Table of Contents

Advertisement

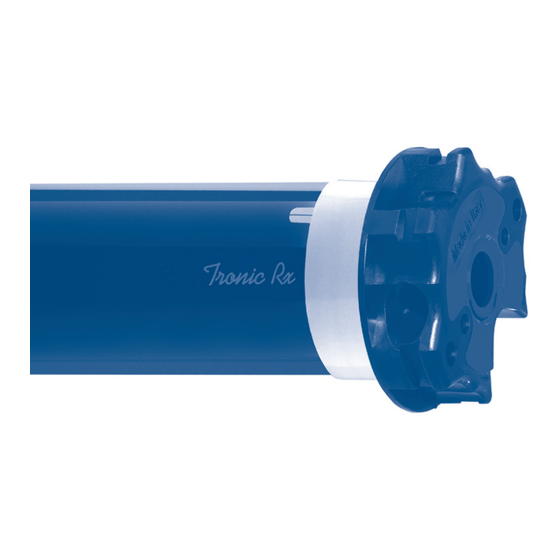

Tronic RX

MOTORE TUBOLARE PER AVVOLGIBILI CON

I

FINECORSA ELETTRONICO

TUBULAR MOTOR WITH ELECTRONIC LIMIT SWITCH

GB

FOR ROLLING SHUTTERS

ROHRMOTOR FÜR ROLLLADEN MIT

D

ELEKTRONISCHER ENDLAGENEINSTELLUNG

MOTEUR TUBULAIRE POUR VOLET ROULANT

F

AVEC FINS DE COURSE ÉLECTRONIQUES

MOTOR TUBULAR PARA PERSIANA CON

E

FIN DE CARRERA ELECTRÓNICO

ISTRUZIONI - INSTRUCTIONS - EINSTELLANLEITUNGEN

INSTRUCTIONS - INSTRUCCIONES

Advertisement

Table of Contents

Summary of Contents for CHERUBINI Tronic RX

- Page 1 Tronic RX MOTORE TUBOLARE PER AVVOLGIBILI CON FINECORSA ELETTRONICO TUBULAR MOTOR WITH ELECTRONIC LIMIT SWITCH FOR ROLLING SHUTTERS ROHRMOTOR FÜR ROLLLADEN MIT ELEKTRONISCHER ENDLAGENEINSTELLUNG MOTEUR TUBULAIRE POUR VOLET ROULANT AVEC FINS DE COURSE ÉLECTRONIQUES MOTOR TUBULAR PARA PERSIANA CON FIN DE CARRERA ELECTRÓNICO...

-

Page 3: Table Of Contents

TRANSLATION OF THE ORIGINAL INSTRUCTIONS Table of contents: How to prepare the motor ..................p. 26 Instruction fixing with clamp ..................p. 27 Electrical connections ....................p. 28 Compatible remote controls / Key to symbols ............p. 29 Command sequences example .................p. 30 Function open/close programming remote control ..........p. 31-32 Setting the first remote control ................p. -

Page 4: How To Prepare The Motor

HOW TO PREPARE THE MOTOR STOP RING NUT ADAPTOR DRIVING PULLEY STOP RING NUT 1. Insert the adaptor in the nut mating the groove with the reference notch and push till they touch. 2. Fix the driving pulley on the motor pin until the stop pin clicks. -

Page 5: Instruction Fixing With Clamp

INSTRUCTION FIXING WITH CLAMP The clamp allows to fix the motor directly on the side-cover bolt (Ø 12 mm). The clamp may be used only for motors until maximal torque of 15 Nm. The bolt has to be in aluminum with minimal Ø 11,5 and maximal Ø 11,9 mm. The clamp is supplied pre-assembled with the tightening of the screw on right side, in case should be necessary to tighten the screw on the left side go on as follows:... -

Page 6: Electrical Connections

ELECTRICAL CONNECTIONS - In order to prevent dangerous situations or malfunctioning, the electrical command elements wired to the motor must be sized according to the motor’s electrical features. - Means for disconnection must be incorporated in the fixed wiring in accordance with the national installation standards. -

