Table of Contents

Advertisement

Quick Links

See also:

Technical Manual

Maintenance Manual for

ECO NO

REV

CHANGED FROM

02-0301

A

RELEASED

HALE PRODUCTS, INC. • A Unit of IDEX Corporation • 700 Spring Mill Avenue • Conshohocken, PA 19428 • TEL: 610-825-6300 • FAX: 610-825-6440

MANUAL P/N 029-0020-69-0, REV B, © 2002 HALE PRODUCTS, INC.,

MANUAL P/N 029-0020-53-0, REV A

Operation and

Hale Booster Pumps

AP

CBP

2CBP

BY

DATE

SAG

10/15/02

Hale Products cannot assume responsibility for product failure resulting from improper maintenance

or operation. Hale Products is responsible only to the limits stated in the product warranty. Product

specifications contained in this material are subject to change without notice.

APVD

MAL

DRAWN BY:

SAG

CHECKED BY:

PRW

HALE PRODUCTS, INC

A Unit of IDEX Corporation

Conshohocken, PA 19428 USA

COPYRIGHT ©

ISSUE DATE:

NOT TO BE REPRODUCED OR USED TO

10/15/02

MAKE OTHER DRAWINGS OR MACHINERY

9615

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for HALE AP

- Page 1 10/15/02 MAKE OTHER DRAWINGS OR MACHINERY HALE PRODUCTS, INC. • A Unit of IDEX Corporation • 700 Spring Mill Avenue • Conshohocken, PA 19428 • TEL: 610-825-6300 • FAX: 610-825-6440 9615 MANUAL P/N 029-0020-69-0, REV B, © 2002 HALE PRODUCTS, INC.,...

-

Page 2: Table Of Contents

Contents Booster SECTION I: INTRODUCTION ..............I-1 Overview................................I-1 Principals Of Operation ......................... I-1 Centrifugal Force ..........................I-1 Pump Stages ............................I-2 Two-Stage Booster Pump ........................I-3 Components of a Booster Pump ........................I-3 Pump Body ............................I-3 Impeller and Shaft Assembly ........................ I-3 Mechanical Seal .......................... - Page 3 AP Pump Body ............................ 5-5 Remove AP Pump Body ........................5-5 Install the Pump body .......................... 5-5 AP IMPELLER AND MECHANICAL SEAL ..................5-5 Remove AP Impeller ..........................5-5 Remove AP Mechanical Seal ......................5-6 Reinstall AP Mechanical Seal ......................5-6 Reinstall the AP Impeller ........................

- Page 4 Booster SECTION VI: PARTS LISTS ..............6-1 AP Pump ............................. 6-2 CBP Pump ............................6-5 2CBP Pump ............................6-8 Hydraulic Adapter ............................6-12 Tachometer Option ............................6-13...

-

Page 5: Section I: Introduction

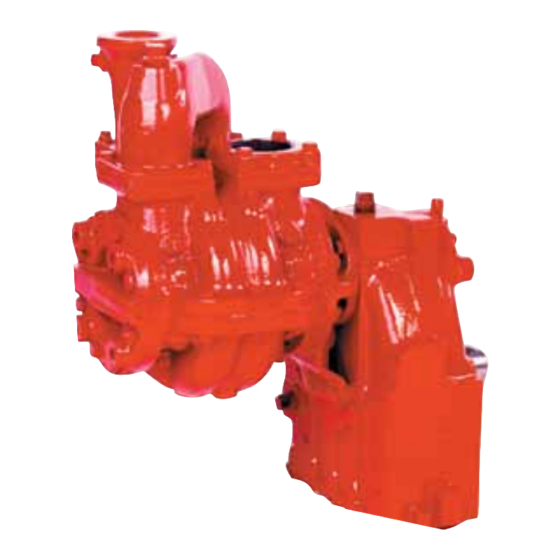

2CBP Unless otherwise indicated, these procedures will apply to all models of Hale booster pumps: Any variations in operations and maintenance of the different models will be addressed within the context of this manual. -

