Table of Contents

Advertisement

DRIVE SYSTEM TYPE

MOWER ORIENTATION

Z – Zero Turning – Hydro Drive

F – Out Front Mower

Z – Zero Turning – Hydro Drive

F – Out Front Mower

Thank you for buying a SNAPPER Product! Before operating your Z-RIDER, read this manual carefully and pay

particular attention to the "IMPORTANT SAFETY INSTRUCTIONS" on Pages 2 - 4. Remember that all power

equipment can be dangerous if used improperly. Also keep in mind that SAFETY requires careful use in

accordance with the operating instructions and common sense!

COPYRIGHT © 2001

SNAPPER INC.

ALL RIGHTS RESERVED

Safety Instructions & Operator's Manual for

MODEL NUMBER EXPLANATION

Z

F

25– Engine Horse Power

52 – Mower Cutting Width

61 – Mower Cutting Width

OUT FRONT Z-RIDER

ZERO TURNING

25

01

POWER UNIT

01 – Series Designation

MOWER UNIT

01 – Series Designation

1

HYDRO DRIVE

SERIES 1

POWER UNIT MODELS

ZF2501KH

MOWER UNIT MODELS

ZF5201M

KH

SERIES DESIGNATION

KH – Kohler Engine

M – Mower Deck

MANUAL No. 7-3699 (REV. 2, 8/29/01)

ZF6101M

ENGINE TYPE

ENGINE HP

Advertisement

Table of Contents

Summary of Contents for Snapper ZF2501KH, ZF5201M, ZF6101M

-

Page 1: Hydro Drive

Z – Zero Turning – Hydro Drive F – Out Front Mower Thank you for buying a SNAPPER Product! Before operating your Z-RIDER, read this manual carefully and pay particular attention to the “IMPORTANT SAFETY INSTRUCTIONS” on Pages 2 - 4. Remember that all power equipment can be dangerous if used improperly. -

Page 2: Important Safety Instructions

If you have any questions pertaining to your machine which your dealer cannot answer to your satisfaction, call or write the Customer Service Department at SNAPPER, McDonough, Georgia 30253. Phone: (1-800-935-2967). -

Page 3: Operation

7. Evaluate the terrain to determine what accessories and attachments are needed to properly and safely perform the job. Only use accessories and attachments approved by SNAPPER. 8. Keep people and pets out of mowing area. Immediately, STOP blades, STOP engine, and STOP machine if anyone enters the area. -

Page 4: Important Safety Instructions

14. Carefully release pressure from components with stored energy. 15. Have machine serviced by an authorized SNAPPER dealer at least once a year and have the dealer install any new safety devices. Never allow untrained personnel to service machine. -

Page 5: Table Of Contents

These structures, when installed and used properly can offer additional security to the operator against serious injury in the event of a tip over accident. Operator Protective Structures may be required by local ordinances. Discuss your mowing application and ordinances with your local Snapper Dealer. IMPORTANT... -

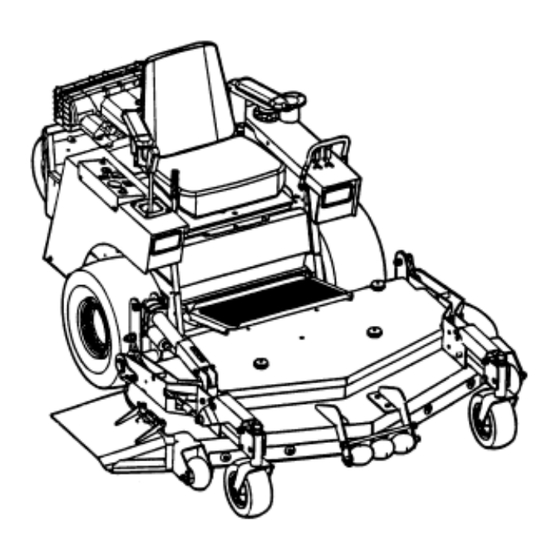

Page 6: Section 1 - Familiarization

FIGURE 1.1 1.2 NOMENCLATURE The nomenclature information above, Figure 1.1, shows the essential parts of the SNAPPER OUT FRONT Z- RIDER. It is recommended that all operator’s of this equipment become thoroughly familiar with the controls, components, and operation of this machine before operating. -

