Table of Contents

Advertisement

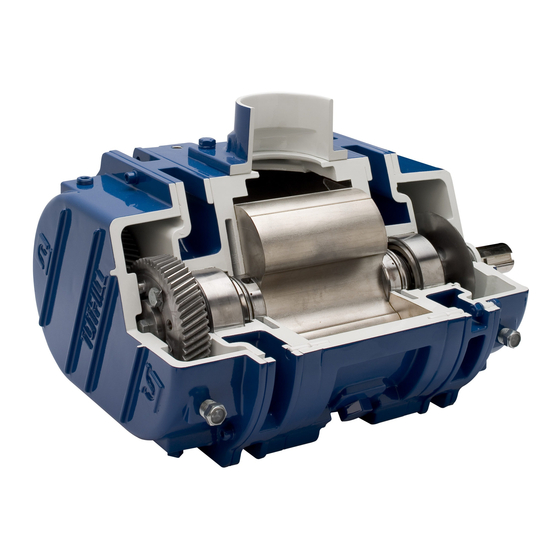

TUTHILL

TI850

Rotary Positive Displacement Air Blowers

SERIES:

17 – Lip/Labyrinth Seals / Air Service – Horizontal Flow

46 – Lip/Labyrinth Seals / Air Service – Vertical Flow

87 – Slinger/Piston Ring Seals / Air Service – Horizontal Flow

88 – Slinger/Piston Ring Seals / Air Service – Vertical Flow

INSTALLATION

OPERATION

MAINTENANCE

REPAIR

MANUAL

WARNING

DO NOT OPERATE BEFORE

READING MANUAL.

05/2006

LEADING THE SEARCH FOR INNOVATIVE SOLUTIONS

4840 West Kearney Street

Springfield, Missouri USA 65803-8702

Tel 417 865-8715 800 825-6937 Fax 417 865-2950

E-mail: vacuum@tuthill.com

http://vacuum.tuthill.com

Advertisement

Table of Contents

Summary of Contents for Tuthill TI850

- Page 1 TUTHILL TI850 Rotary Positive Displacement Air Blowers SERIES: 17 – Lip/Labyrinth Seals / Air Service – Horizontal Flow 46 – Lip/Labyrinth Seals / Air Service – Vertical Flow 87 – Slinger/Piston Ring Seals / Air Service – Horizontal Flow 88 – Slinger/Piston Ring Seals / Air Service – Vertical Flow...

-

Page 2: Safety Instructions & Warning Tags

• Noise level may require ear protection. • Blower heat can cause burns if touched. TUTHILL VACUUM & BLOWER SYSTEMS Springfield, MO USA NOTICE The above safety instruction tags were attached to your unit prior to shipment. Do not remove, paint over or obscure in any manner. -

Page 3: Table Of Contents

In order to assure you of the full benefits of our product warranty, please complete, tear out and return the warranty registration card located on the back cover of this manual, or you can register your product online at http://vacuum. tuthill.com/product_registration SAFETY PRECAUTIONS For equipment covered specifically or indirectly in this instruction book, it is important that all personnel observe safety precautions to minimize the chances of injury. -

Page 4: Introduction

TI850 blowers are built to exacting standards and if properly installed and maintained will provide many years of reliable service. We urge you to take time to read and follow every step of these instructions when installing and maintaining your Blower. -

Page 5: Installation

INSTALLATION WARNING: Users must provide adequate protection, warning and safety equipment necessary to protect personnel against hazards involved in the installation and operation of this equipment in the system or facility. Do not use air blowers on explosive or hazardous gases. Casing pressure must not exceed 25 PSIG (1.72 bar g). -

Page 6: Lubrication & Oil Capacities

LUBRICATION Every Tuthill blower is factory tested, oil drained and shipped dry to its installation point. Both independent oil reservoirs must be filled to the proper level before operation. Shaft bearings at the gear end of the blower are splash lubricated by one or both gears dipping into an oil reservoir formed in the gear end plate and cover. -

Page 7: Preventative Maintenance

PREVENTATIVE MAINTENANCE A good maintenance program will add years of service to your blower. A newly installed blower should be checked frequently during the first month of operation, especially lubrication. Check oil level in both the drive end and gear end of the blower and add oil as needed. Complete oil changes are recommended every 1000 operating hours, or more frequently depending on the type of oil and oil operating temperature. -

Page 8: Troubleshooting

TROUBLESHOOTING Although Tuthill TI850 blowers are well designed and manufactured, problems may occur due to normal wear and the need for readjustment. The chart below lists symptoms that may occur along with probable causes and remedies. SYMPTOM PROBABLE CAUSE REMEDIES Loss of oil. -

