Subscribe to Our Youtube Channel

Summary of Contents for CETAC ASXPRESS PLUS

- Page 1 CETAC ® PRESS Rapid Sample Introduction System Operator’s Manual Manual Part Number 480167 Rev 6...

- Page 2 E-mail custserv@cetac.com Plastics. DuPont™, Kapton®, Tefzel® and Viton® are trademarks or registered trademarks of E.I. du CETAC Technologies strives to provide the REVISIONS Pont de Nemours and Company. scientific community with an unparalleled combination of effective technology and All other marks are the property of their continuing value.

-

Page 3: Table Of Contents

Contents Overview............................ 7 Introduction ......................7 About This Book ........................9 Who Should Read This Book ..................9 Supported Autosamplers ....................9 Rapid Sample Introduction System Standard Components ....... 9 Updates ..........................9 Optional Accessories/Components ................13 Additional Equipment Required ................... 13 Where to Go for More Information ................ - Page 4 Rapid Sample Introduction System Operator’s Manual PRESS Contents Accessing the Interior of the Autosampler .............. 34 Setting the Pump Speed Jumper (ASX-520/ASX-520HS/EXR-8) ..... 42 Upgrading the Firmware ....................42 Supported Firmware Versions ................... 43 Where to Get the Firmware ..................43 Autosampler Programming Configuration ............

- Page 5 Rapid Sample Introduction System Operator’s Manual PRESS Contents Home the valve ......................... 98 Timing Parameters ......................99 Configuring the ASX System ............99 PRESS Operation Controls ......................101 Enable ASXpress Operation ..................101 Extra Loop Rinse ......................101 Enable Vacuum/Autosampler Peri-Pump Timeout ........101 Manual Controls ........................

- Page 6 Returned Product Procedures ................134 Returned Product Warranty Determination ........... 135 Using C-Term™ ........................137 13 Operating a CETAC Autosampler Using a Terminal Program ... 137 Starting C-Term ......................137 Overview of the C-Term Window................138 Configuring C-Term ..................... 139 Using HyperTerminal .....................

-

Page 7: Overview

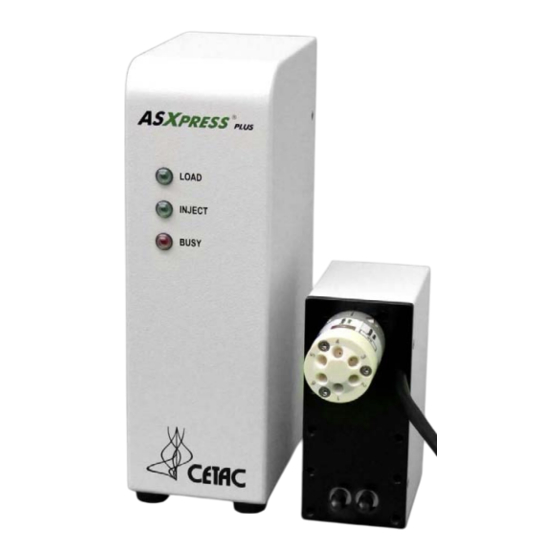

The complete ASX system is comprised of these main components: The ASXpress valve/pump module PRESS The ASXpress Plus electronics module An external rinse pump A power supply An autosampler Windows-based software to configure and coordinate the system... - Page 8 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 1: Introduction “Load Sample” Cycle Diagram Figure 1-1 “Inject/Rinse” Cycle Diagram Figure 1-2...

-

Page 9: About This Book

PerkinElmer S10 Agilent SPS-3 Tubing connection information for some autosamplers is in the corresponding Quick Installation Guide. Updated versions of this manual may be available on the CETAC Web site: Updates www.cetac.com under Service & Support – Service Documents. - Page 10 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 1: Introduction Predominantly aqueous solutions of strong acids (less than 40%). Common organic solvents such as acetone, alcohols, ethyl acetate, Methylethylketone (MEK), petroleum oils and derived fuels, tetrachloroethylene, toluene, and xylene. Prolonged or repeated exposure to temperatures greater than 135°C and to the CAUTION following substances can cause failure of the flow path components:...

- Page 11 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 1: Introduction Output to External Pump Input from Host PC: PRESS Configuration (Serial or USB) Output to Syringe Pump Input from Host PC: (Serial) Autosampler Commands (Serial or USB) Output to Autosampler (Serial) Output to Valve/Pump...

- Page 12 1.0mm Sample Probe. A 1.0mm ID sample probe must be used on the connected CETAC autosampler to operate properly with the ASX system. For the ASX-1400 autosampler, a sample probe/stirrer holder block is supplied to fit the new sample probe.

-

Page 13: Optional Accessories/Components

Please refer to the ASX Rapid Sample Introduction System Accessories PRESS and Supplies Catalog or contact CETAC Technologies if you need additional accessories not listed, need added features to integrate the ASX PRESS Rapid Sample Introduction System into your analytical system, or have unique requirements. -

Page 14: Where To Go For More Information

Where to Go for More Information In addition to this manual, you can refer to the following resources: The ASXpress Plus Quick Installation Guide (In many cases, a version specific to your autosampler will be included with the installation kit.) ... -

Page 15: Choosing A Location

2 Preparing for Installation Installing the ASX system requires preparation. Before you install the Rapid Sample Introduction System, you should evaluate the physical arrangement of the laboratory to choose a suitable location which PRESS allows placement of the ASX PRESS valve/pump module as close to the nebulizer as possible. -

Page 16: Space Requirements

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 2: Preparing for Installation Most analytical applications benefit from utilizing the shortest sample flow Space Requirements path. Therefore, you should place the valve/pump module in close proximity to the nebulizer of the analytical instrument. The required space for ASX system installation includes separate accommodations for both the valve/pump module and for the electronics module as follows: PRESS... -

Page 17: Rapid Sample Introduction System

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 2: Preparing for Installation The valve/pump module receives power from the electronics module. In case of hazard, the autosampler should be disconnected from the power source as well as from the ASX system. - Page 18 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 2: Preparing for Installation This page is intentionally blank.