Page 7: Section 2 - Safety Messages And Symbols

Section 2 – SAFETY MESSAGES AND SYMBOLS CHOKE “ON” CHOKE “OFF” ENGINE SPEED AND CHOKE CONTROLS RABBIT “FAST” TURTLE “SLOW”... - Page 8 Section 2 – SAFETY MESSAGES AND SYMBOLS “START” ENGAGE “ON” “RUN” BLADE “STOP” KEY SWITCH DISENGAGE “OFF” “ON” LIGHT SWITCH HOUR METER “OFF” MOTION CONTROL MULTI-DIRECTIONAL...

-

Page 9: Section 2 – Safety Messages And Symbols

Section 2 – SAFETY MESSAGES AND SYMBOLS DANGER! ROTATING BLADES KEEP CHILDREN AND OTHERS OUT OF MOWING AREA DANGER! ROTATING BLADES... -

Page 10: Section 3 - Operating Instructions

Section 3 - OPERATING INSTRUCTIONS 3.1 PRE-START CHECK LIST Make the following checks and perform the service required before each start-up. 3.1.1. Check tires and add or release air as needed to bring pressure in drive tires to: 12 psi (Turf Type Tires), 5 psi (All Terrain Type Tires) and 25 psi in rear caster tire. -

Page 11: Starting & Stopping Engine, Blades & Parking Brake

Section 3 - OPERATING INSTRUCTIONS 3.2 STARTING & STOPPING – ENGINE, BLADES & PARKING BRAKE This machine is equipped with dual hydrostatic wheel drive transmissions. Each transmission is controlled by a single motion control lever or joystick. This single control lever (joystick) controls the direction of motion, Forward and Reverse, and the speed of motion. -

Page 12: Starting & Stopping Mower Blades

7 seconds, the electric clutch should be checked. Replacement of electric clutch may be necessary. Return the machine to an authorized Snapper dealer for replacement. DO NOT CONTINUE to operate mower if blades fail to stop in 7 seconds. WARNING DO NOT park the machine on slopes. -

Page 13: Driving & Stopping Machine

Section 3 - OPERATING INSTRUCTIONS 3.3 OPERATION – MOTION CONTROL 3.3.1 DRIVING MACHINE IMPORTANT: The joystick lever has to be manually moved to propel machine. Always return the joystick with hand assistance to the neutral position to stop machine. Release the joystick and it will gradually return toward the neutral position. -

Page 14: Section 4 - Maintenance Instructions

Section 4 – MAINTENANCE 4.1 INTRODUCTION To retain the quality of the SNAPPER Out Front Z- Rider, use genuine SNAPPER replacement parts only. Contact a local SNAPPER dealer for parts and service assistance. information for a particular SNAPPER Out Front Z- Rider, always mention the model and serial number. -

Page 15: Check Mower Drive Belt

Section 4 – MAINTENANCE 4.2.3. CHECK MOWER DRIVE BELT 1. Drive Belt Cover Removal a. Lower deck to lowest setting. b. Remove four knobs that secure the deck cover. See Figure 4.3. c. Remove cover to gain access to deck belt. -

Page 16: Front Wheel Bearings Lubrication

Reinstall reservoir cap. See Figure 4.6. IMPORTANT: DO NOT remove or service the transaxle fluid filters. This service should be made periodically by an authorized SNAPPER dealer. See the service schedule to determine the recommended change interval. OIL FILL... -

Page 17: Fuel Filter Replacement

Section 4 – MAINTENANCE 4.5 ANNUALLY (END OF EACH SEASON) (Continued from previous Page) 4.5.2. FUEL FILTER Service fuel filter as instructed below. Turn key to “OFF” position. Engine MUST be stopped and MUST be cold before removing filter. Clamp fuel line to prevent fuel spillage or perform filter change when fuel tank and fuel line are empty. -

