Summary of Contents for Embest SBC8018

- Page 1 SBC8018 Evaluation Board Integrated with SATA, TF, OTG, Audio in/out, USB, Ethernet, LCD, CCD/COMS, Serial, JTAG interface based on 32-bit microprocessor User Manual...

- Page 2 Version update records: Date Description 2011.10.21 Initial version Copyright © 2011 by element14 User Manual - 2 -...

-

Page 3: Table Of Contents

Contents CHAPTER 1 OVERVIEW ......................... 6 1.1 P ......................6 RODUCT NTRODUCTION 1.2 F ..........................7 EATURES CHAPTER 2 HARDWARE SYSTEM ....................9 2.1 CPU ............................9 2.1.1 CPU Introduction ......................9 2.1.2 CPU Features ........................9 2.2 I : .................. 11 NTRODUCTION TO THE XPANDED 2.2.1 TPS65070 ........................ - Page 4 2.3.14 JTAG Interface ......................22 2.3.15 Expansion Interface ..................... 22 2.3.16 DIP Switch ........................25 2.3.17 KEY Switch ........................26 2.3.18 LEDs..........................26 CHAPTER 3 LINUX OPERATING SYSTEM ................. 27 3.1 I ........................27 NTRODUCTION 3.2 S ......................27 OFTWARE ESOURCES 3.3 B (BSP) F...

- Page 5 4.5.3 Downloading NK.bin to NAND flash ................71 4.6 U ......................75 NSTRUCTIONS 4.6.1 How to use Power Management ..................75 4.6.2 How to use CAM8000-A module ..................76 4.7 SBC8018 W CE 6.0 32 API ......77 INDOWS APPLICATION DEVELOPMENT APPENDIX .............................

-

Page 6: Chapter 1 Overview

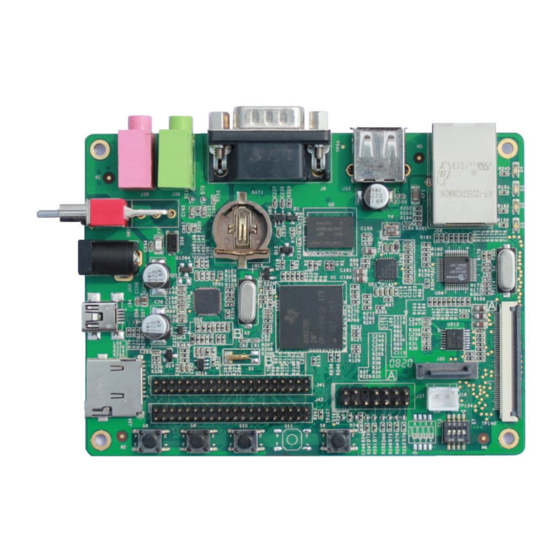

Chapter 1 Overview 1.1 Product Introduction The SBC8018 evaluation board is a compact, low-cost with high-performance evaluation board based on Texas instruments (TI) AM1808 microprocessor. AM1808 is an integration of 375 MHz ARM9 low-power application processor with 128K-Byte On-the chip memory, and provided lots of peripheral interface. -

Page 7: Features

SBC8018 Evaluation Board Functional Block Diagram Figure 1-1 1.2 Features SBC8018 evaluation board is based on AM1808 processor and is one compact board which integrates all functions and features of TI’s AM1808 ARM9 processor. Some of the board features are mentioned below: Mechanical Parameters ... - Page 8 128MB Mobile DDR Audio/Video Interfaces An audio Microphone input interface (3.5mm audio jack, red) A two-channel audio line output interface (3.5mm audio jack, green) A TFT-LCD interface (24 bit color, 1.8 V logic, with touch screen) Data Transfer Interface ...

-

Page 9: Chapter 2 Hardware System

Chapter 2 Hardware System 2.1 CPU 2.1.1 CPU Introduction The AM1808 microprocessor contains an ARM RISC CPU for general-purpose processing and systems control. The AM1808 ARM microprocessor consists of the following primary components: ARM926EJ-S RISC processor core and associated memories ... - Page 10 ARM926EJ-S RISC CPU The ARM Subsystem integrates the ARM926EJ-S processor. The ARM926EJ-S processor is a member of ARM9 family of general-purpose microprocessors. This processor is targeted at multi-tasking applications where full memory management, high performance, low die size, and low power are all important. The ARM926EJ-S processor supports the 32-bit ARM and 16 bit THUMB instruction sets, enabling the user to trade off between high performance and high code density.

