filled with a pressure transmission fluid. Galvanic separation between electronics and metal housing parts Protection rating IP66/IP68 (0.2 bar) only in conjunction with absolute pressure. When used with fulfilled housing protection. VEGABAR 81 • 4 … 20 mA/HART... - Page 80 To extend the area of application, we offer a so-called vacuum service as an option. The following graphics show typical areas of application for different pressure transmission liquids. The characteristic curves are exemplary and can also deviate depending on the process fitting and diaphragm material. mbar 1000 -100 T °C Fig. 46: Area of application for silicone oil VE 2.2, KN 2.2 Standard chemical seal Chemical seal with vacuum service VEGABAR 81 • 4 … 20 mA/HART...

- Page 81 12 Supplement mbar 1000 -100 T °C Fig. 47: Area of application for silicone oil KN 17 Standard chemical seal Chemical seal with vacuum service mbar 1000 -100 T °C Fig. 48: Area of application for high temperature oil VE 32, KN 32 Standard chemical seal Chemical seal with vacuum service VEGABAR 81 • 4 … 20 mA/HART...

- Page 82 12 Supplement mbar 1000 -100 T °C Fig. 49: Area of application for Halocarbon oil KN 21 Standard chemical seal Chemical seal with vacuum service mbar 1000 -100 T °C Fig. 50: Application area for medical white oil KN 92 Standard chemical seal Chemical seal with vacuum service VEGABAR 81 • 4 … 20 mA/HART...

-

Page 83: Dimensions

Chemical seal with vacuum service 12.3 Dimensions The following dimensional drawings represent only an extract of the possible versions. Detailed dimensional drawings can be downloaded at www.vega.com under " Downloads" and " Drawings". Plastic housing ~ 69 mm ~ 84 mm (2.72") - Page 84 Aluminium housing with protection rating IP66/IP68 (1 bar) ~ 105 mm ~ 150 mm (4.13") (5.91") ø 86 mm ø 86 mm (3.39") (3.39") M16x1,5 M20x1,5 M20x1,5 M20x1,5/ ½ NPT Fig. 54: Housing version with protection rating IP66/IP68 (1 bar), (with integrated display and adjustment module the housing is 18 mm/0.71 in higher) Aluminium - single chamber Aluminium - double chamber VEGABAR 81 • 4 … 20 mA/HART...

- Page 85 ø 84 mm (3.31") (3.31") (3.03") M16x1,5 M20x1,5 M20x1,5 M20x1,5 M20x1,5/ ½ NPT Fig. 56: Housing versions in protection rating IP66/IP68 (1 bar), (with integrated display and adjustment module the housing is 9 mm/0.35 in or 18 mm/0.71 in higher) Stainless steel single chamber (electropolished) Stainless steel single chamber (precision casting) Stainless steel double chamber housing (precision casting) VEGABAR 81 • 4 … 20 mA/HART...

- Page 86 12 Supplement Stainless steel housing with protection rating IP69K ~ 59 mm (2.3") ø 80 mm (3.15") M20x1,5/ ½ NPT Fig. 57: Housing version with protection rating IP69K (with integrated display and adjustment module the housing is 9 mm/0.35 in higher) Stainless steel single chamber (electropolished) VEGABAR 81 • 4 … 20 mA/HART...

- Page 87 8 mm (0.12") (0.32") 110 mm x 90 mm (4.33" x 3.54") Fig. 58: VEGABAR 81, IP68 version with external housing Lateral cable outlet Axial cable outlet Plastic single chamber Stainless steel single chamber Seal 2 mm (0.079 in), (only with 3A approval)

- Page 88 (2.17") G1½ ø 39 mm (1.54") ø 60 mm (2.36") Fig. 59: VEGABAR 81, threaded fitting GE G½ A outside PN 160, ISO 228-1; diaphragm: inside; > 105 °C with temperature adapter GK G¾ A outside PN 600, DIN 3852-E; diaphragm: front-flush GL G1 A outside PN 600, ISO 228-1; diaphragm: front-flush GN G1½ PN 600, DIN 3852-A; diaphragm: front-flush VEGABAR 81 • 4 … 20 mA/HART...

- Page 89 Rd78x " 6.14" 1.97" RD44x " inch RD44x " 4.09" 0.79" Fig. 60: VEGABAR 81, tube isolating diaphragm Tube isolating diaphragm for mounting between flanges Tube isolating diaphragm according to DIN 11851 Tube isolating diaphragm according to DIN 11864-1 VEGABAR 81 • 4 … 20 mA/HART...

- Page 90 4 x ø16 2" 19,5 120,7 4 x ø19 2" 19,5 120,7 4 x ø20 48,3 4 x ø19 3" 24,3 152,4 Fig. 61: VEGABAR 81, flange connection, dimensions in mm Flange connection according to DIN 2501 Flange connection according to ASME B16.5 Order-specific Diaphragm diameter VEGABAR 81 • 4 … 20 mA/HART...

- Page 91 0.08" 2" 5.91" 0.77" 4.75" 4 x ø0.79" 3.62" 0.08" 2" 1.9" 1.85" 4 x ø0.75" 3" 7.48" 0.96" 6" 5" 0.08" Fig. 62: VEGABAR 81, flange connection, dimensions in inch Flange connection according to DIN 2501 Flange connection according to ASME B16.5 Order-specific Diaphragm diameter VEGABAR 81 • 4 … 20 mA/HART...

- Page 92 6.5" 0.79" 4.02" 4.92" 0.71" 2.32" 16..100 0.79" 4.02" 2.32" 7.87" 0.79" 5.43" 0.71" 3.5" 16..100 6.3" 0.79" 3.5" 5.43" Fig. 63: VEGABAR 81, flange and cell isolating diaphragm with capillary line Flange isolating diaphragm with capillary line Cell isolating diaphragm with capillary line VEGABAR 81 • 4 … 20 mA/HART...

-

Page 93: Industrial Property Rights

Les lignes de produits VEGA sont globalement protégées par des droits de propriété intellec- tuelle. Pour plus d'informations, on pourra se référer au site www.vega.com. VEGA lineas de productos están protegidas por los derechos en el campo de la propiedad indus- trial. Para mayor información revise la pagina web www.vega.com. - Page 94 Simulation 50 Fault rectification 64 Grounding 23 HART – Mode 52 Linearisation 46 Maintenance 60 Measured value memory 60 Measurement setup 19, 20, 21 Measuring system 11 NAMUR NE 107 61 – Function check 63 VEGABAR 81 • 4 … 20 mA/HART...

- Page 95 Notes VEGABAR 81 • 4 … 20 mA/HART...

- Page 96 Subject to change without prior notice © VEGA Grieshaber KG, Schiltach/Germany 2022 VEGA Grieshaber KG Am Hohenstein 113 Phone +49 7836 50-0 77761 Schiltach E-mail: info.de@vega.com...

Need help?

Do you have a question about the VEGABAR 81 and is the answer not in the manual?

Questions and answers