Summary of Contents for ITT Goulds Pumps 3610

- Page 1 Installation, Operation, and Maintenance Manual Model 3610, API Type BB1 API 610 11th Edition...

-

Page 3: Table Of Contents

Table of Contents Table of Contents Important Safety Reminder ..................... 4 Pump Safety Tips ........................4 Valve Safety Tips ........................5 Ex-approved products ......................5 Introduction and Safety ......................7 Introduction ..........................7 Safety ............................7 Safety terminology and symbols ................... 8 Environmental safety ...................... - Page 4 Table of Contents Bypass-piping considerations ..................... 33 Auxiliary-piping checklist ....................34 Final piping checklist ......................34 Commissioning, Startup, Operation, and Shutdown ............35 Preparation for startup ......................35 Remove the coupling guard ....................36 Check the rotation - Frame Mounted ..................36 Couple the pump and driver ....................

- Page 5 Parts list - Model 3610 - sleeve/ktb ..................102 Cross-sectional diagrams ....................103 Other Relevant Documentation or Manuals ..............104 Local ITT Contacts ......................105 Regional offices ........................105 Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual...

-

Page 6: Important Safety Reminder

Important Safety Reminder Important Safety Reminder To: Our Valued Customers Products manufactured and furnished by Goulds Pumps will provide safe, trouble-free service when properly installed, maintained and operated. We have an extensive network of experienced sales and service professionals to assist in maximizing your satisfaction with our products. -

Page 7: Valve Safety Tips

These are the personnel requirements for Ex-approved products in potentially explosive atmospheres: • All work on the product must be carried out by certified electricians and ITT-authorized mechanics. Special rules apply to installations in explosive atmospheres. • All users must know about the risks of electric current and the chemical and physical characteristics of the gas, the vapor, or both present in hazardous areas. - Page 8 • The yield stress of fasteners must be in accordance with the approval drawing and the product specification. • Do not modify the equipment without approval from an authorized ITT representative. • Only use parts that are provided by an authorized ITT representative.

-

Page 9: Introduction And Safety

This includes any modification to the equipment or use of parts not provided by ITT. If there is a question regarding the intended use of the equipment, please contact an ITT representative before proceeding. -

Page 10: Safety Terminology And Symbols

Introduction and Safety Safety terminology and symbols About safety messages It is extremely important that you read, understand, and follow the safety messages and regulations carefully before handling the product. They are published to help prevent these hazards: • Personal accidents and health problems •... -

Page 11: User Safety

• Report all environmental emissions to the appropriate authorities. WARNING: Do NOT send the product to the manufacturer if it has been contaminated by any nuclear radiation. Inform ITT so that accurate actions can take place. Electrical installation For electrical installation recycling requirements, consult your local electric utility. - Page 12 Introduction and Safety • Provide a suitable barrier around the work area, for example, a guard rail. • Make sure that all safety guards are in place and secure. • Make sure that you have a clear path of retreat. •...

-

Page 13: Ex-Approved Products

Compliance is fulfilled only when you operate the unit within its intended use. Do not change the conditions of the service without the approval of an ITT representative. When you install or maintain explosion proof products, always comply with the directive and applicable standards (for example, IEC/EN 60079–14). -

Page 14: Product Warranty

• The monitoring equipment incorporated in the product is correctly connected and in use. • All service and repair work is done by ITT-authorized personnel. • Genuine ITT parts are used. • Only Ex-approved spare parts and accessories authorized by ITT are used in Ex-approved products. Limitations The warranty does not cover faults caused by these situations: •... -

Page 15: Transportation And Storage

Transportation and Storage Transportation and Storage Inspect the delivery Inspect the package 1. Inspect the package for damaged or missing items upon delivery. 2. Note any damaged or missing items on the receipt and freight bill. 3. File a claim with the shipping company if anything is out of order. If the product has been picked up at a distributor, make a claim directly to the distributor. - Page 16 Transportation and Storage Figure 1: Example of the proper lifting method for a bare pump Baseplate-mounted units have lifting points for use with proper lifting devices. Figure 2: Example of the proper lifting method for baseplate-mounted units without a driver indicating the use of clevices Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual...

