Autonics AiSA-D Series User Manual

Closed-loop stepper system

Hide thumbs

Also See for AiSA-D Series:

- Manual (10 pages) ,

- Manual (12 pages) ,

- Product manual (6 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Autonics AiSA-D Series

- Page 1 Closed-Loop Stepper System AiSA-D Series MMD-AiSAU1-V1.0-2008US Thank you for purchasing an Autonics product. This usere manual contains information about the product and its propoer use, and should be kept in a place where it will be easy to access. www.autonics.com...

-

Page 3: Preface

Preface Preface Thank you for purchasing Autonics product. Please familiarize yourself with the information contained in the Safety Considerations section before using this product. This manual contains information about the product and its proper use, and should be kept in a place where it will be easy to access. -

Page 4: User Manual Guide

The manual's content may vary depending on changes to the product's software and other unforeseen developments within Autonics, and is subject to change without prior notice. Upgrade notice is provided through out the website. We contrived to describe this manual more easily and correctly. However, if there are any ... -

Page 5: User Manual Symbols

Failure to follow instructions can result in serious injury or death. Failure to follow instructions can lead to a minor injury or product damage. An example of the concerned feature's use. ※1 Annotation mark. © Copyright Reserved Autonics Co., Ltd. -

Page 6: Safety Considerations

Do not remove the connector during or after operation for a while. Failure to follow this instruction may result in electric shock or product damage. Emergency stop directly when error occurs. Failure to follow this instruction may result in personal injury or fire. © Copyright Reserved Autonics Co., Ltd. - Page 7 The above specifications, dimensions, etc. are subject to change and some models may be discontinued without notice. Be sure to follow cautions written in the instruction manual, user manual and the technical descriptions (catalog, website). © Copyright Reserved Autonics Co., Ltd.

-

Page 8: Cautions During Use

This product does not prepare protection function for a motor. This unit may be used in the following environments. ① Indoors (in the environment condition rated in ‘Specifications’) ② Altitude max. 2,000m ③ Pollution degree 2 ④ Installation Category II viii © Copyright Reserved Autonics Co., Ltd. -

Page 9: Table Of Contents

Mounting Direction of Motor ..............26 4.2.2 Mounting of Motor ..................27 4.2.3 Connection with Load................28 4.2.4 Installation Conditions ................29 Connection ....................30 Characteristics ..................31 Frame Size 60 mm ................... 31 Frame Size 86mm .................... 31 © Copyright Reserved Autonics Co., Ltd. -

Page 10: Table Of Contents

10.1.2 Torque Mode Drive ..................53 10.2 Other Functions ....................54 10.2.1 Motor GAIN ....................54 10.2.2 Speed Filter ....................55 10.2.3 In-Position ....................56 Protection Function ................57 11.1 Alarm .........................57 Troubleshooting ..................60 © Copyright Reserved Autonics Co., Ltd. -

Page 11: Product Overview

Product Overview Features AiSA-D series AC type 2-phase closed loop steper motor drivers offer accurate and precise position control through feedback from the integrated encoder without the hassle of tuning and vibration of conventional servo motors. The encoder feedback provides information of the current position in reference to the input pulse with a high resolution of 10,000 pulses per revoluion, allowing precise and accurate position control down to 0.036°. -

Page 12: Components And Configuration Diagram

● Brake connector Make sure all of the above components are included with your product package before use. If a component is missing or damaged, please contact Autonics orthe product distributor. ※ I/O cable, motor+encoder cable and power cable are sold separately. -

Page 13: Configuration Diagram

※ In case of unwanted noise generating from peripherals and power, use ferrite core in the wiring. ※ is sold separately. ※ I/O cable, motor+encoder cable and pwer calbe are sold separately. For more information, refer to ‘7.5 Sold Separately’. © Copyright Reserved Autonics Co., Ltd. - Page 14 It may result in product damage. Noise filter for signal line Connect to wiring to suppress external noise. - Depending on frequency, filtered noise may different. Applications Specifications Manufacture Motor wire 28A5776-0A2 Lairdtech Power wire 28A5131-0A2 © Copyright Reserved Autonics Co., Ltd.