-

Page 11: Introduction To The Expanded Chip

2.2.2 K9F1G08U0B The K9F1G08U0B is the 128MB NAND flash memory chips used in SBC8018 evaluation board. This NAND Flash chip is directly interfaced to the CPU for faster memory access and read/write cycles. -

Page 12: H5Ms1G62Mfp

The function of MAX3232 is mainly to convert TTL logic level signal to RS232 logic level, which helps the board at TTL logic to interface with PC working at RS232 logic level. The SBC8018 evaluation board uses UART2 as debugger serial port; the default voltage for this UART2 is 1.8V, Copyright ©... -

Page 13: Hardware Interface

2.3 Hardware Interface The following section provides you the detailed information on the peripherals, with the pin description, and its functionality available on SBC8018 evaluation board. Figure 2-2 Hardware Interface chart 2.3.1 Power Input Jack Table 2-1 power input interface... -

Page 14: Power Output Interface

2.3.2 Power Output Interface Table 2-2 power output interface Signal Function 5V output 2.3.3 Power Switch Table 2-3 power switch Signal Function DC IN VDD Input +5VDC_IN 2.3.4 TFT_LCD Interface Table 2-4 TFT_LCD interface Signal Function B_NU0 Test Point B_NU1 Test Point B_NU2 Test Point... - Page 15 G_NU0 Test Point G_NU1 Test Point LCD_D5 LCD data bit5 LCD_D6 LCD data bit6 LCD_D7 LCD data bit7 LCD_D8 LCD data bit8 LCD_D9 LCD data bit9 LCD_D10 LCD data bit10 R_NU0 Test Point R_NU1 Test Point R_NU2 Test Point LCD_D11 LCD data bit11 LCD_D12 LCD data bit12...

-

Page 16: Audio Output Jack

R_LCD_MISO Slave data out, master data in R_LCD_SPICS SPI enable IIC_CLK IIC master serial clock, NC IIC_DAT IIC serial bidirectional data, NC +1P8V_LDO +1.8V +3P3V +3.3V +5VDC_IN +5VDC_IN RESET +1.8V R_LCD_PWREN Power on enable 2.3.5 AUDIO OUTPUT Jack Table 2-5 Audio out interface Signal Function LINE_OUT_LP... -

Page 17: Camera Interface

2.3.6 Camera Interface Table 2-6 camera interface J35,J43 Signal Function Test Point Test Point R_CAM_D0 VPIF capture data bit 0 R_CAM_D1 VPIF capture data bit 1 R_CAM_D2 VPIF capture data bit 2 R_CAM_D3 VPIF capture data bit 3 R_CAM_D4 VPIF capture data bit 4 R_CAM_D5 VPIF capture data bit 5 R_CAM_D6... -

Page 18: Mic In Jack

CAM_SDA I2C0 serial data CAM_SCL I2C0 serial clock +1P8V_LDO 1.8V 2.3.7 MIC IN Jack Table 2-7 MIC IN interface Signal Function LINE_IN_LP Left input LINE_IN_RP Right input LINE_IN_RP Right input LINE_IN_LP Left input 2.3.8 Serial Ports Table 2-8 serial port Signal Function RSA_RXD... -

Page 19: Lan Interface

2.3.9 LAN Interface Table 2-9 LAN interface Signal Function LAN_TX+ TX+ output LAN_TX- TX- output Link to analog transmit power input with 0R resistance 4&5 Transformer 7&8 Transformer Link to analog transmit power input with 0R resistance LAN_RX+ RX+ input LAN_RX- RX- input Link LED... -

Page 20: Usb Otg Interface

SATA_TXN SATA receive data(negative) SATA_RXN SATA transmit data(negative) SATA_RXP SATA transmit data(positive) 2.3.11 USB OTG Interface Table 2-11 USB OTG interface Signal Function USB0_VBUS USB0_D- USB Data- USB0_D+ USB Data+ USB ID Copyright © 2011 by element14 User Manual - 20 -... -

Page 21: Usb Host Interface

2.3.12 USB HOST Interface Table 2-12 USB HOST interface Signal Function USB1_VBUS USB1_D- USB Data- USB1_D+ USB Data+ CHGND CHGND 2.3.13 TF Card Interface Table 2-13 TF interface Signal Function DAT2 Card data 2 DAT3 Card data 3 Command Signal Clock DAT0 Card data 0... -

Page 22: Jtag Interface

2.3.14 JTAG Interface Table 2-14 JTAG interface Signal Function Test mode select NTRST Test system reset Test data input 1.8V Test data output RTCK Receive test clock Test clock EMU0 Test emulation 0 EMU1 Test emulation 1 2.3.15 Expansion Interface Table 2-15 expansion interface Signal Function... - Page 23 EMA_D_14_EXP GPIO EMA_A_14_EXP GPIO EMA_D_13_EXP GPIO EMA_A_13_EXP GPIO EMA_D_12_EXP GPIO EMA_A_0_EXP GPIO EMA_D_11_EXP GPIO EMA_BA_1_EXP GPIO EMA_D_10_EXP GPIO EPWMN1_TZ0 GPIO EMA_D_9_EXP GPIO ECAP2_APWM2 GPIO EMA_D_8_EXP GPIO AIC_WCLK GPIO EMA_CLK_EXP GPIO AFSR GPIO EMA_SDCKE_EXP GPIO AIC_MCLK GPIO EMA_CSn_5_EXP GPIO EMA_CSn_4_EXP GPIO AIC_BCLK GPIO EMA_CSn_2_EXP...

