Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Rohde & Schwarz ZND Series

- Page 1 ® R&S Vector Network Analyzers Getting Started (=@H72) 1316240702...

- Page 2 ® This manual describes the R&S ZND (2 ports, 9 kHz to 4.5 GHz, unidirectional, N connectors), order no. 1328.5170.92 and its options. Hardware Options ● ® R&S ZND-B7 "High Output Power", order no. 1338.1578.02 ● ® R&S ZND-B10 "GPIB Interface", order no. 1328.5358.02 ●...

-

Page 3: Table Of Contents

® Contents R&S Contents 1 Safety Information..................7 2 Preface....................8 Documentation Overview..................... 8 2.1.1 Getting Started Manual....................8 2.1.2 User Manual and Help....................8 2.1.3 Service Manual....................... 8 2.1.4 Instrument Security Procedures..................9 2.1.5 Basic Safety Instructions....................9 2.1.6 Data Sheets and Brochures.................... 9 2.1.7 Release Notes and Open Source Acknowledgment (OSA).......... - Page 4 ® Contents R&S 4 Instrument Tour..................20 Front Panel........................20 4.1.1 Touchscreen........................21 4.1.2 Function Keys....................... 21 4.1.3 Data Entry Keys......................22 4.1.4 Rotary Knob........................23 4.1.5 Navigation Keys......................23 4.1.6 Standby Key........................24 4.1.7 Front Panel Connectors....................24 Rear Panel........................25 5 Operating the Instrument..............28 Manual Operation .......................28 Control Elements of the Application Window............

- Page 5 ® Contents R&S 5.6.2 Setting the Sweep Range..................... 49 5.6.3 Reference Value and Position..................50 5.6.4 Auto Scale........................50 5.6.5 Circular Diagrams......................51 5.6.6 Set by Marker........................51 5.6.7 Enlarging a Diagram..................... 52 6 Performing Measurements..............54 Transmission S-Parameter Measurement..............54 6.1.1 Connecting the Instrument for Transmission Measurements........55 6.1.2 Selecting the Sweep Range and Other Parameters.............

- Page 6 ® Contents R&S Getting Started 1316.2407.02 ─ 52...

-

Page 7: Safety Information

® Safety Information R&S 1 Safety Information The product documentation helps you use the R&S ZND safely and efficiently. Follow the instructions provided here and in the printed "Basic Safety Instructions". Keep the product documentation nearby and offer it to other users. Intended use The R&S ZND is intended for the development, production and verification of electronic components and devices in industrial, administrative, and laboratory environments. -

Page 8: Preface

® Preface R&S Documentation Overview 2 Preface This chapter provides safety-related information, an overview of the user documenta- tion and the conventions used in the documentation. 2.1 Documentation Overview This section provides an overview of the R&S ZND user documentation. Unless speci- fied otherwise, you find the documents on the R&S ZND product page at: ●... -

Page 9: Instrument Security Procedures

® Preface R&S Documentation Overview 2.1.4 Instrument Security Procedures Deals with security issues when working with the R&S ZND in secure areas. It is avail- able for download on the Internet. 2.1.5 Basic Safety Instructions Contains safety instructions, operating conditions and further important information. The printed document is delivered with the instrument. -

Page 10: Conventions Used In The Documentation

® Preface R&S Conventions Used in the Documentation 2.2 Conventions Used in the Documentation 2.2.1 Typographical Conventions The following text markers are used throughout this documentation: Convention Description [Keys] Key and knob names are enclosed by square brackets. "Graphical user interface ele- All names of graphical user interface elements on the screen, such as ments"... -

Page 11: Putting The Analyzer Into Operation

® Putting the Analyzer into Operation R&S Positioning the Instrument 3 Putting the Analyzer into Operation This section describes the basic steps to be taken when setting up the analyzer for the first time. Simple measurement examples are provided in Chapter 6, "Performing Measure- ments", on page 54;... -

Page 12: Bench Top Operation

® Putting the Analyzer into Operation R&S Bench Top Operation Risk of instrument damage due to inappropriate operating conditions An unsuitable operating site or test setup can damage the instrument and connected devices. Before switching on the instrument, observe the information on appropriate operating conditions provided in the data sheet. -

