Table of Contents

Summary of Contents for icetro ISI-271THN

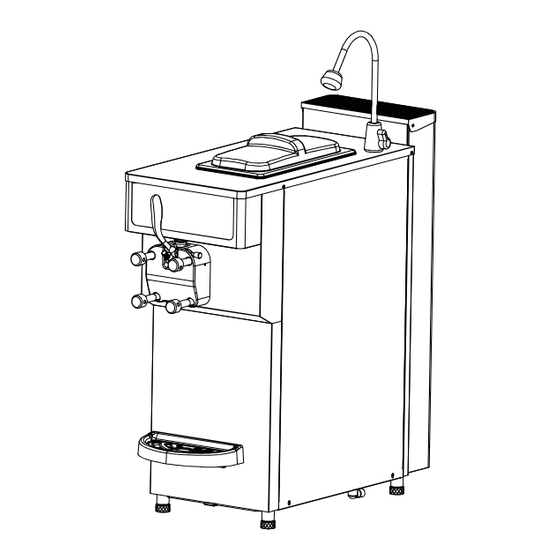

- Page 1 YOGURT & SOFT ICE CREAM MACHINES USER'S MANUAL ISI-271THN This product is designed for indoor use . ● ● Make sure to install it indoors. The appearance, design, color, and parts of the product ● are subject to change without prior notice.

- Page 2 Yogurt & soft ice cream machines offers the following advantages 1.Minimum noise and refreshing cooling system With a high efficiency and low noise motor, we can provide minimal noise from the refreshing cooling system. 2. MICOM control method Use of an artificial intelligence control system achieves an optimal cooling system. 3.

-

Page 3: Table Of Contents

Dear customers Thank you very much for purchasing a soft ice cream freezer made by ICETRO. For correct use of the product and its maintenance, please read this manual carefully. If a problem occurs while using the product, you can refer to this manual for troubleshooting. -

Page 4: Cautions For Your Safety

Cautions for your safety The caution/warning details for safety are intended to prevent accident or danger through safe and proper use. Therefore please follow the details accordingly. The precaution details are categorized into warning and caution, and the respective meanings are as follows. If you neglect this symbol and wrongly use the product, Danger it may cause a fire, serious injury or death. - Page 5 Warning For relocation of the product, call an expert.” Do not disassemble or The product may cause such hazards as falling alter the product. down unless properly installed. Electric shock, fire or It should be installed in accordance with related injury may occur.

- Page 6 Warning Do not touch the power Do not touch any moving part cable or any elctric part inside the product. with wet hands. You may get injured. Explosion, fire or injury may occur. Stop operating the product if Do not climb onto the product you hear any unusual noise or shake or tilt it.

- Page 7 Warning Please do not press “WASH” Do not place any obstacle at button during empty condition the entrance of the air vent. which the cylinder doesn’t contain It may cause the degradation any ingredients or water. of functionality. The bearing of drum can be frayed because there is no lubrication.

- Page 8 Warning If the earth leakage breaker is in the‘OFF’position, If the power cable do not turn it to the‘ON’ needs replacement or position by force. repair, call a service If you turn it ‘on’ while the center or an expert. machine is defective, fire or electric shock may occur.

-

Page 9: For Long-Term Storage

For long-term storage ● The machine will be out of order if water gets frozen due to sub-zero temperature in winter. Be sure to drain water before storing the machine. ● The manufacturer will not be responsible for the freezing and bursting of the machine without Warning draining water. -

Page 10: Name Of Each Part

Name of each part FRONT AIR VENT A WATER FAUCET MIX TANK COVER LCD DISPLAY LEVER DASHER COVER DASHER COVER BOLT USB PORT DRAIN BOX AIR FILTER LEF T RIGHT DRAIN SLUG... - Page 11 ATTACHMENTS DASHER LUG FRONT WHITE MANUAL BRUSH DRUM PACKING DASHER COVER DASHER LUG BACK WHITE BRUSH COVER SHAFT POM PACKING BRUSH 3 O-RING LEVER SHAFT CARBURETOR TUBE CARBURETOR TUBE BODY BRUSH CARBURETOR OUT PACKING PISTION TOP HINES UNION 1/2 PACKING REMOVE HANDLE HOSE 1 EA...

