Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Anton Paar Quantachrome ULTRAPYC UPY-32

- Page 1 ULTRAPYC TRUE VOLUME AND DENSITY ANALYZER Operating Manual Models: UPY-32, UPY-32T, MUPY-32, MUPY-32T, UPY-32F, UPY-32FT Version: 5.xx Original Instructions (English) I15IB010EN-B © 2019 Quantachrome Instruments A brand of Anton Paar 1900 Corporate Drive Boynton Beach FL 33426,...

- Page 2 CONTACT INFORMATION Quantachrome Instruments A brand of Anton Paar 1900 Corporate Drive Boynton Beach, Florida, 33426 Tel: 1-561-731-4999 E-mail: support-sp@anton-paar.com www.quantachrome.com 2 of 124...

-

Page 3: Ultrapyc

Ultrapyc / UltraFoam Pycnometer Operation Manual CALIBRATION DATA ULTRAPYC CALIBRATION DATA Table A-1, Calibration Sphere Data Calibration Sphere Volume (cm Large 56.5592 Medium 28.9583 Small 7.0699 Micro (optional) 1.0725 Nano (optional) 0.0898 Three sizes of sample cells are supplied with the instrument (they are referred to as large, medium, and small in this manual). -

Page 4: Micro-Ultrapyc

Ultrapyc / UltraFoam Pycnometer Operation Manual CALIBRATION DATA MICRO-ULTRAPYC CALIBRATION DATA Table A-3, Micro Calibration Sphere Data Calibration Sphere Volume (cm Micro 1.0725 Nano 0.0898 The three sample holders supplied with the instrument are referred to as "large, medium and small"... -

Page 5: Table Of Contents

Ultrapyc / UltraFoam Pycnometer Operation Manual TABLE OF CONTENTS TABLE OF CONTENTS ULTRAPYC ........................3 MICRO-ULTRAPYC ....................4 TABLE OF CONTENTS ..................... 5 PREFACE ........................9 A. INTRODUCTION ....................10 Summary of Ultrapyc 1200e/Ultrafoam Features ............11 Technical Specifications ...................... 12 B. - Page 6 Ultrapyc / UltraFoam Pycnometer Operation Manual TABLE OF CONTENTS 2.13 Calibration/Analysis Chamber ..................27 2.14 Circulator Bath Connections (Optional) ..............27 D. ULTRAPYC OPERATION ................... 28 Introduction .......................... 28 Navigation Through Ultrapyc Menus ................29 Ultrapyc Menu Map ......................30 Main Menu ..........................

-

Page 7: Appendix

Ultrapyc / UltraFoam Pycnometer Operation Manual TABLE OF CONTENTS Result Reports ........................58 E. ULTRAFOAM OPERATION ................61 Navigation Through The Ultrafoam Menus ..............61 Foam Mode Run Procedure ....................61 Additional Foam Mode Sample Parameters ..............61 Foam Mode Operation ......................63 Sample Preparation ...................... - Page 8 Ultrapyc / UltraFoam Pycnometer Operation Manual TABLE OF CONTENTS Appendix 3 Balance Mode ..................97 Appendix 3.1 Compatible Output Format ..............97 Appendix 3.2 Hardware Setup .................97 Appendix 4 Compatible Printers ................100 Appendix 5 Calibration and Usage of the Nanocell (the Difference Method) ..101 Appendix 6 Computer Network Address Configuration ........103 Appendix 6.1 Configuring a Microsoft Windows system ........103...

-

Page 9: Preface

Ultrapyc / UltraFoam Pycnometer Operation Manual PREFACE PREFACE This is the operating manual for the Ultrapyc–e family of pycnometers, which include the Ultrapycnometer 1000e, Ultrapyc 1200e, Micro-Ultrapycnometer 1000e, and Micro- Ultrapyc 1200e instruments as well as Ultrapycs with Foam Mode. The Ultrapyc and Micro- Ultrapyc instruments use the same principle theory and operational procedures, hence, the generic term “Ultrapyc”... -

Page 10: Introduction

Ultrapyc / UltraFoam Pycnometer Operation Manual A. INTRODUCTION A. INTRODUCTION PYCNOMETRY is derived from the Greek word pyknos, which has long been identified with volume measurements. The pycnometers from Quantachrome are specifically designed to measure the true volume of solid materials by employing Archimedes’ principle of fluid (gas) displacement and the technique of gas expansion (Boyle's law). -

Page 11: Summary Of Ultrapyc 1200E/Ultrafoam Features

Ultrapyc / UltraFoam Pycnometer Operation Manual A. INTRODUCTION 1 Summary of Ultrapyc 1200e/Ultrafoam Features Automatic Functions — Operating simplicity is achieved via PC and a standard web browser or via built-in keypad following prompts or instructions which are automatically presented on the alphanumeric display. -