Page 13: Operation In A 19" Rack

® Putting the Analyzer into Operation R&S EMI Suppression Risk of injury if feet are folded out The feet can fold in if they are not folded out completely or if the instrument is shifted. Collapsing feet can cause injury or damage the instrument. ●... -

Page 14: Connecting The Analyzer To The Ac Supply

® Putting the Analyzer into Operation R&S Starting the Analyzer and Shutting Down Table 3-1: Cable Requirements Cable Type (Connector) Requirement RF cables (PORT 1, ..., PORT N) Double shielded BNC cables (various) Double shielded DB-25 (USER PORT) Double shielded GPIB Standard cable Handler I/O... -

Page 15: Standby And Ready State

® Putting the Analyzer into Operation R&S Standby and Ready State To shut down the analyzer, proceed as follows: 1. Press the standby key. Pressing the standby key causes the instrument to save all loaded recall sets, to ® close the VNA application, to shut down Windows , and to go to standby state. -

Page 16: Connecting External Accessories

® Putting the Analyzer into Operation R&S Connecting External Accessories 3.9 Connecting External Accessories The analyzer's standard PC interfaces (Monitor, USB, LAN) can be used to connect various accessories: ● An external monitor expands/displays the Windows ® desktop, which is, by default, covered by the Vector Network Analyzer (VNA) application window in full-screen mode. -

Page 17: Connecting A Mouse

® Putting the Analyzer into Operation R&S Connecting External Accessories Windows 7: select "Control Panel" > "Clock, Language, and Region" > "Region and Language" > "Keyboards and Languages" from the Windows ® Start menu to configure the keyboard properties. To access Windows ®... -

Page 18: Connecting A Lan Cable

® Putting the Analyzer into Operation R&S Minimizing the VNA Application You can load updated and improved driver versions or new drivers from an installation disk, USB memory stick or another external storage medium. Alternatively, if the ana- lyzer is integrated in a network, you can install driver data stored in a network directory. In either case, use the "Add Printer"... - Page 19 ® Putting the Analyzer into Operation R&S Minimizing the VNA Application A software update restores the original shortcut properties. Getting Started 1316.2407.02 ─ 52...

-

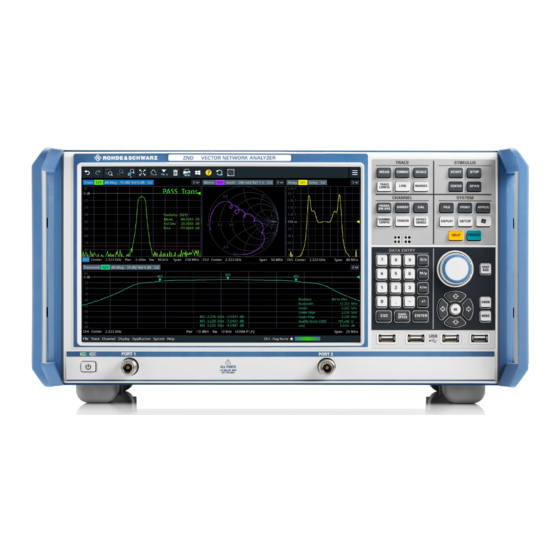

Page 20: Instrument Tour

® Instrument Tour R&S Front Panel 4 Instrument Tour This chapter gives an overview of the control elements and connectors of the R&S ZND and gives all information that is necessary to put the instrument into opera- tion and connect external devices. 4.1 Front Panel The front panel of the network analyzer consists of the touchscreen with the diagrams and softtool panels (left side), the hardkey area (right side) and the test port area... -

Page 21: Touchscreen

® Instrument Tour R&S Front Panel 4.1.1 Touchscreen The analyzer is equipped with a 12.1'' XGA color touchscreen. The touchscreen pres- ents all measurement results, mostly in the form of diagrams. Besides, all instrument functions can be accessed and operated by tapping the control elements on the touch- screen. -

Page 22: Data Entry Keys

® Instrument Tour R&S Front Panel ● The [MARKER] settings position markers on a trace, configure their properties and select the format of the numerical readout. Markers can also be used to locate spe- cific points on the trace, define the sweep range, and scale the diagram. The CHANNEL keys give access to the hardware-related (channel) settings. -