-

Page 19: Preparing An Asx-500/510 Autosampler

Rapid Sample Introduction System, an ASX-500 or ASX-510 autosampler will require: PRESS Upgraded firmware (on an EPROM chip, if CETAC determines that it is needed for your autosampler) Xpress rinse station External pump (required to achieve adequate sample and rinse flow rate) and associated plumbing ... -

Page 20: Upgrade The Firmware

Upgrade the Firmware In some cases, it may be necessary to upgrade the firmware in the autosampler. If you are unsure whether to upgrade the firmware, contact CETAC Technologies for advice. Up-to-date firmware is required to allow the autosampler to respond correctly to the ASX Rapid Sample Introduction System. -

Page 21: Install The Xpress Rinse Station And Rinse Tubing

An Xpress rinse station (Figure 3-1) and associated modified tubing arrangement is required to accommodate the design requirements of the system. If you are connecting the ASXpress Plus system to an ASX-500/510 autosampler with a standard rinse station installed, then you... -

Page 22: Install The External Rinse Pump

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 3: Preparing an ASX-500/510 Autosampler Thread both tubes under the autosampler. Connect the drain tube from the rinse station to a suitable waste container, ensuring that the end of the drain tube does not become submerged below the waste liquid level, as that condition will impede proper drainage. - Page 23 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 3: Preparing an ASX-500/510 Autosampler This will allow air to be drawn in through one channel, while rinse solution is drawn in through the other channel, bringing air bubbles into the rinse station.

-

Page 24: Install The 1.0Mm Id Sample Probe On The Autosampler

Chapter 3: Preparing an ASX-500/510 Autosampler Install the 1.0mm ID Sample Probe on the Autosampler A 1.0mm ID sample probe (Figure 3-5) is provided for use with the CETAC autosampler for proper operation with the ASXpress P system. Follow the autosampler Operator Manual Instructions to replace the probe with the 1.0mm sample probe, which is attached to the ASX... -

Page 25: Preparing An Asx-260 Or Asx-520 Autosampler

Over time, several kinds of 2-channel peristaltic rinse pumps have been built Identifying the Peristaltic Pump into CETAC autosamplers. If the pump on your autosampler looks like the one in Figure 4-1, then it is considered to be a "new" pump for the purposes of this... -

Page 26: Rinse Pump Configurations

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-1 "New" Built-In Peristaltic Pump Several options are available for pumping rinse solution through the rinse Rinse Pump Configurations station: Table 2 Rinse Pump Configurations for ASX-260 and ASX-520 Series Autosamplers Rinse Configuration Pumps Used When to Use... -

Page 27: Installing The Xpress Rinse Station

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Installing the Xpress Rinse Station An Xpress rinse station (Figure 3-1) and associated modified tubing arrangement is required to accommodate the design requirements of the system. -

Page 28: Installing The Gravity Drain With Built-In Pump

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Installing the Gravity Drain with Built-in Pump This is the preferred rinse pump configuration if if your autosampler has a "new" built-in peristaltic pump. Connect a container of rinse solution to one input of the built-in pump, and let the other input take in air. -

Page 29: Notes

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Rinse Tubing Diagram for Built-In or External 2-Channel Pump with Gravity Drain Figure 4-4 Check the direction of pump rotation. Some peristaltic pumps have the input at Notes the top, and some at the bottom. -

Page 30: Installing The Gravity Drain With External Pump

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-5 Rinse Intake Tube Installing the Gravity Drain with External Pump If your autosampler has an "older" built-in peristaltic pump, it is not fast enough to provide an adequate flow of rinse solution when the ASX system is used. -

Page 31: Installing A Pumped-Drain Rinse Arrangement With Both Pumps

Many variations of this configuration are possible, such as using the built-in pump for the supply and using the external pump for the drain. For the EXR-8 extended rack, see the CETAC ASX Rapid Sample PRESS The external pump is powered by the ASX electronics module. -

Page 32: Notes

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Leave one input of the external pump disconnected (open to the atmosphere). Notes The bubbles in the rinse solution improve the cleaning action of the rinse station. - Page 33 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-8 Pumped-Drain Arrangement with External Peristaltic Pump as Supply and Built-In Pump as Drain Figure 4-9 Pumped-Drain Arrangement with External Peristaltic Pump as Drain and Built-In Pump as Supply...

-

Page 34: Installing The 1.0Mm Id Sample Probe

Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Installing the 1.0mm ID Sample Probe A 1.0mm ID sample probe (Figure 3-5) is provided for use with the CETAC autosampler for proper operation with the ASXpress P system. Refer to the autosampler Operators Manual to replace the probe with the 1.0mm sample... - Page 35 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-11 Y-Axis Home Block with Kynar Thumbscrews Remove the entire Z-drive assembly from the Y-arm by pulling the Z-drive assembly forward and off of the autosampler arm as shown (Figure 4-12). Figure 4-12 Z-Drive Removed from Arm Assembly.