Page 12: Technical Specifications

Ultrapyc / UltraFoam Pycnometer Operation Manual A. INTRODUCTION 2 Technical Specifications ULTRAPYC 1200e INSTRUMENT PHYSICAL† Height:............22.7 cm (8.9 in) Width: .............31.1 cm (12.25 in) Depth: ............54.0 cm (21.25 in) Weight: .............9.75 kg (21.5 lbs.) ELECTRICAL Voltage: ............100 - 240 VAC (see nameplate on rear of unit) Frequency:..........50/60 Hz Power (max): ..........150 W Connection: ..........Grounded, single-phase outlet... - Page 13 Ultrapyc / UltraFoam Pycnometer Operation Manual A. INTRODUCTION CALIBRATION Stainless-steel sphere standards; NIST traceable values optional. Each instrument supplied with a full set of spheres housed in protective, padded wooden box. OUTPUTS RS232 serial port for balance interface; two USB port(s) for printer and portable flash drive storage, RJ45 Ethernet port for network/LAN internet connection to PC.

-

Page 14: Safety

Ultrapyc / UltraFoam Pycnometer Operation Manual B. SAFETY B. SAFETY 1 Symbols Used in this Manual CAUTION! This sign denotes a hazard that could result in damage to the instrument. WARNING! This sign denotes a hazard that could result in injury to the operator. ... -

Page 15: Installation

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION C. INSTALLATION 1 Instrument Setup Flow Diagram Shown on the next page is a flow diagram of the Ultrapyc. A simplified flow diagram can also be displayed by accessing the manual mode of the PycWeb computer interface. CAUTION! Familiarize yourself with the instrument’s Flow Diagram before proceeding with Operation and/or accessing the Manual Mode. - Page 16 Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Figure C.1, Schematic diagram of Ultrapyc family of Pycnometers. 16 of 124...

-

Page 17: Start Up And Shutdown

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Start Up and Shutdown The Ultrapyc runs the Linux operating system (OS.) When power is applied to the unit and the power switch is turned on, it takes one full minute to boot the operating system and launch the Ultrapyc control programs. -

Page 18: Sample Cell Holder And Sample Cells

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION CAUTION! Before proceeding, familiarize yourself with the instrument’s Manual Mode (see Section D.5 for a description of valve operation). Follow the steps below after connecting the gas tank to the instrument: 1. Set the tank pressure to 0 psig by fully unwinding the regulator spindle. 2. - Page 19 Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION are available. However, the use of the smaller cells will result in a small loss in accuracy. The micro, meso, and nano cells are used with their respective adapter sleeves. Three sample cells are supplied with the Micro-Ultrapycnometer 1000e and Micro-Ultrapyc 1200e.

-

Page 20: Sample Cell Holder Cover

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Sample Cell Holder Cover In order to insure reproducible cell volumes: 1. When sealing the sample cell inside the calibration/analysis chamber (i.e. inside the sample cell holder), make certain that the O-ring is secured in the groove machined into the inside of the sample cell holder cover. -

Page 21: Pressure Relief Valve

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Figure C.4, NIST Traceable Calibration Spheres Calibration spheres are provided in the shipping kit for calibration of the instrument (for nominal volumes and Part Numbers, refer to Calibration Data Sheet for Ultrapyc and Micro-Ultrapyc on pages 3 and 4). -

Page 22: Vacuum Pump (Optional)

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION When the valve has been cleaned, reassemble and reattach the leads. Knurled Solenoid Ring Gasket Disk Plunger Housing Valve Seat Figure C.5, Exploded View Of Valve 1.10 Vacuum Pump (Optional) The Ultrapyc can be used with a vacuum pump for sample preparation by evacuation as an alternative to purging with a flow of dry inert gas. -

Page 23: Vacuum Accessories (Optional)

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Ring Clamp Vacuum Connection (at rear of instrument or at pump) NW-16 Stub Centering Ring Vacuum Hose Hose Clamp 1.11 Vacuum Accessories (Optional) Table C-1, Part numbers for vacuum accessories. ITEM QTY REQUIRED Pump (105-115) 46030 Pump (200-220) -

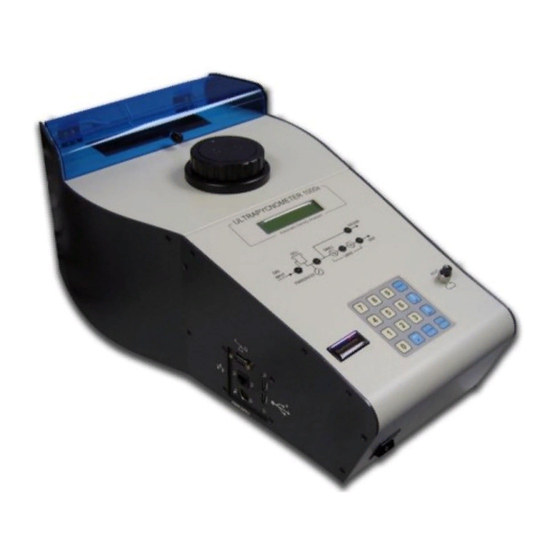

Page 24: Power Input

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Storage Compartment Cover Display LEDs Valve Indicators Reset Button Sample Cell Chamber sealed with Cover Keypad Power Switch Gas and Vacuum Connections Balance Serial Port USB Ports Ethernet Port Optional Circulator Connections Figure C.6, Ultrapyc Controls And Connections Power Input The Power Input (the female-5-pin circular jack) is mounted to the left side panel of the... -