Page 7: Compatible Remote Controls / Key To Symbols

COMPATIBLE REMOTE CONTROLS LED - Skipper Skipper Skipper A530058 Remote Skipper Skipper Control with 4 Display - Skipper independent Skipper Skipper channels Skipper Skipper Channel selector Activating/ Deactivating the Sun sensor Check the specific Skipper instruction book Skipper GIRO GIRO Wall stop DOWN down... -

Page 8: Command Sequences Example

COMMAND SEQUENCES EXAMPLE Most of the command sequences have three distinct steps, at the end of which the motor indicates if the step has been concluded positively or not, by turning in different ways. This section is provided to demonstrate the motor indications. The buttons must be pressed as shown in the sequence, without taking more than 4 seconds between one step and the next. - Page 9 FUNCTION OPEN/CLOSE PROGRAMMING REMOTE CONTROL SKIPPER PLUS - SKIPPER LUX - SKIPPER P-LUX To prevent accidental changes to the programming of the motor during the daily use of the remote control, the possibility of programming is disabled automatically 8 hours after sending the last sequence (A+B or B+C).

-

Page 10: Function Open/Close Programming Remote Control

FUNCTION OPEN/CLOSE PROGRAMMING REMOTE CONTROL SKIPPER - SERIES GIRO To prevent accidental changes to the programming of the motor during the daily use of the remote control, the possibility of programming is disabled automatically 8 hours after sending the last sequence (A+B or B+C). CHECKING THE STATUS OF THE FUNCTION Open programming... -

Page 11: Setting The First Remote Control

ADJUSTMENT OF THE LIMIT SWITCHES Tronic RX tubular motors have an electronic limit switch system with an encoder. This system ensures great reliability and precision in keeping the positions. Limit switch regulation is performed simply with the remote control. During setting, the motor moves only as long as the up or down button is pressed, stopping when the button is released. -

Page 12: Example 1: Setting First The Opening Position

EXAMPLE 1: Setting first the opening position SETTING THE OPENING POSITION If the rolling shutter is completely open, you have first to drive it down by around 20 cm. Hold the button A or C pressed and drive the rolling shutter to the opening position. With physical stops: press button A or C until the motor stops automatically. -

Page 13: Example 2: Setting First The Closing Position

EXAMPLE 2: Setting first the closing position SETTING THE CLOSING POSITION If the rolling shutter is completely closed, you have first to drive it up by around 20 cm. Hold the button A or C pressed and drive the rolling shutter to the closing position. With lockdown hangers: press buttons A or C until the motor stops automatically. -

Page 14: Mode 2: Limit Switch Setting (Semi-Automatic)

MODE 2: LIMIT SWITCH SETTING (semi-automatic) To do the settings in this mode the rolling shutter has to be equipped with lockdown hangers in the closing position, but the rolling shutter does not need to have physical stops in the opening position. This mode of setting is helpful in cases where the factory will set the opening position and the closing position will be set automatically during the normal use. -

Page 15: Setting A Middle Position

SETTING A MIDDLE POSITION This function allows the rolling shutter to be set at a favourite middle position. When this middle position is memorized, you just press the stop button for 2 seconds and automatically the motor will move the shutter to this position. To memorize the middle position, move the rolling shutter to the desired position and then hold the STOP button down (for about 2 sec) until the motor gives confirmation. -

Page 16: Closing Force Adjustment

The Tronic RX is factory set to a closing force of 20 % of the nominal torque. This force can be changed very easily by the remote control. It can be reduced by 10 % or increased up to 40 %, depending on the desired result. -

Page 17: Setting Of Additional Remote Controls

SETTING OF ADDITIONAL REMOTE CONTROLS Up to 15 remote controls can be set. Tn: Already programmed remote control Tx: Additional remote control Tx (2 sec) REMOTE CONTROL MEMORY CLEARING It is possible to delete singly all the memorized remote controls. When the last one is deleted the motor initial condition is restored. -