Page 18: Section 5 - Adjustments And Repair

However, if there is difficulty in making these adjustments and repairs, it is recommended that these repairs be made by an authorized SNAPPER dealer. 5.2.1. MOWER DECK ADJUSTMENT (LEVELNESS) SIDE to SIDE and FRONT to REAR... -

Page 19: Parking Brake Adjustment

When properly adjusted the park brake lever should require 18 to 22 pounds force to set the brake. If this adjustment does not result in proper brake action, contact your authorized Snapper dealer for corrective action. See Figure 5.4. DO NOT operate machine if brakes are not functioning properly. -

Page 20: Mower Blade Replacement

Section 5 - ADJUSTMENTS & REPAIR 5.5 MOWER BLADE REPAIR/REPLACEMENT 5.5.1. BLADE WEAR LIMITS 1. Inspect blade frequently for signs of excessive wear or damage. See Figure 5.5. NEW BLADE DANGEROUS CONDITION! DO NOT USE ON MOWER! REPLACE WITH NEW BLADE. FIGURE 5.5 WARNING DO NOT use a cutting blade that shows signs of... -

Page 21: Battery Removal

Section 5 - ADJUSTMENTS & REPAIR 5.6.2. ENGINE BELT REPLACEMENT 1. Route belt around blade pulleys and idler pulley in same the position as old belt was removed. It may be necessary to use a pry bar to pull idler pulley back to install belt. See Figure 5.8. -

Page 22: Battery Testing

Section 5 - ADJUSTMENTS & REPAIR 5.7.4. BATTERY TESTING There are two types of battery tests: Unloaded and Loaded. The unloaded test is the procedure that will be discussed. It’s the simplest and most commonly used. An unloaded test is made on a battery without discharging current. -

Page 23: Mower Spindles (Field Serviceable Spindles) Bearing Replacement

5.8 MOWER SPINDLES (Field Serviceable Spindles) BEARING REPLACEMENT In the event that a spindle bearing requires replacement, the SNAPPER Field Serviceable Spindles have been designed so that no special tools or presses are required. 1. Remove belt. Loosen blade nut and remove. -

Page 24: Troubleshooting

CORRECTIVE ACTION 1. Service battery. 2. Replace fuse. 3. Clean and check connections for good contact. 4. Contact authorized SNAPPER dealer. 1. Move blade engagement switch to “OFF”. 2. Set park brake. 3. Fill fuel tank with fresh fuel. 4. Move choke control to “CHOKE” position. - Page 25 5. Replace traction drive belt. 1. Move blade switch to the “ON” position. 2. Replace clutch belt. 3. Replace mower belt. 4. Contact authorized SNAPPER dealer. 5. Contact authorized SNAPPER dealer. 6. Connect power transfer shaft or repair damage. 1. Bring to proper pressure.

-

Page 26: Maintenance Parts

ITEM SERVICE PERFORMED Engine Oil Check Oil Level Initial Oil Change Periodic Oil Change Air Pre-Cleaner Clean Sponge Element Air Cleaner Clean or Replace Spark Plug Replace Fuel Filter Replace Clean Shroud & Fins Engine Cooling System Battery Check Electrolyte Charge Battery Testing Battery Check Pressures... -

Page 27: Warranty

For two (2) years from purchase date for the original purchaser's use, SNAPPER, through any authorized SNAPPER dealer will replace, free of charge (except for taxes where applicable), any part or parts found upon examination by the factory at McDonough, Georgia, to be defective in material or workmanship or both. -

Page 28: Primary Maintenance

PRIMARY MAINTENANCE... - Page 29 PRIMARY MAINTENANCE...

- Page 30 PRIMARY MAINTENANCE...

-

Page 31: Primary Maintenance

PRIMARY MAINTENANCE... -

Page 32: Important

Read, Understand, and Follow all warnings and instructions in this manual, the engine manual, and on the machine, engine and attachments. If you have any questions about your Snapper product, contact your local authorized Snapper dealer or contact Snapper Customer Service at Snapper, McDonough, GA.

Need help?

Do you have a question about the ZF2501KH, ZF5201M, ZF6101M and is the answer not in the manual?

Questions and answers