-

Page 15: Ordering Information

Middle ‒ Frame size 60mm: 48mm Frame size: 86mm: 60mm) ⑥ Motor axial length Long ‒ Frame size 60mm: 69mm Frame size: 86mm: 75mm) ⑦ Encoder resolution 10,000PPR (2,500PPRⅹ4-multiply) No mark Standard type ⑧ Brake Built-in brake type © Copyright Reserved Autonics Co., Ltd. -

Page 16: Models

Standard type Driver Motor AiSA-60MA AiSA-D-60MA AiA-M-60MA AiSA-60LA AiSA-D-60LA AiA-M-60LA AiSA-86MA AiSA-D-86MA AiA-M-86MA AiSA-86LA AiSA-D-86LA AiA-M-86LA 1.4.2 Built-in Brake Type Driver Motor AiSA-60MA-B AiSA-D-60MA-B AiA-M-60MA-B AiSA-60LA-B AiSA-D-60LA-B AiA-M-60LA-B AiSA-86MA-B AiSA-D-86MA-B AiA-M-86MA-B AiSA-86LA-B AiSA-D-86LA-B AiA-M-86LA-B © Copyright Reserved Autonics Co., Ltd. -

Page 17: Specifications

In-Position, brake Input resistance 4.7 kΩ (Anode Pull-up) Insulation resistance Over 200 MΩ (500 VDCᜡ megger) Dielectric strength 1,500 VACᜠ 60 Hz for 1 min © Copyright Reserved Autonics Co., Ltd. -

Page 18: Factory Default

Factory default OFF (CW) 1P/2P OFF (2-Pulse input) Function selection DIP switch GS H/L OFF (Standard GAIN) OFF (Standard mode) Resolution 0 (500 PPR) Speed filter 0 (disable) Motor GAIN 0 (Standard×1) In-Position 0 (0) © Copyright Reserved Autonics Co., Ltd. -

Page 19: Motor

※2: Max. holding torque is standard torque when supplying the rated current (2-phase holding) and stopping the motor for comparing the specifications of motors. ※3: The weight includes packaging. The weight in parenthesis is for unit only. © Copyright Reserved Autonics Co., Ltd. -

Page 20: Common Specifications

※3: Amount of radial shaft displacement when adding a radial load (25N) to the tip of the motor shaft. ※4: Amount of axial shaft displacement when adding a axial load (50N) to the shaft. ※Environment resistance is rated at no freezing or condensation. © Copyright Reserved Autonics Co., Ltd. -

Page 21: Encoder

(12 × 10 kg·m Insulation class B type (130 ℃) B type brake Power ON: brake is released, Power OFF: brake is locked Operating time 30 ms 40 ms Releasing time 10 ms 25 ms © Copyright Reserved Autonics Co., Ltd. -

Page 22: Dimensions

3 Dimensions Dimensions Driver (Unit: mm) 3.1.1 Panel Cut-out Be sure that these figures may differ from the actual units. © Copyright Reserved Autonics Co., Ltd. -

Page 23: Motor

3 Dimensions Motor 3.2.1 Standard Type 3.2.1.1 Frame Size 60 mm 3.2.1.2 Frame Size 86 mm Model Model AiA-M-60MA 81.2 AiA-M-86MA 93.3 AiA-M-60LA 102.1 AiA-M-86LA 107.8 © Copyright Reserved Autonics Co., Ltd. -

Page 24: Built-In Brake Type

3 Dimensions 3.2.2 Built-in Brake Type 3.2.2.1 Frame Size 60 mm 3.2.2.2 Frame Size 86 mm Model Model AiA-M-60MA-B 117.8 AiA-M-86MA-B 134.8 AiA-M-60LA-B 138.8 AiA-M-86LA-B 148.8 © Copyright Reserved Autonics Co., Ltd. -

Page 25: Installation

Check the environment of use within the rated specifications and install on the well-heat dissipated area. ※ In case of installing the drivers more than two, keep distance at least 20 mm in the horizontal direction and at least 25 mm in the vertical direction. © Copyright Reserved Autonics Co., Ltd. -

Page 26: Installation Of Motor

Do not apply excessive force on motor cable when mounting motors. Do not forcibly pull or insert the cable. It may cause poor connection or disconnection of the cable. In case of frequent cable movement required application, proper safety countermeasures must be ensured. © Copyright Reserved Autonics Co., Ltd. -

