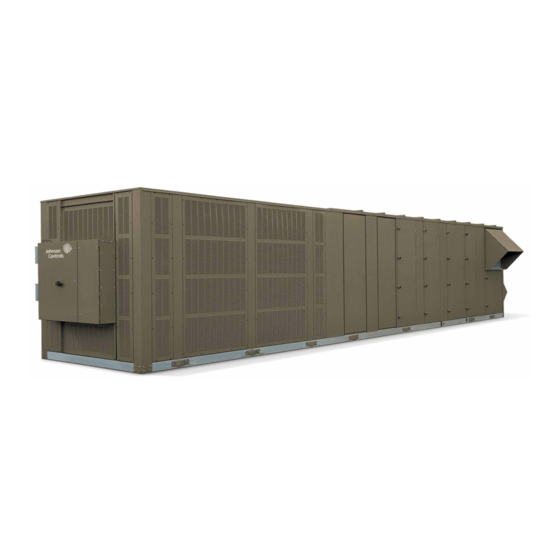

Johnson Controls 100 Series Manuals

Manuals and User Guides for Johnson Controls 100 Series. We have 4 Johnson Controls 100 Series manuals available for free PDF download: Installation Operation & Maintenance, Engineering Manual, Manual

Johnson Controls 100 Series Installation Operation & Maintenance (182 pages)

PACKAGED ROOFTOP UNITS, SINGLE PACKAGED UNITS, YPAL DESIGN LEVEL G

Brand: Johnson Controls

|

Category: Air Conditioner

|

Size: 7 MB

Table of Contents

-

Coils14

-

Controls15

-

-

Electrical16

-

-

Approvals17

-

Limitations17

-

-

-

Filters28

-

Field Wiring29

-

-

Gas Heating39

-

Gas Piping39

-

Duct System38

-

-

-

-

Unit Checks41

-

-

-

-

-

-

-

SZVAV Setup62

-

-

Unit Type59

-

Flexsys60

-

-

Supply Fan67

-

-

-

HGRH Setup82

-

HGRH Status82

-

HGRH Faults84

-

Economizer85

-

Heating86

-

-

HGRH System79

-

-

-

-

-

Flexsys106

-

Flexsys Setup107

-

Cooling108

-

Fan Operation108

-

Heating110

-

Smoke Purge112

-

Menu Select Keys114

-

Navigation Keys114

-

Ventilation99

-

-

-

-

Data Entry Keys113

-

History140

-

Password141

-

Power up Banner141

-

Bacnet Wiring142

-

Communication142

-

Printer130

-

Report Section130

-

Setup130

-

-

Service131

-

-

Date / Time127

-

Options127

-

Program127

-

Setpoints127

-

Schedule128

-

-

-

CO 2 Sensor167

-

Humidity Sensors167

-

Faults169

-

Temperature181

-

Multi Media Card179

Advertisement

Johnson Controls 100 Series Installation Operation & Maintenance (166 pages)

SINGLE PACKAGED UNIT SYPAL DESIGN LEVEL F WITH SIMPLICITY ELITE CONTROL

Brand: Johnson Controls

|

Category: Air Conditioner

|

Size: 6 MB

Table of Contents

-

-

Approvals17

-

Limitations17

-

-

General17

-

-

Location18

-

Unit Weights20

-

-

-

Field Wiring38

-

Thermostat38

-

CO Sensor39

-

Fan Input39

-

Space Sensor39

-

Fault Output40

-

Power Wiring40

-

Controls46

-

Duct System48

-

Gas Heating49

-

Gas Piping49

-

Filters37

-

-

-

-

-

Unit Checks51

-

-

-

-

-

General59

-

-

Belt Tension60

-

-

-

Belts60

-

Fan Motor62

-

-

-

Unit Type67

-

-

-

Economizer79

-

Dry Bulb79

-

-

-

Heating85

-

Loadshed87

-

Redline87

-

Dirty Filter88

-

Manual91

-

Ventilation91

-

Alarm / Change102

-

Test/Up Button102

-

-

Cooling84

-

-

-

Program Button101

-

-

Device Names111

-

Sensor Readings112

-

Fans114

-

Cooling Setup115

-

Cooling Status116

-

Heating Setup117

-

Heating Status118

-

System Options119

-

Outputs/Status120

-

Inputs121

-

Clock122

-

Weekly Schedule123

-

-

Graphic122

-

-

Holiday Schedule124

-

-

Alarms125

-

-

CO Sensor154

-

Humidity Sensors154

-

-

Alarm Codes159

Johnson Controls 100 Series Engineering Manual (102 pages)

SINGLE PACKAGE ROOFTOP UNITS

70–105 Tons

Cooling and Heating (Gas, Electric, Water, and Steam)

R-410A

Brand: Johnson Controls

|

Category: Air Conditioner

|

Size: 6 MB

Table of Contents

-

Weight Data22

-

Controls61

Advertisement

Johnson Controls 100 Series Manual (56 pages)

PACKAGED ROOFTOP UNITS

Brand: Johnson Controls

|

Category: Air Conditioner

|

Size: 1 MB

Table of Contents

-

-

-

Occupied30

-

Unoccupied31

-

Advertisement

Related Products

- Johnson Controls 105

- Johnson Controls 10 Series

- Johnson Controls 16 Seer-CZF Series

- Johnson Controls 13 Seer-TCGF

- Johnson Controls 14.5 Seer-TCGF

- Johnson Controls 13 SEER - GCGD

- Johnson Controls 14.5 Seer-TCJD

- Johnson Controls 13 Seer-YCJD

- Johnson Controls 13 Seer-YCJF

- Johnson Controls 14.5 Seer-YCJD