-

Page 17: Storage Guidelines

Treat bearing and machined surfaces so that they are well preserved. Refer to the drive unit and coupling manufacturers for their long-term storage procedures. For questions about possible long-term storage treatment services, please contact your local ITT sales representative. Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... -

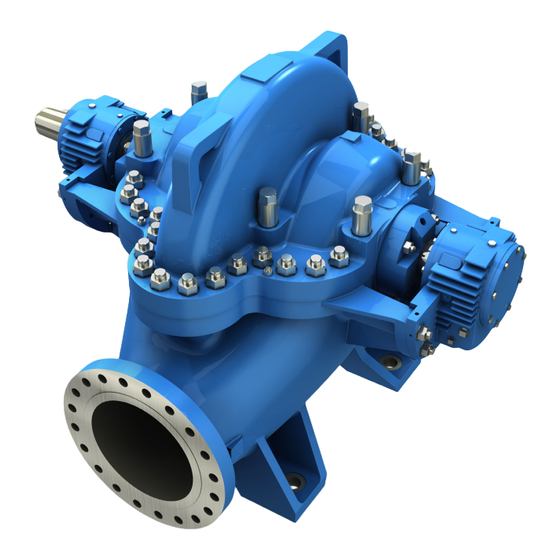

Page 18: Product Description

Product Description Product Description General description Product description The Model 3610 is a horizontal centrifugal pump that meets the requirements of API 610 8th through 11th Editions (ISO 13709 1st and 2nd Editions) and has these characteristics: • Safety, Reliability, and Versatility •... -

Page 19: Nameplate Information

Product Description • No machining is required in order to convert the standard ring oil lube to either purge or pure mist. Pure mist applications require minor bearing housing modifications. • Pressure lubrication is required with hydrodynamic thrust bearings. Bearings Bearing type Characteristics Inboard (radial) - Page 20 Product Description Nameplate field Explanation MODEL Pump model SIZE Size of the pump FLOW Rated pump flow, in gallons per minute HEAD Rated pump head, in feet Rated pump speed, in revolutions per minute HYDRO PRESS Hydrostatic pressure at 100°F, in pounds per square inch MAX.

- Page 21 If they are not compatible, do not operate the equipment and contact your ITT representative before you proceed. Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual...

-

Page 22: Installation

The coupling used in an ATEX classified environment must be properly certified. • NOTICE: Supervision by an authorized ITT representative is recommended to ensure proper installation. Failure to do so may result in equipment damage or decreased performance. Pump location guidelines WARNING: Assembled units and their components are heavy. -

Page 23: Foundation Requirements

Installation Foundation requirements Requirements • The foundation must be able to absorb any type of vibration and form a permanent, rigid support for the unit. • The location and size of the foundation bolt holes must match those shown on the assembly drawing provided with the pump data package. -

Page 24: Prepare The Foundation For Mounting

Installation 1. Make sure that all baseplate surfaces that will contact grout are free from contamination such as rust, oil, and grime. 2. Thoroughly clean all baseplate surfaces that will come in contact with grout. Make sure to use a cleaner that will not leave residue. NOTICE: You may need to sandblast the surfaces of a baseplate that come in contact with grout, and then coat those surfaces with a primer that is grout-compatible. -

Page 25: Install The Pump, Driver, And Coupling

Installation Figure 10: Jackscrew locations, top view 1. Lower the baseplate carefully onto the foundation bolts. The baseplate will rest on top of the foundation on the jackscrews provided on the baseplate. 2. Adjust the leveling jackscrews, located adjacent to the foundation bolt holes, until the baseplate rests 1 to 2 in. -

Page 26: Pump-To-Driver Alignment

Installation Pump-to-driver alignment Precautions WARNING: • Follow shaft alignment procedures in order to prevent catastrophic failure of drive components or unintended contact of rotating parts. Follow the coupling installation and operation procedures from the coupling manufacturer. • Always disconnect and lock out power to the driver before you perform any installation or maintenance tasks. -

Page 27: Permitted Indicator Values For Alignment Checks

Installation When After you grout the baseplate This ensures that no changes have occurred during the grouting process. After you connect the piping This ensures that pipe strains have not altered the alignment. Final alignment (hot alignment) checks When After the first run This ensures correct alignment when both the pump and the driver are at operating temperature. -

Page 28: Perform Angular Alignment For A Vertical Correction

Installation b) Attach the other indicator (A) so that the indicator rod comes into contact with the inner end of the driver coupling half. This indicator is used to measure angular misalignment. Figure 11: Dial indicator attachment 2. Rotate the pump coupling half (X) in order to check that the indicators are in contact with the driver coupling half (Y) but do not bottom out. -