Page 27: Mounting Of Motor

When mounting motors, use hexagon socket screws, spring washers and flat washers. Do not draw the wire with over strength 30 N after wiring the encoder. © Copyright Reserved Autonics Co., Ltd. -

Page 28: Connection With Load

4.2.3.1 Direct Load Connection with Coupling ※ Use Autonics flexible coupling (ERB Series) When connecting a load such as Ball screw or Tm screw directly to the shaft of the motor, use flexible coupling as image showing above. -

Page 29: Installation Conditions

The place with less salt content ⑫ The place with less electronic noise occurs by welding machine, motor, etc. ⑬ The place where radioactive substances and magnetic fields does not exist and is not in the vacuum status © Copyright Reserved Autonics Co., Ltd. -

Page 30: Connection

5 Connection Connection ※1. Corresponding connector is for built-in brake type only. © Copyright Reserved Autonics Co., Ltd. -

Page 31: Characteristics

6 Characteristics Characteristics Frame Size 60 mm Frame Size 86mm © Copyright Reserved Autonics Co., Ltd. -

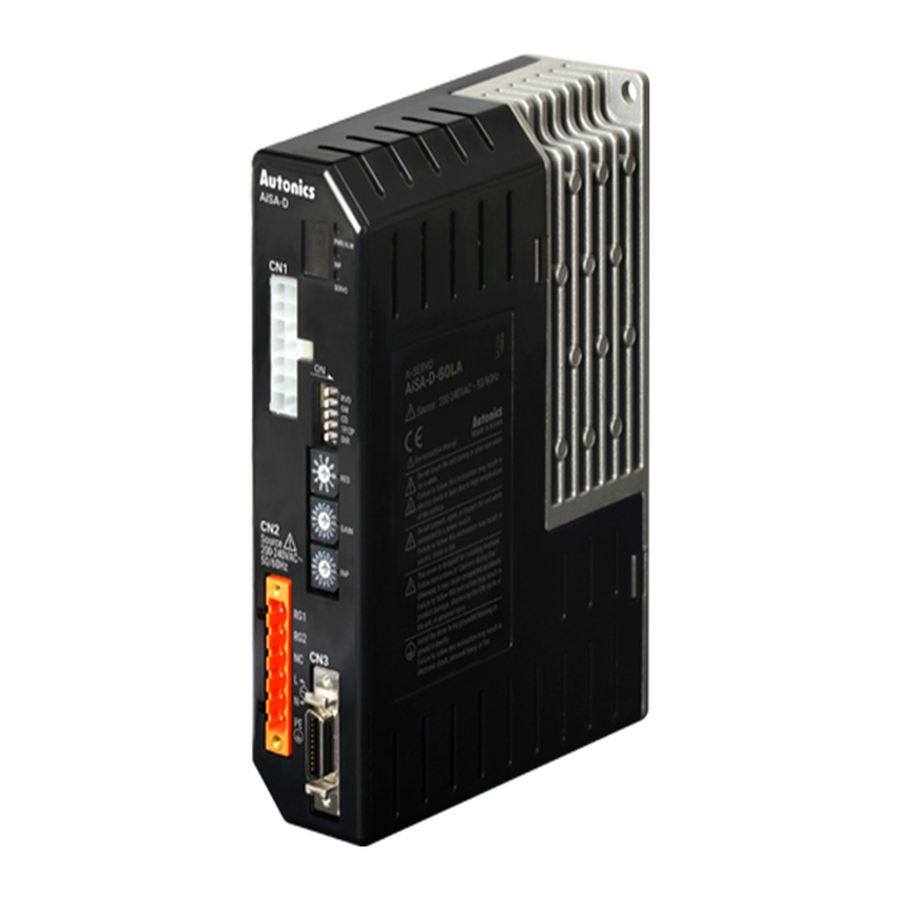

Page 32: Driver Unit Descriptions

8. Speed filter/limit setting rotary switch (S.F) 9. In-Position setting rotary switch (INP) 10. Motor+encoder connector (CN1) 11. Power connector (CN2) 12. I/O connector (CN3) 13. Brake connector (CN4) ※1 ※1: Corresponding connector is for built-in brake type only. © Copyright Reserved Autonics Co., Ltd. -

