Table of Contents

Advertisement

Quick Links

TC10 Power Take-of f Overhaul Instructions

TC10 Power Take-of f Overhaul Instructions

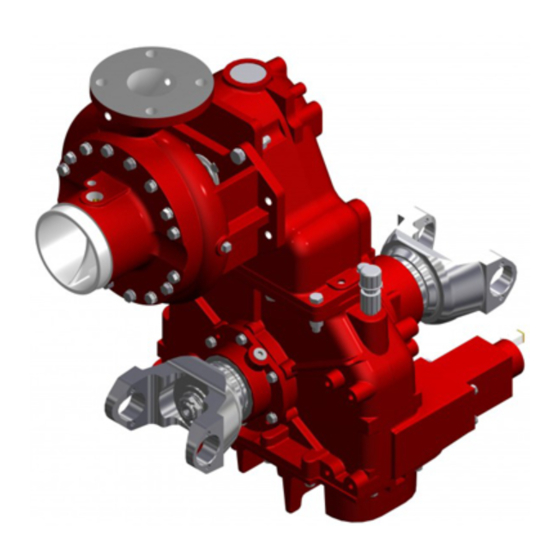

TC10 Power Take-Off

Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

All content in this instruction is property of the Waterous Company. Instructions subject to change without notice.

All content in this instruction is property of the Waterous Company. Instructions subject to change without notice.

All content in this instruction is property of the Waterous Company. Instructions subject to change without notice.

Table of Contents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly of PTO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Facing End Yoke/Rear Facing Hydr. Pump Prov.

Rear Facing End Yoke/Front Facing Hydr. Pump Prov.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Bearings, Oil Seals and Gaskets

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Front Facing End Yoke/Rear Facing Hydr. Pump Prov.

Rear Facing End Yoke/Front Facing Hydr. Pump Prov.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instructions subject to change without notice.

Overhaul Instructions

Form No.

T-360

1

1.

1

2.

1

3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

1

4.

1

5.

2

6.

3

7.

3

8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

9.

4

10.

5

11.

Removal of Mid-Section from Cap

5

12.

. . . . . . . . . . . . .

6

19.

7

20.

7

7

21.

8

22.

8

23.

9

30.

. . . . . . . . . . . .

9

31.

. . . . . . . . . . .

10

32.

10

33.

11

34.

11

35.

12

36.

13

37.

13

38.

13

39.

13

40.

14

41.

Installing the Chain

15

42.

16

43.

. . . . . . . . . . .

17

44.

. . . . . . . . . . .

18

45.

19

46.

20

47.

. . . . . . . . . . .

21

48.

23

49.

. . . . . . . . . . . . .

24

50.

26

51.

28

52.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29, 30

31

32

. . . . . . . . . . . . . . .

33

34

. . . . . . . . . . . . . . .

35

35

Issue Date

Rev. Date

1/9/18

01/19/06

Illustrations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2

3

3

4

4

5

5

5

6

7

7

11

11

12

12

13

20

21

21

22

23

23

24

24

25

25

26

26

27

27

28

28

29

30

31

31

32

33

33

Advertisement

Table of Contents

Summary of Contents for Waterous TC10

-

Page 1: Table Of Contents

Instructions subject to change without notice. All content in this instruction is property of the Waterous Company. Instructions subject to change without notice. All content in this instruction is property of the Waterous Company. Instructions subject to change without notice. -

Page 2: Introduction

This instruction provides the necessary steps required to overhaul the TC10 power take-off. These instructions are divided into Disassembly and Reassembly sections. Also, refer to the Service Parts List (SPL documents) furnished with your TC10 to aid in further part identification and repair parts ordering. -

Page 3: Eclipse Es Cafsystem Removal

Figure 1. Eclipse ES CAFSystemt Removal Figure 2. Eclipse ES - Air Clutch Assembly (Side View) T-360 Page 2 of 35... -