Page 23: Rotary Knob

® Instrument Tour R&S Front Panel The keys in the DATA ENTRY keypad are used to enter numbers, units, and charac- ters. The data entry keys are only enabled while the cursor is placed on a data input field in a dialog or in the Help navigation pane. ●... -

Page 24: Standby Key

® Instrument Tour R&S Front Panel The keys in the NAVIGATION keypad are used to navigate within the touchscreen and the help system, to access and control active elements. The "Cursor Up" and "Cursor Down" keys are used to: ● Scroll up and down in lists, e.g. -

Page 25: Rear Panel

® Instrument Tour R&S Rear Panel ● With 2 test ports, full two-port measurements are possible; see Chapter 6.1, "Transmission S-Parameter Measurement", on page 54. However, to use port 2 of a R&S ZND as driving port, you need one of the "bidirec- tional measurements"... - Page 26 ® Instrument Tour R&S Rear Panel Figure 4-2: Rear Panel R&S ZND The following connectors are available on all instruments: ● LAN is an RJ-45 connector. Use this connector to integrate the instrument to a Local Area Network, primarily for remote control purposes; see Chapter 7.3.1, "Assigning an IP Address",...

- Page 27 ® Instrument Tour R&S Rear Panel ● Option R&S ZN-B14, Handler I/O (Universal Interface), provides a Centronics 36 input/output connector. Input levels, EMC The maximum input levels and voltages of the input connectors at the front and rear panel must not be exceeded. Match signals with 50 Ω to comply with EMC directives. See also Chapter 3.5, "EMI Suppression",...

-

Page 28: Operating The Instrument

® Operating the Instrument R&S Manual Operation 5 Operating the Instrument The following sections describe the basics of manual operation, i.e. how to access instrument functions and settings via the analyzer GUI. Manual operation is particularly useful for getting to know the instrument and for trouble shooting. Manual and remote control of the instrument Manual control of the R&S ZND is possible either via its touchscreen and frontpanel keys, via locally connected keyboard and mouse (see... - Page 29 ® Operating the Instrument R&S Manual Operation Figure 5-1: Function Keys Customizing the screen The contents of the screen and the size and position of many display and control ele- ments are not fixed. You can display or hide most elements. You can also drag and drop traces, info fields, and even the softtool panel to your preferred position;...

- Page 30 ® Operating the Instrument R&S Manual Operation left = unidirectional R&S ZND right = bidirectional R&S ZND 2. Activate the desired softtool tab, e.g. "Z←Sij". left = unidirectional R&S ZND right = bidirectional R&S ZND 3. Select a control element, e.g. "Z←S11". The diagram immediately reflects your selection.

- Page 31 ® Operating the Instrument R&S Manual Operation Using the menu bar The menu bar at the bottom of the application screen provides alternative access to all instrument functions. To repeat the measured quantity selection described above, ► Select TRACE – [MEAS] > "Z←Sij" > "Z←S11". The diagram immediately reflects your selection.

- Page 32 ® Operating the Instrument R&S Manual Operation left = unidirectional R&S ZND right = bidirectional R&S ZND 2. Select "S-Parameter" to open the "Meas" > "S-Params" softtool tab. left = unidirectional R&S ZND right = bidirectional R&S ZND 3. Select "Z←Sij" > "Z←S11". Getting Started 1316.2407.02 ─...

-

Page 33: Control Elements Of The Application Window

® Operating the Instrument R&S Control Elements of the Application Window left = unidirectional R&S ZND right = bidirectional R&S ZND 5.2 Control Elements of the Application Window The application window of the analyzer provides all control elements for the measure- ments and contains the diagrams for the results. -

Page 34: Title Bar

® Operating the Instrument R&S Control Elements of the Application Window These methods are described in more detail in the following sections. 5.2.1 Title Bar By default, the analyzer GUI is shown in full screen mode, covering the whole screen and hiding the Windows taskbar. -

Page 35: Softtools

® Operating the Instrument R&S Control Elements of the Application Window These icons represent the undo and redo actions that are also available via the menu bar items "System" > "Undo" / "Redo". Undo reverses the last action, redo reverses the last undo action (if possi- ble). -

Page 36: Menu Bar

® Operating the Instrument R&S Control Elements of the Application Window Figure 5-2: Scale softtool A softtool consists of a title area with a close/re-open icon and a tabbed panel below it. The title area remains displayed when the softtool is closed, which allows you to reopen a closed softtool at any time. -