Page 29: Perform Parallel Alignment For A Vertical Correction

Installation 2. Rotate the indicator through the top-center position to the right side, 180° from the start position (3 o’clock). 3. Record the indicator reading. When the reading value is... Then... Negative The coupling halves are farther apart on the right side than the left. -

Page 30: Perform Parallel Alignment For A Horizontal Correction

Installation When the reading value is... Then... 1. Shims Figure 14: Example of incorrect vertical alignment (side view) 4. Repeat the previous steps until the permitted reading value is achieved. Perform parallel alignment for a horizontal correction A unit is in parallel alignment when the parallel indicator (P) does not vary by more than 0.002 in. -

Page 31: Perform Complete Alignment For A Horizontal Correction

Installation 4. Make corrections according to the separate instructions for angular and parallel alignment until you obtain the permitted reading values. Perform complete alignment for a horizontal correction A unit is in complete alignment when both the angular indicator (A) and the parallel indicator (P) do not vary by more than 0.002 in. -

Page 32: Piping Checklists

Installation 6. Fill the remainder of the baseplate with grout, and allow the grout to set for at least 48 hours. 1. Baseplate 2. Grout 3. Foundation 4. Dam 5. Bolt Figure 17: Fill remainder of baseplate with grout 7. Remove the leveling jackscrews after the grout hardens in order to remove any stress points. -

Page 33: Suction-Piping Checklist

Installation Check Explanation/comment Checked Check that only necessary fittings This helps to minimize friction losses. are used. Do not connect the piping to the — pump until: • The grout for the baseplate or sub-base becomes hard. • The hold-down bolts for the pump are tightened. - Page 34 Installation Check Explanation/comment Checked Suggested suction strainers are Suction strainers help to prevent used. Check that they are at least debris from entering the pump. three times the area of the suction Liquids with specific gravity less piping. than 0.60 a pressure drop across Monitor the pressure drop across the suction strainer may be due to the suction strainer.

-

Page 35: Discharge Piping Checklist

When to install a minimum-flow orifice You can size and install a minimum-flow orifice in a bypass line in order to prevent bypassing excessive flows. Consult your ITT representative for assistance in sizing a minimum-flow orifice. When a minimum-flow orifice is unavailable Consider an automatic recirculation control valve or solenoid-operated valve if a constant bypass (minimum-flow orifice) is not possible. -

Page 36: Auxiliary-Piping Checklist

Installation Auxiliary-piping checklist Precautions WARNING: • Cooling systems such as those for bearing lubrication and mechanical-seal systems must be operating properly to prevent excess heat generation, sparks, and premature failure. • Sealing systems that are not self-purging or self-venting, such as plan 23, require manual venting prior to operation. -

Page 37: Commissioning, Startup, Operation, And Shutdown

Commissioning, Startup, Operation, and Shutdown Commissioning, Startup, Operation, and Shutdown Preparation for startup DANGER: Avoid death or serious injury. Explosion and/or seizure of pump can cause fire and/or burns. Never operate pump past the pressure and temperature limits shown on the nameplate on the pump. WARNING: •... -

Page 38: Remove The Coupling Guard

Commissioning, Startup, Operation, and Shutdown • Flush and clean the system thoroughly to remove dirt or debris in the pipe system in order to prevent premature failure at initial startup. • Bring variable-speed drivers to the rated speed as quickly as possible. At initial startup, do not adjust the variable-speed drivers or check for speed governor or over- speed trip settings while the variable-speed driver is coupled to the pump. -

Page 39: Couple The Pump And Driver

Commissioning, Startup, Operation, and Shutdown Couple the pump and driver WARNING: • Always disconnect and lock out power to the driver before you perform any installation or maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical injury. -

Page 40: Coupling Guard Assembly

Commissioning, Startup, Operation, and Shutdown Coupling guard assembly Precautions WARNING: • Never operate the pump without the coupling guard correctly installed. • Avoid death or serious injury. Assure mechanical seal guard is properly installed using supplied fastening hardware. • Always disconnect and lock out power to the driver before you perform any installation or maintenance tasks. - Page 41 Commissioning, Startup, Operation, and Shutdown 6. 3/8 in. washer 7. 3/8-16 x 2 in. hex head bolt, 3 required Install the coupling guard 1. Is the end plate (pump end) already installed? • If yes: Make any necessary coupling adjustments and then proceed to step 2. •...

