Summary of Contents for Cascade TEK TVO-2-SV

- Page 1 Vacuum Ovens TVO-2-SV TVO-2-2-SV TVO-5-SV TVO-5-2-SV Installation and Operation Manual...

- Page 2 The TVO-2-SV and TVO-5-SV ovens require a 110 – 120-volt power outlet. Standard NEMA 5-15R wall socket The TVO-2-2-SV and TVO-5-2-SV ovens require a 220 – 240 volt power outlet. Standard Standard NEMA 6-15R CEE7/7 wall socket wall socket Warning: This product contains chemicals, including triglycidyl isocyanurate, known to the State of California to cause cancer as well as birth defects or other reproductive harm.

- Page 3 CTVS522 CTVS522-EA The Part ID denotes the specific build version of the model. This oven is manufactured for Cascade TEK by Sheldon Manufacturing, INC, an ISO-certified manufacturer. Safety Certifications These units are CUE listed by TÜV SÜD as vacuum ovens for professional, industrial or educational use where the preparation or testing of materials is done at an ambient air pressure range of 22.14 –...

-

Page 4: Table Of Contents

TABLE OF CONTENTS INTRODUCTION ................................. 7 Read this Manual ..................................7 Safety Considerations and Requirements ........................7 Contacting Assistance ................................8 Manufacturing Warranty ..............................8 Engineering Improvements..............................8 Vacuum Supply Requirements ............................9 Oven Chamber Gaskets ..............................10 RECEIVING YOUR OVEN ............................11 Inspect the Shipment ................................ - Page 5 Vacuum ....................................60 Temperature ..................................60 Power ...................................... 60 PARTS LIST ................................61 Replacement Gaskets ................................ 62 P a g e...

- Page 6 TABLE OF CONTENTS P a g e...

-

Page 7: Introduction

INTRODUCTION Thank you for purchasing a Cascade TEK oven. We know you have many choices in today’s competitive marketplace when it comes to constant temperature equipment. We appreciate you choosing ours. We stand behind our products and will be here if you need us. -

Page 8: Contacting Assistance

Therefore, some changes, modifications, and improvements may not be covered in this manual. If your unit’s operating characteristics or appearance differs from those described in this manual, please contact your Cascade TEK dealer or customer service representative for assistance. -

Page 9: Vacuum Supply Requirements

INTRODUCTION ACUUM UPPLY EQUIREMENTS Pump or Building System Required The oven does not come with a vacuum pump. A pump must be separately purchased for the oven. Vacuum Pump Building Vacuum Supply Required Flow Rate For the chamber to seal, the vacuum pump or system must be able to evacuate at least 1 cubic foot per minute (cfm) for each cubic foot of oven chamber volume (CuFt). -

Page 10: Oven Chamber Gaskets

INTRODUCTION HAMBER ASKETS Wear and Replacement Chamber liner gaskets are non-warranty, high-wear consumable items subject to compression forces, heat, and outgassed byproducts. Heavy usage rates may necessitate frequent replacements. The manufacturer strongly recommends keeping a spare gasket on hand during operation. Included Chamber Gasket Each oven comes with a replaceable silicone gasket installed on the chamber liner which seals the oven chamber when the door is closed and the chamber is under vacuum. -

Page 11: Receiving Your Oven

Tall Shelves Short Bottom Shelf Leveling Feet TVO-5-SVs Shelves Shelf Clips Leveling Feet Power Cords NEMA 5-15P NEMA 6-15P CEE 7/7 Model 125 Volt 240 Volt (US) 250 Volt (Euro) TVO-2-SV TVO-5-SV TVO-2-2-SV TVO-5-2-SV 11 | P a g e... -

Page 12: Orientation Images

RECEIVING RIENTATION MAGES TVO-5-SV and TVO-5-2-SV Side-Mounted Back of Units: See next page. Vacuum Hand Valve Oven Chamber Door Shelf Standard Rail Shelf Chamber Gasket Seal KF-25 Vacuum Port Main Control Leveling Foot Vacuum Control Temperature Panel and Display Panel and Display Sensor Probe 12 | P a g e... - Page 13 RECEIVING Back of TVO-5-SV and TVO-5-2-SV KF-16 Port. Includes blank and clamp. Auxiliary KF-25 Port. Includes blank and clamp. Chamber Inlet Vent Port ¼ inch (6.35 mm). KF-25 Vacuum Operated by Port. Does not front panel include a blank or control valve.