Page 6: Pump Stages

Figure 1-3: Single-stage Water Flow There are three models of Hale booster pumps. (The anticipated use determines which model is selected.) The AP and CBP booster pumps are single stage and provide initial attack pump performance per NFPA 1901 standards. The 2CBP is a two-stage series operation pump, is used as a high-pressure booster pump. -

Page 7: Two-Stage Booster Pump

The volume of water delivered at the discharge, however, is the same. Figure 1-4 shows the flow of water through a Hale 2CBP booster pump. Figure 1-5: Parts of the Hale Booster Pump booster pump. -

Page 8: Pump Drives

Additionally, the pump can be heat-treated nickel steel, transfers engine power configured to discharge in a variety of positions. to the impeller. Hale offers a variety of pump Since some PTOs match engine rotation and gear ratios to accommodate a wide range of... -

Page 9: Accessories

Hale booster pumps In addition to the basic parts of Hale booster use Rotary Vane Positive Displacement type pumps described above, the following items are pumps for priming. -

Page 10: Priming Valves

2. The Hale PVG Priming Valve (Figure 1 - 10) is mounted on the pump operator’s panel. The PVG is a combination valve and A Hale priming pump has a single control to switch. -

Page 11: Thermal Relief Valveb (Trv

System is a sacrificial metal, which helps prevent corrosion. The anode will fit on any Hale truck mounted pump, regardless of age or model. It is designed to be easily installed requiring four bolts and a gasket. Total time to install is just fifteen minutes, yet it will provide years of protection for the pump. -

Page 12: Explanation Of Terms

Booster Pumps EXPLANATION OF TERMS Priming Pump An auxiliary positive displacement pump which Atmospheric Pressure pumps air out of the booster pump creating a vacuum in order to prime the pump. The Static air pressure. Air pressure is 14 pounds priming pump is a rotary vane type, electric per square inch at sea level. -

Page 13: Section Ii Operating Procedures

Booster Pumps SECTION II OPERATING PROCEDURES This section supplies information and procedures for the operation of Hale booster pumps. Included in this section are procedures for pumping from an on-board tank, a hydrant, from draft, and post-operation procedures. Unless otherwise indicated, these instructions apply to all Hale booster pumps. -

Page 14: Draft Limiting Factors

Booster Pumps 13. If the pump overheats and it is not equipped with a Hale TRV valve, open the valve to access the bypass line, if it is furnished, or open the valve to the booster tank (both suction and discharge sides) to circulate water. - Page 15 15. If the pump overheats and is not equipped crease. Water may also be heard discharg- with the Hale TRV valve, open the valve to ing to the ground. access the pump auxiliary cooling system, or...

-

Page 16: Pump And Roll Operation

Valve System. Be sure to select the correct PUMP AND ROLL OPERATION procedure, for the equipment on the truck. Hale booster pumps are primarily driven by a 1. Set the pressure indicator on the PMD transmission mounted Power-Take-Off (PTO) control valve to a position slightly above the unit. -

Page 17: Process Of Cavitation

Booster Pumps Process of Cavitation More complete and detailed information can be found in the relief valve manual. 1. When increased discharge demand exceeds the intake, bubbles form in the low-pressure region (eye) of the impeller. THE PRESSURE INDICATOR ON THE PANEL IS ONLY A ROUGH INDICATION 2. -

Page 18: Warning Signs Of Cavitation: Discharge And Gauges

Booster Pumps illustrates the amount of lift loss as Warning Signs of Cavitation: Discharge temperatures rise. If there is a marked loss and Gauges of suction capacity, the pump may be near cavitation. Discharge Pressure In a properly functioning pump, an increase in NOTE: When water reaches 95°... - Page 19 Booster Pumps Hose Elevation Lift-Loss in Feet 3" 4" 4 ½" 5" 6" Dual Diameters (76) (102) (114) (127) (152) 6" Feet (Meters) (Meters) (mm) FLOWS GPM Lift Loss 2,000 (609) NFPA Baseline (LPM) 3,000 (914) 1.1 (0.33) (19.7) 4,000 (1219) 2.2 (0.67) (9.5) 5,000 (1524)