Page 33: Driver Status Indicator

Turns ON when motor is placed at command In-Position INP. Orange position after positioning input. Turns OFF in indicator torque mode. Servo On/Off Turns ON when servo is operating, SERVO Blue indicator turns OFF when servo is not operating. © Copyright Reserved Autonics Co., Ltd. -

Page 34: Switches

Set the resolution of driver. Setting Resolution Setting Resolution 3600 1000 5000 1600 6400 2000 7200 3200 10000 Modified setting values are not applied in the running status and the values will be applied after motor stopped. © Copyright Reserved Autonics Co., Ltd. -

Page 35: Motor Gain Setting Rotary Switch

It determines the responsiveness of the motor to the command and smoothly follows the speed even if the load changes or disturbance occurs. For more information, refer to ‘10.2.2 Speed Filter’. © Copyright Reserved Autonics Co., Ltd. -

Page 36: In-Position Setting Rotary Switch

After position commad pulse has finished, if the gap between target position and real position is under. In-Position setting value, positioning completion pulse is outpu. Modified setting values are not applied in the running status, and the values will be aapplied after motor stipped. © Copyright Reserved Autonics Co., Ltd. - Page 37 7 Driver Unit Descriptions For more information, refer to ‘10.2.3 In-Position’. © Copyright Reserved Autonics Co., Ltd.

-

Page 38: Connectors

Encoder Z � Encoder Z N·C Motor A Motor B Motor A � Motor B � 7.3.2 CN2: Power Connector Connects with 200-240VACᜠ power. Pin no. Function Connect regenerative resistance N·C AC power input © Copyright Reserved Autonics Co., Ltd. -

Page 39: Cn3: I/O Connector

Brake + Brake - Connector Specifications Specifications Type Manufacture Connector Connector Housing terminal Motor+Encoder 5557-14R 5556T Molex Power 5ESDVM-06P-OR Dinkle I/O connector 10120-3000PE 10320-52F0-008 Brake connector ESC250V-S2330704P Dinkle Above connectors are suitable for AiSA-D Series. © Copyright Reserved Autonics Co., Ltd. -

Page 40: Sold Separately

E.g.) CO20-MP070-R: 7m I/O cable 7.5.2 Motor+Encoder Cable (Normal: C1D14M-□/Moving: C1DF14M-□) □ of model name indicates the cable length (1, 2, 3, 5, 7, 10, 15, 20). E.g.) C1DF14M-10: 10m moving type motor+encoder cable © Copyright Reserved Autonics Co., Ltd. -

Page 41: Electromagnetic Brake

In case of using auxiliary power supply for electromagnetic brake, do not mix the power with the power supply for I/O signals. Failure to follow this instruction may result in electromagnetic brake damage or malfunction due to outer disturbnace. © Copyright Reserved Autonics Co., Ltd. -

Page 42: Brake Connection

Brake error (ED) alarm occurs. For more information, refer to ‘11.1 Alarm’. When Servo is On, brake is released automatically. The brake remains lock inn all status except Servo On status. ※ Brake lock is manually controllable using the Brake ON/OFF input signal. © Copyright Reserved Autonics Co., Ltd. -

Page 43: Control Input/Output

(1) Differential Line Driver (2) Open Collector 9.1.1.2 External Input (Servo On/Off, Alarm Reset) Use external power (VEX) 24 VDCᜡ in external input Servo On/Off and Alarm Reset. (1) PNP Circuit (2) NPN Circuit © Copyright Reserved Autonics Co., Ltd. -

Page 44: Exclusive Input

Signal Descriptions CW + Rotates CW direction CW - CCW + Rotates CCW direction CCW - Servo On/Off + Releases motor torque manually Servo On/Off - Alarm Reset + Alarm reset Alarm Reset - © Copyright Reserved Autonics Co., Ltd. - Page 45 Rotate to CCW direction OFF (CW) Increase position when position Decrease position when position setting setting Rotate to CCW direction Rotate to CW direction ON (CCW) Decrease position when position Increase position when position setting setting © Copyright Reserved Autonics Co., Ltd.

- Page 46 CCW: reverse rotation signal input [H]: photocoupler ON (voltage of both ends 4-8VDCᜡ) [L]: photocoupler OFF (voltage of both ends 0-0.5VDCᜡ) ※ Use noise filter for signal line to avoid disturbance when using extension cable. © Copyright Reserved Autonics Co., Ltd.