Page 25: Power Switch

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION Power Switch The Power Switch (rocker switch) is located on the right side panel of the Ultrapyc. Press | to switch ON and to switch OFF. NOTE! The power switch should not be used to abort a run in progress (use Reset Button instead). -

Page 26: Evacuation Rate Regulator Valve

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION NOTE! Small cells pressurize more quickly when used with the proper adapter sleeve, than medium and large cells. Cell containing larger sample quantities pressurize more quickly than the same size cells containing lesser sample amounts. -

Page 27: Storage Compartment

Ultrapyc / UltraFoam Pycnometer Operation Manual C. INSTALLATION 2.12 Storage Compartment The Storage Compartment is located at the top of Ultrapyc (near rear-end). It can be used for storage of accessories (it also contains the Flow Control and Evacuation Rate Control Valves). To access storage compartment, lift up the blue cover using a mounted handle. -

Page 28: Ultrapyc Operation

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION D. ULTRAPYC OPERATION 1 Introduction For the greatest accuracy, allow a minimum of one hour for warm-up and thermal equilibration. The optional circulating bath accessory may be used to provide constant temperature conditions (see Section C.1.3). -

Page 29: Navigation Through Ultrapyc Menus

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION where n is the number of runs and is the mean value of x. 2 Navigation Through Ultrapyc Menus When the Ultrapyc starts up the option messages associated with its Main Menu are displayed on its 2-line by 20-character LCD-display. -

Page 30: Ultrapyc Menu Map

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Ultrapyc Menu Map 30 of 124... -

Page 31: Main Menu

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 3 Main Menu 1 – Run. Enter the Run submenu. 2 – Calibrate. Enter the Calibration submenu. 3 – System Setting. Enter the System setting submenu. 4 – User ID. Set a User ID string of up to 16 characters that will be used in the report printouts. 5 –... -

Page 32: Purge Mode

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 6 – Print/Send Reports. Report files are always saved on the Ultrapyc file system. Select this menu option to determine how report files generated from the run will be distributed. Files can be printed to a USB printer, copied to a USB flash memory device, and/or emailed to the user. -

Page 33: Sample Parameters Menu

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION is not achieved the measurement cycles will continue until the maximum number of runs occurs. 3.1.2 Sample Parameters Menu The Sample-Parameters Routine is selected by sequence: Main Menu → 1 – Run → 2 - Sample Parameters The Sample Parameter routine is called to set the sample weight and sample ID. - Page 34 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 4 – Copy Reports to USB. This choice initiates a routine to copy report files stored on the Ultrapyc file system to a USB flash memory device inserted into one of the Ultrapyc’s USB ports.

-

Page 35: Network Menu

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 3.3.1 Network Menu The Network Menu is selected by sequence: Main Menu → 3-System Settings → 2-System Configuration→1-Network Configuration The Ultrapyc has a web based network interface called PycWeb. PycWeb runs on any modern web browser. -

Page 36: Initial Software Setup

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION The Balance Mode menu is used to select how the sample weight is entered into the Ultrapyc. There are two choices 1-Balance or 2-Keypad. If the sample weight will be entered manually using the Ultrapyc keypad, choose 2-keypad. - Page 37 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION to control the Ultrapyc from a remote computer. In order to use PycWeb the Ultrapyc network port needs to be connected to the computers network. Most offices and laboratories employ computer networks called local area networks (LANs). The Ultrapyc has a 100 Base-T Ethernet port and can easily be hooked up to a LAN.

- Page 38 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION display. Press the ENTER key when the IP address has been entered correctly. Enter IP address 192.168.0.3 Enter the network mask. Enter subnet mask 255.255.255.0 Pressing the CLEAR key will clear the display. Press the ENTER key when the network mask has been entered correctly.

-

Page 39: Connecting The Ultrapyc Directly To A Computer

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 4.2.2 Connecting the Ultrapyc Directly to a Computer Some laboratories may not have a computer network. If no network is available, the Ultrapyc can be connected directly to a computer workstation’s Ethernet port using the Ethernet crossover cable supplied with the Ultrapyc. - Page 40 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION CAUTION! While in the manual mode, it is possible to over-pressurize and damage the pressure transducer. Do not allow the pressure to exceed 25 psig. When manual mode is entered, the display shows the pressure, the V in use and temperature.