- Page 42 Commissioning, Startup, Operation, and Shutdown 1. Annular groove 2. Deflector fan guard 3. Coupling guard half 3. Install clip-on nut to on one of the flat tabs on the bottom part of the coupling guard. Make sure to align the nut with the round hole at the front end of the guard half with nut on the outside.

- Page 43 Commissioning, Startup, Operation, and Shutdown 6. Slightly spread the opening of the remaining coupling guard half and place it over the installed coupling guard half so that the annular groove in the remaining coupling guard half faces the driver. 1. Annular groove 2.

- Page 44 Commissioning, Startup, Operation, and Shutdown 7. Place the end plate over the driver shaft and locate the end plate in the annular groove at the rear of the coupling guard half. 1. Annular groove 2. End plate 8. Repeat steps 3 through 5 for the rear end of the coupling guard half, except that you hand tighten the bolt.

-

Page 45: Bearing Lubrication

Commissioning, Startup, Operation, and Shutdown 12. Place one washer over the bolt and insert the bolt through the round hole where the push nut and clip-on nut are located. Be sure to tighten the bolt firmly. Bearing lubrication Precautions WARNING: Make sure to properly lubricate the bearings. -

Page 46: Oil Volumes

Commissioning, Startup, Operation, and Shutdown Oil volumes Oil volume requirements for ball/ball and sleeve/ball bearings This table shows the required amount of oil for oil-lubricated bearings. All frames in this table use a Watchdog Oiler, which has a capacity of 4 oz. (118 ml). Size Nameplate radial Bearing housing oil volume... -

Page 47: Lubricate The Bearings With Pure Or Purge-Oil Mist (Optional)

Commissioning, Startup, Operation, and Shutdown a) Fill the bearing chamber through the main body of the Watchdog until it reaches the optimum fluid level visible in the bullseye sight. b) Fill the watchdog reservoir using a funnel. c) Verify o-ring is on the Watchdog oiler spout. d) Place your thumb over the reservoir spout. -

Page 48: Lubricate The Bearings After A Shutdown Period

Commissioning, Startup, Operation, and Shutdown Convert to oil-mist lubrication NOTICE: Make sure that pipe threads are clean and apply thread sealant to plugs and fittings. You can convert from ring-oil lubrication to oil-mist lubrication in pumps with ball bearing construction. The radial and thrust end bearing housings (134) have pre-drilled connections for oil misting: •... -

Page 49: Connection Of Sealing Liquid For Mechanical Seals

Cartridge seals installed by the user require disengagement of the holding clips prior to operation, allowing the seal to slide into place. If the seal has been installed in the pump by ITT, these clips have already been disengaged. Other mechanical seal types For other types of mechanical seals, refer to the instructions provided by the seal manufacturer for installation and setting. -

Page 50: Prime The Pump With The Suction Supply Above The Pump

Commissioning, Startup, Operation, and Shutdown WARNING: A build-up of gases within the pump, sealing system, or process piping system may result in an explosive environment. Make sure the process piping system, pump and sealing system are properly vented prior to operation. Before the pump is started, the pump must be fully primed and the suction pipe must be full of liquid. -

Page 51: Prime The Pump With A Separate Hand Or Manually Controlled Priming Pump

Commissioning, Startup, Operation, and Shutdown 1. From outside supply 2. Shutoff valve 3. Vent plug 4. Discharge gate valve 5. Foot valve Figure 20: Prime with an outside supply Prime the pump with a separate hand or manually controlled priming pump This method ensures that the pump will remain primed if the foot valve is tight. -

Page 52: Prime The Pump By Bypassing The Discharge Check Valve

Commissioning, Startup, Operation, and Shutdown 1. Priming pump 2. Shutoff valve 3. Vent plug 4. Discharge gate valve 5. Foot valve Figure 21: Separate hand, or manually controlled, priming pump Prime the pump by bypassing the discharge check valve This method can be used only when there is liquid under some pressure in the discharge line. The original prime must be induced from an outside source. -

Page 53: Prime The Pump With An Ejector

Commissioning, Startup, Operation, and Shutdown 1. Vent plug 2. Discharge gate valve 3. Shutoff valve 4. Discharge check valve 5. Bypass line 6. Foot valve Figure 22: Bypassing the discharge check valve Prime the pump with an ejector On suction lift installations, you can prime the pump using an ejector to remove air from the casing and suction line. -