Page 4: Removal End Yokes

Disassembly of the TC10 The TC10 consists of three sections; the cap, the mid-section and the bottom Removal of End Yokes section. The order of disassembly is bottom section, mid-section and then cap. 1. Remove the end yokes from the driven, drive and coupling shafts. Do NOTE: Out of chassis overhaul will require supporting the PTO initially in not reuse self-locking nuts. -

Page 5: Coupling Shaft Housing Removal

Coupling Shaft Housing Removal Removing the Bottom Section 1. Invert the case as shown in Figure 3. 1. Remove the hex head screws and lock washers attaching the coupling shaft housing to the mid-section. 2. Remove lower cap screws connecting the driveshaft housing to the bottom section. -

Page 6: Removal Of The Chain

Removal of Chain Removal of Drive Shaft and Housing 1. Rotate the drive shaft until removeable connecting pin set of the chain 1. Remove the remaining hex head screws and lock washers attaching is visible at the drive sprocket. The removable connecting pin set has a the drive shaft housing to the mid-section. -

Page 7: Removal Of Shift Components (Pneumatic, Electric Shift)

Figure 10a. Removal of Shift Component - (Internal) Removal of Shift Components 1. Remove the shift shoe from the locking arm. 2. Slip locking arm off pivot pin. Shift Shoe NOTE: The pivot pin and shift shaft bushing (typically pressed into the bottom section) need only be removed if bent or otherwise damaged. -

Page 8: Removal Of Mid-Section From Cap

Removal of Mid-Section from Cap Disassembly of Driven Shaft Assembly The cap does not need to be removed from the mid-section unless either is Front Facing End Yoke being replaced. NOTE: Removal will make it easier to handle the assembly 1. -

Page 9: Rear Facing End Yoke

Rear Facing End Yoke Front Facing Hydraulic Pump Provision 1. Remove the four cap screws that fasten the hydraulic pump adapter 1. Remove the four cap screws that fasten the bearing cover and oil seal and bearing cover to the cap. Remove adapter and cover. Discard oil housing to the cap. -

Page 10: Rear Facing Hydraulic Pump Provision

Rear Facing Hydraulic Pump Provision Front Facing End Yoke / Rear Facing Hydraulic Pump Provision 1. Remove the four cap screws that fasten the hydraulic pump adapter and bearing cover to the cap. Remove adapter and cover. Discard oil 1. Remove the four cap screws that fasten the hydraulic pump adapter seal. -

Page 11: Eclipse Mounted Cafs

Rear Facing End Yoke / Eclipse Mounted CAFS Front Facing Hydraulic Pump Provision 1. Remove the four cap screws that fasten the bearing cover and oil seal housing to the cap. Remove cover, housing and yoke spacer. 1. Remove the four cap screws that fasten the hydraulic pump adapter and oil seal housing to the cap. -

Page 12: Disassembly Of Coupling Shaft Assembly

Disassembly of Coupling Shaft Assembly Disassembly of Drive Shaft Assembly 1. Press coupling shaft housing off of bearings if not previously removed. 1. Slide shift collar from teeth on the drive shaft. 2. Pull outer bearing from the shaft. NOTE: If the transmission is equipped with an electronic tachometer, remove the pick-up from the housing prior to removal of the drive... -

Page 13: Inspection And Repair

Figure 22. Needle Bearing Removal from Sprocket Disassembly of Drive Shaft Assembly Cont'd 4. Remove spacer if applicable. 5. Place shaft and sprocket assembly in an arbor press in a vertical posi tion with the threaded end up and supported on the bottom face of the sprocket. -

Page 14: Reassembly

Reassembly Guidelines for Installing Bearings, Oil Seals, O-Rings and Hardware Installing Bearings Installing Oil Seals Keep new bearings wrapped until they are to be installed. When pressing the Before installing an oil seal in its housing, apply a thin coat of sealant to hous bearing on a shaft or into a bore, coat appropriate surfaces with grease. -