-

Page 41: Calibration Routine

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 6 Calibration Routine Calibrate V Before a calibration can be done, the operator must set a few Ultrapyc parameters. Many parameters are shared between Calibration runs and Sample Volume Measurement runs. Before starting a V-added calibration navigate to the Run Parameters Menu and set the target pressure using the sequence: Main Menu →... - Page 42 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION NOTE! If the user intends to use a small cell for density measurements, select 2- Small, and perform small Va calibration with the small cell. If the user intends to use a medium or a large cell for density measurements, select 1- Large and perform large Va calibration with the large cell.

- Page 43 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Save on USB key? 1 – Yes 2 - No 5. After pressing 1 or 2 the window will display: Start Blank Run Press Enter To Start Before pressing ENTER, the user must ensure that the cell holder (chamber) has only the proper (large or small) empty sample cell inserted (small cell requires use of its adapter sleeve), and that it is properly sealed.

-

Page 44: Calibrate

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Press the REV key to display the result of the V calibration. For example, Va Completed Vadded: 83.8502 cc This value is automatically stored in memory and is used to calculate the volume of the sample cell and the samples. - Page 45 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Calibration Mode 1 – Vadded 2 - Vcell 2. Select 2 to bring up the V calibration window. 3. The display will then prompt the user to enter the size of the sample holder. Choose Cell Size Cell Size: 4.

- Page 46 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Enter Run Deviation Deviation: 0.005 Any value from 0.001 to 100 can be entered. Press CLEAR to delete entry errors. Press ENTER to accept the value. The Ultrapyc will continue to test the cell until the percent deviation for three consecutive runs is equal to or less than the specified value or until the maximum number of runs has been reached.

-

Page 47: Calibration Data Review

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION When ENTER is pressed, the run will begin with a 1-minute purge. The Ultrapyc will then proceed with the cell calibration measurements. After the run is completed, the display will show: Vc Completed Press CLEAR for Main or: Press PRINT to print... - Page 48 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 48 of 124...

-

Page 49: Sample Volume Measurements (Runs) Routine

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Table D-2, Nominal Values for Va and Vc Models UPY-30, UPY-30T, UPY-30F, and Models MUPY-30 and MUPY-30T UPY-30FT 12.3468 cc – 13.0431 cc 1.50 cc – 1.70 cc Va small Va small-nano 78.108 cc –... -

Page 50: Set The Equilibrium Time

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 1 – Target Pressure: Set a desired target pressure In some cases, low pressures (e.g. 6 psig) may be desirable, particularly if the sample is compressible e.g., foams). If it is not, high target pressures (e.g., 17 psig) are preferred. Enter Target Press. -

Page 51: Set The Run Mode

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Enter Purge Mode 1 – Flow 2 – Pulse 3 - Vac For most accurate results, samples should be properly purged or outgassed before commencing an analysis. Three outgassing modes are built into the Ultrapyc. Each can be selected from the keypad when prompted by the display. - Page 52 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION runs to be averaged then only the last "n" runs will be used for calculations; where "n" is the number of runs to be averaged as specified by the operator. NOTE! If less than 3 runs are specified the instrument will default to the single run mode and the % deviation window will not be displayed.

-

Page 53: Set The Cell Size

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION NOTE! If the user selects the smallest allowable deviation (0.001 %), the maximum number of runs will most likely be used. A deviation of 0.01% is recommended for filled cells. A cell filled to 1/10 of its capacity should be ... -

Page 54: Set Pressure Units

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION the report file names are shortened to 8 characters plus the .txt or .pdf extension. See Section D.8, report files, for an explanation of how the file names are shortened. Save on USB key? 1-Yes 2-No ... -

Page 55: Set Sample Weight

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION 7.2.1 Set Sample Weight The Ultrapyc can obtain the sample weight from a Digital Balance connected to the serial port or by manual entry from the keypad. See the “Balance Mode” routine description in Section D.4.3 and Appendix 3, for more details. -

Page 56: Set Sample Id

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION key may be used to clear the weight displayed, in order to correct any entry errors. Press ENTER when the correct weight has been entered. Enter Weight Weight: 12.1234 grams 7.2.2 Set Sample ID Enter the sample ID (up to 16 characters): Enter Sample ID... -

Page 57: Review Results

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Error 2 occurred Restart: Press clear Review Results After the run is completed, the display will cycle through the following choices. Run Completed Press PRINT to Print Run Completed Press REV to Review Run Completed CLEAR for Next Run If the PRINT key is pressed, a printout of all of the results, run parameters and statistics will be... -

Page 58: Result Reports

Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION Volume Std. Dev. 0.0004 % The sample weight is displayed: Sample Weight 0.0898 grams By continuing to press the REV key, the user can scroll through the volume and density measurements for each run. When all of the runs have been displayed, pressing the REV key again will start the review sequence over. - Page 59 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION file names need to be differentiated and correlated to a particular run. The Ultrapyc extends the ultraReport.txt file name by appending the sample ID used during the run onto the base file name.

- Page 60 Ultrapyc / UltraFoam Pycnometer Operation Manual D. ULTRAPYC OPERATION the file name on the USB key will be ulmple-1.txt. Other examples are vaReport.txt on the Ultrapyc becomes vaReport.txt on the USB key, vcReport.txt becomes vcReport.txt, vaReport-1.txt becomes vaport-1.txt, and vcReport-1.txt becomes vcport-1.txt. It may be undesirable to store too many report files on the Ultrapyc.