- Page 14 RECEIVING Side-Mounted Manual TVO-2-SV and TVO-2-2-SV Vacuum Hand Valve Back of Units: See next page. Oven Chamber Door Tall Shelf Tall Shelf Short Shelf (Bottom) Chamber Gasket Seal KF-25 Vacuum Port Temperature Vacuum Control Main Control Sensor Probe Panel and Display...

- Page 15 RECEIVING Back of TVO-2-SV and TVO-2-2-SV KF-16 Port. Includes blank and clamp. Auxiliary KF-25 Port. Includes KF-25 blank and clamp. Chamber Vent Inlet Port ¼ inch (6.35 mm). Operated by front panel KF-25 Vacuum control valve. Port. Does not include a blank or clamp.

-

Page 16: Dimension Visuals

RECEIVING IMENSION ISUALS TVO-5-SVs See page 20 for the required ventilation clearances. Depth: 38.6 inches (981 mm) Height: 33.2 inches (844 mm) Exterior Width: 31.1 inches (790 mm) Chamber Height: 18.1 inches (459 mm) Chamber Depth: 24.1 inches (612 mm) Interior Chamber Width: 18.1 inches (459 mm) Shelves... - Page 17 RECEIVING TVO-2-SVs See page 20 for the required ventilation clearances. Depth: 34.9 inches (886 mm) Height: 27.1 inches (689 mm) Exterior Width: 24.5 inches (623 mm) Chamber Height: 12.0 inches (304 mm) Chamber Depth: 20.0 inches (508 mm) Interior Chamber Width: 12.0 inches (304 mm) Tall Shelves Shelf Depth: 19.0 inches (483 mm)

-

Page 18: Record The Data Plate Information

RECEIVING ECORD THE LATE NFORMATION The data plate contains the unit model number, serial number, part number, and part ID. Customer Support will need this information during any support call. Record it below for future reference. The data plate is located on the back of the oven above the power inlet. •... -

Page 19: Installation

INSTALLATION NSTALLATION ROCEDURES HECKLIST For installing the oven in a new workspace location. Pre-Installation Verify a vacuum supply source suitable for your application is available and can be connected to the oven, page 9. See page 27 for the oven gas and vacuum port locations. •... -

Page 20: Required Ambient Conditions

INSTALLATION EQUIRED MBIENT ONDITIONS This oven is built for use indoors at room temperatures between 15°C and 40°C (59°F and 104°F), at no greater than 80% Relative Humidity (at 25°C / 77°F). The ambient temperature should not change by 2°C (3.6°F) or more during operation. Operating outside these conditions may adversely affect the oven temperature performance. -

Page 21: Power Source Requirements 110 - 120 Volts

110 – 120 V OWER OURCE EQUIREMENTS OLTS TVO-2-SV TVO-5-SV When selecting a location for the unit, verify each of the following requirements is satisfied. Power Source: The wall power outlet must meet the power requirements listed on the unit data plate. Model... -

Page 22: Power Source Requirements 220 - 240 Volts

INSTALLATION 220 – 240 V OWER OURCE EQUIREMENTS OLTS TVO-2-2-SV TVO-5-2-SV When selecting a location for the unit, verify each of the following requirements is satisfied. Power Source: The wall power outlet must meet the power requirements listed on the unit data plate. -

Page 23: Lifting And Handling

INSTALLATION IFTING AND ANDLING The oven is heavy. Use appropriate lifting devices that are sufficiently rated for these loads. Follow these guidelines when lifting the oven: Lift the oven only from its bottom surface. • Doors, handles, and knobs are not adequate for lifting or stabilization. •... -

Page 24: Install The Oven

INSTALLATION NSTALL THE Install the unit in a workspace location that meets the criteria discussed in the previous entries of the Installation section. Do not connect the oven to its power source at this time. • NSTALLATION LEANING The manufacturer recommends cleaning the shelving and oven chamber prior to installation of the shelving in the chamber. -

Page 25: Shelving Installation

INSTALLATION HELVING NSTALLATION Heating in a vacuum environment takes place primarily through conduction. Heat flows from oven elements inside the chamber walls and floor to the shelves. Install the shelves as described below to ensure proper heat conduction and temperature measurement. Never place samples or product on the oven chamber floor. - Page 26 INSTALLATION Shelving Installation Continued TVO-5-SVs Shelving To ensure accurate temperature measurement, one shelf bottom must be in close proximity to the oven temperature probe. This probe extends out from the chamber back wall. Do not place the shelf in direct contact with the probe. Shelf Probe Install 4 Shelf Clips...

