Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Lenze SDS Series

- Page 1 BA 13.0011−EN .CD( Operating Instructions SDS.. SDSGS Synchronous servo motors...

- Page 2 Please read these instructions before you start working! Follow the enclosed safety instructions. 0Fig. 0Tab. 0 BA 13.0011−EN 1.0...

-

Page 3: Table Of Contents

Contents About this documentation ..........Document history . - Page 4 Contents Commissioning and operation ..........Important notes .

-

Page 5: About This Documentation

If the information and notes provided in this documentation do not meet your requirements, please refer to the controller and/or gearbox documentation. Tip! Documentation and software updates for further Lenze products can be found on the Internet in the "Services & Downloads" area under http://www.Lenze.com... -

Page 6: Conventions Used

Stator resistance phase Terminology used Term In this text used for Synchronous motor, versions according to product key, ^ 15 Motor Controller Any servo inverter Drive system Drive systems with servo motors and other Lenze drive components BA 13.0011−EN 1.0... -

Page 7: Notes Used

About this documentation Notes used Notes used The following pictographs and signal words are used in this documentation to indicate dangers and important information: Safety instructions Structure of safety instructions: Danger! (characterises the type and severity of danger) Note (describes the danger and gives information about how to prevent dangerous situations) Pictograph and signal word Meaning... -

Page 8: Safety Instructions

ƒ This is vital for a safe and trouble−free operation as well as for achieving the specified product features. Only qualified, skilled personnel is permitted to work on and with Lenze drive ƒ components. According to IEC 60364 / CENELEC HD 384, these are persons who ... - Page 9 Safety instructions General safety instructions for drive components Transport, storage Transport and storage in a dry, low−vibration environment without aggressive ƒ atmosphere; preferably in the packaging provided by the manufacturer. – Protect against dust and shocks – Comply with climatic conditions according to the technical data. Before transport ƒ...

-

Page 10: Application As Directed

Safety instructions Application as directed Application as directed Low−voltage machines are no household appliances, they are designed as components for industrial or professional use in terms of IEC/EN 61000−3−2 only. They comply with the harmonised standards of the series IEC/EN 60034. Low−voltage machines are components for installation into machines as defined in the Machinery Directive 2006/42/EC. -

Page 11: Residual Hazards

Safety instructions Residual hazards Residual hazards Protection of persons Do not use the integrated brakes as fail−safe brakes. It cannot be ruled out that ƒ certain disruptive factors that cannot be influenced such as oil ingress due to a defective shaft sealing ring at the drive end may reduce the braking torque. Motor protection Integrated temperature sensors do not provide full protection for the machine. -

Page 12: Product Description

Product description Identification Nameplate Product description Identification 3.1.1 Nameplate LKA−SDSGS−001.iso BA 13.0011−EN 1.0... - Page 13 Product description Identification Nameplate General information Manufacturer Applicable conformity declarations and approvals Data on the complete drive system Drives Type of drive Inverter data Inverter Voltage / I=I Type of inverter Fieldbus RS232 Input Encoder data Encoder / feedback Encoder voltage Type of encoder Indicated voltage Gearbox data...

- Page 14 Product description Identification Nameplate Gearbox Pos. Contents Manufacturer Gearbox type Manufacturing date Commission number Torque M [Nm] Ratio CE designation Brakes Reference to installed brake Pos. Contents Type / size of brake Voltage [V] DC Electrical power [W] Braking torque [Nm] Material number BA 13.0011−EN 1.0...

-

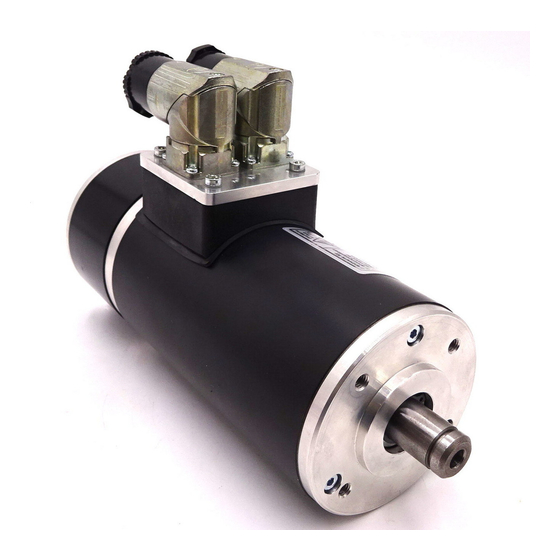

Page 15: Product Key

Product description Identification Product key 3.1.2 Product key LLL − Synchronous servo motors Product key legend Product group Small drives Current type Three−phase AC current Ventilation Self ventilation (cooling by convection and radiation) Design/housing Smooth and round housing Machine type Synchronous machine Built−on accessories Resolver... -