- Page 36 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-13 Rinse Station If the autosampler has a standards rack which is attached to the front of the autosampler, remove the standards rack. Remove the three screws and pull it forward.

- Page 37 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-15 Removing the Tray (ASX-520) Next, the front cover is to be removed. Remove the four corner screws (Figure 4-16). Figure 4-16 Front View of ASX-520 Autosampler Showing Front Cover Screws...

- Page 38 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler The front cover is removed by lifting it slightly and pulling forward (Figure 4-17). Figure 4-17 ASX-520 Autosampler with the Front Cover Being Removed The screws that hold the inner shield must be removed. Move the Y-axis assembly all the way to the left (Figure 4-18 shows screw locations).

- Page 39 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler The inner shield can be removed by moving the arm to the right or left then lifting it up while pulling forward.(Figure 4-19). Removal of Inner Shield (ASX-520) If you have a newer shield/splash guard combination proceed as follows.

- Page 40 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Remove the two shield pieces. Notice that the splashguard goes under the chassis on the top and over the chassis on the bottom. When you replace the splashguard, ensure it is oriented in this manner.

- Page 41 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Remove the splashguard by pulling it out from one side. It may be necessary to reach under the guard and remove it from the support standoffs. Figure 4-22 Splashguard Removal...

-

Page 42: Setting The Pump Speed Jumper (Asx-520/Asx-520Hs/Exr-8)

In most cases, a firmware upgrade is not required. If you do need to upgrade the autosampler firmware, do it now, before reassembling the autosampler. The CETAC autosampler requires a firmware version which is compatible with the ASX system. If an upgrade is necessary, you can purchase a Rabbit processor module with firmware pre-loaded. -

Page 43: Supported Firmware Versions

ASX-520/ASX-520HS: firmware version 2.00 or later. The software needed to upgrade the firmware on the autosampler and the Where to Get the Firmware firmware upgrade file can be downloaded from the CETAC web site. To download the software and the firmware, go to http://www.cetac.com/downloads/download.html and select Autosampler Firmware Update. - Page 44 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-24 Jumpers on Board in Normal Position (ASX-520) On the ASX-260 board, move jumper JP2 to JP4 and leave JP3 in place (Figure 4-25 shows jumpers). Jumpers on Board in Normal Position (ASX-260) Figure 4-25...

-

Page 45: Loading The Firmware Upgrade

Start a terminal emulator program, as described in " Operating a CETAC Autosampler Using a Terminal Program" on page 137. Enter the VERSS command. The system will respond with the current firmware version. - Page 46 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Figure 4-26 Rabbit Field Utility Application When the Rabbit Field Utility has opened, select “Setup”, and then “Communications”.

- Page 47 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler In the Communications Options window, in the “Comm Port” field, select the COM port on the computer that is connected to the autosampler. Click the OK button.

-

Page 48: Upgrading (Loading) The Firmware

Note: The .bin file name in Figure 4-29 (i.e. ASXpress_1_19) will vary depending on which era ASXpress FW is being loaded. CETAC Technologies makes every effort to update the firmware as needed to ensure that the most beneficial functionality is provided to the customer. - Page 49 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler “Choose Flash Image” Window. Select the firmware file by filling in the field by selecting the “browse” button Figure 4-66 to the right of the field (denoted by […]) (Figure 3-66), and then selecting the correct file from the CD as depicted in Figure 3-67 or Figure 3-68.

-

Page 50: Returning The Autosampler To Normal (Non-Programming Mode) Configuration

ASXpress_HS_1_19) will vary depending on which era ASX FW is being PRESS loaded. CETAC Technologies makes every effort to update the firmware as needed to ensure that the most beneficial functionality is provided to the customer. As of December 2009, the most current firmware version file name is “ASXpress_1_19”... -

Page 51: Closing Up The Autosampler

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler Verification of Firmware Upgrade Start a terminal emulator program. Enter VERSS. The system should respond with the new firmware version. Closing Up the Autosampler Once the firmware has been upgraded and the pump speed has been set, you can close up the autosampler. - Page 52 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 4: Preparing an ASX-260 or ASX-520 Autosampler This page is intentionally blank.

-

Page 53: Preparing An Asx-1400/1600 Autosampler

5 Preparing an ASX-1400/1600 Autosampler To work properly with the ASX system, an ASX-1400 or ASX-1600 autosampler will require: PRESS Adequate sample and rinse flow rate Xpress rinse station Modified rinse tubing arrangement Xpress stirrer/probe block ... - Page 54 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler INJURY HAZARD WARNING Ensure that AC power to the autosampler is off before proceeding with installation. If power to the autosampler is not turned off, the autosampler could begin moving while you are working on it.

- Page 55 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Install the Xpress Rinse Station and Modified Rinse Tubing Arrangement An Xpress rinse station and associated modified tubing arrangement is required to accommodate the design requirements of the ASX system.

- Page 56 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Figure 5-2 Removing the Rinse Station Screw Gently tilt the rinse station away from the autosampler the pull it out. Figure 5-3 Removing the Rinse Station Remove the tubing connecting the rinse station to the peristaltic pump. Remove the tubing connecting the rinse station to the drain/waste container.

- Page 57 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Thread the rinse intake tubing and the drain tubing under the autosampler. Figure 5-5 Rinse Station Tubing Connect the rinse intake tubing to the “rinse in” fitting of the rinse station. Figure 5-6 Rinse Solution Flow As seen from above, rinse solution flows into the rinse station through the two holes for the stirrer and probe, then out through the single drain hole.