-

Page 27: Connect To The Vacuum Supply

INSTALLATION ONNECT TO THE ACUUM UPPLY KF-25 Side-Mounted Port KF-25 Auxiliary Port 1. Connect the vacuum supply to the KF-25 Side-Mounted Vacuum Port KF-25 Side-Mounted Vacuum Port • Chamber atmosphere evacuates through this port. Connect the vacuum source to the oven here. The port does not come with a KF-25 blank or clamp. -

Page 28: Connect To A Gas Backfill Supply

INSTALLATION ONNECT TO A ACKFILL UPPLY Optional The maximum allowed gas backfill pressure is 15 psi delivery at both ports. KF-16 Port Optional: Connect a gas supply to the Vent Port (Backfill Inlet) Gas Supply Vent Port (Backfill Inlet) – 1/4 Inch (6.35 mm) OD •... -

Page 29: Graphic Symbols

GRAPHIC SYMBOLS The oven is provided with multiple graphic symbols on its interior and exterior surfaces. The symbols identify hazards and the functions of the adjustable components, as well as important notes in the operation manual. Symbol Definition Consult the operation manual Consulter le manuel d'utilisation Over Temperature Limit system Thermostat température limite contrôle haute... - Page 30 SYMBOLS 30 | P a g e...

-

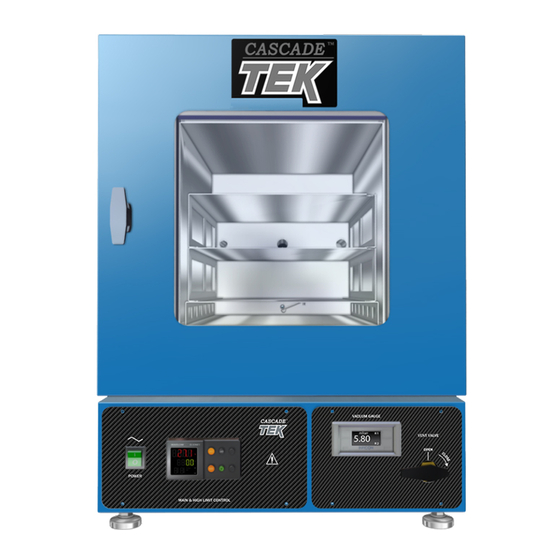

Page 31: Control Overview

CONTROL OVERVIEW Control Panels Power Switch The switch illuminates when in the ON ( I ) position. Temperature Controller - Display on Homepage Top Line (Red): Present chamber shelving temperature Middle Line (Green): The constant temperature setpoint Bottom Line: Flashing “2” indicates active heating While on the homepage, the Up and Down arrow buttons adjust the constant temperature setpoint. - Page 32 CONTROLS Vacuum Gauge ~810 torr – Room atmosphere pressure for N or near sea level Shows the chamber pressure level in torr and millitorr (mTorr). The gauge that this display connects to measures the pressure of pure nitrogen (N ) and is used to control the automated backfill function. Backfilling is commonly done using N or other inert gases.

-

Page 33: Operation

OPERATION Safe operation of the oven is dependent on the actions and behavior of the oven operators. Operating personnel must read and understand the Operating Precautions in this section prior to operating the oven. The operators must follow these instructions to prevent injuries and to safeguard their health, environment, and the materials being treated in the oven, as well as to prevent damage to the oven. -

Page 34: Theory Of Operation

OPERATION HEORY OF PERATION Vacuum Vacuum is supplied by an external vacuum supply (a pump or building system) connected to the KF- 25 vacuum port mounted on the left side of the oven. Vacuum levels obtained in the oven chamber are dependent on pump type and performance, valve settings, and the nature of the application or process, including the volume of outgassed materials. - Page 35 OPERATION Heating in a Vacuum In conventional ovens, powered elements transfer heat into the chamber air. The hot air then circulates by natural convection or blower fan action, surrounds the product on the shelves, gradually bringing it to temperature. In a vacuum oven, heat transfer occurs in part through direct infrared radiation.

-

Page 36: Put The Oven Into Operation

OPERATION UT THE VEN INTO PERATION Perform the procedures below after the unit has been installed in a new workplace location. These verify the integrity of the vacuum system and prepare the oven for normal use. Attach the Power Cord Attach the power cord that came with the unit to the power inlet receptacle on the back of the oven. - Page 37 OPERATION Continued from the previous page Verify Vacuum Integrity Use the Evacuating and Backfilling the Oven Chamber procedure on page 39 to pump down and hold the oven chamber under vacuum for 10 minutes to verify the integrity of the vacuum supply system. 10 Minutes Minimum Pump Setting the Operating Temperature...