Page 37: Menu Structure

® Operating the Instrument R&S Control Elements of the Application Window ● The "Display" menu provides all display settings and the functions for activating, modifying and arranging different diagrams. ● The "Applications" menu gives access to applications and tools that extend the functionality of the analyzer firmware. -

Page 38: Hardkey Panel

® Operating the Instrument R&S Control Elements of the Application Window 5.2.6 Hardkey Panel The (virtual) "Hard Key" panel provides on-screen access to the function keys (plus the [UNDO] and [REDO] key) of the R&S ZND. Most of the function keys open a related softtool. -

Page 39: Working With Dialogs

® Operating the Instrument R&S Working with Dialogs ● the LXI status symbol (if enabled; see SYSTEM – [SETUP] > "Remote Settings" > "LXI settings") A flashing green LXI status symbol indicates that a LAN connection has been established; a red symbol indicates that no LAN cable is connected. ●... -

Page 40: Handling Diagrams, Traces, And Markers

® Operating the Instrument R&S Handling Diagrams, Traces, and Markers For a unidirectional R&S ZND, the bidirectional calibrations are not available. All dialogs are operated in a similar way. ● To open a dialog, select a softtool button with three dots appearing in its label (e.g. "Start... - Page 41 ® Operating the Instrument R&S Handling Diagrams, Traces, and Markers To create a trace: 1. Drag the "Trc+" icon from the toolbar into a diagram. The diagram changes its color scheme and contents as shown below. 2. Select the adequate drop position, depending on whether you want to display the new trace in the existing diagram, or whether you want to add a new diagram.

-

Page 42: Adding New Markers

® Operating the Instrument R&S Handling Diagrams, Traces, and Markers left = bidirectional R&S ZND right = unidirectional R&S ZND The R&S ZND generates a new trace for the selected S-parameter. Alternative control elements To measure a different quantity, select TRACE – [MEAS]. Drag and drop a softkey rep- resenting a measured quantity to create a trace. -

Page 43: Deleting Display Elements

® Operating the Instrument R&S Handling Diagrams, Traces, and Markers Active trace, alternative control elements The trace line of the active trace in the upper part of the diagram is highlighted. If the diagram contains several traces, first activate the target trace, then add the marker. The TRACE –... -

Page 44: Entering Data

® Operating the Instrument R&S Entering Data Table 5-1: Drag and drop functionality for various screen elements Screen element Action Drag and drop... Diagram Create Chapter 5.4.1, "Adding New Traces and Diagrams", on page 40 Resize Separator between adjacent diagrams Delete Chapter 5.4.3, "Deleting Display Elements",... - Page 45 ® Operating the Instrument R&S Entering Data To enter a numeric value: 1. Select a numeric data input field to activate it. 2. Press the data entry keys. ● Use [0] to [9] to enter the corresponding numbers. ● Use [.] to enter a decimal point. ●...

-

Page 46: Using The Numeric Editor

® Operating the Instrument R&S Entering Data 5.5.2 Using the Numeric Editor The "Numeric Editor" is a tool for convenient entry and modification of numeric values. It is available for all numeric input fields in the analyzer GUI. Operation with touchscreen or mouse: 1. -

Page 47: Using The Windows ® On-Screen Keyboard

® Operating the Instrument R&S Entering Data 1. Activate a character data input field in a softtool or a dialog. 2. Double-tap/click the input field to open the on-screen keyboard. 3. Select character buttons to compose the input string. 4. Select "Enter" to apply your selection and close the keyboard. ®... -

Page 48: Scaling Diagrams

® Operating the Instrument R&S Scaling Diagrams 5.6 Scaling Diagrams The analyzer provides various tools for customizing the diagrams and for setting the sweep range. Choose the method that is most convenient for you. 5.6.1 Using the Graphical Zoom The graphical zoom function magnifies a rectangular portion of the diagram (zoom win- dow) to fill the entire diagram area. -

Page 49: Setting The Sweep Range

® Operating the Instrument R&S Scaling Diagrams Use the "Zoom Reset" icon to restore the original diagram. Alternatively, you can drag and drop the "Zoom" label from the additional channel info line onto the toolbar but- ton. Alternative settings ● The TRACE –... -