- Page 24 +3P3V 3.3V +1P8V_LDO 1.8V Table 2-16 expansion interface Signal Function uP_SPI1_CLK SPI1 clock uP_McBSP1_CLKR_EXP McBSP1 receive clock uP_SPI1_SOMI SPI1 data slave-out-master-in uP_McBSP1_CLKX_EXP McBSP1 transmit clock uP_SPI1_SIMO SPI1 data slave-in-master-out McBSP1 sample rate generator uP_McBSP0_CLKS_EXP clock input uP_SPI1_SCSn0 SPI1 chip selects AIC_DOUT McBSP1 receive frame sync uP_SPI1_ENAN...

-

Page 25: Dip Switch

I2C0_SCL I2C0 serial clock I2C0_SDA I2C0 serial data uP_SPI0_CLK SPI0 clock uP_SPI0_SOMI SPI0 data slave-out-master-in uP_SPI0_SIMO SPI0 data slave-in-master-out uP_SPI0_SCSn0 SPI0 chip selects +5VDC_IN uP_SPI0_ENAN 1.8V +3P3V +3.3V +1P8V_LDO +1.8V 2.3.16 DIP Switch Table 2-17 DIP Switch Function PWR_BOOT Link to PWR_BOOT with 1K resistor Link to GND with 1K resistor Link to GND with 1K resistor PWR_BOOT... -

Page 26: Key Switch

2.3.17 KEY Switch Table 2-18 KEY Switch Function uP_RESETn Device reset input USER_BACK GPIO USER_MENU GPIO USER_HOME GPIO 2.3.18 LEDs Table 2-19 LED Signal Function User_LED_1 User Definitude User_LED_2 User Definitude User_LED_3 User Definitude +3P3V 3.3V power indicator Copyright © 2011 by element14 User Manual - 26 -... -

Page 27: Chapter 3 Linux Operating System

2) Master relative embedded Linux development technology. 3.2 Software Resources This chapter provides an overview of software system components of SBC8018. A basic software system consists of four parts: u-boot, kernel and rootfs. The Figure 3-2 shows the structure of the... -

Page 28: Board Support Package (Bsp) Features

The SBC8018 Board Support Package (BSP) is used for customizing and generating the Linux operating system applicable to SBC8018 hardware platform. Users can conduct a secondary development on the basis of this BSP. The BSP in the CD provided with the SBC8018 evaluation kit contains as bellows:... -

Page 29: System Development

3.4 System Development 3.4.1 How to Setup Operating System Development Environment Before executing software development on SBC8018, the user has to install Linux cross development environment on its computer. How to install a cross development environment will be explained below by taking Ubuntu operating system as an example. -

Page 30: System Compilation

3.4.2.2 X-loader Image Generation The SBC8018 evaluation board supports UART boot or NAND boot. The image files are different for the different boot modes, and the methods for mapping are also different. Copyright © 2011 by element14... - Page 31 Launches the ASIgen, click “File”-> “Load Configuration” to open AM1808-UART.cfg from the CD under the folder CD\linux\tools\. b) Added the u-boot file under the folder [d:\sbc8018\] to the [ARM Application File:] c) Sets the output file path [AIS Output File] as [d:\sbc8018\u-boot-uart-ais.bin].

- Page 32 Launches the ASIgen, click “File”-> “Load Configuration” to open AM1808-NAND.cfg under the folder CD\linux\tools\. Added the u-boot file under the folder [d:\sbc8018\] to the [ARM Application File:] Sets the output file path [AIS Output File] as [d:\sbc8018\u-boot-nand-ais.bin]. Click [Generate AIS], “u-boot-nand-ais.bin” will be generated under the folder [d:\sbc8018].

-

Page 33: System Customization

#define LCD_7INCH 2) Kernel compilation cd linux-03.20.00.14 make distclean make sbc8018_defconfig make uImage After completing the above steps, the required uImage file will be generated under the directory arch/arm/boot. 3.4.2.4 Generation of File System cd $HOME/work sudo $HOME/tools/mkfs.jffs2 –r rootfs –o jffs2.img After completing the above steps, the current directory will generate the the required “jffs2.img”... - Page 34 If an error occurs in the system when make menuconfig is input, it is necessary to install ncurse in the Ubuntu system; ncurse library is a character graphic library, used for make menuconfig of kernel; the specific installation instruction is: sudo apt-get install ncurses-dev How do perform the system customization is described below using USB gadget and USB mass storage device as an example:...

- Page 35 Figure 3-4 3) Select USB Gadget Support Figure 3-5 Copyright © 2011 by element14 User Manual - 35 -...

