Samsung AM FN1DEH Series Installation Manual

Cassette type series

Hide thumbs

Also See for AM FN1DEH Series:

- Installation manual (40 pages) ,

- User manual (60 pages) ,

- User manual (32 pages)

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Samsung AM FN1DEH Series

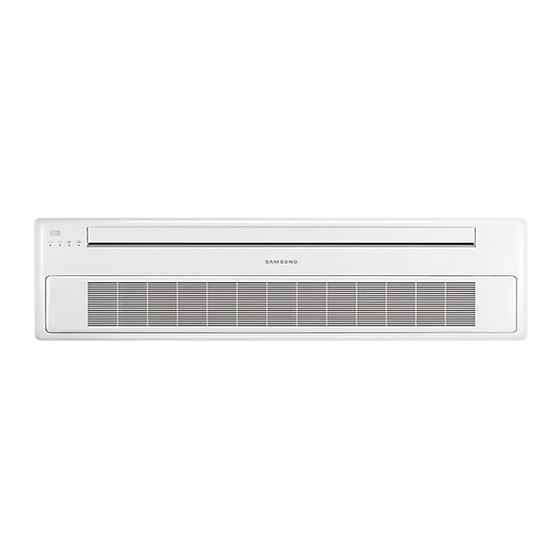

- Page 1 Cassette Type Series Slim 1 Way cassette : AM✴✴✴FN1DEH✴ AM✴✴✴JN1DEH✴ 2 Way cassette : AM✴✴✴FN2DEH✴ 4 Way cassette : AM✴✴✴FN4DEH✴ Air Conditioner installation manual imagine the possibilities Thank you for purchasing this Samsung product. DB68-03862A-08...

-

Page 2: Table Of Contents

Contents Safety Precautions ....................3 Accessories . -

Page 3: Safety Precautions

In order to prevent electric shocks, fires or injuries, always stop the unit, disable the protection switch and contact SAMSUNG’s technical support if the unit produces smoke, if the power cable is hot or damaged or if the unit is very noisy. - Page 4 Safety Precautions Installing the unit IMPORTANT: When installing the unit, always remember to connect first the refrigerant tubes, then the electrical lines. Always disassemble the electric lines before the refrigerant tubes. Upon receipt, inspect the product to verify that it has not been damaged during transport. If the product appears damaged, DO NOT INSTALL it and immediately report the damage to the carrier or retailer (if the installer or the authorized technician has collected the material from the retailer.) After completing the installation, always carry out a functional test and provide the instructions on how to operate...

- Page 5 • Make sure that you earth the cables. CAUTION Do not connect the earth wire to the gas pipe, water pipe, lighting rod or telephone wire. If earthing is not complete, electric shock or fire may occur. • Install the circuit breaker. If the circuit breaker is not installed, electric shock or fire may occur.

-

Page 6: Accessories

Accessories The following accessories are supplied with the indoor unit. The type and quantity may differ depending on the specifications. AM****N1DEH* Dimension gauge Installation template Insulation drain Flexible hose Rubber Installation manual AM***FN2DEH* Installation Dimension gauge Insulation drain Flexible hose Rubber Installation manual template... - Page 7 Space Requirements for Indoor Unit AM✴✴✴FN1DEH✴/AM✴✴✴JN1DEH✴/AM✴✴✴FN2DEH✴ AM✴✴✴FN4DEH✴ • The units must be installed according to distances declared, in order to permit accessibility from each CAUTION side, either to guarantee correct operation of maintenance or repairing products. The unit’s parts must be reachable and removable completely under safety condition (for people or things).

- Page 8 Selecting the Installation Location Insulation Guide 2 Way cassette (Unit : mm) Thickness: more than 10mm Indoor unit 5.2~7.2kw 880x185 880x185 570x185 570x185 880x570 (890x230x575) • Insulate the end of the pipe and some curved area by using separate insulator.

- Page 9 Dimension of the indoor unit AM✴✴✴FN1DEH✴ (Unit : mm) 1150 (Suspension position) 1035.8 (Ceiling opening) Drain hole Celling 1198 Name Description Liquid pipe connection ø6.35 Gas pipe connection ø12.70 Drain pipe connection OD ø32, ID ø26 Power supply connection Air discharge grille Air suction grille...