Page 54: Prime With An Automatic Primer Pump

Commissioning, Startup, Operation, and Shutdown 1. Valve S 2. Ejector 3. Valve E 4. Steam, compressed air, or water under pressure 5. Discharge gate valve Figure 23: Priming the pump with an ejector Prime with an automatic primer pump This system works well in situations where there is a fluctuating suction lift that occasionally drops below the normal limits of the pump. -

Page 55: Start The Pump

Commissioning, Startup, Operation, and Shutdown Start the pump WARNING: Immediately observe the pressure gauges. If discharge pressure is not quickly attained, stop the driver immediately, reprime, and attempt to restart the pump. CAUTION: • Immediately observe the pressure gauges. If discharge pressure is not quickly attained, stop the driver, reprime, and attempt to restart the pump. -

Page 56: Pump Operation Precautions

Commissioning, Startup, Operation, and Shutdown Pump operation precautions General considerations CAUTION: • Rotate shaft by hand to ensure it rotates smoothly and there is no rubbing which could lead to excess heat generation, sparks and premature failure. • Vary the capacity with the regulating valve in the discharge line. Never throttle the flow from the suction side since this can result in decreased performance, unexpected heat generation, and equipment damage. -

Page 57: Shut Down The Pump

Commissioning, Startup, Operation, and Shutdown Operation at reduced capacity WARNING: Never operate any pumping system with a blocked suction and discharge. Operation, even for a brief period under these conditions, can cause confined pumped fluid to overheat, which results in a violent explosion. -

Page 58: Make The Final Alignment Of The Pump And Driver

Commissioning, Startup, Operation, and Shutdown Make the final alignment of the pump and driver WARNING: • Always disconnect and lock out power to the driver before you perform any installation or maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical injury. -

Page 59: Dowel For Cold Service

Commissioning, Startup, Operation, and Shutdown 6. Set the motor back onto the baseplate with the shims in the correct location. Tighten the hold-down bolts. 7. Loosen the pump and motor hold-down bolts. Confirm that the pump and motor are not bolt-bound in order to make sure that the final drilled holes will be correctly located. -

Page 60: Maintenance

Maintenance Maintenance Maintenance schedule Maintenance inspections A maintenance schedule includes these types of inspections: • Routine maintenance • Routine inspections • Three-month inspections • Annual inspections Shorten the inspection intervals appropriately if the pumped fluid is abrasive or corrosive or if the environment is classified as potentially explosive. -

Page 61: Bearing Maintenance

Cartridge seals installed by the user require disengagement of the holding clips prior to operation, allowing the seal to slide into place. If the seal has been installed in the pump by ITT, these clips have already been disengaged. Other mechanical seal types For other types of mechanical seals, refer to the instructions provided by the seal manufacturer for installation and setting. -

Page 62: Disassembly

Maintenance Mechanical seal life The life of a mechanical seal depends on the cleanliness of the pumped fluid. Due to the diversity of operating conditions, it is not possible to give definite indications as to the life of a mechanical seal. Disassembly Disassembly precautions WARNING:... -

Page 63: Prepare For Disassembly

Maintenance • Tap • Torque wrench with sockets • Lifting eyebolt (dependent on pump size) Prepare for disassembly CAUTION: Allow all system and pump components to cool before you handle them to prevent physical injury. NOTICE: Use insulated gloves to handle coupling hub. Coupling hub will get hot and can cause physical injury. -

Page 64: Disassemble The Radial End (Ball Bearing Pumps)

Maintenance Disassemble the radial end (ball bearing pumps) 1. Unbolt and remove the cover bolts (371C) and the outboard end cover (160). Loosen the inboard end cover (160A) and cover bolts (371C). The outboard labyrinth seal (332A) and the bearing housing gasket (360A) will come off with the outboard cover (160). - Page 65 Maintenance 8. Use a bearing puller in order to remove the radial bearing (168) from the shaft. 9. Remove the inboard bearing cover (160A), the inboard labyrinth seal (333A), and the inner bearing cover bolts (371C). 10. Remove the seal plate nuts (355) and the mechanical seal (250). Refer to the instructions provided by the mechanical seal manufacturer.