-

Page 61: Ultrafoam Operation

Ultrapyc / UltraFoam Pycnometer Operation Manual E. ULTRAFOAM OPERATION E. ULTRAFOAM OPERATION 1 Navigation Through The Ultrafoam Menus The keypad can be used to navigate through the various UltraFoam menus in order to set an UltraFoam parameter or call an UltraFoam routine. The UltraFoam menu “tree” is arranged almost exactly like the Ultrapyc menus diagrammed in earlier chapters. - Page 62 Ultrapyc / UltraFoam Pycnometer Operation Manual E. ULTRAFOAM OPERATION 62 of 124...

-

Page 63: Foam Mode Operation

Ultrapyc / UltraFoam Pycnometer Operation Manual E. ULTRAFOAM OPERATION 4 Foam Mode Operation Sample Preparation The foam sample should have as regular a cubic or cylindrical geometry as possible. Therefore, it will normally be necessary to cut a test piece from a larger sample of foam polymer. Use a fine toothed hobby saw or craft knife to cut the specimen such that it has smooth surfaces (within the limitations of the cellular nature of the material!) A single 2.5 cm x 2.5 cm x 2.5 cm (1 in x 1 in x 1 in) cube is recommended for use with the medium sample cell, or two such cubes, if preferred,... -

Page 64: Uncorrected Open And Closed Cell Measurement

Ultrapyc / UltraFoam Pycnometer Operation Manual E. ULTRAFOAM OPERATION Each of the procedures is described in detail below. The number after the title, "Procedure,” is the last procedure selected and is the analysis that will be performed until it is changed. ENTER returns the operator to the RUN MENU. -

Page 65: Compressibility

Ultrapyc / UltraFoam Pycnometer Operation Manual E. ULTRAFOAM OPERATION 4.3.5 Compressibility This procedure measures both the compressibility of the specimen and the uncorrected open cell content as a function of increasing applied pressure. The user specifies a starting pressure (no less than 2 psig is recommended), an ending pressure (at least 10-12 psig is recommended), and a pressure increment (an interval of 1or 2 psi is recommended). - Page 66 Ultrapyc / UltraFoam Pycnometer Operation Manual E. ULTRAFOAM OPERATION Cell fracture is calculated as the percentage volume decrease with respect to the first volume measured at the lowest (starting) target pressure. This test is extremely useful in determining whether the open/closed cell measurement is significantly affected by the pressure applied to the sample without manually having to re-run the sample many times.

-

Page 67: Operating Sequence

Ultrapyc / UltraFoam Pycnometer Operation Manual F. OPERATING SEQUENCE F. OPERATING SEQUENCE This section contains an explanation of the operating sequence employed in the Ultrapyc to determine calibration and sample volumes. This explanation includes a description of the state of the valve status LEDs at each step of the measurement. - Page 68 Ultrapyc / UltraFoam Pycnometer Operation Manual F. OPERATING SEQUENCE Run Number: 1 Press A: 19.7570 where "#1" is the run number and "19.7570" is the cell pressure in psig with V out. The V input valve will then open as shown in Figure F.8. The introduction of V into the system will cause a pressure drop, which is proportional to the change in volume due to the introduction of V...

- Page 69 Ultrapyc / UltraFoam Pycnometer Operation Manual F. OPERATING SEQUENCE Run Number: 1 Density: 1.00875 g/cc After a short vent period, the instrument will begin the next run (if required). After the analysis is complete, the system will be in the state shown in Figure F.1. The sample may now be removed and the results displayed by the operator.

- Page 70 Ultrapyc / UltraFoam Pycnometer Operation Manual F. OPERATING SEQUENCE Figure F.3, System Vented to Ambient (Zeroing Transducer). Figure F.4, V valve Closed (Checking for Stability in Isolated Cell Chamber). Figure F.5, Vent Valve Closed. Figure F.6, Pressurizing Cell. 70 of 124...

- Page 71 Ultrapyc / UltraFoam Pycnometer Operation Manual F. OPERATING SEQUENCE Figure F.7, Input Valve Closed (Reading Press A). Figure F.8, V Input Valve Open (Reading Press B). Figure F.9, Venting Cell + V 71 of 124...

-

Page 72: Sources Of Error

Ultrapyc / UltraFoam Pycnometer Operation Manual G. SOURCES OF ERROR G. SOURCES OF ERROR Under normal operating conditions (using filled sample cells), the user can expect acquired deviations less than ±0.01% using the large sample cell. With the medium and small sample cells, the acquired deviation should be less than ±0.015%. -

Page 73: Additional Recommendations

Ultrapyc / UltraFoam Pycnometer Operation Manual G. SOURCES OF ERROR 0.5 cm can occur. Corrections for this error can be made with knowledge of the gas molecules' effective diameter (i.e., van der Waals diameter) and the powder's specific surface area. 1 Additional Recommendations 1. - Page 74 Ultrapyc / UltraFoam Pycnometer Operation Manual G. SOURCES OF ERROR Error 2 occurred Low Pressure NOTE! Error detection for codes 3 & 4 is disabled when a preset equilibration is selected. Error 8 is a failure of the clock calendar circuit. This will be displayed in a printout but will not affect the results of the analysis.