Page 16: Technical Data

Technical data General data and operating conditions General data Technical data General data and operating conditions 4.1.1 General data Conformity and approval Conformity 2006/95/EC Low−Voltage Directive Approvals UL/CSA File no. E210321 Protection of persons and equipment Degree of protection See nameplate Degrees of protection only apply to horizontal installation All unused plug−in connections must be sealed with protective caps or dummy connectors. -

Page 17: Operating Conditions

Technical data General data and operating conditions General data Operating conditions Ambient conditions Climatic Transport IEC/EN 60721−3−2 2K3 (−20 ... +70 °C) Storage IEC/EN 60721−3−1 1K3 (−20 ... +60 °C) < 3 months 1K3 (−20 ... +40 °C) > 3 months Operation IEC/EN 60721−3−3 Without brake −15 °C ... -

Page 18: Dimensions

Technical data Dimensions General data Dimensions Motor type Frame size SDSGSLL 035−22 IEC56C80 SDSGSLL 047−22 IEC56C80 SDSGSLL 047−22 IEC63C90 SDSGSLL 056−22 IEC63C90 SDSGSLL 063−22 IEC71C105 Motor type Frame size Weight approx. SDSGSLL 035−22 IEC56C80 10.2 1.9 − 2.9 SDSGSLL 047−22 IEC56C80 10.2 3.0 −... -

Page 19: Rated Data

The indicated torques and weights are guide values for the selection of the ƒ transmission elements and foundations. The rated data indicated on the nameplate refer to operation with Lenze servo ƒ inverters of the 9300 and 9400 series at an inverter input voltage (mains voltage) of 400 V. -

Page 20: Rated Data

Technical data Rated data General data Rated data SDSGSLL 035−22 Unit Rated voltage [V] AC Rated power Rated frequency [Hz] Rated current 0.56 0.36 Power factor cosj Rated speed [rpm] 3000 3000 3000 3000 3000 Rated torque [Nm] 0.45 0.45 0.45 0.45 0.45... - Page 21 Technical data Rated data General data SDSGSLL 056−22 Unit Rated voltage [V] AC Rated power Rated frequency [Hz] Rated current 12.5 1.93 Power factorcosj Rated speed [rpm] 3000 3000 3000 Rated torque [Nm] Degree of protection 54/55 54/55 54/55 Thermal class Maximum current 62.5 9.65...

-

Page 22: Shaft Loads

Technical data Rated data Shaft loads 4.5.1 Shaft loads The permissible loads listed in the table (Tab. 3) are either radial forces or axial forces. KL−SDS−001 Fig. 1 Points of action of radial and axial loads Ref. to the nominal bearing Permissible axial load service life of 10,000 h Permissible radial load, acts on the middle of the shaft... -

Page 23: Mechanical Installation

Mechanical installation Preparation Mechanical installation Preparation Remove the corrosion protection from the shaft ends and flanges. If necessary, remove dirt using standard cleaning solvents. Stop! Bearings or seals must not come into contact with the solvent − material damages. After a long storage period (> 1 year) you have to check whether moisture has entered the motor. -

Page 24: Installation

Mechanical installation Installation Important notes Installation The mounting surface must be dimensioned for the design, weight and torque of ƒ the motor. The foot and flange faces must rest flat on the mounting surface. ƒ – Incorrect motor alignment reduces the service life of the roller bearings and transmission elements. - Page 25 If long motor supply cables are used, pay attention to the ohmic voltage drop along the cable and compensate for it with a higher voltage at the input end of the cable. The following applies to Lenze system cables: ) 0.08 W...

-

Page 26: Permanent Magnet Holding Brakes

Mechanical installation Holding brake (option) Permanent magnet holding brakes 5.4.2 Permanent magnet holding brakes These brakes are used as holding brakes and serve to hold the axes without backlash at standstill or in the deenergised state. When activating the brake, it must be ensured that the brake is released or engaged at zero speed to avoid unnecessary and rapid wear of the brake. - Page 27 Mechanical installation Holding brake (option) Permanent magnet holding brakes Wear of permanent magnet brakes If applied as directed (application as holding brakes), the permanent magnet brakes of the servo motors are wear free and intended for long operating times. The wear on the friction lining is due to e.g.