-

Page 66: Disassemble The Thrust End (Ball Bearing Pumps)

Maintenance Disassemble the thrust end (ball bearing pumps) 1. Unbolt the cover bolts (371C) and remove the outboard thrust bearing end cover (109). Loosen the inboard end cover (160A) and cover bolts (371C). The bearing housing gaskets (360A) will remain on the end covers (109A or 160). 2. -

Page 67: Disassemble The Radial End (Sleeve/Ball Bearing Pumps)

Maintenance S group pumps have a bearing spacer (217). 10. Remove the inboard bearing cover (160A), the inboard labyrinth seal (333A), and the inner bearing cover bolts (371C). 11. Remove the seal plate nuts (355) and the mechanical seal (250). Refer to the instructions provided by the mechanical seal manufacturer. - Page 68 Maintenance Notice that the bearing is pinned to the bearing housing. 5. Remove the dowel pins (469J) that hold the lower half of the bearing housing to the casing flange. 6. Loosen and remove the nuts (427J) that hold the bearing housing in place. 7.

- Page 69 Maintenance 9. Remove the outboard labyrinth seal (332A), the two oil rings (114), and the inboard labyrinth seal (333A). Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual...

-

Page 70: Disassemble The Thrust End (Sleeve/Ball Bearing Pumps)

Maintenance Disassemble the thrust end (sleeve/ball bearing pumps) 1. Remove the outboard end cover (109) by removing the end cover bolts (371C). 2. Remove the upper half of the bearing housing (134A) from the lower half: a) Remove the dowel pins between the upper and lower halves of the bearing housing (134A). - Page 71 Maintenance d) Remove the top half of the thrust bearing (134A) housing with the upper half of the sleeve bearing (117). Notice that the bearing is pinned to the housing. 3. Remove the outboard oil ring (114A). Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual...

-

Page 72: Disassembly Of The Sleeve/Kingsbury Bearing Arrangement

Maintenance 4. Remove the dowel pins (469J) that hold the lower half of the bearing housing to the casing flange. 5. Loosen the nuts (427J) that hold the bearing housing in place. The bearing housing will rest on the studs. 6. -

Page 73: Disassemble The Rotating Assembly

Maintenance Disassemble the rotating assembly 1. Remove dowel pins (469G). 2. Loosen and remove the case parting nuts (425). 3. Use the jackscrews provided with the pump to loosen the upper half of the casing (100). 4. Use a sling in order to lift the upper half from the casing. Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... - Page 74 Maintenance CAUTION: Cast lifting lugs in upper half are intended for upper half removal from the pump. They are not intended to be used to lift the entire pump. Table 1: Minimum Headroom for U.H. Removal Frame Pump Size (From Suct C/L) inches (mm) 6x8-14A 25 (635) 6x8-11A...

-

Page 75: Preassembly Inspections

Maintenance You do not need to remove the thrust locknut (130) from the shaft unless you plan to replace either the thrust locknut or the shaft. Preassembly inspections Replacement guidelines Casing check and replacement WARNING: Avoid death or serious injury. Leaking fluid can cause fire and/or burns. Inspect and assure gasket sealing surfaces are not damaged and repair or replace as necessary. - Page 76 Maintenance Impeller replacement This table shows the criteria for replacing the impeller: Impeller parts When to replace Vane edges When you see cracks, pitting, or corrosion damage Impeller checks • Check and clean the impeller bore diameter. Impeller areas to inspect A.

-

Page 77: Shaft Replacement Guidelines

Maintenance Impeller locknut areas to inspect Locknut surfaces must be smooth and free of grooves and scratches, especially in the areas indicated by arrows in the figure. Also check the outside diameter of the locknuts. Cartridge mechanical seal replacement Cartridge-type mechanical seals should be serviced by the seal manufacturer. Refer to the instructions from the mechanical seal manufacturer for assistance. -

Page 78: Bearings Inspection

Maintenance Shaft straightness check NOTICE: Do not use shaft centers for the runout check as they may have been damaged during the removal of the bearings or impeller. Shaft surface check Check the shaft surface for damage. Replace the shaft if it is damaged beyond reasonable repair. -

Page 79: Replace The Wear Parts

Maintenance Checklist Perform these checks when you inspect the bearings: • Inspect the bearings for contamination and damage. • Note any lubricant condition and residue. • Inspect the ball bearings to see if they are loose, rough, or noisy when you rotate them. •... - Page 80 Maintenance b) Chill the new bushing using dry ice or other suitable chilling substance, and install the bushing into the fit of the case (100) and head (184). Be prepared to tap the bushing in place with a hardwood block or soft-faced hammer. WARNING: Dry ice and other chilling substances can cause physical injury.

