Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Monoprice MP Delta Pro

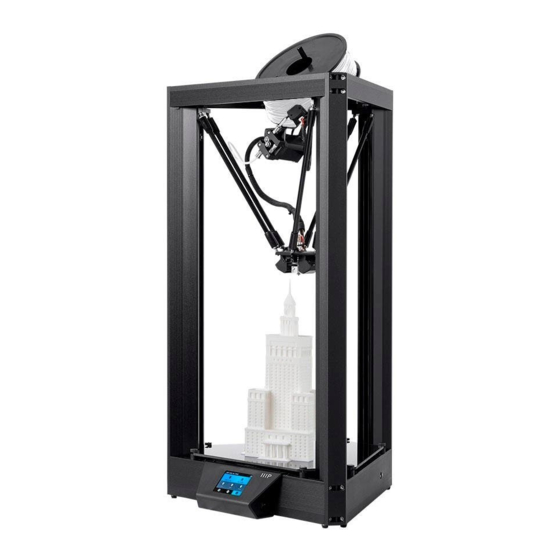

- Page 1 MP Delta Pro 3D Printer P/N 30993, 33346 User's Manual...

-

Page 2: Table Of Contents

CONTENTS SAFETY WARNINGS AND GUIDELINES ................................3 CUSTOMER SERVICE ........................................... 4 PACKAGE CONTENTS ........................................5 SLICING SOFTWARE..........................................5 SLICER SETTINGS ........................................... 6 LOADING FILAMENT ...........................................7 UNLOADING FILAMENT ........................................8 SWAPPING HOTENDS ........................................8 PRINTING A MODEL ..........................................9 AUTO LEVELING ........................................... 10 ADJUSTING THE Z-OFFSET...................................... -

Page 3: Safety Warnings And Guidelines

SAFETY WARNINGS AND GUIDELINES Please read this entire manual before using this device, paying extra attention to these safety warnings and guidelines. Please keep this manual in a safe place for future reference. • Be careful not to damage the glass build plate. •... -

Page 4: Customer Service

If you have any problem with your order, please give us an opportunity to make it right. You can contact a Monoprice Customer Service representative through the Live Chat link on our website www.monoprice.com or via email at support@monoprice.com. -

Page 5: Package Contents

PACKAGE CONTENTS Please take an inventory of the package contents to ensure you have all the items listed below. If anything is missing or damaged, please contact Monoprice Customer Service for a replacement. 1x Monoprice Delta Pro 3D Printer 1x MP Select PLA Plus Filament Roll (Black, 1 kg) -

Page 6: Slicer Settings

SLICER SETTINGS If you choose to use slicing software other than KISSlicer, use the settings in the table below to configure it for use with the Delta Pro 3D printer. Build Plate/Bed Diameter 270mm Build Envelope Height 340mm Firmware 5D Absolute E File Extension .gcode Fan On... -

Page 7: Loading Filament

LOADING FILAMENT 1. Place the filament spool on the holder so that the end of the filament hangs down to the right. 2. Using a pair of scissors or diagonal cutters, cut the end of the filament at an angle. 3. -

Page 8: Unloading Filament

UNLOADING FILAMENT 1. Turn the printer on, then preheat the nozzle to the appropriate temperature for the material being used (e.g., 200°C for PLA). 2. Once the nozzle is up to temperature, touch > > Unload. 3. Hold the filament sensor and carefully rotate the filament spool while the filament is unloading to avoid tangles. -

Page 9: Printing A Model

4. Remove the Bowden tube from the effector by removing the plastic pneumatic connector clips and depressing the top of the connector while pulling the tube. 5. Disconnect the heater and thermistor connectors from the cable harness. 6. While holding the hotend, use the included 1.5mm hex wrench to loosen the two headless hex screws on the side of the heat sink below the effector, then remove the hotend. -

Page 10: Auto Leveling

AUTO LEVELING Before you begin your first print, and anytime you remove the build plate, you should run an auto-level to ensure that your models adhere properly to the build plate. Perform the following steps to auto-level the printer. 1. Ensure that the hotend is at room temperature. 2. -

Page 11: Adjusting The Z-Offset

4. Once the process is complete, remove the auto-level sensor. ADJUSTING THE Z-OFFSET The Z-offset is the distance between the glass build plate and the nozzle. The auto-level process ensures that this distance is consistent across the build plate, but the distance itself must be manually calibrated. -

Page 12: Cleaning The Build Plate

10 microns or so, you may want to the adjust the firmware to correct the discrepancy. Perform the following steps to calibrate the dimensional accuracy. 1. Go to the Delta Pro page (30993/33346) on the monoprice.com website and download the Sample Prints for Calibration package. -

Page 13: Pid Tuning

5. Touch Push Rod Length, erase the old value, then enter the new value. PID Tuning If you find that the nozzle fails to maintain a stable temperature or fails to reach the target temperature, you can run the auto-PID tuning procedure to attempt to correct the issue. If nozzle temperature issues persist after running the auto-PID tune, you may need to replace the thermistor or heater. - Page 14 2. Touch > Temperature > Hotend 1 Settings > PID Settings > Auto PID Tuning. Wait for the process to complete.

-

Page 15: Preferences

PREFERENCES Changing the LCD Screen Color To change the LCD screen color, touch > System > 1 Tap Preheat Temperature You can change the default 1 Tap preheat target temperature by touching > Temperature > Preheat Setting > 1 Tap Preheat, then enter the desired target temperature value. -

Page 16: Maximum Temperatures

Maximum Temperatures By default, the maximum temperatures allowed by the firmware are set to the maximum safe operating temperature of the PTFE-lined hotend, which is 260°C. If you want to increase this while using the all-metal hotend, touch > Temperature > Hotend 1 Setting >... -

Page 17: Updating The Firmware

UPDATING THE FIRMWARE In the event that the printer's firmware has been updated, it will be linked on the product page (30993/33346) on the monoprice.com website. You should download and install the latest firmware. Perform the following steps to update the firmware. -

Page 18: Care And Maintenance

DO NOT use any solvents or cleaning fluids on the display. TECHNICAL SUPPORT Monoprice is pleased to provide free, live, online technical support to assist you with any questions you may have about installation, setup, troubleshooting, or product recommendations. If you ever need assistance with your new product, please come online to talk to one of our friendly and knowledgeable Tech Support Associates. -

Page 19: Specifications

SPECIFICATIONS Model 30993, 33346 Printing Technology Fused Filament Fabrication Maximum Print Area ø270 x 300 mm Build Volume 17.16 liters Build Platform Heated glass Extruder Count Nozzle Diameter 0.4mm Nozzle Material Brass Z-Axis Resolution 50-300 µm XY-Axis Resolution 10 µm Print Cooling Two part-cooling fans On-board Calibration... -

Page 20: Regulatory Compliance

Modifying the equipment without Monoprice's authorization may result in the equipment no longer complying with FCC requirements for Class B digital devices. In that event, your right to use the equipment may be limited by FCC regulations, and you may be required to correct any interference to radio or television communications at your own expense. -

Page 21: Radio Notice For Fcc

This FCC Part 15 radio device operates on a non-interference basis with other devices operating at this frequency. Any changes or modification to said product not expressly approved by Monoprice, including the use of non-approved antennas, could void the user’s authority to operate this device.

Need help?

Do you have a question about the MP Delta Pro and is the answer not in the manual?

Questions and answers