- Page 36 TF card and reboot the system. Now execute the following commands to stimulate the TF card into USB mass storage device to use with PC: root@sbc8018:~# cd /media/mmcblk0p1/ root@sbc8018:/media/mmcblk0p1# insmod g_file_storage.ko file=/dev/mmcblk0p1 stal l=0 removable=1 g_file_storage gadget: File-backed Storage Gadget, version: 20 November 2008...

-

Page 37: How To Update The System Image

3.5 How to Update the System Image The SBC8018 evaluation board NAND Flash by default comes with the installed Linux + 4.3-inch screen display. It can be booted without connecting TF card once it’s powered ON or RESET and input “root”... -

Page 38: How Update Images From Ethernet

U-BOOT will load default parameter. 3.5.2 How Update Images From Ethernet The SBC8018 evaluation board image can be updated through Ethernet port as well, in thi section we will explain how to update the image using Ethernet port. - Page 39 Launch the “tftpd32.exe” from the CD under the folder CD\linux\tools, and click “Browse” to set the sharing space, the directory will be giving an example as “d:\sbc8018”. Figure 3-10 tftpd32 tool Copy “u-boot-nand-ais.bin”, “uImage_4.3”, “uImage_7”, “jffs2.img” from the CD under the folder [CD\linux\image\] to the folder [d:\sbc8018] According to your LCD size (4.3"...

- Page 40 Skipping bad block at 0x0ffe0000 Write U-BOOT U-Boot > tftp 0xc0700000 u-boot-nand-ais.bin;nand write.i 0xc0700000 0x20000 ${filesize} Using device TFTP from server 192.192.192.154; our IP address is 192.192.192.215 Filename 'u-boot-nand-ais.bin'. Load address: 0xc0700000 Loading: ############### done Bytes transferred = 210860 (337ac hex) NAND write: device 0 offset 0x20000, size 0x337ac 210944 bytes written: OK U-Boot >...

- Page 41 2299904 bytes written: OK Write file system U-Boot > tftp 0xc2000000 jffs2.img;nand write.i 0xc2000000 0x600000 ${filesize} Using device TFTP from server 192.192.192.154; our IP address is 192.192.192.215 Filename 'jffs2.img'. Load address: 0xc2000000 Loading: ################################################################# ######T ########################################################### ################################################################# #######################################################T ######### ##### done Bytes transferred = 3889116 (3b57dc hex) NAND write: device 0 offset 0x600000, size 0x3b57dc...

-

Page 42: Test Procedures

1 > /sys/class/leds/led3/brightness 3.6.1.2 Key Switch Testing The SBC8018 evaluation board is having three users key switches S8, S9 and S10; users can perform the following testing: First, enter the following command, and then press the S9, S8, S10 keys... - Page 43 The development board contains the hardware clock for save and to synchronize the system time. User can perform the RTC test by following steps below: Set the system time as Mon Dec 05 20:00:00 2011 root@sbc8018: # date 120520002011 Mon Dec 08 20:00:00 UTC 2011 Write the system clock into RTC...

- Page 44 # date Mon Dec 08 20:00:00 UTC 2011 Now the system time has been set as hardware time. The SBC8018 Development board RTC battery can use model CR1220, user needs to prepare themselves. 3.6.1.5 TF Card Testing First insert the TF card in the board, the system will automatically mount the file system of the...

- Page 45 After booting the system, please configure the system using the below commands through HyperTerminal: root@Sbc8018:~# ifconfig usb0 192.168.1.115 root@Sbc8018:~# ifconfig Link encap:Local Loopback inet addr:127.0.0.1 Mask:255.0.0.0 UP LOOPBACK RUNNING MTU:16436 Metric:1 RX packets:26 errors:0 dropped:0 overruns:0 frame:0 TX packets:26 errors:0 dropped:0 overruns:0 carrier:0 collisions:0 txqueuelen:0 RX bytes:2316 (2.2 KiB) TX bytes:2316 (2.2 KiB)

- Page 46 Figure 3-12 Now use the ping command from the HyperTerminal to test whether the development board IP address has been configured successfully. root@Sbc8018:~# ping 192.168.1.15 PING 192.168.1.15 (192.168.1.15): 56 data bytes 64 bytes from 192.168.1.15: seq=0 ttl=128 time=0.885 ms 64 bytes from 192.168.1.15: seq=1 ttl=128 time=0.550 ms If you receive ping response like above, indicates the successful communication between the board and the PC.

- Page 47 To test the recording functionality, first plug-in the microphone and use the below command to start the recording: root@Sbc8018:~# arecord -t wav -c 1 -r 44100 -f S16_LE -v k Recording WAVE 'k' : Signed 16 bit Little Endian, Rate 44100 Hz, Stereo...

- Page 48 To playback, plug-in the headphones and enter the below command to hear what you have just recorded; root@Sbc8018:~# aplay -t wav -c 2 -r 44100 -f S16_LE -v k Playing WAVE 'k' : Signed 16 bit Little Endian, Rate 44100 Hz, Stereo...