-

Page 58: Connecting The Rinse Tubing

Rapid Sample Introduction System vacuum pump outlet (see Figure 5-8). If that is not possible, or if the rinse station is overflowing, contact CETAC Technologies. PRESS Set up so that the rinse drain tubing drops directly into the waste receptacle with no coiling and without being submerged below the liquid level of the waste receptacle. - Page 59 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Figure 5-8 Typical Rinse Connections for an ASX-1400/1600 Autosampler with Diaphragm Pump and Gravity Drain. This configuration is recommended for most applications.

-

Page 60: Rinse Connections Using The Existing Peristaltic Pump

If you find the flow rate to be inadequate to keep up with the ASX Rapid Sample Introduction System, an additional pump may be required. Contact CETAC Technologies for recommendations. PRESS Remember to use Viton tubing (not PharMed) for the peristaltic pump tubing if the rinse solution is kerosene. -

Page 61: Installing The 1.0Mm Id Sample Probe On The Autosampler

Chapter 5: Preparing an ASX-1400/1600 Autosampler Installing the 1.0mm ID Sample Probe on the Autosampler A 1.0mm ID sample probe is provided for use with the CETAC autosampler for proper operation with the ASX system. The sample probe/stirrer holder block must also be replaced, to accommodate the larger sample probe. -

Page 62: Removing The Sample Probe

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler NOTE The 1.0mm I.D. sample probe must be installed on the autosampler or the Rapid Sample Introduction System will not perform properly. It is PRESS identified by double blue bands (Figure 5-12) installed on the probe tubing. Double Blue Bands Identify the 1.0mm I.D. -

Page 63: Removing The Stirrer Assembly

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Figure 5-14 Loosening the Thumbscrew Removing the Stirrer Assembly With the power off, manually push the stirring assembly ¾ of the way down. Remove the thumbscrew and pull the stirring assembly straight up. Figure 5-15 Lifting Out the Stirring Assembly Replacing the holder block Remove the 4 screws which hold the plate to the Z-drive assembly. -

Page 64: Reinstalling The Stirrer Assembly

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Figure 5-16 Removing the Plate Remove the 4 screws which hold the block to the plate. Figure 5-17 Removing the Block from the Plate Put the old block aside. Label it so it is clear which block to use in case the autosampler ever needs to be configured for use without the ASX system. -

Page 65: Installing The Sample Probe

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler Installing the Sample Probe Push the probe straight down. Make sure the bottom of the sample probe is even with the end of the stirring paddle, then tighten the thumbscrew. Follow the autosampler Operator Manual Instructions to replace the probe with the 1.0mm sample probe. - Page 66 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 5: Preparing an ASX-1400/1600 Autosampler This page is intentionally blank.

-

Page 67: Installing The Valve/Pump Module

6 Installing the Valve/Pump Module Once the autosampler is prepared for use, the ASX valve/pump module should be connected to the autosampler and to the nebulizer of your spectrometer. PRESS All tubing (except the sample loop and probe) is pre-connected to the ASX valve/pump module to allow convenient inter-connection to the autosampler and to the nebulizer per Figure 6-1. - Page 68 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Valve/Pump Module Tubing Connections Figure 6-1 PRESS...

-

Page 69: Install The 6-Port Valve

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Install the 6-Port Valve If the 6-port valve is not already installed on the valve/pump module, you need to install it as described in this section. If the 6-port valve is already installed, you may need to change its orientation (see “Replacing or Reorienting the 6- Port Valve”... -

Page 70: Install The Sample Loop

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module No gap Hex screw Figure 6-2 Reseating the 6-Port Valve Tighten the hex screw. Place the valve/pump module into position near the instrument's nebulizer. NOTE After you connect the electronics module and install the Xpress Config software, don't forget to home the valve as described on page 98. -

Page 71: Connect The Autosampler Probe To The Valve/Pump Module

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Connect the Autosampler Probe to the Valve/Pump Module Install the autosampler probe in the autosampler per the instructions included with the autosampler. Connect the tube from the probe to port #2 of the 6-port valve. Connect the Valve/Pump Module to the Nebulizer Ensure that the 60”... - Page 72 PRESS manufacturers’ instruments. To allow for the closest proximity placement of the ASX valve/pump module to the instruments nebulizer, CETAC PRESS Technologies offers a modular articulating support stand, which allows for stable mounting and flexible positioning of the valve/pump module. Contact...

-

Page 73: Optional: Installing An Internal Standard Addition Mixing Tee

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Optional: Installing an Internal Standard Addition Mixing Tee The optional internal standard addition mixing tee provides a practical and consistent way to dose each sample with an internal standard. This technique is commonly used to correct for a variable matrix or plasma-related effects. -

Page 74: Optional: Installing A Passive Bubbling Tee

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Figure 6-8 Flow Diagram with Internal Standard and Passive Bubbling Tee (Carrier Solution Bubbles Added After the Instrument's Peristaltic Pump) Optional: Installing a Passive Bubbling Tee Adding bubbles to the carrier solution helps clean the tubing and reduces carryover between samples. - Page 75 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Figure 6-10 Flow Diagram with Internal Standard and Passive Bubbling Tee (Carrier Solution Bubbles Added Before the Instrument's Peristaltic Pump) Attach a short length of tubing to the green fitting which comes with the valve/pump module.

