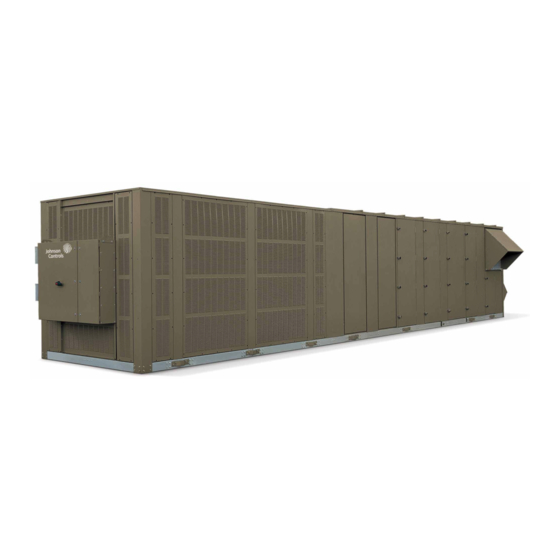

Johnson Controls 100 Series Installation Operation & Maintenance

Single packaged unit sypal design level f with simplicity elite control

Hide thumbs

Also See for 100 Series:

- Engineering manual (102 pages) ,

- Installation operation & maintenance (182 pages) ,

- Manual (56 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Need help?

Do you have a question about the 100 Series and is the answer not in the manual?

Questions and answers