- Page 81 Maintenance d) Install the setscrews (320) and upset threads. 3. Check the casing wear-ring (164) runout and distortion by measuring the bore at each setscrew location with inside micrometers or vernier calipers. Machine any distortion in excess of 0.003 in. (0.08 mm) before you trim the new impeller wear rings (142).

-

Page 82: Reassembly

Maintenance Minimum running clearances Impeller wear rings Replace wear rings when the diametrical clearance exceeds the values shown in this table or when the hydraulic performance has decreased to unacceptable levels: Diameter of rotating member at clearance Minimum diametrical clearance <2.000 <50.00 0.010... - Page 83 Maintenance NOTICE: • Make sure that all parts and threads are clean and that you have followed all directions under the Preassembly inspections section. • Check for magnetism on the pump shaft and demagnetize the shaft if there is any detectable magnetism.

-

Page 84: Install The Rotating Element

Maintenance API limits are listed in the Shaft and rotor runout requirements table. 5. Install the casing wear rings (164) over each impeller ring (142). Be certain the smaller outer diameter is nearest the impeller when installing. 6. Install the throat bushing (125) on each side of the impeller. Be certain the smaller outer diameter is nearest the impeller when installing. - Page 85 Maintenance 5. Mount the cartridge mechanical seal (250) on the shaft. Do not tighten the gland nuts at this time. Figure 26: Mount the cartridge mechanical seal on the radial end Figure 27: Mount the cartridge mechanical seal on the thrust end Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual...

-

Page 86: Assemble The Thrust End (Ball Bearing Pumps)

Maintenance Confirm the seal chamber runout The bearing housings are doweled to the casing (100) during the original build. However, in order to assure the correct running position of the shaft, use this procedure in order to confirm the seal chamber runout before you install the cartridge mechanical seals: 1. - Page 87 Maintenance NOTICE: Make sure that the expulsion port is at the 6 o'clock position and is properly seated. 2. Assemble the inboard end cover (160A) and the inboard bearing end-cover gasket (360A) onto the shaft. 3. Assemble the thrust bearings (112A) in a back-to-back arrangement onto the shaft (122): The bearings are interference fit.

- Page 88 Maintenance h) When you have achieved the proper bearing assembly, set the lockwasher tab in the slot in the locknut. 4. Install the bearing housing (134) over the bearings. Finger-tighten the nuts (427J) on the studs (371T). Insert the dowel pins (469J); then tighten the nuts (427J). The bearing housing is doweled to the bearing saddle flange of the casing (100) during the original build to assure the correct running position of the shaft.

-

Page 89: Assemble The Radial End (Ball Bearing Pumps)

Maintenance Assemble the radial end (ball bearing pumps) 1. Assemble the inboard labyrinth seal (333A) into the inboard radial-end cover (160A): a) Clean the end cover with a solvent. b) Fit the labyrinth seal (333A) into the bore of the cover (160A). c) Tap the seal in with a hammer. - Page 90 Maintenance 4. Install the oil-ring sleeve (324) and tighten the setscrew (388L). 5. Install the bearing housing (134). The bearing housing is doweled to the casing (100) during the original build to assure the correct running position of the shaft. NOTICE: The bearing housing flange must fit metal-to-metal (no gap) to the bearing saddle flange.

-

Page 91: Assemble The Thrust End (Sleeve/Ball Bearing Pumps)

Maintenance Assemble the thrust end (sleeve/ball bearing pumps) 1. Install the inboard labyrinth seal (333A). Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... - Page 92 Maintenance NOTICE: Make sure that the expulsion port is at the 6 o'clock position and is properly seated. 2. Place the inboard oil rings (114) on the shaft. 3. Assemble the thrust bearings (112A) in a back-to-back arrangement onto the shaft (122): The bearings are interference fit.

-

Page 93: Assemble The Radial End (Sleeve/Ball Bearing Pumps)

Maintenance b) Install the dowel pins in the pre-drilled dowel pin holes between the housing flange and the head-bearing flange. c) Tighten the nuts (427J) on the bearing housing to the head studs (371T). d) Place the upper half of the sleeve bearing (117) on the shaft, moving the oil rings aside. When the bearing top half is in place, move the oil rings back into the bearing housing and sleeve grooves. - Page 94 Maintenance 3. Place the outboard labyrinth seal (333A) in the lower half of the bearing housing (134), which is not yet attached. 4. Lift the lower half of the housing into place, positioning the inner oil rings (114) in the bearing housing grooves.