-

Page 20: Post Operation Procedure

Open the discharge valves, remove suction tube caps, and discharge valve caps. b. Open the pump body drain cocks or Hale multiple drain valve. If a multiple drain valve is used, all pump drain lines should be connected to this valve. -

Page 21: Section Iii Preventive Maintenance

Checking any auxiliary engine. OVERVIEW Verifying all gauges are in working order. Operating pump controls. Hale Booster Pumps require very little care and maintenance. However, the little required is Inspecting water and foam tanks. important. Preventive maintenance tasks take little time to accomplish and consist of leak Checking roof and bumper turrets testing, lubrication and cleaning. -

Page 22: Valve Maintenance

Booster Pumps proper valve operation. Check and Clean the Intake Strainers 6. Return the relief valve hand wheel and the Remove the strainers. Clean any debris out of apparatus to normal operational condition. the intake. Flush the pump if required by department procedures. -

Page 23: Monthly Maintenance

Change the oil every 12 months, depending on pump usage. Recommended oil 6. Test the suction hose as follows: for Hale booster pumps is SAE EP-90, 80W-90, or synthetic 75W-80 gear oil a. Attach the suction hose to the pump. -

Page 24: Annual Pump Maintenance

Booster Pumps 3. Inspect the magnetic drain plug. If of metal Place caps on all valves filings are present on the drain plug, remove the cooler or coverplate to visually inspect Connect a positive pressure and clean the internal components. Repair or source replace as necessary. -

Page 25: Performance Testing Overview

Booster Pumps Example PUMP RATING GPM (LPM) CAPACITY PRESSURE 1000 PSI (BAR) (946) (1325) (1703) (1893) (2839) (3785) FULL 150 (10) 1000 (946) (1325) (1703) (1893) (2839) (3785) 200 (13) (662) (927) (1192) (1325) (1987) (2650) 250 (17) (473) (662) (852) (946) (1419) - Page 26 Booster Pumps Refer to local procedures for pump testing 1. Check the relief valve according to the Relief procedures and practices. Valve Testing procedure under Weekly Maintenance. For Pitot gauge accuracy, the nozzle pressures should be between 30 and 85 PSIG. See the 2.

- Page 27 Booster Pumps GPM AT VARIOUS NOZZLE SIZES Nozzle Size NOZZLE ½” 5/8” ¾” 7/8” 1" 1 1/8" 1 ¼” 1 3/8” PRESS GPM AT VARIOUS NOZZLE SIZES Nozzle Size NOZZLE 1 ½” 1 5/8” 1 ¾” 1 7/8” 2” 2 1/4" 2 ½"...

-

Page 28: Worn Clearance Rings And Impeller Hubs

"undersized " clearance rings can be installed to delay a complete rebuild. Contact Customer Service at Hale Products and refer to part 321-0070-01-0 for CBP Often, replacement of the clearance rings will reduce the bypass and restore the pump to near original performance. -

Page 29: Section Iv: Troubleshooting

SECTION IV: TROUBLESHOOTING Table 4-1 lists the symptoms of some common problems and possible corrective measures. Before calling Hale or a Hale authorized parts service center for assistance, eliminate problem causes using this guide. If the problem cannot be corrected, please have the following information... - Page 30 CONDITION POSSIBLE CAUSE SUGGESTED CORRECTION Suction lift too high PUMP LOSES PRIME OR Do not attempt lifts exceeding WILL NOT PRIME (cont'd.) 22 feet. Restricted suction strainer Remove obstruction from suction hose strainer. Suction Connections Clean and tighten all suction connections.

- Page 31 CONDITION POSSIBLE CAUSE SUGGESTED CORRECTION PUMP LOSES PRIME OR 3. After priming, shut off the Air Leaks (cont'd.) WILL NOT PRIME (Cont'd.) engine. Audible detection of a leak is often possible. 4. Connect the suction hose from the hydrant or the discharge of another pumper to pressurize the pump with water, and look for visible...