- Page 76 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 6: Installing the Valve/Pump Module Figure 6-12 Passive Bubbling Tee in Rinse Solution Bottle Connect the clear tubing of the bubbling tee to the input of the instrument's peristaltic pump. Fully Connected Passive Bubbling Tee Makes sure that all of the tubing connections are tight.

-

Page 77: Installing The Electronics Module

7 Installing the Electronics Module The ASX electronics module needs to be connected to the power supply, to the ASX valve/pump module, to the autosampler, and to the host computer. PRESS PRESS The electronics module needs two connections to the host computer: GUI COM: This connection allows the Xpress Configuration Tool software to configure timing and other parameters in the electronics module. -

Page 78: Connecting The Electronics Module To The Power Supply

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module Figure 7-1 Overview of ASX Electrical Connections PRESS Connecting the Electronics Module to the Power Supply Turn the power switch on the electronics module OFF. Check the plug on the power cord to verify that it is of the correct type for your country. -

Page 79: Connecting The Electronics Module To The Valve/Pump Module

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module Connecting the Electronics Module to the Valve/Pump Module The ASX valve/pump module connects to the electronics module via its integrated cable with DIN style connector as shown in Figure 7-2. PRESS Plug the valve/pump module’s cable connector into the electronics module’s VP MODULE connector. -

Page 80: Connecting The Electronics Module To The Autosampler

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module Figure 7-3 Connecting the External Pump to the Electronics Module Connecting the Electronics Module to the Autosampler The ASX electronics module connects to the autosampler via an RS- 232C serial connection. -

Page 81: Establishing An Oem Com Connection (Rs-232)

PC to the electronics module. These commands are then re-issued, if appropriate, through the AUTOSAMPLER serial port. The serial interface kit provided with the CETAC autosampler includes a serial cable equipped with two female DB9 connectors. Use the interface kit to establish a serial communications interface with the host computer. -

Page 82: Establishing An Oem Com Connection (Usb)

D-submini receptacle or 25 pin D-submini plug or receptacle) must be used, use the mating connector from the CETAC Technologies universal port adapter kit. You can order the adapter kit from CETAC Technologies or purchase an adapter locally to convert the serial port to a DB9M. Do not use a “null modem”... - Page 83 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module If a driver is not found, click Back to begin installation from the CD-ROM. Figure 7-4 Message showing that a driver was not found a. Insert the CD-ROM. b.

- Page 84 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module Select Search removable media. Figure 7-6 Choosing to Install USB Driver from a CD d. Wait while the computer searches the CD. Figure 7-7 Searching the CD...

- Page 85 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module e. When the driver is found, select it and click Next. Figure 7-8 Selecting the Driver The driver installation is complete. Figure 7-9 Driver Installation is Complete...

-

Page 86: Establishing A Gui Com Connection (Rs-232)

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 7: Installing the Electronics Module If a message is displayed showing which COM port number was chosen (look for a “bubble” in the lower-right corner of the screen), make a note of Confirm that the COM port selected for the USB matches the port selected in the host computer's ICP software. -

Page 87: Installing The Xpress Configuration Tool

8 Installing the Software The Xpress Configuration Tool software is used to enable/disable and configure the autosampler and its control of the ASX system, as well as providing access to manual functions of the ASX system and autosampler. The ASX system is controlled by the autosampler, which PRESS executes a macro automatically when the probe is placed into the sample. - Page 88 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Setup Launcher Follow the prompts of the Installation Wizard to complete the installation of Figure 8-1 ASX PRESS the Xpress Configuration Tool software package as follows: When the Xpress Config Installation Wizard window opens, click Next to begin the software installation process (Figure 8-2).

- Page 89 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Figure 8-3 License Agreement Reviewing the README information, then click Next (Figure 8-4). Figure 8-4 Readme Information Window Click Next to select the default location, or click Change to modify the folder name.

- Page 90 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Figure 8-5 Destination Folder Window Review the selected settings. Click Back to change any selected settings. Click Install to begin the installation process with the selected settings. Figure 8-6 “Ready to Install the Program” Window The “InstallShield Wizard Completed”...

- Page 91 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Figure 8-7 “InstallShield Wizard Completed” Window The Xpress Configuration Tool loads and the main window appears. (Figure 8-8). The parameter labels, fields and select buttons will be grayed-out as shown until after the ASX /autosampler system is “queried”.

-

Page 92: Running The Xpress Configuration Tool For The First Time

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Figure 8-8 Configuration Tool Software Window (before connecting) Running the Xpress Configuration Tool for the First Time It is important to verify that all system components are in good working order Inspecting the ASX System Components PRESS... -

Page 93: Making Sure The System Is Ready

If you detect a leak or other damage to any ASX component, you must replace it. For more information, refer to the appropriate section in Chapter “Maintaining the ASXpress Plus Rapid Sample Introduction System.” PRESS Verify that: Making sure the system is ready The equipment is positioned so that you can quickly disconnect power if something goes wrong. - Page 94 Configuration Tool parameter fields. More information regarding use of the Xpress Configuration Tool can be found in “Configuring the ASXpress Plus System” beginning on page 99. Figure 8-9 shows the Xpress Config Tool window appearance after connecting.