-

Page 38: Set The High Temperature Limit

OPERATION ET THE EMPERATURE IMIT Note: Test the high limit system once per year for functionality. Set the high temperature limit at least 10°C above the highest temperature the oven will run at during your recipe program or constant-temperature application. See the High Temperature Limit system explanation on page 35. -

Page 39: Evacuating And Backfilling The Oven Chamber

OPERATION VACUATING AND ACKFILLING THE HAMBER Put the oven chamber under vacuum and hold for at least 10 minutes when first putting the oven into operation in a new location to verify the integrity of the vacuum supply system. The oven chamber must be drawn down to at least 500 torr in order to seal. -

Page 40: Setting The Constant Temperature Setpoint

OPERATION ETTING THE ONSTANT EMPERATURE ETPOINT Adjust the constant temperature setpoint on the homepage Stay 10°C below the high limit • setpoint. Note: Holding down an arrow button will cause the temperature to advance in increments of ten (10). Adjust Release the arrow buttons after adjusting the setpoint There may be a brief pause as the oven controller •... -

Page 41: High Temperature Limit Activated

OPERATION EMPERATURE IMIT CTIVATED The High Limit system cuts off heating in the oven whenever the chamber temperature meets or exceeds the Limit setting. Heating remains disabled until the oven operator clears the Limit cutoff. Indicators When heating is cut off, the oven display flashes two alternating alert screens. Alternating Alert Screens Additionally, an illuminated “4”... -

Page 42: Changing The Unit Of Measurement

OPERATION ⁰C ⁰F HANGING THE NIT OF EASUREMENT The controller can display temperatures in either Celsius or Fahrenheit. 1. Starting on the homepage, push the green Advance button 5 times, advancing to the “C_F1” units of measurement option. 2. Use the Arrow buttons to change the measurement parameter on the top display line to your preferred unit of measurement. -

Page 43: Data Ports

OPERATION ORTS 25-Pin Port The 25-pin RS485 data port, located on the back of the oven, connects to the oven temperature controller. The port is primarily intended for updating the controller software but can be used for data logging and graphical temperature recipe programming. Accessing the controller with a computer requires a 25-pin RS485-to-USB converter cable and driver software. - Page 44 OPERATION 44 | P a g e...

-

Page 45: Operator Maintenance

OPERATOR MAINTENANCE Warning: Disconnect the unit from its power supply prior to maintenance or cleaning of this unit. Avertissement: Avant d'effectuer toute maintenance ou entretien de cet appareil, débrancher le cordon secteur de la source d'alimentation. LEANING If a hazardous material or substance has spilled in the unit, immediately initiate your site Hazardous Material Spill Containment protocol. -

Page 46: Maintaining Atmospheric Integrity

MAINTENANCE Oven Exterior Cleaning Guidelines Disconnect the unit from its power supply. 2. The manufacturer recommends cleaning the unit with a mild soap and water solution. Do not use abrasive cleaners, these will damage metal surfaces. • Cleaning agents must be compatible with steel and powder coat paint surfaces. •... -

Page 47: Heating Issues - Diagnostic Questionnaire

MAINTENANCE — D EATING SSUES IAGNOSTIC UESTIONNAIRE If the unit is experiencing heating issues, use this questionnaire to gather information on the unit prior to contacting Customer Support. Gathering and sharing this information aids Customer Support in making timely and accurate remote diagnoses. Additionally, datalogger files as well as pictures and videos of the unit in its failure mode are valuable diagnostic resources that can be shared with Customer Support. - Page 48 MAINTENANCE Note: Does the car actually have gas in the tank? Have you physically verified the computer is plugged in? Yes, we are going to ask some very basic questions. Please bear with us. Methodical verifications and the elimination of potential failure causes are often the quickest means of getting a unit back into operation.

- Page 49 MAINTENANCE Optional: Obtain a temperature reference device. A calibrated digital thermometer with a vacuum- rated thermocouple feedthrough. The device must be accurate to at least 0.1°C. Preparing for the Heating Diagnostic Observations The unit must be connected to a power source that meets the requirements in the Installation chapter (page 21) and turned on.

- Page 50 MAINTENANCE Heating Diagnostic Questions Record the answers in the log on page 51. etpoint? What is the current temperature setpoint? Chamber Temperature in Red Setpoint in Green hamber Temperature? What temperature is presently showing on the temperature controller display? eference? Optional: What temperature is the reference device presently showing for the chamber? eating Indicator On? Is the heating active indicator on the temperature controller display flashing or otherwise...

