Autonics AiSA-D Series Manual

Ac type 2-phase closed-loop stepper motor driver

Hide thumbs

Also See for AiSA-D Series:

- User manual (62 pages) ,

- Manual (12 pages) ,

- Product manual (6 pages)

Table of Contents

Advertisement

Quick Links

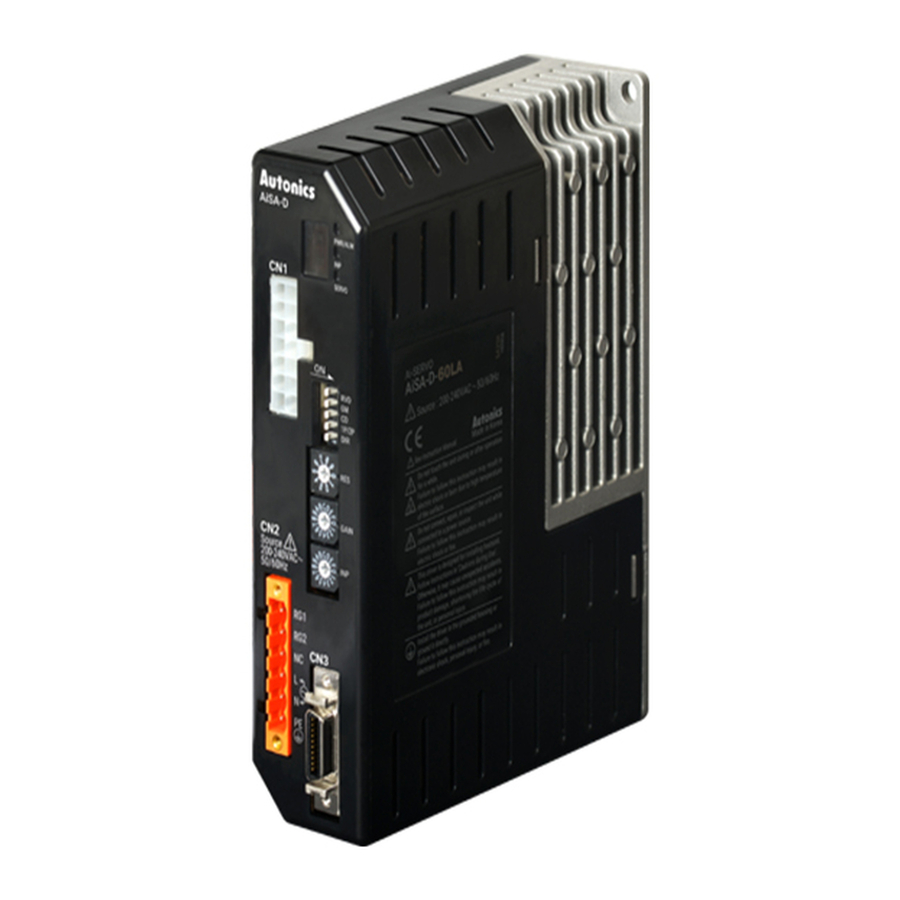

AiSA-D Series

AC Type 2-Phase Closed-Loop Stepper Motor Driver

Features

Higher cost-efficiency compared to servo motor drivers

Alarm/Status display part (7 segment)

Lower driver noise than stepper motor driver

Rapid response which is advantageous for the short distance continuous operation

Able to implement Low frequency operation and high torque in low speed area

Low current drive at middle . high speed area

Max. stop torque at current down mode (available vertical load attaching)

Easy to use as much as unskilled people can use with tuning unnecessary method

(Gain setting with the switch)

Applicable to the precision equipment such as optical inspection equipment with the

features of maintaining torque in stop and having no micro vibration (hunting)

Various resolutions

: 500, 1000, 1600, 2000, 3200, 3600, 5000, 6400, 7200, 10000 (10 steps)

Various alarms output

: overcurrent, over speed, motor connection error, encoder connection error,

and etc., overall 12 types

Frame size 60mm, 86mm supported

Applied motor: AiA-M series

Please read "Safety Considerations" in operation

manual before using.

Applications

Filed requiring preciseness such as semiconductor equipment, 3D printer, Optical inspection equipment, chip mounter,

cartesian robot, conveying equipment, and alignment stage.