-

Page 12: Product Specification

Product specification CLASSIFICATION SPECIFICATION Product name Ice Cream Machines Model name ISI-271THN Rated power 1PH, 230V, 50Hz / 220V, 60Hz Power consumption 2200 W Current consumption 11 A WIDTH(W) 380 mm Product size (Applicable to DEPTH(D) 905 mm rubber feet) -

Page 13: Check Prior To Use

Check prior to use 【 Make sure to check them prior to use ! 】 This product is for 230V, 50Hz / 220V, 60Hz. Install it independently in an earth leakage circuit breaker with more than 20A and provide an external grounding. (Ask a qualified electrical technician for the installation.) The power cable should be connected before the product can be operated normally. -

Page 14: Button Display Names And Functions

Button display names and functions DISPLAY WINDOW ‘ ’ Displays the degree of soft ice ● cream formation in operation. [ A u t o ] ■■■■■■ ■ BUSY ■ ■■■■■■ ‘ ’ Button is used to change DEC. Press the‘DEC.’&‘INC.’ INC. -

Page 15: Functional Description Of The Buttons

Functional description of the buttons 【 】 Detail description of each mode Pour the raw material in the mixing tank and press the Making soft ice cream in‘AUTO’mode ‘AUTO’button. The following status display will be shown. [ A u t o ] ①... - Page 16 【 】 Detail description of each mode If the soft ice cream is not used for a long time, then its shape “REGENERATION” mode. will be degraded. In this case, you can use the ‘Regeneration’ function to make it look better. [ R e g n r .

- Page 17 【 】 Detailed description of each mode If pasteurization is not done every day, and the ingredients “PASTEURIZE” mode. are stored at a temperature below 5℃, after 2 or 3 days, it can cause deformation or decay. [ H e a t ] H o p p e r T e m p To prevent decay and to maintain the initial refreshing ①...

- Page 18 【 】 Check the setting Press the‘SET’button lightly to enter the mode where DEC. INC. set-up value can be confirmed, as shown below. In the confirmation mode, Press the‘SET’button to see the setting values in the following order. Press the“+”or“INC”buttons to move to next step. SELECT The temperature setting in the hopper [ T e m p e r a t u r e ]...

- Page 19 No-load current of the dasher motor is displayed. [ N o L o a d A M P 1 ] First: No-load current at an initial stage F i r s t 2 . 9 7 A / 2 . 9 7 A Run: No-load current during operation R u n 3 .

- Page 20 Check the record DEC. INC. Press the ‘SELECT’ button for three seconds to check the records in the order of Sterilization, Washing, and Error, as shown in the right. Display items can be changed with the‘DEC.’,‘INC.’ buttons. SELECT To check the date, there has to be at least one record. Press the ‘SELECT’...

-

Page 21: Explanation Of The Function Button

Explanation of the function button 【 Change the setting 】 Press the ‘SET’ button for three seconds to enter the setting change mode as follows. DEC. INC. Move to other items using the ‘DEC.’ and ‘INC.’ buttons. Press the ‘SET’ button. While the setting value is flashing, change the value using the ‘DEC.’... - Page 22 3-3 : Adjusting Cold Storage Temperature of Storage Tank [ 3 - 3 ] H o p p e r T e m p . This adjusts the cold storage temperature of the storage tank. High number indicates that the storage L e f t 3 .

- Page 23 3-4 : Select the address of the selling [ 3 - 4 ] C M S o n g S e r v i c e and commercial song. 9. A d d r e s s You can choose from number of sales songs, S a l e S o n g / C M S o n g from number 401 to number 410.