Page 50: Reference Value And Position

® Operating the Instrument R&S Scaling Diagrams To change the sweep range of the active channel, use one of the following methods: ● Use the [START], [STOP], [CENTER], and [SPAN] function keys from the STIMU- LUS section. ● Double-tap (with a mouse: double-click) the "Start" or "Stop" label in the channel list. -

Page 51: Circular Diagrams

® Operating the Instrument R&S Scaling Diagrams ● Select "Auto Scale Trace" or "Auto Scale Diagram" from the "Trace" > "Scale" menu. 5.6.5 Circular Diagrams The radial scale of a circular diagram ("Polar", "Smith" or "Inverted Smith") can be changed with a single linear parameter, the "Ref Value". The reference value defines the radius of the outer circumference. -

Page 52: Enlarging A Diagram

® Operating the Instrument R&S Scaling Diagrams Set "Start" and "Stop" values in the diagram: 1. Create two normal markers, e.g. the markers "Mkr 1" (default label "M1") and "Mkr 2" (default label "M2"). Chapter 5.4.2, "Adding New Markers", on page 42. 2. - Page 53 ® Operating the Instrument R&S Scaling Diagrams ● The SYSTEM – [DISPLAY] > "Config" softtool tab defines optional display elements for the interior of the diagrams. Use the context menu of the diagram, the SYSTEM – [DISPLAY] key or the "Display" menu to access the display settings.

-

Page 54: Performing Measurements

® Performing Measurements R&S Transmission S-Parameter Measurement 6 Performing Measurements This chapter takes you through a sample session with a R&S ZND network analyzer and describes basic operation tasks. Safety considerations Before starting any measurement on your network analyzer, please note the instruc- tions given in Chapter 3, "Putting the Analyzer into Operation",... -

Page 55: Connecting The Instrument For Transmission Measurements

® Performing Measurements R&S Transmission S-Parameter Measurement 6.1.1 Connecting the Instrument for Transmission Measurements To prepare a transmission measurement, you have to connect your DUT (which for simplicity we assume to have appropriate connectors) in-between a pair of analyzer test ports. It is recommended that you preset the R&S ZND to start from a well-defined instrument state. -

Page 56: Selecting The Sweep Range And Other Parameters

® Performing Measurements R&S Transmission S-Parameter Measurement 6.1.2 Selecting the Sweep Range and Other Parameters After a system preset the display shows a diagram with a dB magnitude scale, and the S-parameter S is selected as a measured quantity. This S-parameter is the forward transmission coefficient of the DUT. - Page 57 ® Performing Measurements R&S Transmission S-Parameter Measurement phase shift of the waves. Both effects impair the accuracy of the S-parameter mea- surement. The analyzer provides a wide range of sophisticated calibration methods for all types of measurements. The calibration method to select depends on the expected system errors, the accuracy requirements of the measurement, on the test setup and on the types of calibration standards available.

- Page 58 ® Performing Measurements R&S Transmission S-Parameter Measurement 5. Select the test port connector type and gender (here: N 50 Ω, female, correspond- ing to a male Through standard), and the calibration kit (here: R&S ZV-Z121). 6. Tap"Start". 7. The calibration dock widget indicates the standard measurements that make up a "Trans Norm"...

-

Page 59: Evaluating Data

® Performing Measurements R&S Transmission S-Parameter Measurement The analyzer performs a calibration sweep for the measured quantity S . The magnitude and phase of the result is displayed in two diagrams, together with the expected typical result for a Through standard. The similarity of real and expected traces indicates that the Through standard has been properly connected. -

Page 60: Saving And Printing Data

® Performing Measurements R&S Transmission S-Parameter Measurement The group delay represents the propagation time of the wave through the DUT; it is displayed in a Cartesian diagram. The marker info field shows the frequency and group delay at the marker position. Refer to the information on trace formats in the help system or in the user manual to learn more about the diagram properties. -

Page 61: Reflection S-Parameter Measurement

® Performing Measurements R&S Reflection S-Parameter Measurement 6. Select SYSTEM – [FILE] > "Recall Sets" > "Save..." to open the "Save" dialog for recall sets. 7. In the "Save" dialog: a) Select a file location ("Look in:"). b) Enter a name for the recall set file ("File name:"). c) Select "Save". - Page 62 ® Performing Measurements R&S Reflection S-Parameter Measurement A full 2-port calibration (TOSM, UOSM, TNA ...) corrects the system errors for all transmission and reflection S-parameters. ● Some of the trace formats are particularly suited for reflection measurements. For instance, you can display the measured reflection coefficient S in a Smith chart to obtain the complex input impedance at port 1.