- Page 32 CONDITION POSSIBLE CAUSE SUGGESTED CORRECTION INSUFFICIENT PUMP Relief Valve improperly set If the relief valve control is set CAPACITY (cont'd.) too low the relief valve will open and bypass water. Reset the relief valve control per the procedures in Section III. Other bypass lines (such as foam system or in-line valves) may reduce pump capacity or...

- Page 33 CONDITION POSSIBLE CAUSE SUGGESTED CORRECTION Worn pump impeller(s) and / or Installation of new parts clearance rings required. Blockage in the impeller can Impeller blockage prevent loss of both capacity and pressure. Back flushing the pump from discharge to suction may free blockage. Removal of the pump head may be required (this is considered a major repair).

- Page 34 CONDITION POSSIBLE CAUSE SUGGESTED CORRECTION Lack of lubrication Recommended weekly DISCHARGE VALVES lubrication of discharge and DIFFICULT TO OPERATE suction valve, use an approved lubricant. Refer to the valve manual for more information. Cavitation Troubleshooting Pump is beginning to Discharging more water than Increase the flow into the pump cavitate the pump is taking in.

- Page 35 It is possible to reassemble the pump incorrectly or with the wrong parts. Always compare the replacement parts with the original hardware. Contact customer service at Hale Products to answer questions or concerns. Verify the new impeller vanes Wrong impeller installed are oriented the same as the old impeller before installing.

- Page 36 Sec IV- 8 Troubleshooting...

-

Page 37: Section V Maintenance And Repair

NOTE: Unless otherwise indicated, these pump body. Disconnect cooling tubes from instructions apply to all Hale booster pumps. the water manifold and pump as required. General Repair Guidelines 8. Label and disconnect all wiring from the pump. - Page 38 Booster Pumps Model Gearbox O il Capacity 1 ¾ QTS. (1.66L) CBP2 & 3 = 1 ¾ Q T S. (1.66L) CBP4 & 5 = 1 Q T . (.95L) 2CBP2 & 3 = 1 ¾ Q T S. (1.66L) 2CBP 2CBP4 &...

-

Page 39: Recommended Cleaners

Recommended Cleaners NOTE: These procedures refer to Figures 5-2 and 5-3. Please review the General Repair and Cleaning and Inspection Guidelines on page 37 Hale recommends: before beginning these procedures. Safety Kleen Remove the Pump from the Apparatus Stoddard Solvent 1. - Page 40 2. Lift the pump and gearbox assembly into position on the equipment. Connect the 9. Return the apparatus to normal operation. Figure 5-3: CBP Pump and Gearbox Figure 5-2: AP Pump and Gearbox Assembly with Gearbox Cover Assembly with Optional Cooler Maintenance and Repair...

-

Page 41: Ap Pump Disassembly

4. Apply Loctite™ 242 (or equal) to the threads and install the 7/16-14 UNC x 1 cap screws Figure 5-4: AP Pump and that hold the pump body to the pump head. Gearbox Assembly Refer to Table 5-2 for recommended torque values for fastener size and material. -

Page 42: Remove Ap Mechanical Seal

6. Clean the pump shaft with alcohol swabs. Remove AP Mechanical Seal 7. Apply a generous coating of PAC-EASE 1. Remove the impeller key from the pump Rubber Lubricant Emulsion (or equal) to the shaft. -

Page 43: Reinstall Ap Pump Head

Booster Pumps Figure 5-5: AP Pump and Gearbox for Parts Identification 2. Remove the 7/16-14 X 1" long cap screws the pump head. that secure the pump head to the gearbox. 7. Inspect and clean all components according 3. With the cap screws removed, pull the to the Cleaning and Inspection Guidelines pump head from the gearbox. -

Page 44: Ap Gearbox

Cleaning and Inspection Guidelines. fold, remove the 5/16-18 UNC cap screws and remove the water manifold and gasket Reassemble and Reinstall AP Gearbox from the gearbox. 1. Place the gearbox housing on a steady flat If the pump is not equipped with a water surface with drive shaft opening facing up. - Page 45 Booster Pumps shaft into the gearbox housing bore. in the water manifold. 6. Install the retaining ring to hold the bearing 18. Reinstall the pump onto the apparatus and and drive shaft in place. check for leaks. 7. Install a new oil seal. 8.