- Page 47 : Regarded as Servo On signal and phase current is supplied to gain torque. The Servo On indicator, the In-Position output and indicator turns ON. For the safety reason, this is not available while motor is in operation. Must use when the motor is completely stopped. © Copyright Reserved Autonics Co., Ltd.

- Page 48 : alarm is reset and the alarm indicator and alarm output turns OFF. The driver returns to normal status. If alarm causes are not removed, the diver does not return to normal status. © Copyright Reserved Autonics Co., Ltd.

-

Page 49: Output

100 to 150 Ω in parallel to both ends (A, A � , B, B � , Z, Z � ) Connect the terminal resistance R of each phase of encoder. (1) Differential line driver © Copyright Reserved Autonics Co., Ltd. -

Page 50: Exclusive Output

Signal Descriptions Alarm Out + Alarm output Alarm Out - In-Position + In-Position output In-Position - Encoder A Encoder A � Encoder B Encoder B � Encoder signal output Encoder Z Encoder Z � © Copyright Reserved Autonics Co., Ltd. - Page 51 The signal outputs depending on the set In-Position value For more information, refer to ‘10.2.3 In-Position’. Encoder A, A � , B, B � , Z, Z � 9.2.2.3 Encoder signals output in each differential line driver. © Copyright Reserved Autonics Co., Ltd.

-

Page 52: Driver Function

Make sure to use absolute position mode (ABS) in torque mode when input pulse. The current torque size can be checked through the alarm/status display part. Alarm/Status Torque size (%) display part · · · © Copyright Reserved Autonics Co., Ltd. -

Page 53: Torque Mode Drive

6th Torque setting: Select the torque size by entering position value 0 to 100. If the position value is 10, the torque size is controlled at 10%. Select to rotate the motor in the desired direction. For more detailed connection information, refer to ‘PMC user manual’ and ‘atMotion user manual’. © Copyright Reserved Autonics Co., Ltd. -

Page 54: Other Functions

×15 ×7 ×15 ×8 ×16 ×8 ×16 Rasie the GAIN value until the motor vibrates at the lowest load of the system and then set the GAIN value to 1 to 2 steps lower. © Copyright Reserved Autonics Co., Ltd. -

Page 55: Speed Filter

It is available to set motor drive response according to the swtich setting. Set the speed filter value for time delay between the command position and motor. It is able to drive softly even though load changing or disturbnace occurs. Setting Value (ms) Disable © Copyright Reserved Autonics Co., Ltd. -

Page 56: In-Position

Fast Response Accurate Response Setting Value Setting Value ±1 ±1 ±2 ±2 ±3 ±3 ±4 ±4 ±5 ±5 ±6 ±6 ±7 ±7 For accurate control, check the in-position output before the next drive. © Copyright Reserved Autonics Co., Ltd. -

Page 57: Protection Function

When alarm occurs, indicators flash with interval of 0.4 sec and turn OFF with interval of 0.8 sec until the alarm is cleared <E.g.: In case of alarm no. 3 > © Copyright Reserved Autonics Co., Ltd. - Page 58 When motor cable connection error cable connection. 6 (E6) connection connection error 2. Burnout of the inverter in the 2. Replace burned parts of the error occurs at driver driver inverter in the driver. © Copyright Reserved Autonics Co., Ltd.

- Page 59 1. Check auxiliary power power applied. When brake failed to 2. Check brake connector and 13 (ED) Brake error 2. Brake connector or cable operate cable connection error 3. Replace brake motor 3. Brake is damaged © Copyright Reserved Autonics Co., Ltd.

-

Page 60: Troubleshooting

Connection between motor and Check the Motor+Encoder connection cable. encoder is unstable. When motor drive is unstable Check motor GAIN setting rotary switch (GAIN) Motor gain value is not correct. value. © Copyright Reserved Autonics Co., Ltd. - Page 61 12 Troubleshooting © Copyright Reserved Autonics Co., Ltd.

- Page 62 * 본 매뉴얼에 기재된 사양, 외형치수 등은 제품의 개선을 위해서 예고 없이 변경되거나 일부 모델이 단종될 수 있습니다.

Need help?

Do you have a question about the AiSA-D Series and is the answer not in the manual?

Questions and answers