Page 18: Full Memory Clearing

FULL MEMORY CLEARING This full memory clearing does not delete the setting of the limit switch. The full memory clearing can be performed in two ways: 1) WITH THE REMOTE CONTROL Tn: Already programmed remote control Tn (4 sec) 2) WITH THE WHITE WIRE Do this operation only in case of emergency, if all remote controls are no longer operating.To delete the memory we have to access the white wire of the motor. -

Page 19: Special Functions

SPECIAL FUNCTIONS SHORT-TERM SETTING OF A REMOTE CONTROL This function makes it possible to store a remote control temporarily, for example, with the purpose of setting the limit switches during assembly in the factory. A later final saving of the remote control will be possible using the appropriate command sequence (see: “SETTING THE FIRST REMOTE CONTROL”). -

Page 20: Setting The A530058 Pocket Remote Control

SETTING THE A530058 POCKET REMOTE CONTROL NB: The new pocket remote control can be set only after programming of a previous remote control as the traditional Cherubini remote controls (Skipper or Giro - 3 buttons Up-Down-Stop remote control). HOW TO PROCEED TO SET THE BUTTON ON THE POCKET REMOTE CONTROL... -

Page 21: Electric Wiring To Motor Command With 2 Independent Buttons

ELECTRIC WIRING TO MOTOR COMMAND FOR UP-DOWN MODE (2 independent UP-DOWN buttons) To connect the switch, use only kind of switches with mechanical or electrical interlock, to prevent to press both buttons at same time. The motor automatically recognizes the switch-type (with 1 or 2 buttons) and sets the proper operational mode. -

Page 22: Command Management From White Wire Up-Stop-Down-Stop / Up-Down / Up-Down "Dead Man

COMMAND MANAGEMENT FROM WHITE WIRE UP-STOP-DOWN-STOP / UP-DOWN / UP-DOWN “DEAD MAN” NB: The default function provided in the motors leaving the factory is UP-STOP-DOWN- STOP for singular UP/DOWN button switch. (Not for the switch with two independent UP-DOWN buttons!) PROCEDURE TO CHANGE THE CONTROL MODE: Tn: Already programmed remote control Tn (2 sec) -

Page 23: Super-Sensitivity Obstacle Detection Management During Downwards Movements (Only For Ø 35 Motors)

SUPER-SENSITIVITY OBSTACLE DETECTION MANAGEMENT DURING DOWNWARDS MOVEMENTS - only for Ø 35 motors - Where required it is possible to activate/deactivate a high level of obstacle detection sensitivity during downwards movement. This Super-sensitivity is automatically disabled when the blinds slats begin to pile up. ACTIVATING THE SUPER-SENSITIVITY FUNCTION Tn: Already programmed remote control Tn (2 sec) - Page 24 FORCED REMOTE CONTROL RE-PROGRAMMING WITH FURNITURE FUNCTION ACTIVE If the remote control has been lost it’s possible, by enabled “Furniture” function, to memorize a new remote control. To memorize a new remote control proceed as follows: • Disconnect the power supply. •...

-

Page 25: Eu Declaration Of Conformity

Il testo completo della dichiarazione di conformità UE è disponibile facendone richiesta sul sito: www.cherubini.it. EU DECLARATION OF CONFORMITY CHERUBINI S.p.A. declares that the product is in conformity with the relevant Union harmonisation legislation: Directive 2014/53/EU, Directive 2011/65/EU. The full text of the EU declaration of conformity is available upon request at the following website: www.cherubini.it. - Page 26 Note - Bem - Notes - Notas:...

- Page 28 CHERUBINI S.p.A. Via Adige 55 25081 Bedizzole (BS) - Italy Tel. +39 030 6872.039 | Fax +39 030 6872.040 info@cherubini.it | www.cherubini.it CHERUBINI Iberia S.L. Avda. Unión Europea 11-H Apdo. 283 - P. I. El Castillo 03630 Sax Alicante - Spain Tel.

Need help?

Do you have a question about the Tronic RX and is the answer not in the manual?

Questions and answers