Page 15: Rear Facing End Yoke

Figure 24. Rear Facing End Yoke Reassembly of the Driven Shaft Rear Facing End Yoke 1. Use high pressure grease to coat the driven shaft. Cap Screw Oil Seal 2. Press the bearing to the shoulder on the yoke end of the driven shaft. Lock Washer 3. -

Page 16: Front Facing Hydraulic Pump Provision

Figure 25. Front Facing Hydraulic Pump Provision Front Facing Hydraulic Pump Provision Reassembly of the Driven Shaft 1. Use high pressure grease to coat the driven shaft. Cap Screw 2. Press the bearing to the shoulder on the internal spline end of driven Lock Washer shaft. -

Page 17: Rear Facing Hydraulic Pump Provision

Rear Facing Hydraulic Pump Provision Figure 26. Rear Facing Hydraulic Pump Provision Reassembly of the Driven Shaft 1. Use high pressure grease to coat the driven shaft. Cap Screw 2. Press the bearing to the should on the internal spline end of the drive Lock Washer shaft. - Page 18 Front Facing End Yoke Figure 27. Front Facing End Yoke Rear Facing Hydraulic Pump Provision Reassembly of the Driven Shaft Rear Facing Hydraulic Pump Provision Cap Screw 1. Use high pressure grease to coat the driven shaft. Oil Seal Lock Washer 2.

- Page 19 Rear Facing End Yoke Figure 28. Rear Facing End Yoke Front Facing Hydraulic Pump Provision Reassembly of the Driven Shaft Front Facing Hydraulic Pump Provision Cap Screw 1. Use high pressure grease to coat the driven shaft. Oil Seal Lock Washer 2.

-

Page 20: Eclipse Mounted Cafs

Eclipse ES Mounted CAFS Figure 29. Eclipse ES Mounted CAFS Reassembly of the Driven Shaft 1. Use high pressure grease to coat the driven shaft. Cap Screw Spacer 2. Press the bearing (1) onto the shaft and secure in place with retaining Lock Washer Oil Seal ring. -

Page 21: Dowel Pins And Spacer Installation

Position cap on spacer and tap dowel pins into place. Secure with appropriated hardware (see Service Parts List SPL82747 - TC10 or SPL82821 - TC10 Eclipse ES). Cap Screw Note: If shims are required, install between cap and spacer. -

Page 22: Reassembly Of The Shift Assembly (Pneumatic Or Electric)

Reassembly of the Shift Assembly File and clean sealing surfaces of the mid-section and clean out any Shift Assembly metal chips or shavings. Invert mid-section. Apply a small amount of grease to the O-ring and install on the groove Attach shift arm to shift shaft with spirol pin (see Figure 32). of the pivot pin. - Page 23 5. Slide the shift lever into the sector gear aligning the holes (see Figure Figure 33. Shift Assembly 33). 6. Set shift lever/sector gear over the shift shaft opening in the mid-sec tion. Shift 7. Slide shift shaft up through the shift shaft opening, engaging spacer Shoe and shift lever or shift lever/sector gear.

-

Page 24: Reassembly Of The Cap And Mid-Section

Reassembly of the Cap and Mid-Section 1. Make sure the face of the mid-section is clean and free of nicks and 5. Install cap or cap and spacer to mid-section. burrs. a. Cap only: Position cap on mid-section and tap dowel pins into mid- 2. -

Page 25: Reassembly Of The Drive Shaft And Drive Shaft Housing

Reassembly of the Drive Shaft and Drive Shaft Housing Drive Shaft Assembly 7. Install the thrust washer onto the drive shaft. 8. Apply grease and install the ball bearing. 1. File and clean the sprocket faces and check teeth for burrs. 9. -

Page 26: Drive Assembly Into Drive Housing

Drive Shaft Housing Assembly Drive Shaft/Housing Assembly Installation 1. Apply a light coat of silicone to the housing bore and install the oil seal. 1. Apply grease to stud on the shift shoes for temporary installation. Then, install the drive shaft assembly into the mid-section and onto the 2. -