- Page 46 Booster Pumps Figure 5-7: CBP for Parts Identification Maintenance and Repair Sec V- 10...

-

Page 47: Cbp Pump Repair

Booster Pumps 2. Install the pump body on the pump head, be CBP PUMP REPAIR careful not to damage the clearance ring or impeller. Please review the General Repair and Cleaning 3. Apply Loctite™ 242 (or equal) to the and Inspection Guidelines before beginning threads and install the eight 3/8-16 X 7/8 these procedures. -

Page 48: Reinstall Cbp Impeller

Booster Pumps Reinstall CBP Impeller 2. Clean the bore of the pump head using alcohol swabs and install the stationary seat. 1. Install the impeller key in the keyway on the pump shaft. Carefully slide the impeller over NOTE: Oil and grease will damage the pump shaft aligning the keyway with the mechanical seal face. -

Page 49: Reinstall Cbp Pump Head

Booster Pumps described. CBP GEARBOX Remove and Disassemble CBP Gearbox 1. Remove the pump and gear- box assembly from apparatus as Figure 5-9 Figure 5-8 described above. Do not damage the pump shaft. 2. Place the pump and gearbox on a work stand. -

Page 50: Reassemble And Reinstall Cbp Gearbox

Booster Pumps 10. With the set screw removed, insert a drift 5. Install the other 207K bearing over the drive punch into the 1/2-13 hole and begin push- shaft into the gearbox housing bore. ing the drive shaft from gearbox while protecting the drive gear from falling. - Page 51 Booster Pumps Figure 5-11: 2CBP for Parts Identification Maintenance and Repair Sec V- 15...

-

Page 52: 2Cbp Pump Repair

Booster Pumps 2CBP PUMP REPAIR 7. Hold the impeller with a strap wrench. Use a 1 3/4" socket or wrench to remove the impeller nut and washer. Please review the General Repair and Cleaning and Inspection Guidelines before beginning 8. To avoid warping, use a puller to remove the these procedures. - Page 53 Booster Pumps the carbon seal ring seats against the Apply a generous coating of PAC-EASE stationary seat. If binding occurs, apply Rubber Lubricant Emulsion (or equal) to the additional lubricant. Slide the spring and outside of the stationary seat. cupwasher (supplied with the seal) onto the shaft.

-

Page 54: Disassemble The 2Cbp Gearbox

Booster Pumps lower pump body. lose the pump gear key in the gearbox. 10. If previously removed, insert the dowel pins 7. Remove the 306W bearing, pump gear, into the lower pump body pump gear key, and 208M bearing from the pump shaft or gearbox housing. -

Page 55: Reassemble And Reinstall 2Cbp Gearbox

Booster Pumps Reassemble and Reinstall 2CBP Gearbox install the gasket and bearing cover. Secure with 7/16-14 UNC x 1 inch long capscrews. Torque to 40ft-lbs (54Nm). 1. Place the gearbox housing on a steady flat surface with drive shaft opening facing up. 15. - Page 56 Hale Products supplies repair kits designed 546-1560-01-0 2CBP Pump Level 2 specifically for each pump and gearbox. Other Intermediate Repair Kit parts can be ordered by calling Hale Products Customer Service at 1-800-220-3473. 546-1560-02 through 05-0 CBP Pump Level 3 Overhaul kit.

-

Page 57: Section Vi: Parts Lists

Booster SECTION VI: PARTS LISTS This section contains part lists and exploded views for the following Booster Pump models: 2CBP Hydraulic Drive Option Tachometer Option Parts Lists Sec VI-1... - Page 58 Booster Figure 6-1 AP Pump Parts Lists Sec VI-2...