- Page 49 3.6.1.9 Network Testing The board is having a 10/100M self-adapting DM9000 network card, users can directly connect the board to the LAN network and enter the following commands for network testing: root@sbc8018:~# ifconfig eth0 192.192.192.203 root@sbc8018:~# # ifconfig eth0 Link encap:Ethernet HWaddr 00:11:22:33:44:55 inet addr:192.192.192.203 Bcast:192.192.192.255 Mask:255.255.255.0...

- Page 50 CONTROL+C to quit the test. 3.6.1.10 Camera Testing If you have bought the specific camera module for SBC8018 evaluation board, first connect the CAMERA module and LCD screen to the board. To install the camera please use the camera drivers from [drivers/media/video/tvp514x.c]. After installation of camera module enter the...

-

Page 51: Application Development

-l /media/ drwxr-xr-x 2 root root 1024 Apr 15 2009 mmc1 drwxr-xr-x 2 root root 4096 Jan 1 1970 mmcblk0p1 drwxr-xr-x 2 root root 4096 Jan 1 1970 sda5 root@sbc8018:~# ls -l /media/sda5/ -rwxr-xr-x 1 root root 6 Apr 14 20:25 hello.txt... - Page 52 return -1; if((f_led2 = open(LED_D4, O_RDWR)) < 0){ printf("error in open %s",LED_D4); return -1; for(i = 0; i < 100; i++) { dat1 = (i & 0x1)? '1': '0'; dat2 = (i & 0x2)? '1': '0'; write(f_led1, &dat1, sizeof(dat1)); write(f_led2, &dat2, sizeof(dat2)); usleep(300000);...

-

Page 53: Chapter 4 Wince Operating System

Chapter 4 WinCE Operating System 4.1 Introduction This section will introduces you to the SBC8018 evaluation board application development using Windows Embedded CE 6.0 R3, software resources on the disc, software features, installation of development environment, and how to “sysgen” and build BSP (board support package). -

Page 54: Software Features

4.3 Software Features Resources of BSP: Table 4-1 Source code Catalog Item binary NAND Source EBOOT source Source KILT(EMAC) Source Boot parameter Source Watchdog Source Source System timer Source Interrupt controller Source Source Serial Debug Port Source Kernel Profiler-use timer0, high 32 bits Source Library Abstractions (PSC, PLL, GPIO, Source... - Page 55 I2C driver Source SPI driver Source MCASP driver Source AIC3106 Audio driver Source USB 1.1 OHCI HOST driver Source USB OTG 2.0 HOST driver Source USB OTG 2.0 FUNCTION driver Source USB OTG driver Source USB CDMA driver Source Raster LCD Display driver Source Character LCD Display driver Source...

-

Page 56: System Development

4.4 System Development 4.4.1 Installation of IDE(Integrated Development Environment) Please install items below to windows XP/Vista: Visual Studio 2005 Visual Studio 2005 SP1 Visual Studio 2005 SP1 Update for Vista (vista system require) Windows Embedded CE 6.0 Platform Builder Windows Embedded CE 6.0 SP1 Windows Embedded CE 6.0 R2 Windows Embedded CE 6.0 Product Update Rollup 12/31/2008 Windows Embedded CE 6.0 R3... -

Page 57: Sysgen & Build Bsp

“NK.nb0” will be created at the directory location [C:\WINCE600\OSDesigns\OMAPL138_AM18X_SAMPLE\OMAPL138_AM18X_SAMPL E\RelDir\OMAPL138_AM18X_ARMV4I_Release]. Now copy “EBOOTNANDFLASH.nb0” to the directory [D:\sbc8018\bin] and copy “NK.bin”, “NK.nb0” to the TF card (FAT/FAT32 format). Now to update the system image please refer to the section 4.5 below “How to Update the System Image”... -