Configuration Diagram

200-240VACᜠ

Circuit breaker

Surge protector

(LT-C12G801W)

L3

E

L1

Noise filter

(RNS-2010)

Q-2

Motor+Encoder

cable

(sold separately)

CABLE

AiA-M Series

(motor)

Regenerative

resistance

(IRC100)

Settings of start, stop,

rotation direction, etc.

AiSA-D Series

(motor driver)

PLC

PC & atMotion

PMC Series

(motion controller)

I/O cable

(sold separately)

External I/O

Advertisement

Table of Contents

Summary of Contents for Autonics AiSA-D Series

- Page 1 AiSA-D Series AC Type 2-Phase Closed-Loop Stepper Motor Driver Features Higher cost-efficiency compared to servo motor drivers Alarm/Status display part (7 segment) Lower driver noise than stepper motor driver Rapid response which is advantageous for the short distance continuous operation Able to implement Low frequency operation and high torque in low speed area Low current drive at middle .

-

Page 2: Ordering Information

AC Type 2-Phase Closed-Loop Stepper Motor Driver Ordering Information Photoelectric Sensors Encoder resolution Fiber 10,000PPR (2,500PPR×4-multiply) Optic Motor length Sensors 82.8mm 60 60×60mm Door/Area 103.8mm Motor frame size Sensors 94.9mm 86 86×86mm Proximity 109.4mm Sensors Item Driver Power Pressure AC Power Sensors Category Standard... - Page 3 AiSA-D Series Dimensions (unit: mm) Panel cut-out 2-Ø5.5 2-M5 Driver Unit Descriptions Power/Alarm indicator (green/red) Alarm/Status display part In-Position indicator (orange) Servo On/Off indicator (blue) Motor+Encoder connector (CN1) Function selection DIP switch (SW1) Resolution setting switch (SW2) Motor gain setting switch (SW3)

-

Page 4: Driver Setting

AC Type 2-Phase Closed-Loop Stepper Motor Driver Driver Status Indicators Photoelectric Sensors Indicator & LED color Function Descriptions Display part Green Power indicator Turns ON when the unit operates normally after supplying power Fiber Optic PWR/ALM Sensors When alarm occurs, it flashes in various ways depending on the situation. Alarm indicator Refer to ' Control Input/Output >... - Page 5 AiSA-D Series SW3: Motor gain setting switch - SW3 shifts motor gain between high and low, depending on 4th pin in SW1. Motor gain -Motor gain is selectable from 32 gains. - The larger gain is, the more improved transient response becomes and the less error occurs.

- Page 6 AC Type 2-Phase Closed-Loop Stepper Motor Driver 4. Example of input circuit connection ● Input pulse (CW, CCW) Photoelectric Sensors - It is recommended to use 5VDC at V and short the R -In case V is over 5VDC, calculate R value using following formula and use V below 30VDC.

- Page 7 AiSA-D Series 2. Alarm ● Alarm - This function stops motor to protect driver, depending on the error status such as over current or over speed. -In case of normal status, output is [H], and in case of alarming status, output is [L].

-

Page 8: Sold Separately

10320-52F0-008 Panel CN3 I/O connector Meters CJ-MP20-HP (sold separately) - Autonics ※ Above connectors are suitable for AiSA-D Series. Tacho / Speed / Pulse Meters Sold Separately Display Units ※ It is recommended to use ferrite core at I/O cable and Motor+Encoder cable. - Page 9 AiSA-D Series Connection for Motor and Driver 220Ω CCW+ 220Ω Motor CCW- 10kΩ Encoder Servo On/Off+ Servo On/Off- 10Ω Alarm Out+ Alarm Out- 10kΩ Alarm Reset+ Alarm Reset- 10Ω In-Position+ +5VDC In-Position- N . C N . C N . C...

-

Page 10: Troubleshooting

AC Type 2-Phase Closed-Loop Stepper Motor Driver Options for Power Connector (CN2) Photoelectric Sensors Options Model Specifications Manufacture Resistance: 100Ω ±5%, IRC100 RARA Electronics Corp. Fiber Rated power: 60W(standby), 100W(with heatsink) Regenerative Optic Sensors resistance Used when the load inertia is large or the deceleration time is short. Forced cooling is required when the surface temperature of the regenerative resistor is high.

Need help?

Do you have a question about the AiSA-D Series and is the answer not in the manual?

Questions and answers