- Page 75 Ultrapyc / UltraFoam Pycnometer Operation Manual G. SOURCES OF ERROR Table G-1, Error Codes POSSIBLE ERROR DESCRIPTION CAUSES Pressure unstable with system isolated from ambient A, B, D Low pressure input. Cell pressure less than 75 % of target C, D, E, F, G, H pressure after 1.5 minute pressurization Pressure unstable with V isolated and system pressurized...

-

Page 76: Pycweb Computer Interface

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE H. PycWeb COMPUTER INTERFACE 1 Introduction The Ultrapyc has a small web server running on it. A user can connect to the Ultrapyc web server from a networked computer using a web browser. Web servers and web browsers communicate using a standard protocol called HTTP. - Page 77 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-1, Logging Onto The Pycnometer After entering your username and password, select “OK”. PycWeb should now launch automatically to the PycWeb home page. Figure H-2, "PycWeb" Home Page 77 of 124...

-

Page 78: Ultrapyc Web

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE 3 Ultrapyc Web Pages The Ultrapyc home page (index.html) has two links “Run” and “Reports”. Figure H-3, Links On Pycweb Home Page The “Run” page is used to operate the pycnometer remotely. Selecting “Run” from the home page will launch the three-pane “Run”... - Page 79 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE be viewed in the lower the left pane by selecting the “Manual Mode” link on the lower left keypad pane. Selecting “Manual Mode” in the lower left pane also brings up an alternative manual mode keypad (Figure H-5, Manual Mode Display) that sits below the manual mode display.

-

Page 80: Run Parameters

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-6, Setting Run Parameters NOTE! Name fields of the Run Parameters form should contain only numerals and letters. Spaces and special characters should not be used. The name fields of the Run Parameters form are Parameter File Name, User ID, and Type of Gas Used. -

Page 81: Sample Parameters

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-7, Loading Configuration Files Figure H-8, Loaded Configuration File Note that the instrument is able to save a maximum of fifty .rcfg files. It may be necessary to delete .rcfg files from the machine once at capacity. To delete a .rcfg file copy and paste the .rcfg file into the dialogue box that reads “Enter file name to delete”... -

Page 82: Instrument Parameters

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-9, Setting Sample Parameters Red indicates that Green indicates that the valve is closed. the valve is open. Figure H-10, Viewing Valve States 3.1.3 Instrument Parameters To adjust Instrument Parameters or to access the Email function, click on the “Instrument” link at the top of the “Run”... - Page 83 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE The top of the “Instrument Parameters” page has an additional link: “Email”. Click on this link to display the “Email Parameters” page (Figure H-12, Setting Email Parameters). If the Ultraapyc is attached to a local computer network that has a mail server running, reports can be sent from the Ultrapyc to the email address on the local network as specified in this form.

-

Page 84: Parameter Files

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE 3.1.4 Parameter Files To re-use “Sample” and “Run Parameters” click on the “Parameter Files” link at the top of the “Run” page. The “Parameter Files” page shows a list of stored configuration files (see Figure H-13, Saving Configuration Files) where the file type .scfg holds sample parameters, .icfg instrument configurations, and .rcfg run (analysis) parameters. - Page 85 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-14, Viewing List Of Reports 85 of 124...

- Page 86 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-15, Sample Report The file can be saved to the computer by right clicking the extension and saving the file to the chosen location or by copying the file from the FTP site. Copying files from the FTP site (Figure H-18, FTP Site) can work more quickly because a large quantity of files can be copied and saved in one step.

- Page 87 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE requesting a user name and password, these will be the same username and password that are used when launching PycWeb initially (both are set to “pyc” by factory settings). H-16, Launching FTP Site from “View” Drop Down Menu H-17, Log On - FTP Site ...

-

Page 88: Sample Measurement Run Using Pycweb

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE H-18, FTP Site 4 Sample Measurement Run Using PycWeb A typical sample measurement session might be: 1. Open up a web browser and connect to the Ultrapyc Home page. 2. Open the Run Parameters page. Set all run parameters that pertain to the measurement run. Click the save button. -

Page 89: Pycweb Foam Extension

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-19, Blank Status Display Panel 6 PycWeb Foam Extension Extended Run Parameters (Foam Mode) If your Ultrapyc supports the optional UltraFoam mode, the PycWeb “Run Parameters” web page will have an additional variable named “Instrument Mode.” The instrument-mode variable can be set to 1 for Ultrapyc mode or 2 for UltraFoam mode. - Page 90 Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-20, Selecting Foam Operation If you change the instrument mode from 1 to 2 and the Run Parameters save button is pushed, an update of the Run Parameters page will contain the additional foam parameters. The foam mode “Run Procedure”...