-

Page 95: Assembly Of The Sleeve/Kingsbury Bearing Arrangement

Maintenance NOTICE: Make sure that the expulsion port is at the 6 o'clock position and is properly seated. 9. Install the upper half of the bearing housing (134). 10. Position the dowel pins between the upper and lower halves of the bearing housing. Tighten the bearing-housing hex screws. -

Page 96: Assembly References

Maintenance Assembly references Maximum torque values for fasteners Lubricated values are 2/3 of the unlubricated values. Fastener size (diameter in inches) – threads per inch 2210 material ft-lb (Nm) 2229 material ft-lb (Nm) 2239 material ft-lb (Nm) Lub. Unlub. Lub. Unlub. - Page 97 Maintenance Spare parts Critical service spare parts For critical services, stock these parts, where applicable: • Impeller (101) • Thrust bearing end cover, outboard (ball and sleeve bearing construction only) (109A) • Shaft (122) • Radial bearing end cover, inboard (ball bearing construction only) (160) •...

-

Page 98: Troubleshooting

Change the rotation. The rotation must match the arrow on the bearing housing or pump casing. The foot valve or suction pipe opening is not Consult an ITT representative for the proper sub- submerged enough. mersion depth. Use a baffle in order to eliminate vortices. -

Page 99: Alignment Troubleshooting

Troubleshooting Alignment troubleshooting Symptom Cause Remedy Horizontal (side-to-side) alignment cannot The driver feet are bolt-bound. Loosen the pump's hold-down bolts, and be obtained (angular or parallel). slide the pump and driver until you achieve horizontal alignment. The baseplate is not leveled properly and 1. Determine which corners of the base- is probably twisted. -

Page 100: Parts Listings And Cross-Sectionals

Parts Listings and Cross-Sectionals Parts Listings and Cross-Sectionals Parts list - Model 3610 - ball/ball Table 4: Parts list with materials of construction for ball/ball bearing arrangement The materials in this table are typical. Refer to the order documentation for the actual materials furnished. 3610 Parts List - Balloon Numbers Materials of Construction Item... -

Page 101: Cross-Sectional Diagrams

Parts Listings and Cross-Sectionals Cross-sectional diagrams Model 3610 - ball/ball Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... -

Page 102: Parts List - Model 3610 - Sleeve/Ball

Parts Listings and Cross-Sectionals Parts list - Model 3610 - sleeve/ball Table 5: Parts list with materials of construction for sleeve/ball bearing arrangement The materials in this table are typical. Refer to the order documentation for the actual materials furnished. 3610 Parts List - Balloon Numbers Materials of Construction Item... -

Page 103: Cross-Sectional Diagrams

Parts Listings and Cross-Sectionals Cross-sectional diagrams Model 3610 - sleeve/ball Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... -

Page 104: Parts List - Model 3610 - Sleeve/Ktb

Parts Listings and Cross-Sectionals Parts list - Model 3610 - sleeve/ktb Table 6: Parts list with materials of construction for ball/ball bearing arrangement The materials in this table are typical. Refer to the order documentation for the actual materials furnished. 3610 Parts List - Balloon Numbers Materials of Construction Item... -

Page 105: Cross-Sectional Diagrams

Parts Listings and Cross-Sectionals Cross-sectional diagrams Model 3610 - sleeve ktb Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... -

Page 106: Other Relevant Documentation Or Manuals

Other Relevant Documentation or Manuals Other Relevant Documentation or Manuals For additional documentation For any other relevant documentation or manuals, contact your ITT representative. Model 3610, API Type BB1 API 610 11th Edition Installation, Operation, and Maintenance Manual... -

Page 107: Local Itt Contacts

Local ITT Contacts Local ITT Contacts Regional offices Region Address Telephone North America (Headquarters) ITT - Goulds Pumps Asia Pacific ITT Industrial Process +65 627-63693 +65 627-63685 10 Jalan Kilang #06-01 Singapore 159410 Europe ITT - Goulds Pumps +44 1297-630250... - Page 108 Goulds Pumps 240 Fall Street Seneca Falls, NY 13148 Tel. 1–800–446–8537 Fax (315) 568–2418 Form en_US.2015.04.IOM.3610 © 2015 ITT Corporation The original instruction is in English. All non-English instructions are translations of the original instruction.

Need help?

Do you have a question about the Goulds Pumps 3610 and is the answer not in the manual?

Questions and answers