- Page 10 Selecting the Installation Location AM✴✴✴JN1DEH✴ (Unit : mm) 1380 (Suspension position) 1260 (Ceiling opening) 1200 Celling 1410 Name Description AM056JN1✴✴✴✴ : ø6.35 (1/4”) Liquid pipe connection AM071JN1✴✴✴✴ : ø9.52 (3/8”) AM056JN1✴✴✴✴ : ø12.70 (1/2”) Gas pipe connection AM071JN1✴✴✴✴ : ø15.88 (5/8”) Drain pipe connection OD ø32, ID ø26 Power supply connection...

- Page 11 AM✴✴✴FN2DEH✴ (Unit : mm) 136.5 1030 Name Description ✴✴056✴✴ : ø6.35 Liquid pipe connection ✴✴071✴✴ : ø9.52 ✴✴056✴✴ : ø12.7 Gas pipe connection ✴✴071✴✴ : ø15.88 Drain pipe connection VP25 (OD ø32, ID ø25) Power supply connection Air discharge grille Air suction grille...

- Page 12 Selecting the Installation Location AM✴✴✴FN4DEH✴ (Unit : mm) 890~910 (Celling opening) 735 (Suspension position) Sub duct connection MODEL ✴✴045✴✴ ✴✴071✴✴ ✴✴128✴✴ ✴✴112✴✴ ✴✴056✴✴ ✴✴090✴✴ ✴✴140✴✴ Liquid pipe connection ø6.35 ø9.52 Gas pipe connection ø12.7 ø15.88 Drain Hose connection OD : ø32.0, ID : ø26.5...

-

Page 13: Indoor Unit Installation

Indoor Unit Installation It is recommended to install the Y-joint before installing the indoor unit. 1. Place the pattern sheet on the ceiling at the spot where you want to install the indoor unit. • Since the diagram is made of paper, it may shrink or stretch slightly due to temperature or humidity. -

Page 14: Purging The Unit

Indoor Unit Installation 6. Adjust the height of the indoor unit by using the jigs. • You should adjust the jigs and the pattern sheet to fit the cutting dimensions of ceiling. • Noise may occur if you do not adjust the location of the indoor unit according to location of the jigs during installation. -

Page 15: Connecting The Refrigerant Pipe

Connecting the Refrigerant Pipe There are two refrigerant pipes of differing diameters: • A smaller one for the liquid refrigerant • A larger one for the gas refrigerant • The inside of copper pipe must be clean & has no dust. 1. -

Page 16: Cutting/Flaring The Pipes

Cutting/Flaring the Pipes 1. Make sure that you prepared the required tools. (pipe cutter, reamer, flaring tool and pipe holder) 2. If you want to shorten the pipe, cut it using a pipe cutter ensuring that the cut edge remains at 90° with the side of the pipe. There are some examples of correctly and incorrectly cut edges below. - Page 17 5. Check if you flared the pipe correctly. There are some examples of ncorrectly flared pipes below. Correct Inclined Damaged Surface Cracked Uneven Thickness 6. Align the pipes and tighten the flare nuts first manually and then with a torque wrench, applying the following torque. Connection Torque Flare Outer diameter...

-

Page 18: Performing Leak Test & Insulation

Performing Leak Test & Insulation Leak test LEAK TEST WITH NITROGEN (before opening valves) In order to detect basic refrigerant leaks, before recreating the vacuum and recirculating the R-410A, it’s responsible of installer to pressurize the whole system with nitrogen (using a pressure regulator) at a pressure above 4.1MPa (gauge). - Page 19 5. Select the insulation of the refrigerant pipe. • Insulate the gas side and liquid side pipe referring to the thickness according to the pipe size. • Indoor temperature of 30°C and humidity of 85% is the standard condition. If installing in a high humidity condition, use one grade thicker insulator by referring to the table below. If installing in an unfavorable conditions, use thicker one.

- Page 20 Performing Leak Test & Insulation Refrigerant pipe before EEV kit and MCU or without EEV kit and MCU • You can contact the gas side and liquid side pipes but the pipes should Insulation not be pressed. Insulation • When contacting the gas side and gas side pipe, use 1 grade thicker insulator.

-

Page 21: Drain Pipe And Drain Hose Installation

Drain pipe and Drain Hose Installation Care must be taken when installing the drainpipe and drain hose for the indoor unit so that condensate water is drained correctly outside. 1. Fix the flexible hose to the drainpipe. AM✴✴✴FN1DEH✴/AM✴✴✴JN1DEH✴/AM✴✴✴FN2DEH✴ PVC Tube Joint +VP25 Flexible hose •... - Page 22 Drain pipe and Drain Hose Installation Drainpipe Connection 1. The drain pipe should be installed within 100mm from the flexible hose, lift up from 100mm to 550mm and lift down 20mm or more. 2. Install horizontal drainpipe with a slope of 1/100 or more and fix it by hanger space of 1~1.5m. 3.

