Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for SprayTECH 1150

- Page 1 Diaphragm Pumps Diaphragm Pumps 1150 1150 Piston Pumps Piston Pumps EP2105 EP2105 EP2205 EP2205 EP2300 EP2300 EP2300se EP2300se EP2400 EP2400 EP2510 EP2510 GP2605 GP2605 GP2905 GP2905 HVLP HVLP CS5100 CS5100 CS8100 CS8100 CS9100 CS9100 Maxum II Gun Maxum II Gun...

- Page 3 Plus ED1 1 50 Airless Sprayer Owner's Manual Model no. 0294059 Form no. 0294968C © 1996 Wagner Spray Tech. All rights reserved.

-

Page 4: Before You Call

THIS UNIT IS PROVIDED WITH A THERMALLY PROTECTED AUTOMATIC RESET. IF AN OVERLOAD OCCURS THE THERMALLY PROTECTED AUTOMATIC RESET DISCONNECTS THE MOTOR FROM THE POWER SUPPLY. • Motor will restart without warning when protector automatically resets. • Always disconnect motor from power supply before working on equipment. •... -

Page 5: Safety Precautions

SAFETY PRECAUTIONS This manual contains information which must be read and understood before using the equipment. When you come to an area which has one of the following symbols, pay particular attention and make certain to heed the safeguard. Important safety information indicates a hazard which may cause serious injury or loss of life. Important information that tells how to prevent damage to equipment or how to avoid causes of minor injuries. - Page 6 HAZARD Injection Injury - A high pressure stream of paint pro- duced by this equipment can pierce the skin and underlying tissues, leading to serious injury and pos- sible amputation. DO NOT TREAT AS A SIMPLE CUT! Injection- can lead to amputation. See a physician im- mediately.

- Page 7 HAZARD Explosion or fire - Solvent and paint fumes can explode or ignite causing property damage and/or severe injury. WARNING • Exhaust and fresh air introduction must be provided to keep the air within the spray area free from accumulation of flammable vapors.

- Page 8 HAZARD Explosion hazard incompatible materials - May cause property damage or severe injury. Hazardous vapors - Paints, solvents, insecticides, and other materials may be harmful if inhaled causing se- vere nausea, fainting, or poisoning. General - May cause property damage or severe injury. WARNING •...

-

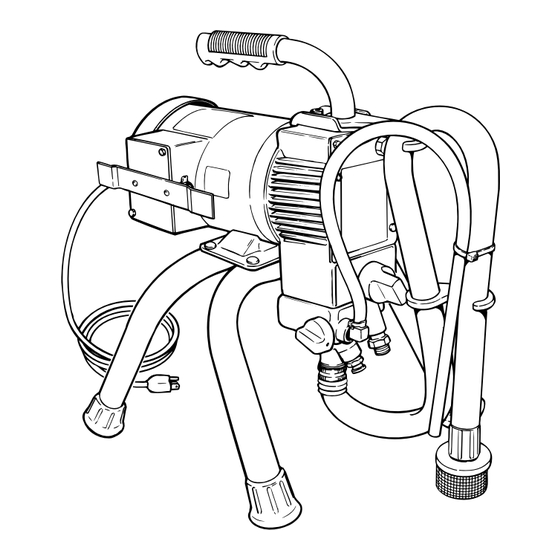

Page 9: General Description

GENERAL DESCRIPTION Be sure to read the IMPORTANT SAFETY INFORMA- TION on pages 3 thru 6 before using this sprayer. Your SprayTECH sprayer is a powerful, easy to operate and easy to service machine. Since it operates on the airless principle, no air compressor is needed. Power is supplied by a 3/4 horsepower, TEFC electric motor. -

Page 10: Hydraulic Pump

HYDRAULIC PUMP For the hydraulic pump location, see Figure 1. It operates as follows: The electric motor is connected to the eccentric bearing, which is inside the hydraulic pump. The piston rests on the bearing. The movement of the bearing causes the piston to move up and down. -

Page 11: Suction Set

The outlet valve also contains a device to dislodge a stuck valve. Simply push the plunger button located on the side of the paint block before starting the pump. CAUTION The plunger button should never be pushed during operation as this may cause premature failure of the outlet valve. -

Page 12: Spray Gun

SPRAY GUN The spray gun is connected to the sprayer by the paint hose. The gun will spray when the unit is running, the suction and return tubes are in the spray material, the priming knob is turned to the pressure control valve is adjusted, and the spray gun trigger is pulled back. - Page 13 3. Loosen the tip nut slightly. Turn the tip guard about 1/16 turn counterclockwise from desired spray angle. See Figure 4. TIGHTEN WITH WRENCH FROM THIS POINT Figure 4.- Spray Gun Tip Guard Postion Before Tightening. 4. Tighten tip nut. The tip guard should now be in the proper position.