Page 27: Optional Electronic Tachometer

Figure 40. Optional Electronic Tachometer Optional Electronic Tachometer 1. Install the O-ring onto the tachometer pick-up. Pick-Up 2. Rotate drive shaft until tach tooth lines up with the tach opening. Hex Nut 3. Install the tachometer pick-up into the drive shaft housing until it con O-ring tacts the tach pulse generator. -

Page 28: Connecting Pin Set

Figure 42. Connecting Pin Set Figure 43. Connecting Pin Orientation Connecting Pin Set (Spirol pin on opposite side must be tapped in to complete installation.) Connecting Rocker Joining End of Chain Spirol Pin Guide Link IL2433 T-360 Page 27 of 35... -

Page 29: Reassembly Of The Bottom Section

Reassembly of the Bottom Section to the Cap and Mid-Section 1. Apply Loctite #242 to the shift shaft bushing and install into the bottom 4. Tap back the drive shaft assembly to allow for the bottom section of the case. installation. -

Page 30: Shift Position Adjustments

Shift Position Adjustments 1. Check the distance from shift collar to face of coupling shaft housing 2. Adjust as necessary. bore. Distances should read as follows: 3. Install retainers. Apply grease into the slots to help secure retainers. ROAD mode: 1-3/8 inches (right adjusting screw) PUMP mode: 2-11/16 inches (left adjusting screw) Note: Locking arm must not rotate beyond 90_ from center position to avoid disengagement of shift shoe. -

Page 31: Locking Arm Rotation Restrictions

Shift Position Adjustments (Continued) Figure 47. Locking Arm Rotation Restrictions Outside Edge of Coupling Shaft Housing Bore Sector Gear Pivot Pin Sector Gear Drive Sprocket Drive Locking Arm Sprocket Pilot Bearing 90 _ IL3161 IL3162 Locking Arm Shift Shoe Shift Shoe Shift Fork Shift Shoe in Fork Pilot Bearing... -

Page 32: Coupling Shaft And Housing Assembly

Coupling Shaft and Housing Assembly Coupling Shaft Assembly Coupling Shaft Housing Assembly 1. Use high pressure grease and press bearing, spacer and bearing onto 1. Coat the seal outer diameter evenly with sealant. Be sure that the seal, shaft. shaft and housing are clean. Always install a seal with the seal lip facing in. -

Page 33: Coupling Shaft Housing To Case Assembly

Figure 50. Assembling Coupling Shaft Housing to Case Coupling Shaft Housing Assembly to Case Assembly The driveline assembly was factory shimmed to limit the axial float of the drive line. If any of the drive line parts have been changed, it may be necessary to change the total thickness of shims between the coupling shaft housing and the transmission case. -

Page 34: Reassembly Of Miscellaneous Items And Accessories

Reassembly of Miscellaneous Items and Accessories End Yoke Assembly Shift Accessory Assembly 1. Slide yoke onto the coupling shaft and drive shafts. 1. Attach the switch to the switch bracket using a seal and locking nut. Install the cap. 2. Secure in place using washers and self-locking nuts. Anti-seize should be applied to the threads before installing a self-locking nut. -

Page 35: Eclipse Es Cafsystem Installation Onto Pto

Eclipse ES CAFSystemt Installation onto PTO (See Figure 1) To install the Eclipse ES CAFSystem onto the TC10, perform the following 7. Install the hex hd screw that attaches the air clutch assembly to the steps: anti-rotation bracket). 1. Support the Eclipse ES unit with a lifting strap placed under the air 8. -

Page 36: Propeller Shaft Connection And Accessory Installation

Propeller Shaft Connection and Accessory Installation Electrical Connections Drain Valve Connect the tachometer cable, electric shift wiring and primer motor wiring as Connect the manifold drain valve. required. Propeller Shaft Primer Connect the propeller shafts to the drive and coupling shafts Connect the priming pump and hose to the priming pump.

Need help?

Do you have a question about the TC10 and is the answer not in the manual?

Questions and answers