-

Page 95: Configuring The Personality

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Figure 8-9 Configuration Tool Software Window (after connecting) The ASX Rapid Sample Introduction System responds to autosampler Configuring the personality commands which it intercepts. Since different autosamplers have different command languages, it is necessary to configure the ASX electronics PRESS... -

Page 96: Performing Some Basic Communication Tests

NOTE The list of available personalities, as well as more detailed instructions, can be found in the CETAC ASXPRESS PLUS Rapid Sample Introduction System Guide to Configuring Firmware Personalities available on the CD or at www.cetac.com. The list of available personalities is updated frequently, so if you do not see the personality you need in the version on CD, please check the version on the Web site. - Page 97 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software Figure 8-10 Config Tool Software Window--Expanded First, test communication with the ASX valve/pump module: Click the “Load” button. PRESS This positions the ASX 6-port valve into the mode which loads the sample loop, and illuminates the “Load”...

-

Page 98: Home The Valve

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 8: Installing the Software queried parameters of the Xpress Configuration Tool software settings. This is also a useful function for loading the tubing and priming the rinse pump. Turn the vacuum pump on and off several times. Next, test communication with the autosampler: Click Home AutoSampler and verify that the probe moves to the home position. -

Page 99: Timing Parameters

9 Configuring the System PRESS NOTE After changing any parameters, you must click the "Save Configuration to ASXpress+" button to copy the parameters to the electronics module. Adjusting a value in the Xpress Configuration Tool window does not immediately change the value used by the ASX system. - Page 100 Rinse Station Refill specifies the amount of time to allow the rinse station to refill once the In most cases, the timing parameters will have been configured by a CETAC vacuum pump stops. representative during installation. Make a note of those initial values before making any changes.

-

Page 101: Configuring The Asx Operation Controls

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 9: Configuring the ASXpress Plus System Operation Controls Enable ASXpress operation for normal operation. Enable ASXpress Operation Disable ASXpress operation if you want to test how the autosampler responds to commands, as if the autosampler were connected directly to the host PC without the ASX system. -

Page 102: Autosampler Pump Control

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 9: Configuring the ASXpress Plus System Turns the rinse pump on and off. This control affects both the autosampler's Autosampler Pump Control built-in peristaltic pump and any pump which is connected to the electronics module’s EXTERNAL PUMP connector. -

Page 103: Additional Xpress Configuration Tool Features

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 9: Configuring the ASXpress Plus System Additional Xpress Configuration Tool Features For general instructions, click the Help icon: Built-In Help For help on an individual field, click the What's This help icon, then "hover" the... - Page 104 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 9: Configuring the ASXpress Plus System Figure 9-1 Notes Window Use the Notes window if: You would like to see the notes every time the Xpress Configuration Tool window is opened.

-

Page 105: Service Log

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 9: Configuring the ASXpress Plus System This feature can be used during troubleshooting, at the request of CETAC Service Log Service & Support. To save a service log: On the Tools menu, click Save Service Log. - Page 106 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 9: Configuring the ASXpress Plus System This page is intentionally blank.

-

Page 107: Using The Rapid Sample Introduction System

10 Using the Rapid Sample Introduction System The ASX Rapid Sample Introduction System is both reliable and easy to use. Before using it, however, ensure that your lab environment provides operating conditions that will prolong the life of the ASX system. -

Page 108: Creating The Lab Environment

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 10: Using the Rapid Sample Introduction System NOTE Damage or malfunction that results from exposure to inappropriate operating conditions may constitute misuse and abuse and be excluded from warranty coverage. To create satisfactory operating conditions in your lab environment, follow Creating the Lab Environment these guidelines: ... -

Page 109: Purchasing Supplies

When you need to purchase additional supplies, it is extremely important that Purchasing Supplies you choose the appropriate sizes and materials. To order additional supplies, refer to the CETAC Accessories and Supplies Catalog for the ASX Rapid Sample Introduction System. -

Page 110: Starting The System

“tune” the settings to the actual process will yield the maximum benefit of the ASX Rapid Sample Introduction System’s PRESS ability to affect positive impact on laboratory productivity. Contact CETAC Technologies for further information regarding optimal setup and operation of the ASX system and associated parameters. -

Page 111: Shutting Down The System

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 10: Using the Rapid Sample Introduction System Shutting Down the System To shut down the ASX Rapid Sample Introduction System, complete the following steps: PRESS Drain the system by removing the rinse solution uptake tubing from the rinse solution sources (autosampler and ICP/ICP-MS). -

Page 112: Flushing The Rinse Station And Flow Path

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 10: Using the Rapid Sample Introduction System Flushing the Rinse Station and Flow Path The rinse station and flow path should be flushed in the following circumstances: Initial startup Flushing the rinse system during initial startup of the ASX Rapid Sample Introduction System removes any contaminants that could cause interference during sample analysis. -

Page 113: Developing A Method

Chapter 10: Using the Rapid Sample Introduction System Developing a Method This is an outline for method development which has worked well for many laboratories. If you need further assistance, CETAC Technologies is happy to help. Determine the approximate volume of sample to be consumed during analysis and at what pump speed. - Page 114 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 10: Using the Rapid Sample Introduction System This page is intentionally blank.

-

Page 115: Press Plus

11 Maintaining the Rapid PRESS Sample Introduction System Routine maintenance of the ASX Rapid Sample Introduction System consists of daily and weekly cleaning of specific components. Routine maintenance also includes checking ASX components for leaks or PRESS other damage. Additional periodic maintenance tasks may be required, including replacement of the following components: peristaltic pump tubing, PRESS rinse tubing, and sample probe. - Page 116 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Regular Inspection of ASX Components It is important to verify that all system components are in good working order PRESS and are undamaged prior to operation.