Page 58: Source Code Path Of All Drivers In Bsp

4.4.4 Source code path of all drivers in BSP Table 4-2 EDMA driver bsp\OMAPL138_AM18X\SRC\DRIVERS\EDMA bsp\OMAPL138_AM18X\SRC\DRIVERS\I2C I2C driver bsp\OMAPL13X_TI_V1\I2C bsp\OMAPL13X_TI_V1\SPI SPI driver bsp\OMAPL138_AM18X\SRC\DRIVERS\SPI McASP driver bsp\OMAPL13X_TI_V1\MCASP AIC3106 Audio driver bsp\OMAPL138_AM18X\SRC\DRIVERS\WAVEDEV2 USB 1.1 OHCI Host driver OMAPL138_AM18X\SRC\DRIVERS\USB\OHCI bsp\OMAPL13X_TI_V1\USB\USBH USB 2.0 OTG Host driver bsp\OMAPL138_AM18X\SRC\DRIVERS\USB\USBH USB 2.0 OTG Function bsp\OMAPL13X_TI_V1\USB\USBFN... - Page 59 Character LCD Display bsp\OMAPL138_AM18X\SRC\DRIVERS\CHARLCD driver bsp\OMAPL13X_TI_V1\LIDD bsp\OMAPL13X_TI_V1\EMAC NDIS Ethernet driver bsp\OMAPL138_AM18X\SRC\DRIVERS\EMAC bsp\OMAPL138_AM18X\SRC\COMMON\NAND NAND Flash driver bsp\OMAPL138_AM18X\SRC\DRIVERS\NAND bsp\OMAPL13X_TI_V1\SERIAL Serial driver bsp\OMAPL138_AM18X\SRC\DRIVERS\SERIAL bsp\OMAPL13X_TI_V1\UPP UPP driver bsp\OMAPL138_AM18X\SRC\DRIVERS\UPP bsp\OMAPL13X_TI_V1\SDHC SD/MMC Host Controller bsp\OMAPL138_AM18X\SRC\DRIVERS\SDHC driver bsp\OMAPL13X_TI_V1\SDBUS bsp\OMAPL13X_TI_V1\PWM PMW driver bsp\OMAPL138_AM18X\SRC\DRIVERS\PWM Notification LED driver bsp\OMAPL138_AM18X\SRC\DRIVERS\NLED Touch Screen driver bsp\OMAPL138_AM18X\SRC\DRIVERS\TOUCH bsp\OMAPL13X_TI_V1\MCBSP McBSP driver...

-

Page 60: How To Update System Image

Figure 4-1 4.5 How to Update System Image The SBC8018 evaluation board supports “NK.bin” or “NK.nb0” boot from TF Card and NAND flash, this chapter will introduce you to the both of these system boot methods. 4.5.1 Downloading EBOOT to NAND Flash EBOOT can be downloaded to NAND Flash by using “sfh_OMAP-L138.exe”... - Page 61 \sbc8018 Run the flash tool to erase the NAND Flash: (change COM port if required) sfh_OMAP-L138.exe -erase -targetType AM1808 -flashType NAND -p COM1 Power ON the Kit. You should see the erase cycle in progress, wait until it completes, and then power OFF the kit.

- Page 62 Figure 4-3 10) Power OFF the Kit and set DIP switches as; S7-1 to ON, all others to OFF. Figure 4-4 11) Start your serial terminal application, Hyper Terminal (115200 baud, 8N1) 12) Now power ON the evaluation board and you will see the system boot up with the new EBOOT image.

-

Page 63: Update Tf Card Nk Runtime Images

4.5.2 Update TF Card NK runtime images Format TF card Format the TF Card in FAT/FAT32 file system. Copy NK runtime image Navigate to the directory [WINCE600/image/lcd7inch] or [WINCE600/image/lcd4.3inch], according to the LCD size. Copy “NK.nb0/NK.bin” to TF card. Change the EBOOT settings to boot NK from TF Card Insert the TF card into the evaluation board, turn the power ON and press space key to enter into the EBOOT menu. - Page 64 INFO: MAC address: 00:08:ee:00:00:00 WARN: Invalid BSP_ARGS data found (using defaults) WARN: Unable to get hardware entropy Hit space to enter configuration menu 2 -------------------------------------------------------------------------------- Main Menu -------------------------------------------------------------------------------- [1] Show Current Settings [2] Boot Settings [3] Network Settings [5] Video Settings [6] Save Settings [7] Peripheral Tests [R] Reset Settings To Default Values...

- Page 65 [8] Allow DSP to Boot [0] Exit and Continue Selection: 2 -------------------------------------------------------------------------------- Select Boot Device -------------------------------------------------------------------------------- [1] EMAC [2] NK from SD [3] NK from NAND flash [0] Exit and Continue Selection (actual NK from SD): 2 Boot device set to NK from SD Press the key [0] ->...

- Page 66 Selection: 0 -------------------------------------------------------------------------------- Main Menu -------------------------------------------------------------------------------- [1] Show Current Settings [2] Boot Settings [3] Network Settings [5] Video Settings [6] Save Settings [7] Peripheral Tests [R] Reset Settings To Default Values [0] Exit and Continue Selection: 0 Device ID set to AM1808-0 BLFlashDownload: LogicalLoc - 0x01C40000 Loading from SD card +ReadNKFromSDMMC...

- Page 67 InitMasterBootRecord: Partition 0, FAT32, start 0x7e00, length 0x753f8200 InitPartition: Offset 0x7e00, length 0x753f8200 ReadFileFromSDMMC: file size = 16138467 bytes UnpackBINImage: unpacking binary from 0xc2000000 UnpackBINImage: Image start = 0x80000000 UnpackBINImage: Image length = 0x102fd2c UnpackBINImage: record 0, start=0x80000000, length=0x4, checksum=0x1eb …….