-

Page 91: Extended Sample Parameters (Foam Mode)

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-21, Foam Parameters Extended Sample Parameters (Foam Mode) When in UltraFoam mode, the PycWeb “Sample Parameters” page will have an extended set of sample parameters. The Shape parameter can be set to 1 for cube, 2 for cylinder, or 3 to enter the volume manually. -

Page 92: Reports Extended Information (Foam Mode)

Ultrapyc / UltraFoam Pycnometer Operation Manual H. PycWeb COMPUTER INTERFACE Figure H-22, Sample Parameters Reports Extended Information (Foam Mode) When a foam mode volume measurement cycle, completes the results are stored in a report file. The report file is stored in the Ultrapyc flash memory file system. Section D.8 of this manual describes the naming conventions used when naming calibration report files, and Ultrapyc (non-Foam) report files. -

Page 93: Theory

Ultrapyc / UltraFoam Pycnometer Operation Manual I. THEORY I. THEORY NOTE! Refer to the Flow Diagram of the Ultrapyc (see Section C.1.1). By opening the solenoid valves to the sample cell, the system is brought to ambient pressure P after being purged with helium. - Page 94 Ultrapyc / UltraFoam Pycnometer Operation Manual I. THEORY Since P is made to read zero, that is, all pressure measurements are relative to P which is zeroed prior to pressurizing, Equation (I.9) becomes: (I.10) Equation (I.10) is the working equation employed by the Ultrapyc/UltraFoam (i.e. the V is the measured volume of the sample and closed pores).

-

Page 95: Appendices

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES J. APPENDICES Appendix 1 Calibration Spheres The table below shows the various spheres that are available for calibrating the instrument. Table J-1, Calibration Spheres And Nominal Sizes QTY IN QTY IN PART DIAMETER VOLUME SIZE NUMBER... -

Page 96: Appendix 2 Operation With Temperature Control Option

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 2 Operation with Temperature Control Option Ultrapycs manufactured for use with the optional Temperature Control Capability have two open brass tubes projecting from the right side panel of the instrument. (Note: Ultrapycs without this option cannot be upgraded outside the factory). -

Page 97: Appendix 3 Balance Mode

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 3 Balance Mode Appendix 3.1 Compatible Output Format A digital balance can be connected to the Ultrapyc serial port. A data stream containing weight information flows from the balance to the Ultrapyc through the serial port cable. The serial data output from a digital balance come in a wide variety of formats. - Page 98 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Ultrapyc to use this mode. A cable for this purpose is supplied by the balance manufacturer although its connector may have to be replaced / rewired.** The display will show the following menu: Enter Baud Rate Selected: 1200 To accept the baud rate shown, press the ENTER key or enter a new value then press the...

- Page 99 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Enter communication Timeout: 60 Upon entry of the timeout, the instrument will return to the Main Menu. The Ultrapyc COMM port is wired exactly like a standard PC. If the digital balance and serial port cable is functional when attached to a PC COMM port, then the balance and cable should work when attached to the Ultrapyc COMM port.

-

Page 100: Appendix 4 Compatible Printers

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 4 Compatible Printers The Ultrapyc is Linux based and many Hewlett-Packard (HP) printers are supported under Linux. The Ultrapyc can automatically configure itself to work with most of the HP printers via the Add Printer menu item. -

Page 101: Appendix 5 Calibration And Usage Of The Nanocell (The Difference Method)

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 5 Calibration and Usage of the Nanocell (the Difference Method) Any error in the calibration volume of the nanocell will be much more pronounced due to the small volume involved. The difference method provides a more accurate determination of sample volume. - Page 102 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES use the average values. The calculation gives the volume of the sample. When the nanosphere is measured this way, the result should yield 0.0898 cc with a maximum error no greater than 2 % (0.0018 cc) for the Micro-Ultrapyc.‡‡ ‡‡...

-

Page 103: Appendix 6 Computer Network Address Configuration

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 6 Computer Network Address Configuration Appendix 6.1 Configuring a Microsoft Windows system If the computer is running the Microsoft Windows operating system, open the network connections service from the Control Panel: Figure J.1, Windows Control Panel, Some Versions Of Windows May Look Different If the computer has a network card, the user will see its network in the list. - Page 104 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Double clicking brings up the network connection dialog box: Figure J.3, Network Connection Dialog Box Click on the “Properties” button. Select “Internet Protocol (TCP/IP): Figure J.4, Select Internet Protocol Click on the “Properties” button. Select the “Use the following IP address”...