-

Page 24: How To Make Soft Ice Cream

How to make soft ice cream 1. Open mix tank cover and put in sufficient amount of ingredients. 2. Insert the carburetor body and carburetor tube into the mix tank. CARBURETOR TUBE CARBURETOR BODY 3. Cover the carburetor hole and insert the impeller. -

Page 25: How To Pasteurize The Ice Cream Mix

How to pasteurize the ice cream mix 1. Cover the carburetor hole inside the mix tank cover. 2. Press the ‘PASTEURIZE’ button. This function is used to suppress the growth of micro PASTEURIZE STAND-BY MIX-LOW organisms and maintain the ingredients fresh for a long PASTEURIZE WASH STAND-BY... -

Page 26: How To Improve Ice Cream Quality

How to improve ice cream quality 1. Block the carburetor hole of the mixing tank. 2. Press the 'STOP' button of the control panel, PASTEURIZE STAND-BY MIX-LOW then press the 'DEFROST' button. PASTEURIZE WASH STAND-BY BOILING DEFROST AUTO STOP REGENERATION 3. -

Page 27: Soft Ice Cream Discharge Speed Control

Soft ice cream discharge speed control 1. By adjusting 'Screw Adjust' at the bottom of the lever (out lever), you can adjust the discharge speed of soft ice cream. As shown in the figure on the left, release the 'Screw Adjust' to increase the discharge speed of soft ice cream. -

Page 28: Adjustment Method For Carburetor

Adjustment method for carburetor The carburetor is made up of two parts. The part that is inserted into the hole of the mixing tank is called CARBURETOR TUBE BODY the body and a tube is inserted into this. The tube has a hole at the top and at the bottom. -

Page 29: Cleaning Method

Cleaning method 1. Press 'STOP' button, and then 'DEFROST' on the PASTEURIZE STAND-BY MIX-LOW operation panel. PASTEURIZE WASH STAND-BY (Wait about ten minutes until soft ice cream is melted in the cylinder.) BOILIN G DEFROST AUTO STOP REGENER ATION 2. Open the cover of the hopper(mix tank), CARBURETOR TUBE and then remove and clean the carburetor (the body) and the impeller. - Page 30 7. Loose the dasher cover bolts diagonally by the order shown in the picture and separate the dasher cover from the soft ice cream machine. 8. Draw the dasher and separate it from the cylinder. BLADE Clean the inside of the cylinder with a brush and wipe with a soft cloth.

- Page 31 13. Clean carburetor body and tube with brush. 14. After cleaning, dry and reassemble the parts in reverse order. 【 Condenser and filter cleaning method 】 1. Filter Decomposition method ● Ware floor filter Slowly pull the filter from the front bottom part to remove it.

-

Page 32: Unpacking And Installation

Unpacking and Installation The soft serve machine has been fully inspected and tested at the factory prior to shipping. If you detect damage to the wooden package or apparent distortion of the shape of the system after unpacking the product, immediately inform your distributor or manufacturer. Find the serial number marked on the packing and the machine before starting installation. -

Page 33: Installation

Installation The raw water supply valve may vary depending on the installation environment ● of the system. Consult with the engineers of the company for the details of installation of the system to ensure ● optimal performance of the system (change of the installation site of the system also requires consultation with the engineer of the company). -

Page 34: Dasher And Dasher Cover Assembly Method

Dasher and dasher cover assembly method 【 Dasher assembly 】 ① BLADE 1. Insert the dasher blade into the raised spoton the back of the dasher. DASHER ASSY Grab the dasher and the dasher blade and MIXING SHAFT insert the dasher blade into the front. 2. -

Page 35: How To Upgrade The Program

3. Wait for approximately 5~10 minutes until the front LCD screen lights up. 4. Remove the USB memory stick and select a model to reset the product (Item no. 4). ex) ISI-271THN 5. Power off the product and restart it. -

Page 36: How To Copy A Program To Usb

How to copy a program to USB This is the folder that contains the product's program file (HEX). This is the folder that contains the voice instruction files (mp3). 1. Create hex folder and voice_data folder as above in the USB root and copy four files (1195.mp3, downld.ex, main.ex, update.sh) into the root. - Page 37 3. Delete hex files in existing hex folder. 4. Delete all existing hex files and only leave the copied files.

- Page 38 5. Delete date and version from the HEX file name.