- Page 68 MiscFlags 0x0002 Extensions : 0x80001070 Tracking Mem Start : 0x00000000 Tracking Mem Length : 0x00000000 ------------------------------------------------ Image Start ..: 0x00000000 Image Size ..: 0x00000000 Image Launch Addr .: 0x00000000 Image ROMHDR ..: 0x00000000 Boot Device/Type ..: 3 / 6 ADEhellounch Windows Embedded CE by jumping to 0xc0000000... Windows CE Kernel for ARM (Thumb Enabled) Built on Oct 20 2009 at 18:39:19 OEMInit: init.c built on Sep 28 2011 at 15:51:27.

- Page 69 PLL0:SYSCLK6 ..456000000 Hz (ARM Subsystem) PLL0:SYSCLK7 ..76000000 Hz (EMAC) PLL0:AUXCLK ..24000000 Hz (I2C0, Timers, McASP0 serial clock, RTC, USB2.0 PHY) PLL1 ..... 264000000 Hz PLL1:SYSCLK1 ..264000000 Hz (DDR2/mDDR PHY) PLL1:SYSCLK2 ..132000000 Hz (Optional for: McASP0,McBSP,ePWM,eCAP,SPI1) PLL1:SYSCLK3 ..

- Page 70 SDHC_CARD_DETECT = 1 SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout SDHC CommandCompleteHandler: Command response timeout Copyright ©...

-

Page 71: Downloading Nk.bin To Nand Flash

VS2005 utility: Confirm you have performed the release build in C:\WINCE600\OSDesigns\OMAPL138_AM18X_SAMPLE\ OMAPL138_AM18X_SAMPLE.sln. Connect PC and SBC8018 evaluation board using with RJ45 Cable. DIP switch position: S7-1 to ON position, other switches to OFF position: Figure 4-5 Boot up from NAND Flash Select EMAC as boot media in EBOOT menu, press key [2]->[2]->[1] , steps by step as below:... - Page 72 [2] Select Boot Device [3] Select Boot Delay [4] Select Debug Device [5] Force Clean Boot [6] Write Download RAM NK to Flash [7] Set Device ID String [8] Allow DSP to Boot [0] Exit and Continue Selection: 6 Enable Write Download RAM NK to Flash (actually disabled) [y/-]: y Write Download RAM NK to Flash enabled Press key [0] to return to EBOOT main menu, now press key [3] to set the network property.

- Page 73 Click [Target->Connectivity Options] in VS2005 Menu, you will see a Connectivity Options pop up window like below, select Ethernet from Download drop down menu: Figure 4-6 Now click on Settings button (located in the right of Download drop down menu), this will pop up another window as shown below.

- Page 74 Figure 4-7 10) Now go to [Target] -> [Attach Device] in VS2005 menu and click on Start to download “NK.bin”. A dialog will pop up to indicate the download progress, once the download process completed the serial terminal would display the below message: OEMWriteFlash: NK written ROMHDR at Address 80000044h Image Start ..: 0x80000000...

-

Page 75: User Instructions

11) Now power OFF the board and power ON and press the space key to enter into the EBOOT menu. Form EBOOT menu press key [2]->[2]->[3] step by step to select NK from NAND flash, and press [0] -> [0] to start the system from NAND flash. 4.6 User Instructions 4.6.1 How to use Power Management This BSP release implements support for some basic power management states and system... -

Page 76: How To Use Cam8000-A Module

Power Management Tools When power management is enabled a number of tools are available: pmtimeout – Sets the idle timeouts used for transition between PM states pmsuspend – Sets an RTC alarm and puts the platform into suspend ... -

Page 77: Sbc8018 Windows Ce 6.0 Win 32 Api Application Development Demo

Click [Build-> Rebuild Solution] in VS2005 to perform “sysgen” and build BSP. Update “NK.bin” and “NK.nb0” after sysgen and build BSP completed. Confirm CAM8000-A module is connect to SBC8018 correctly, boot system with updated NK, copy [C:\WINCE600\PLATFORM\SBC8018\files\CameraDshowApp_analog.exe] to run Windows CE OS on the kit and click “CameraDshowApp_analog.exe” to view camera preview. -

Page 78: Appendix

Appendix Appendix I: Hardware Dimensions Figure Appendix 1-1 Hardware Dimensions Diagram Copyright © 2011 by element14 User Manual - 78 -... -

Page 79: Appendix Ii: The Installation Of Ubuntu

Appendix II: The Installation Of Ubuntu How to install Ubuntu in Windows environment using VirtualBox. The screenshots in this tutorial use Ubuntu 11.04, but the same principles also applies to Ubuntu 10.10, 11.04, and any future version of Ubuntu. Actually, you can install pretty much any Linux distribution this way. - Page 80 After you launch VirtualBox from the Windows Start menu, click on New to create a new virtual machine. When the New Virtual Machine Wizard appears, click Next. Figure Appendix 2-2 You can name the machine whatever you want to name it, we are installing Ubuntu so it makes sense to name it as Ubuntu.