-

Page 28: Spring−Applied Holding Brakes

The formula below provides a simplified way to calculate friction energy per switching cycle which must not exceed the limit value for emergency stops that depends on the operating frequency (^ motor catalogue; Lenze drive solutions: Formulas, dimensioning, and tables). - Page 29 Mechanical installation Holding brake (option) Spring−applied holding brakes Component Cause Effect Influencing factors Friction lining Emergency stops Wear on the Applied friction energy friction lining Overlapping wear when the drive starts and stops Active braking by the drive motor with the help of the brake (quick stop) Starting wear if motor is mounted Number of start−stop...

-

Page 30: Electrical Installation

Electrical installation Important notes Electrical installation Important notes Danger! Hazardous voltage on the power connections even when disconnected from mains: residual voltage >60 V! Before working on the power connections, always disconnect the drive component from the mains and wait until the motor is at standstill. Verify safe isolation from supply! Stop! Electrical connections must be carried out in accordance with the national and... -

Page 31: Wiring According To Emc

Wiring according to EMC The EMC−compliant wiring of the motors is described in detail in the Operating Instructions for the Lenze controllers. Use of metal EMC cable glands with shield connection. ƒ Connect the shielding to the motor and to the device. -

Page 32: Connection Plan

Electrical installation Connection plan Connection plan ... for motor and brake SDSGSLL − Pin No. Connection name Connection to: Pin assignment Brake 035−22 047−22 Circuit breaker 056−22 063−22 Motor phase 063−22/32 ... for resolver and thermal contact SDSGSLL − Pin No. Connection name Connection to: Pin assignment... -

Page 33: Commissioning And Operation

Commissioning and operation Important notes Commissioning and operation Important notes Stop! Ensure that the drives are disconnected from the power supply when ƒ working on them! The drive must only be commissioned by qualified personnel! ƒ Do not use the drive in rooms exposed to explosion danger! ƒ... -

Page 34: Before Switching On

Before switch−on, you must ensure that the motor starts with the intended direction of rotation. Lenze motors rotate CW (looking at the driven shaft) if a clockwise three−phase field L1 W U1, L2 WV1, L3 W W1 is applied. Before initial commissioning, before commissioning after an extended standstill period, or before commissioning after an overhaul of the motor, the following must be checked: Measure the insulation resistance, in case of values £1 kWper volt of rated voltage, dry... -

Page 35: Functional Test

Commissioning and operation Functional test Functional test Functional test Check all functions of the drive after commissioning: ƒ Direction of rotation of the motor ƒ – Direction of rotation in the disengaged state (see chapter "Electrical connection"). Torque behaviour and current consumption ƒ... -

Page 36: Maintenance/Repair

Maintenance/repair Important notes Maintenance/repair Important notes Danger! Hazardous voltage on the power connections even when disconnected from mains: residual voltage >60 V! Before working on the power connections, always disconnect the drive component from the mains and wait until the motor is at standstill. Verify safe isolation from supply! Shaft sealing rings and rolling−contact bearings have a limited service life. -

Page 37: Repair

Inspection of the brake integrated in the motor: Check ventilation function and After 1 million cycles at the latest activation/deactivation Shorter intervals in the case of frequent emergency stops! Repair It is recommended to have all repairs performed by Lenze Service. ƒ BA 13.0011−EN... -

Page 38: Troubleshooting And Fault Elimination

Note! Also observe the corresponding chapters in the operating instructions to the other components of the drive system. If the fault cannot be remedied using one of the listed measures, please contact the Lenze Service. Danger! Only work on the drive system when it is in a deenergised state! ƒ... - Page 39 Troubleshooting and fault elimination Fault Cause Remedy Motor does not start Voltage supply interrupted Check error message at the controller Check electrical connection (chapter 6) Controller inhibited Check display at drive controller Check controller enable Resolver cable is interrupted Check error message at the controller Check resolver cable Brake does not release Check electrical connection...

- Page 40 © 07/2010 Lenze Drives GmbH Service Lenze Service GmbH Postfach 10 13 52 Breslauer Straße 3 D−31763 Hameln D−32699 Extertal Germany Germany +49 (0)51 54 / 82−0 00 80 00 / 24 4 68 77 (24 h helpline) Ê Ê...

Need help?

Do you have a question about the SDS Series and is the answer not in the manual?

Questions and answers