-

Page 39: Wiring Diagram

Wiring diagram... -

Page 40: Refrigeration Circuit Diagram(Capillary Type)

Refrigeration circuit diagram HOPPER ASS'Y Normal operation SYLINDER ASS'Y 냉동AXV 냉장 CAPILLARY TUBE SOLENOID VALVE HOT GAS CHECK CAPILLARY VALVE ACCUMULATOR EXPANSION CHECK VALVE VALVE 4WAY VALVE FAN PRESS S/W CONDENSER HIGH PRESSUER ASS'Y COMPRESSOR RECEIVER FITER DRYER HOPPER ASS'Y Sterilization operation SYLINDER ASS'Y 냉동AXV 냉장 CAPILLARY TUBE SOLENOID VALVE HOT GAS CHECK... -

Page 41: Cautions For Operation Of Soft Ice Cream Machine

Cautions for operation of soft ice cream machine If the temperature is too low (overfreezing) while operating the product, issues may arise such as interrupted operation or damage on a part or the power delivery axis. Some issues may involve too much noise or burning smell due to friction, and foreign substance may come out with the ice cream due to damage of a part inside the product. -

Page 42: Before Requesting Service

Before requesting service The soft ice cream freezer can operate abnormally because you are not familiar with the method for use or due to another insignificant reason. It does not necessarily mean a malfunction. In this case, check the following items to resolve a simple problem on your own without the help from your distributor. If you still can’t resolve it after checking the following items, please contact your distributor. -

Page 43: Replacement Cycle Of Consumable Parts

State Please check There are lumps 1. If the ingredient has too much milk fat, lumps may be formed in proportion. of milk fat in the The carburetor hole needs to be smaller if you happen to serve fewer cups of ice cream ice cream. -

Page 44: Error Codes And Corrective Actions

Error Codes and Corrective Actions The soft ice cream freezer may malfunction due to incorrect operation procedure or a trivial cause other than machine defect or failure. If the following corrective actions fail to correct the problem, or the error code is not presented below, or the same error persists, contact the nearest After Service Center. - Page 45 Error code Possible Cause Corrective Action Release Action vend pcb communication Er44 Vend Comm. pcb fault(contact A/S Center) Auto release Stop error Er50 Power IC Er. Power IC error Sensor failure (contact A/S Center) Auto release Stop Er51 Carburetor Er. Carburetor sensor error Caburator Sensor failure Auto release...

-

Page 46: Part List

Part List... - Page 49 DASHER LUG BACK WHITE PISTON LEVER DASHER ASSY SCREW ADJUST+ NUT PACKING PISTON TOP DASHER LUG FRONT WHITE SHAFT LEVER MIXING SHAFT WHITE O-RING LEVER SHAFT JOINT BOLT TOP DASHER COVER STAR MADE PACKING DASHER COVER...

- Page 51 DUCT COVER AS SIDE PANEL L DRAIN SLUG TOP COVER BACK PANEL DUCT GUIDE CONDENSOR DRAIN SLUG BKT OUT PANEL AS TURBO FAN MOTOR COVER BOLT FRONT DRAWING ASSY BUTTON DISPLAY SPEAKER TURBO FAN MOTOR CONDENSOR OUT DUCT BUTTON DISPLAY ANGLE ASSY FRONT CASE UP BUTTON DISPLAY FILTER 271 COVER BASE FRONT COVER TOP ASSY DISPLAY PCB DRAIN FIX BOLT FRONT COVER SUP BKT SOL VV2 DRAIN BOX UP MAIN PCB DRAIN BOX SIDE PANEL L BKT MAIN PCB...

-

Page 52: Warranty

Warranty If the warranty policy or receipt has not been kept or is lost, or if it is hard to determine the date of purchase due to other reasons, warranty is applied after 6 months from the manufacturing date. [ Free repair ] 1. - Page 53 MEMO...

- Page 54 MEMO...

- Page 55 MEMO...

- Page 56 온 라 인 인 터 넷 서 비 스 http://www.icetro.com 3 2 4 0 3 9 3 - 0 0...

Need help?

Do you have a question about the ISI-271THN and is the answer not in the manual?

Questions and answers