- Page 81 Click Next. Figure Appendix 2-4 If this is your first time using VirtualBox (which it probably is if you need a tutorial on how to use it), then you do want to create new hard disk and then click Next. Figure Appendix 2-5 Click Next again.

- Page 82 Figure Appendix 2-6 Select Fixed-size storage and click Next again. Figure Appendix 2-7 Ubuntu's default installation is less than 8 GB. If you plan on adding software or downloading large files in your virtualized Ubuntu, you should select more space accordingly. Copyright ©...

- Page 83 Figure Appendix 2-8 Figure Appendix 2-9 Click Finish and wait for the virtual hard drive to be created. This is actually just a very large file that lives inside of your Windows installation. Copyright © 2011 by element14 User Manual - 83 -...

- Page 84 Figure Appendix 2-10 Click Finish. The virtual hard drive is successfully created. Copyright © 2011 by element14 User Manual - 84 -...

- Page 85 3. Installing Ubuntu Figure Appendix 2-11 Figure Appendix 2-12 Before Installing Ubuntu in a virtual machine, the first thing to make the (currently blank) virtual hard drive useful is to add the downloaded Ubuntu disk image (the .iso) boot on your virtual machine.

- Page 86 Figure Appendix 2-13 Once you've selected it, click OK. Then double-click your virtual machine to start it up. Figure Appendix 2-14 Copyright © 2011 by element14 User Manual - 86 -...

- Page 87 Figure Appendix 2-15 Click OK Figure Appendix 2-16 Copyright © 2011 by element14 User Manual - 87 -...

- Page 88 Figure Appendix 2-17 Select language and click Install Ubuntu. Figure Appendix 2-18 Click Forward. Copyright © 2011 by element14 User Manual - 88 -...

- Page 89 Figure Appendix 2-19 Click Forward. Figure Appendix 2-20 This is the no-turning-back point. If you decide to do this, your hard drive will be repartitioned and part or all of it will be formatted. Before you click this button “Install Now” to continue, make sure you have everything backed up.

- Page 90 Figure Appendix 2-21 While Ubuntu is preparing files to copy over for installation, it'll ask you some questions. They're self-explanatory. Figure Appendix 2-22 Copyright © 2011 by element14 User Manual - 90 -...

- Page 91 Figure Appendix 2-23 Figure Appendix 2-24 Copyright © 2011 by element14 User Manual - 91 -...

- Page 92 Figure Appendix 2-25 Figure Appendix 2-26 The installation will finish (the whole thing can take anywhere between 15 minutes and an hour, depending on the speed of your computer). Copyright © 2011 by element14 User Manual - 92 -...

- Page 93 Figure Appendix 2-27 Afterwards, in order to use your virtualized installation (instead of continually booting from the live CD), you have to change the CD/DVD Device entry to be Empty again. Copyright © 2011 by element14 User Manual - 93 -...

-

Page 94: Appendix Iii: Driver Installation For Linux Usb Ethernet /Rndis Gadget

Appendix III: Driver Installation for Linux USB Ethernet/RNDIS Gadget 1. If you haven’t install the driver for Linux USB Ethernet/RNDIS Gadget, when you connect the device, PC will find the new hardware and pops up a window on the screen, please select “From list or designated location”, then click “Next”... - Page 95 Figure Appendix 3-2 3. When the following appears, select “Continue” Figure Appendix 3-3 Copyright © 2011 by element14 User Manual - 95 -...

- Page 96 4. Please wait until the installation is completed Figure Appendix 3-4 Copyright © 2011 by element14 User Manual - 96 -...

-

Page 97: Appendix Iv: The Setup O Ftftp Server

Appendix IV: The Setup Of TFTP Server 1. Install client $>sudo apt-get install tftp-hpa $>sudo apt-get install tftpd-hpa 2. Install inet $>sudo apt-get install xinetd $>sudo apt-get install netkit-inetd 3. Configure the server First, create “tftpboot” under root directory, and set the properties as “a random user can write and read”... - Page 98 server_args = -s /tftpboot -c per_source = 11 = 100 2 4. Reboot the server: $>sudo /etc/init.d/xinetd restart $>sudo in.tftpd -l /tftpboot 5. Test the server Conduct a test; create a file under folder /tftpboot $>touch abc Enter into another folder $>tftp 192.168.1.15 (192.168.1.15was the server IP) $>tftp>...

-

Page 99: Customer Service & Technical Support

Centralized technical support mail box: knode_tech@element14.com Community: http://www.element14.com/community/docs/DOC-41892 Notes This board was designed by element14’s design partner- Embest, you can contact them to get the technical support as well. Marketing Department: Tel: +86-755-25635656 / 25636285 Fax: +86-755-25616057 E-mail: market@embedinfo.com...

Need help?

Do you have a question about the SBC8018 and is the answer not in the manual?

Questions and answers