- Page 51 MAINTENANCE Heating Diagnostic Data Log Record answers to the Heating Diagnostic questions in this log. These document the unit behavior. Diagnostic Questions Record Answers and Any Notes Here etpoint, present setting: hamber Temperature, present reading: eference Device, present reading: eating Indicator On, Y/N? igh Limit Activated, Y/N? mbient, present temperature:...

-

Page 52: Vacuum Leak Issues - Diagnostic Questionnaire

MAINTENANCE Vacuum Leak Issues – D IAGNOSTIC UESTIONNAIRE If the unit is experiencing vacuum leak issues, use this questionnaire to gather information on the unit prior to contacting Customer Support. Gathering and sharing this information aids Customer Support in making timely and accurate remote diagnoses. - Page 53 MAINTENANCE Does the car actually have gas in the tank? Have you physically verified the computer is Note: plugged in? Yes, we are going to ask some very basic questions. Please bear with us. Methodical verifications and the elimination of potential causes of failure are often the quickest means of getting a unit back into operation.

- Page 54 MAINTENANCE Vacuum Diagnostic Setup Check the primary chamber gasket for damage. This is the gasket mounted on the chamber liner that seals the oven chamber when the door is closed. Look for: Cuts or nicks on the gasket caused by removing shelves or samples •...

- Page 55 MAINTENANCE Vacuum Diagnostic Questions Record the answers in the log on page 57. ump On and Running? Yes or no? ent Valve Closed? The vent (backfill inlet port) must be closed before applying vacuum to the chamber. Failure to do so may result in damage to your vacuum pump.

- Page 56 MAINTENANCE eak Rate? Calculate and record the leak rate of the evacuated and isolated oven chamber: 1. Verify the oven chamber and shelving are at room temperature (20 – 25°C). 2. Verify the oven chamber is clean and dry to prevent outgassing from contaminants or water. 3.

- Page 57 MAINTENANCE Vacuum Leak Diagnostic Data Log Record the diagnostic question answers in this log. These questions document the unit behavior. Diagnostic Questions Record Answers and Any Notes Here ump On and Running, Y/N? ent Valve Closed, Y/N? acuum Valve Open, Y/N? isplay Reading, Vacuum Gauge: eak Rate, in torr or mTorr...

- Page 58 MAINTENANCE 58 | P a g e...

-

Page 59: Unit Specifications

UNIT SPECIFICATIONS Please refer to the oven data plate for individual electrical specifications. Technical data specified applies to units with standard equipment at an ambient temperature of 25°C and at nominal voltage. The temperatures specified are determined in accordance to factory standard following DIN 12880 respecting the recommended wall clearances of 10% of the height, width, and depth of the inner chamber. -

Page 60: Vacuum

70 Minutes 120 Minutes 175 Minutes TVO-5-SVs 70 Minutes 120 Minutes 175 Minutes OWER Model AC Voltage Amperage Frequency TVO-2-SV 110 – 120 10.0 50/60 Hz TVO-5-SV 110 – 120 13.0 50/60 Hz TVO-2-2-SV 220 – 240 50/60 Hz TVO-5-2-SV 220 –... -

Page 61: Parts List

Parts Number Power Cord, TVO-2-2-SV and TVO-5-2-SV Adjustable Leveling Feet 250 volt, 10 Amp, 8ft 2in (2.5m), CEE 7/7 2700506 1800500 Fuse, TVO-2-SV and TVO-5-SV Short Shelf, TVO-2-SVs T16A 250V 5x20mm 3300513 9751342 Fuse, TVO-2-2-SV Tall Shelf, TVO-2-SVs T6.3A 250V 5x20mm... -

Page 62: Replacement Gaskets

(458 x 458 mm) Ordering Parts and Consumables Parts may be ordered from Cascade TEK by calling 1-888-835-9250. Please have the model, part, and serial numbers and Part ID of the unit ready, as Customer Support will need this information to match your unit to its correct part. - Page 63 PARTS 63 | P a g e...

- Page 64 Corporate Headquarters Cascade TEK Solutions, LLC 2010 Century Center Blvd, Suite 21 Irving, Texas 75062 support@cascadetek.com cascadetek.com 1-888-835-9250 1-971-371-4096...

Need help?

Do you have a question about the TVO-2-SV and is the answer not in the manual?

Questions and answers