- Page 23 Centralized Drainage 1. Install main air vent at the front of the farthest indoor unit from the main drain when installed indoor units are more than 3. 2. You may need to install individual air vent to prevent water flow back at the top of each indoor unit drainpipe. 1~1.5m Hanger Main air vent...

-

Page 24: Wiring Work

Wiring Work Power and communication cable connection 1. Before wiring work, you must turn off all power source. 2. Indoor unit power should be supplied through the breaker(MCCB, ELB) separated by the outdoor power. 3. The power cable should be used only copper wires. 4. - Page 25 Specification of electronic wire Power supply MCCB Power cable Earth cable Communication cable Max : 242V XA, 30mmA 2.5mm 2.5mm 0.75~1.5mm Min : 198V 0.1 s • Decide the capacity of ELB and MCCB by below formula. The capacity of ELB, MCCB X [A] = 1.25 X 1.1 X ΣAi ✴...

- Page 26 Wiring Work Example of Installation Total power cable length L = 100(m), Running current of each units 1[A] Total 10 indoor units were installed 10[A] 9[A] 1[A] MCCB Indoor unit1 Indoor unit2 Indoor unit10 0[m] 10[m] 20[m] 100[m] • Apply following equation. Coef×35.6×L ×i 10% of input...

- Page 27 • Select the power cable in accordance with relevant local and national regulations. • Wire size must comply with local and national code. CAUTION • Power Supply cords of parts of appliances for outdoor use shall not be lighter than polychloroprene sheathed flexible cord.

- Page 28 Wiring Work How to connect your extended power cables 1. Prepare the following tools. Connection sleeve Tools Crimping pliers Insulation tape Contraction tube (mm) (mm) Spec MH-14 20xØ6.5(HxOD) Width 19mm 70xØ8.0(LxOD) Shape 2. As shown in the figure, peel off the shields from the rubber and wire of the power cable.

- Page 29 5. Wrap it with the insulation tape twice or more and position your contraction tube in the middle of the insulation tape. Three or more layers of insulation are required. Method 1 Method 2 Insulation tape Insulation tape 40 mm 35 mm 6.

-

Page 30: Setting An Indoor Unit Address And Installation Option

Setting an indoor unit address and installation option Set the indoor unit address and installation option with remote controller option. Set the each option separately since you cannot set the ADDRESS setting and indoor unit installation setting option at the same time. You need to set twice when setting indoor unit address and installation option. The procedure of option setting MR-DC00, MR-DH00 MR-EC00, MR-EH00... - Page 31 Option setting Status 1. Setting SEG2, SEG3 option Press Low Fan button( ) to enter SEG2 value. Press High Fan button( ) to enter SEG3 value. SEG2 SEG3 Each time you press the button, … will be selected in rotation. 2.

- Page 32 Setting an indoor unit address and installation option Option setting Status 13. Setting SEG16, SEG17 option Press Low Fan button( ) to enter SEG16 value. Press High Fan button( ) to enter SEG17 value. 1. Each time you press the button, …...

- Page 33 Setting an indoor unit address (MAIN/RMC/MCU) 1. Check whether power is supplied or not. When the indoor unit is not plugged in, there should be additional Indoor Unit power supply in the indoor unit. 2. The panel(display) should be connected to an indoor unit to receive option. 1(L) 2(N) 3.

- Page 34 Setting an indoor unit address and installation option • When “A”~”F” is entered to SEG5~6, the indoor unit MAIN ADDRESS is not changed. • If you set the SEG 3 as 0, the indoor unit will maintain the previous MAIN ADDRESS even if you input CAUTION the option value of SEG5~6.

- Page 35 02 series installation option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 Use of external room temperature Use of central FAN RPM Evaporator Drying sensor / Minimizing control compensation fan operation when thermostat is off SEG7 SEG8 SEG9 SEG10 SEG11 SEG12 Use of hot water EEV Step when Use of drain pump heater...

- Page 36 Setting an indoor unit address and installation option 02 series installation option(Detailed) Option No. : 02XXXX-1XXXXX-2XXXXX-3XXXXX Option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 Use of external room temperature sensor / Minimizing Explanation PAGE MODE Evaporator Drying Use of central control FAN RPM compensation fan operation when thermostat is off Details...