-

Page 105: Appendix 6.2 Configuring Network Address On Linux (Or Unix)

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Ultrapyc IP address 192.168.0.2, network mask 255.255.255.0. Your Computer IP address 192.168.0.1, network mask 255.255.255.0. Figure J.5, Specifying IP Address And Subnet Mask Click on the OK button to complete the configuration procedure. Appendix 6.2 Configuring Network address on LINUX (or UNIX) There is a lot of variability on graphical-user-interface methods of setting network addresses... - Page 106 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Figure J.6, Linux ifconfig Output If the network interface has not been configured, ifconfig will not display any information. To set the IP address and network mask type “ifconfig eth0 192.168.0.1 netmask 255.255.255.0 up”.

-

Page 107: Report File Transfer And Firmware Update Via Ftp Or Via Filezilla

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 7 Report File Transfer and Firmware Update FTP or FileZilla NOTE! If you experience any issues in this section, please contact Quantachrome Support at support-sp@anton-paar.com The PYCNOMETER has a small file transfer protocol (FTP) server running on it. FTP is a prevalent standardized internet protocol used for file transfer. - Page 108 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES NOTE! If you do not know the Pycnometer’s IP address, you can display it by using the following sequence from the instrument’s keypad: Main Menu → Settings → 2-Network Configuration → 1- 3-System Display IP Address (see also Section D.3.3.1 Network Menu, of this manual).

- Page 109 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES File Transfer FileZilla An example session, used to download report files from the Ultrapyc to a Microsoft Windows computer, is described below. Enter the IP address of the pycnometer into the Host box of FileZilla, enter the user name “pyc”, the password is “pyc”.

- Page 110 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Figure J.9, FileZilla Screen 110 of 124...

-

Page 111: Appendix 7.2 Updating Pycnometer's Firmware

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 7.2 Updating Pycnometer’s Firmware In case the pycnometer requires firmware update, please contact Quantachrome to obtain the pycUpdate.qcz update file. Save this file on a computer’s hard drive and note the directory where the user saved the file. - Page 112 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Figure J.12, Change Directory To "Users" NOTE! Hit ENTER key to execute any command that is typed-in, and wait for response. Figure J.13, Users Directory 6. After directory has been successfully changed, open the ftp session, by typing-in the following command: “ftp xxx.xxx.xxx.xxx”, where “xxx.xxx.xxx.xxx”...

- Page 113 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES 7. After the ftp session is open, proceed with login. At the user prompt, type-in “pyc” (hit ENTER to execute). Similarly, at the password prompt, type “pyc” again (hit ENTER to execute). At this point, you should be successfully logged in the ftp session: Figure J.16, Logging Into Ftp Server 8.

- Page 114 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES 10. Next, reboot the pycnometer’s operating system. Use the instrument’s keypad to follow the sequence: Main Menu → 8-Shutdown After pycnometer shuts down, wait for ~5 seconds then cycle the power switch (OFF/ON). ...

-

Page 115: Appendix 8 Leak Check

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 8 Leak Check The Ultrapyc can perform an automated leak test. The automatic leak test can be selected using keypad sequence Main menu → 3-System Settings → 9-LeakCheck. The automatic leak test checks for leaks in the three sections of the Ultrapyc, the cell volume section, the small Vadded volume section, and large Vadded volume section. - Page 116 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES 116 of 124...

- Page 117 Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES When the Ultrapyc pauses to display one of the error messages, or runs to completion and displays the “No leaks found” message, it waits for user input before returning to the “System Settings” menu. Press the CLEAR or RESET buttons when ready to continue. 117 of 124...

-

Page 118: Appendix 9 Gpl / Lgpl Source Code

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 9 GPL / LGPL Source Code The Quantachrome Pycnometer uses a Linux based operating system. Use of the Linux operating system and Linux utilities are licensed under the GNU General Public License (GPL.) The Pycnometer application code was compiled with the GNU GCC compiler tool chain and linked against the GNU GLIBC libraries. -

Page 119: Appendix 10 Foam Cutting Accessory

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 10 Foam Cutting Accessory The UltraFoam instruments include a foam-cutting accessory, which facilitates cutting uniform cubes and cylinders of foam for analysis. This accessory is available separately from Quantachrome (SAP# 193287 as well. This accessory comes with illustrated instructions on its use. -

Page 120: Appendix 11 Pyc-Time Zones

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 11 Pyc-Time Zones 120 of 124... -

Page 121: Appendix 11.1 Pyc-Time Zones-Continued

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 11.1 Pyc-Time Zones-Continued 121 of 124... -

Page 122: Appendix 11.2 Pyc-Time Zones-Continued

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 11.2 Pyc-Time Zones-Continued 122 of 124... -

Page 123: Appendix 11.3 Pyc-Time Zones-Continued

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 11.3 Pyc-Time Zones-Continued 123 of 124... -

Page 124: Appendix 12 Preventative Maintenance Plan

Ultrapyc / UltraFoam Pycnometer Operation Manual APPENDICES Appendix 12 Preventative Maintenance Plan In order to keep your instrument running at a high standard consistently it is advised that a maintenance plan is established using the following guidelines recommended by Quantachrome Instruments.

Need help?

Do you have a question about the Quantachrome ULTRAPYC UPY-32 and is the answer not in the manual?

Questions and answers