-

Page 117: Cleaning The System

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Cleaning the System Cleaning the ASX Rapid Sample Introduction System is the primary maintenance task you perform. Failure to do so regularly causes increased wear and reduces the system’s life. -

Page 118: Cleaning The 6-Port Valve

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Take whatever precautions are necessary to protect yourself and the work area from splashes of the rinse solution. Twist the filter enclosure and pull it open. - Page 119 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System To clean the valve, complete the following steps: Turn off and unplug the ASX Rapid Sample Introduction System. Remove all tubing and connectors from the 6-port valve.

-

Page 120: Checking For Leaks

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Checking for Leaks The tubing has a finite lifespan, and will wear out under normal use. Standard maintenance procedures require that you periodically check for leaks. To do... -

Page 121: Replacing Or Reorienting The 6-Port Valve

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Replacing or Reorienting the 6-Port Valve The 6-Port valve assembly has a finite lifespan that is dependent upon the conditions and sample media to which it is exposed. Exposure to higher sample solids levels reduces the valve lifespan. - Page 122 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System In the Xpress Config software, select the “Load” button then the “Inject” button. Do this twice. This will tell the electronics that the valve needs to be re-homed.

- Page 123 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Figure 11-7 Error message displayed when the valve is ready to re-home Tighten the hex screw on the locking collar. Toggle the valve between Load and Inject once again.

-

Page 124: Replacing The Battery

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Replacing the Battery The battery in the electronics module is used to store data in SRAM memory. When the battery is low, an error message will be displayed by the Xpress Configuration Tool. - Page 125 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Figure 11-9 Separating the Cover Be careful not to break or strain Battery these wires Figure 11-10 Location of the Battery Note the orientation of the battery, then pull it out.

-

Page 126: Updating Firmware

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 11: Maintaining the ASXpress Plus Rapid Sample Introduction System Updating Firmware You may need to update the firmware in the electronics module in order to use the ASX Rapid Sample Introduction System with a different autosampler or to take advantage of new features. -

Page 127: Troubleshooting The Rapid Sample Introduction System

This chapter explains how to troubleshoot ASX Rapid Sample Introduction System problems. If you cannot solve a problem using the steps given in this chapter, you should contact CETAC Technologies Customer Service PRESS and Support. If the Valve/Pump Module Does Not Appear to be Operating Check that “Enable ASXpress Operation”... -

Page 128: If The 6-Port Valve Is In The Wrong Position (Re-Homing)

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System If the 6-Port Valve Is In the Wrong Position (Re- Homing) It is possible for the 6-port valve to become rotated away from its proper position. -

Page 129: Power System Problems

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System If using an internal standard, verify that there are no bubbles in the tee and inspect the peristaltic pump tubing and replace if necessary. If QC continues to fail, the ICP/ICP-MS might need troubleshooting. Power System Problems A possible cause of ASX Rapid Sample Introduction System... -

Page 130: Communications Interface Problems

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System probe should move up and the autosampler should initialize. After initialization, the status LED on the front of the autosampler should light up. If the cords are properly connected, power is available, the external power supply is good, and the unit still does not initiate, •... -

Page 131: Software Configuration Problems

Click the “Load” button. The ASXpress Plus system should move the 6-Port Valve to the “Load” position (no other apparatus operates). - Page 132 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System Xpress Configuration Tool—Expanded to access manual functions Figure 12-1 Check that the “Enable ASXpress Operation” box in the Xpress Configuration Tool is checked. Unchecking this box would allow the autosampler to run independently of the ASX system, as if the autosampler were connected directly to the host PC.

-

Page 133: Returning The Product To Cetac For Service

PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System Returning the Product to CETAC for Service Refer to the following information if you need to return the product to CETAC Technologies for service. Follow these guidelines when shipping the product: Shipping the Product ... -

Page 134: Returned Product Procedures

CETAC reserves the right to change or improve the design of any unit without assuming any obligation to modify any unit previously manufactured. -

Page 135: Returned Product Warranty Determination

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System After CETAC’s examination, warranty or out of warranty status will be Returned Product Warranty Determination determined. If a warranted defect exists, the product will be repaired at no charge and shipped prepaid back to the buyer. - Page 136 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 12: Troubleshooting the Rapid Sample Introduction System This page is intentionally blank.

-

Page 137: Operating A Cetac Autosampler Using A Terminal Program

Windows 2000 and later. (recommended) HyperTerminal. This program was supplied with versions of the Windows operating system through Windows XP. This chapter explains how to operate a CETAC autosampler using either of the two programs. Using C-Term™... -

Page 138: Overview Of The C-Term Window

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 13: Operating a CETAC Autosampler Using a Terminal Program On the Start Menu, click All Programs, then CETAC Xpress Config, then Support Tools, then C-Term. Figure 13-1 Starting C-Term Once C-Term is loaded, the window shown in Figure 13-2 will open. The Overview of the C-Term Window majority of C-Term’s functions are available from this window. -

Page 139: Configuring C-Term

By default, C-Term attempts to open COM1 the first time it is executed. If the Configuring C-Term COM port that the CETAC device is connected to is not the default (COM1), then it will be necessary to configure C-Term to use the desired port. -

Page 140: Using Hyperterminal

The window will close and the settings will be saved. These new settings will be applied immediately and used thereafter unless changed again. NOTE Except for the ASX-8x00, all CETAC devices communicate at 9600 baud (which is the default.) NOTE Only installed COM ports, including USB virtual COM ports, will appear in the Comm Port menu. - Page 141 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 13: Operating a CETAC Autosampler Using a Terminal Program A window will appear as in Figure 13-6. Enter COM 1 in the name box. Press the OK button. Figure 13-6 “Connection Description” Window In the Connect To window, set Connect Using to COM 1, then click OK.