- Page 37 Option SEG13 SEG14 SEG15 SEG16 SEG17 SEG18 Setting the output of external control / Explanation PAGE Use of external control External heater signal / Cooling operation S-Plasma ion Buzzer control Hours of filter usage signal / Free Cooling control signal Indication Details Indication Details Indication...

- Page 38 Setting an indoor unit address and installation option *Advanced function: Controlling cooling/heating current or power saving with motion detect. (*1) When Cooling or dry mode is off. The indoor fan operate in setting minutes. (*2) Minimizing fan operation when thermostat is off - Fan operates for 20 seconds at an interval of 5 minutes in heat mode.

- Page 39 05 series installation option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 Use of Auto Change Over (When setting SEG3) (When setting SEG3) (When setting SEG3) for HR only in Auto mode / Standard heating temp. Standard cooling temp. Standard for mode change Use of Cooling only indoor Offset Offset...

- Page 40 Setting an indoor unit address and installation option Option SEG13 SEG14 SEG15 SEG16 SEG17 SEG18 Control variables when using hot water / external Explanation heater (*4) Details Indication Details Indication Set temp. for heater Delay time for On/Off heater On At the same time as No delay thermo on...

- Page 41 (*1) Height difference : The difference of the height between the corresponding indoor unit and the indoor unit installed at the lowest place. For example, When the indoor unit is installed 40m higher than the indoor unit installed at the lowest place, select the option “1”. (*2) Distance : The difference between the pipe length of the indoor unit installed at farthest place from an outdoor unit and the pipe length of the corresponding indoor unit from an outdoor unit.

- Page 42 Setting an indoor unit address and installation option Changing a particular option You can change each digit of set option. Option SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 The tens’ digit of an The unit digit of an The option mode Explanation PAGE MODE...

-

Page 43: Final Checks And User Tips

Final Checks and User Tips To complete the installation, perform the following checks and tests to ensure that the air conditioner operates correctly. Check the followings. • Strength of the installation site • Tightness of pipe connection to detect a gas leak •... -

Page 44: Troubleshooting

Troubleshooting Troubleshooting Detection of errors • If an error occurs during the operation, an LED flickers and the operation is stopped except the LED. • If you re-operate the air conditioner, it operates normally at first, then detect an error again. LED Display on the receiver &... - Page 45 LED Display Error Abnormal condition code Green (*Ice (*Yellow Blue) Green) 1. COND mid sensor is detached E241 2. Refrigerant leakage (2nd detection) E554 3. Abnomally high temperature on Cond (2nd detection) E450 4. Low pressure s/w (2nd detection) E451 5.

- Page 46 Troubleshooting LED Display Abnormal condition Error code Operation Defrost Timer Filter Indoor fan error E154 1. Error on outdoor temperature sensor (Short or Open) E221 2. Error on cond sensor E237 3. Error on discharge sensor E251 Other outdoor unit sensor error that is not on the above list 1.

-

Page 47: Instruction For Packing And Unpacking The Unit

Instruction for packing and unpacking the unit • Packing the unit as below procedure 1. Put the indoor unit onto the cushion-bottom. 2. Put the cushion-top onto the indoor unit. 3. Put the packing case from the top of set. 4. -

Page 48: Technical Specifications

Technical Specifications MODEL AM022FN1DEH/TK AM028FN1DEH/TK AM036FN1DEH/TK AM056JN1DEH/TK AM071JN1DEH/TK CLIMATES CLASS RATED VOLTAGE & 220 - 240 V~ 50 Hz FREQUENCY COOLING 0.20 A 0.20 A 0.23 A 0.23 A 0.25 A 0.25 A 0.28 A 0.28 A 0.40 A 0.40 A RATED CURRENT HEATING(H1) - Page 49 MODEL AM090FN4DEH/TK AM112FN4DEH/TK AM128FN4DEH/TK AM140FN4DEH/TK CLIMATES CLASS RATED VOLTAGE & 220 - 240 V~ 50 Hz FREQUENCY COOLING 0.43 A 0.43 A 0.55 A 0.55 A 0.51 A 0.51 A 0.62 A 0.62 A RATED CURRENT HEATING(H1) 0.43 A 0.55 A 0.51 A 0.62 A RATED...

Need help?

Do you have a question about the AM FN1DEH Series and is the answer not in the manual?

Questions and answers