Page 9: Recommended Shutdown Procedure

RECOMMENDED SHUTDOWN PROCEDURE TO MINIMIZE RISK OF FREEZING OR CORROSION When high humidity or moisture is present in an air piping system, condensation of water can occur after the blower is shut down and the blower begins to cool. This creates an environment favorable to corrosion of the iron internal surfaces, or in cold weather, the formation of ice. -

Page 10: Disassembly

DISASSEMBLY Remove all oil drain plug and vent plug from both ends of the blower. Before removing any parts, match mark each component with a punch. This will allow the blower to be reassembled in the same position. Match mark covers, endplates, housing, cover extension, and both rotors. -

Page 11: Assembly

ASSEMBLY GEAR END ASSEMBLY Check all parts to insure the parts are clean and free of burrs or nick that may have occurred when the blower was being disassemble. Check repair kit for the correct parts needed to complete the assembly of the unit. Make sure you have the proper tooling and training required to assemble the blower. - Page 12 Timing Shim on Rotor Shaft Figure 4 – Correct Positioning of Timing Gears for Installation or Removal DRIVE END ASSEMBLY Remove blower from fixture and turn until drive shaft is facing upward. With a straightedge placed on the blower housing, check the clearance between the rotor and the straight edge using feeler gauges. Make sure the drive end has the proper clearances.

- Page 13 Install pipe plugs and sight glasses to the proper location. The direction of flow of the blower will determine their location. ASSEMBLY CLEARANCES Model Gear End Drive End Interlobe Tip-Port Tip-Dowel TI850 .004” – .009” .013” –.018” .013” – .017” .006” –.010” .003”– .007” (.10 – .23 mm) (.33 – .46 mm) (.33 – .45 mm) (.15 –...

-

Page 14: Internal Assembly Drawing & Parts List

TI850 INTERNAL ASSEMBLY AND PARTS LIST Item Description Qty. Item Description Qty. DRIVE ROTOR CAP SCREW, HEX HEAD DRIVEN ROTOR CAP SCREW, HEX HEAD HOUSING CAP SCREW, HEX HEAD END PLATE CAP SCREW, SOCKET HEAD COVER EXTENSION CAP SCREW, SOCKET HEAD... -

Page 15: External Assembly Drawings

TI850 EXTERNAL ASSEMBLY (Reference Parts List on Facing Page) 17/87 SERIES (HORIZONTAL AIR FLOW) 46/88 SERIES (VERTICAL AIR FLOW) NOTES:... -

Page 16: Seal & Bearing Installation Tools

SEAL & BEARING INSTALLATION TOOL DRAWINGS 1.200" 5.125" 0.128" 4.500" 0.300" 3.012" 1.954" 2.363" 1.628" 1.908" +.008 2.365" -.008 SECTION A-A .040" x 45° SECTION A-A DRIVE SHAFT SEAL TOOL CLEARANCE SETTING SPACER 6.200" 2.300" 0.200" ø 3.502" 3.500" 3.496" 2.850"... -

Page 17: Recommended Lubricants

DTE EXTRA HEAVY ® F (50 (ISO 150) (ISO 150) (ISO 150) (ISO 150) RECOMMENDED SYNTHETIC BASED LUBRICANTS* NOTE: Tuthill Vacuum & Blower Systems cannot accept AMBIENT TUTHILL EXXONMOBIL SHELL responsibility for damage to seals, O-rings and gaskets TEMPERATURE caused... -

Page 18: Warranty

WARRANTY Subject to the terms and conditions hereinafter set forth and set forth in General Terms of Sale, Tuthill Vacuum & Blower Systems (the seller) warrants products and parts of its manufacture, when shipped, and its work (including installation and start- up) when performed, will be of good quality and will be free from defects in material and workmanship. -

Page 19: Warranty Registration Card

NOTES IMPORTANT All blowers manufactured by Tuthill Vacuum & Blower Systems are date coded at time of shipment. In order to assure you of the full benefits of the product warranty, please complete, tear out and return the product registration card below, or you can visit our product registration web page at http://vacuum.tuthill.com/product_registration... - Page 20 NO POSTAGE NECESSARY IF MAILED IN THE UNITED STATES BUSINESS REPLY MAIL FIRST-CLASS MAIL PERMIT NO. 2912 SPRINGFIELD MO POSTAGE WILL BE PAID BY ADDRESSEE ATTN CUSTOMER SERVICE TUTHILL VACUUM & BLOWER SYSTEMS PO BOX 2877 SPRINGFIELD MO 65890-2150...

Need help?

Do you have a question about the TI850 and is the answer not in the manual?

Questions and answers