-

Page 63: Administrative Tasks

® Administrative Tasks R&S Windows Operating System 7 Administrative Tasks This chapter describes some topics that are only needed occasionally, or if a special instrument configuration is required. 7.1 Windows Operating System ® The analyzer is equipped with a Windows operating system which has been config- ured according to the instrument's features and needs. -

Page 64: Firmware Installation

® Administrative Tasks R&S Remote Operation in a LAN 7.2 Firmware Installation Upgrade versions of the analyzer firmware are supplied as single executable setup files (*.exe). Administrator account You need administrator rights to install a new firmware version. See note on "User accounts and password protection"... -

Page 65: Assigning An Ip Address

® Administrative Tasks R&S Remote Operation in a LAN ● Control the measurement from a remote computer using Remote Desktop or a sim- ilar application. ● Use external network devices (e.g. printers). Virus protection An efficient virus protection is a prerequisite for secure operation in the network. Never connect your analyzer to an unprotected network. - Page 66 ® Administrative Tasks R&S Remote Operation in a LAN To enter the TCP/IP address information manually 1. Obtain the IP address and subnet mask for the analyzer and the IP address for the local default gateway from your network administrator. If necessary, also obtain the name of your DNS domain and the IP addresses of the DNS and WINS servers on your network.

-

Page 67: Using Computer Names

® Administrative Tasks R&S Remote Operation in a LAN 7.3.2 Using Computer Names In a LAN that uses a DNS server (Domain Name System server), each PC or instru- ment connected in the LAN can be accessed via an unambiguous computer name instead of the IP address. -

Page 68: Remote Desktop Connection

® Administrative Tasks R&S Remote Operation in a LAN 7.3.3 Remote Desktop Connection ® Remote Desktop is a Windows application which you can use to access and control the analyzer from a remote computer through a LAN connection. While the measure- ment is running, the analyzer screen contents are displayed on the remote computer, and Remote Desktop provides access to all of the applications, files, and network resources of the analyzer. - Page 69 ® Administrative Tasks R&S Remote Operation in a LAN ● Select "Allow an app or feature through Windows Defender Firewall" to enable "File and Printer Sharing". (Windows 7: select "Change Settings > Allow a program or feature through Windows Firewall" to enable "File and Printer Sharing"). ●...

-

Page 70: Maintenance

® Maintenance R&S Cleaning 8 Maintenance The R&S ZND vector network analyzer does not require any special maintenance. For our support center address and a list of useful R&S contact addresses, refer to the "Contact" page at the beginning of the Help system. 8.1 Cleaning Risk of electric shock If moisture enters the casing, for example if you clean the instrument using a moist... -

Page 71: Storing And Packing The Instrument

® Maintenance R&S Storing and Packing the Instrument 8.2 Storing and Packing the Instrument The vector network analyzer can be stored at the temperature range quoted in the data sheet. When it is stored for a longer period of time, the unit must be protected against dust. -

Page 72: Contacting Customer Support

® Contacting Customer Support R&S 9 Contacting Customer Support Technical support – where and when you need it For quick, expert help with any Rohde & Schwarz product, contact our customer sup- port center. A team of highly qualified engineers provides support and works with you to find a solution to your query on any aspect of the operation, programming or applica- tions of Rohde &... -

Page 73: Index

® Index R&S Index Graphic zoom ..............48 Ground connector ............. 26 AC Supply ................. 14 Accessories (connect) ............16 Administrative tasks ............63 Hardkey panel ..............38 Application cards ..............9 Application notes ..............9 Auto scale ................. 50 Instrument calibration ............ - Page 74 ® Index R&S REF OUT / IN ..............26 Reference position ............50 Reference value ..............50 Reflection measurement (example) ........61 Release notes ..............9 Remote desktop ..............68 Rotary knob ............... 23 S-Parameter Wizard ............54 Safety information ............... 7 Safety instructions ...............

Need help?

Do you have a question about the ZND Series and is the answer not in the manual?

Questions and answers