Table of Contents

Advertisement

Quick Links

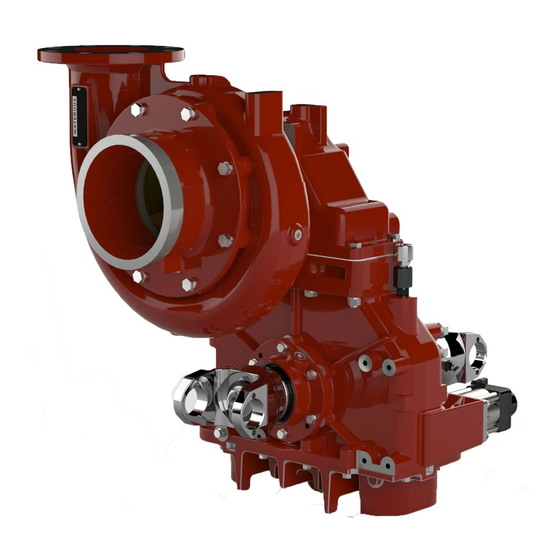

S100 Series Centrifugal

Fire Pumps

Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000

Instructions subject to change without notice.

Operation and Maintenance

Form No.

Section

F-1031

2117

Table of Contents

Safety Information----------------------------------------------- 2, 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Components .................................................................... 4

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pump Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pumping from Water Tank ................................................ 6

Pumping from Hydrant or in Relay .............................. 7

Pumping from Draft ..................................................... 8

Fire Hose Testing ........................................................ 9

Optional Zinc Intake Screens............................ 10

Optional Zinc Anodes ....................................... 10

Mechanical Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . 11

Overheat Protection Manager (OPM) . . . . . . . . . . . . 11

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Read through the safety information and

operating instructions carefully before

using your Waterous Fire Pump.

Visit us at www.waterousco.com

Issue Date

Rev. Date

02/22/02

6/21/18

Advertisement

Table of Contents

Summary of Contents for Waterous S100 Series

-

Page 1: Table Of Contents

Lubrication ........12 Read through the safety information and operating instructions carefully before using your Waterous Fire Pump. Visit us at www.waterousco.com Waterous Company 125 Hardman Avenue South, South St. Paul, Minnesota 55075 USA (651) 450-5000 Instructions subject to change without notice. -

Page 2: Safety Information

Safety Information Read through the safety information and operating instructions carefully before using your Waterous Fire Pump. WARNING WARNING Death or serious personal injury might occur if proper Unexpected Truck Movement. May result in serious operating procedures are not followed. The pump oper- personal injury or death. - Page 3 Safety Information Read through the safety information and operating instructions carefully before using your Waterous Fire Pump. WARNING Hose Testing Hazard. May result in serious personal injury. Due to a potential for catastrophic hose failure during service testing of fire hose, it is vital that safety precautions be taken to prevent exposure of anyone to this danger.

-

Page 4: Introduction

Introduction This instruction contains the information needed for operation and maintenance of S100 Series centrifugal pumps. General Description The S100 series pumps are single stage centrifug al end suction pumps providing capacities up to 2000 GPM (7570 L/min). ® S100 models are midship mounted with a Victaulic intake fitting, S101 models are midship mounted with an intake crosspipe. -

Page 5: Pump Models

Pump Models S100C20 Series S100PA Series End Suction Intake End Suction Intake C20 Series Chain Drive Transmission PA Series Chain Drive Transmission S101C20 Series S100D Series End Suction Intake Direct Crosspipe Intake Drive, Pedestal Mounted C20 Series Chain Drive Transmission F-1031, Section 2117 Page 5 of 12... -

Page 6: Operating Instructions

Operating Instructions Transmission Operation Refer to the C20 Transmissions: Operation and Maintenance Instructions, See F-1031-2413 Refer to the PA Transmissions: Operation and Maintenance Instructions, See F-1031-2207 Pumping from Water Tank CAUTION WARNING Do not attempt to pump more water than is avail- Pressure Hazard. -

Page 7: Pumping From Hydrant Or In Relay

Pumping from Hydrant or in Relay 4. S100C20 and S101C20 Only: Open discharge valves WARNING and accelerate engine to obtain desired discharge pres- sure and capacity. Pressure Hazard. May result in personal injury or 5. Set relief valves or other pressure governing device to death. -

Page 8: Pumping From Draft

Pumping from Draft 1. Prime the pump (see separate instructions supplied with WARNING primer). 2. S100D Only: Engage pump drive and accelerate en- Pressure Hazard. May result in personal injury or gine to obtain desired discharge pressure and capacity. death. Prior to connection of hoses, caps or other closures with 3. -

Page 9: Fire Hose Testing

Fire Hose Testing WARNING Hose Testing Hazard. May result in serious personal injury. Due to a potential for catastrophic hose failure during service testing of fire hose, it is vital that safety precautions be taken to prevent exposure of anyone to this danger. Fire pumps on fire department apparatus are not designed for and should not be used for service testing of fire hoses. -

Page 10: Maintenance

Maintenance Corrosion Protection Optional Zinc Intake Screens Threaded Anodes Once per month check to make sure the intake screens are not clogged or damaged. Also check for corrosion, and replace screens if damage is severe. For the zinc screen to adequately control corrosion, there must be a strong electrical contact between the screen and the fitting. -

Page 11: Mechanical Seal

Mechanical Seal A mechanical shaft seal is used and no adjustment is If the mechanical seal leaks, replace the entire seal. required. When the pump operates, the water being The S100 is equipped with drain notches on the pump pumped cools and lubricates the shaft seal to prevent it body/transmission mounting flange or bearing housing. -

Page 12: Lubrication

Lubrication 1. Check the lubrication fluid level monthly by check- comes first. Lubrication fluid may be added through ing the sight plug or by removing the oil level plug. the oil level hole or by removing the breather and The fluid should be level with the bottom of the oil adding fluid through the opening.

Need help?

Do you have a question about the S100 Series and is the answer not in the manual?

Questions and answers