-

Page 14: Operation

OPERATION START UP PROCEDURE 1. CHECK TO BE SURE THE MOTOR SWITCH IS OFF— play it safe. 2. LOCK SPRAY GUN—The spray gun will not spray when the trigger lock is locked. 3. CHECK THE HYDRAULIC OIL— The sprayerer was shipped with the proper amount of hydraulic oil in the hydraulic pump. - Page 15 2. Avoid sharp bending and kinking of the paint hose. The paint hose and electric cord should be kept clear of traffic and sharp cutting edges or objects. 3. Use the lowest pressure possible when spraying. Too much pressure shortens equipment life. It also causes faster than normal wear on the spray tip.

- Page 16 SPRAY TIP PLUGGING The spray tip can be plugged by foreign matter and “skin” in the paint. Excessively large paint pigments can also plug the tip. If the tip becomes plugged while spraying, proceed as follows: 1. Lock spray gun trigger OFF so that the spray gun can't spray.

-

Page 17: Shut Down And Clean-Up

SHUTDOWN AND CLEANUP You should clean and oil your sprayer as soon as you finish a job. Do not store the sprayer unless it has been cleaned and oiled. When you shut down, clean up with water if you were using latex paint and clean up with solvent if you were using oil base paint. -

Page 18: Suction Filter Cleaning

SUCTION FILTER CLEANING The suction filter is located on the end of the suction tube. A clean suction filter gives full delivery capacity and a constant level of spraying pressure. Clean the suction filter as needed with a brush dipped in solvent. CHECKING OPERATION OF INLET VALVE See Figure 14 for location of inlet valve. - Page 19 REPLACING DIAPHRAGM OR DIAPHRAGM PARTS The diaphragm is the only separation between the paint pump and the hydraulic pump. It pumps paint, but it also serves as a gasket between the hydraulic pump and paint pump. If the diaphragm membrane ruptures, paint will probably get into the hydraulic housing.

-

Page 20: Troubleshooting

Provided you have followed the instructions, the sprayer will operate efficiently and give trouble-free service. Should any unexpected problem arise you can, in most cases, remedy the problem by following the chart below. Problom Sprayer does not startup Sprayer starts up but does not draw up paint Sprayer draws up paint but pressure does not... - Page 21 TROUBLESHOOTING (Continued) Problem Sprayer draws up paint, pressure builds up, but drops away markedly when gun is opened (low performance) Pressure fluctuation Paint in hydraulic housing Spray gun won't shut off Remedy Cause 1. Put on correct tip 1. No spray tip on gun 2.

-

Page 22: Before You Call

TROUBLESHOOTlNG (Concluded) Problem Spray gun leaks Spray gun won't spray Low paint output from spray Spray gun sprays without trigger being pulled back NOTE1: If a return line that is completely submerged in paint causes bubbles after priming, you probably have a vacuum leak in the suction set. - Page 23 ITEM PART NO. DESCRIPTION 0288478 Grip, 0294511 Handle 0088328 Washer, Lock, 5/16" 9800325 Screw, Soc. Hd. 8mm x 16mm Lg. 1 0089935 Elbow, Barb 0270504 Tubing, 5/16" O.D., 3/16" I.D. 0294656 Filter 9822515 Ring, Retaining 0270501 Washer 0005311 Spring 0089937 Gasket 0294513 Cover...

- Page 24 ‰ Paint Pump Assembly — Figure 19 ©1995 WAGNER SPRAY TECH CORPORATION. ALL RIGHTS RESERVED.

- Page 25 PAINT PUMP ASSEMBLY — Figure 19 ITEM PART NO. DESCRIPTION 0270201 Diaphragm assy. 0270494 Ring, diaphragm 0294216 Pusher assy, outlet valve (Includes O-ring P/N 9971327) 0294672 Kit, repair outlet valve 0010778 Seal, ball seat 0294264 Housing assy., outlet seat 0270491 Ball 0278907 Kit, Repair, Outlet Spring...

-

Page 26: Suction Set Assembly

0294218 SUCTION SET ASSEMBLY ITEM PART NO. DESCRIPTION 0279305 Filter, housing 0294217 Suction Hose 9871047 O-ring 0294665 Clip, hose 0269321 Return tube Filter Part No. Application Type Synthetic resin 0089960 Enamels, clean Extrafine varnishes, stains azures Base coat enamels, 0089959 Primer enamels, Fine fillers, marking... - Page 27 What Is Covered By This Warranty: This product, manufactured by SprayTech Corporation (SprayTech), is warranted against defects in material and workmanship for one (1) year following date of purchase if operated in accordance with SprayTech's printed recommendations and instructions. For SprayTech EP and GP (piston) sprayers: warrants non-wear parts of the fluid section, drive train and mechanical pressure control components against defects in material and workmanship for two (2) years from the date of purchase.

Need help?

Do you have a question about the 1150 and is the answer not in the manual?

Questions and answers