- Page 142 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 13: Operating a CETAC Autosampler Using a Terminal Program Figure 13-8 “COM1 Properties” Window Click OK. The HyperTerminal window will open. “Com 1 Hyperterminal” Window On the File menu, click Properties. Figure 13-9...

- Page 143 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 13: Operating a CETAC Autosampler Using a Terminal Program On the Settings tab, click ASCII Setup “Com 1 Properties” Window Click ASCII Setup. Figure 13-10 Enable “Echo typed characters locally” and “Append line feeds to incoming line...

-

Page 144: Autosampler Commands

Moves z-axis to upper most postion. Table 13-1 Autosampler Commands You can use these commands to determine if the CETAC autosampler is communicating and functioning properly. If more assistance is needed, please contact CETAC customer service. -

Page 145: Commands

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 13: Operating a CETAC Autosampler Using a Terminal Program Commands The ASX Rapid Sample Introduction System can be controlled PRESS through the same serial interface as the autosampler. ASX commands are prefixed with the “@” symbol. - Page 146 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 13: Operating a CETAC Autosampler Using a Terminal Program This page is intentionally blank.

-

Page 147: Safety And Regulatory Information

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 14: Safety and Regulatory Information 14 Safety and Regulatory Information Review this product and related documentation to familiarize with safety markings and instructions before you operate the instrument. Characteristics Environmental Characteristics Operating Temperature +13°... -

Page 148: Electrical Characteristics

External Pump Reserved for future use. Connect only to a pump provided by CETAC Technologies for this purpose. (0-24 V DC power and control signals for an external peristaltic pump.) Syringe Pump Reserved for future use. Connect only to a pump provided by CETAC Technologies for this purpose. - Page 149 Chapter 14: Safety and Regulatory Information V/P Module Control and 0-24 V DC power for the valve/pump module. Connect only to the provided CETAC valve/pump module, Table 14-3: Electrical Input and Output Connectors on the Electronics Module using the provided cable.

-

Page 150: Safety Notices

PRESS Chapter 14: Safety and Regulatory Information Safety Notices If the equipment is used in a manner not specified by CETAC Technologies, WARNING the protection provided the equipment may be impaired. Repair or service that this not covered in this manual should only be performed by qualified personnel. -

Page 151: Cleaning Instructions

To reduce the risk of fire hazard and electrical shock, do not expose the unit to rain or humidity. To reduce the risk of electrical shock, do not open the cabinet. All maintenance is to be performed by an Authorized CETAC Service Provider. -

Page 152: Explanation Of Caution And Warning Notices

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 14: Safety and Regulatory Information Explanation of Caution and Warning Notices Warning symbol marked on equipment. This symbol means “Attention! Refer to the manual.” The WARNING notice denotes a hazard. It calls attention to a procedure, WARNING practice, or the like, that, if not correctly performed or adhered to, could result in personal injury. -

Page 153: Avertissements En Français

Rapid Sample Introduction System Operator’s Manual PRESS Chapter 14: Safety and Regulatory Information Avertissements en Français This section provides French translations of notices which may appear on the instrument or on other instruments used as part of the measurement system. AVERTISSEMENT POUR UNE PROTECTION CONTINUÉ... -

Page 154: Electromagnetic Interference

The FCC requires the user to be notified that any changes or modifications made to this device that MODIFICATIONS are not expressly approved by CETAC Technologies may void the user's authority to operate the equipment. Connections to this device must be made with shielded cables with metallic RFI/EMI connector CABLES hoods to maintain compliance with FCC Rules and Regulations. -

Page 155: 15 Glossary

® FEP: Fluorinated Ethylene Propylene. Host Computer: The computer that controls operation of the ICP / ICP-MS instrument to which the CETAC autosampler is attached, and through which the ASXPRESS PLUS is controlled. Hz: Hertz I/O Auxiliary Port: The connector used for establishing communication and power between the ASX system and the autosampler. - Page 156 Rapid Sample Introduction System Operator’s Manual PRESS Chapter 15: Glossary Sample Loop: The loop of tubing, of predetermined length/volume, which holds the precise sample volume specific to the users unique analytical system requirements. Sample Probe: The tube that moves the analyte from the sample vial to the sample transfer tubing.

- Page 157 LED, 10, 131 definition, 155 chemical compatibility, 10, 108 mains disconnect, 150 cleaning, 117, 151 manual controls, 101 commands Manual Cycle, 97, 102 ASXpress Plus, 145 method development, 113 autosampler, 144 methods condensation. See humidity saving, 102 C-Term, 137 missed samples, 128...

- Page 158 Rapid Sample Introduction System Operator’s Manual PRESS Index rinse evacuation delay, 99 tubing Rinse Station Fill time, 100 connecting, 71 Rinse Station Refill time, 100 kinks, 17 safety information, 147 lifespan, 120 sample loop, 70 material, 9 sample probe. See probe, See replacing, 120 probe, See probe rinse, 21, 23, 27, 29, 55, 60, 112...

- Page 160 480167 Manual Part Number Rev 6 Printed in USA...

Need help?

Do you have a question about the ASXPRESS PLUS and is the answer not in the manual?

Questions and answers