-

Page 59: Ap Pump

Item Part Number Description 001-0750-00-0 AP PUMP BODY 001-0750-01-0 AP PUMP BODY (OPP ENG) BRASS 001-0750-02-0 AP PUMP BODY (4.5 ISO) O.E. ROT 001-0750-03-0 AP PUMP BODY (4-1/2 NST) O.E.ROT 001-0750-04-0 AP PUMP BODY(4"NPT)O.E.ROT. 001-0760-00-0 AP PUMP BODY 001-0760-01-0 AP PUMP BODY (ENG ROT) BRASS 001-0760-02-0 AP PUMP BODY (4.5 ISO) ENG ROT... - Page 60 207K BEARING 250-0208-20-0 208M BEARING 250-0306-20-0 306W BEARING 296-2210-00-0 60R-296 OIL SEAL 296-2610-00-0 MG PUMP SHAFT OIL SEAL (CR) 296-5021-09-0 AP/MG MECH SEAL (WELDED SPRING) 321-0150-00-0 4D-321 CLEARANCE RING 604-0033-00-0 3/8 OD X.032 WALL COPPER TUBE Parts Lists Sec VI-4...

- Page 61 Booster Figure 6-2 CBP Pump Parts Lists Sec VI-5...

-

Page 62: Cbp Pump

Booster CBP Series Pump Item Part Description Number 001-0190-00-0 CBP-320LD BODY-VOLUTE(OPP.END) 001-0190-01-0 CBP-B320LD BODY-VOLUTE(O.E.) 001-0200-00-0 CBP-320LD BODY-VOLUTE ENG ROT 001-0200-01-0 CBP-B320RD BODY PUMP(ENG.ROT) 002-0170-00-0 CBP-2F HEAD-PUMP 002-0170-01-0 CBP-B2F HEAD-PUMP 004-0091-00-0 CBP2,3 GEARBOX HSG 004-0380-00-0 CBP4,5 GEARBOX HSG 008-0150-00-0 CBP-61D BEARING-CAP 016-0230-00-0 CBP-16L-6 1/2 IMPELLER OPP ENG R 016-0240-00-0... - Page 63 Booster Item Part Description Number 046-5270-01-0 CBP D U GASKET 077-1180-05-0 78S118 RETAINING RING 077-2810-00-0 79S281 RETAINING RING 097-0810-01-0 WASHER-5/16 STL ZINC PL FLAT 097-0960-00-0 WASHER. 101-0082-00-0 GEARBOX SERIAL NUMBER PLATE 110-2701-11-0 NUT-3/4-16 NYL LOCK STNLS JAM. 217-0201-00-0 1/4 NPT SQUARE HEAD STEEL PLUG 217-0301-00-0 PLUG-3/8 NPT SQUARE HEAD.

- Page 64 Booster Figure 6-3 2CBP Pump Parts Lists Sec VI-8...

- Page 65 Booster 2CBP PARTS LIST Item # Part Number Description 001-0230-00-0 2CBP PUMP BODY 1 & 2 001-0230-03-0 2CBP PUMP BODY BRONZE 002-0180-00-0 2CBP-2D HEAD-PUMP 002-0180-01-0 2CBP-2D HEAD-PUMP BRONZE 004-0091-00-0 CBP GEARBOX HSG 004-0380-00-0 40FW DRIVE UNIT HSG 007-0260-00-0 2CBP CROSS OVER TUBE 007-0260-01-0 2CBP CROSS OVER TUBE BRONZE 007-0270-00-0...

-

Page 66: 2Cbp Pump

Booster Item Part no Description 031-0851-00-0 40FC8 DRIVE GEAR (46T) 031-0361-00-0 CBP DRIVE GEAR (51T) 031-0371-00-0 CBP DRIVE GEAR (71T) 031-0381-00-0 40FW DRIVE GEAR (74T) 031-0400-00-0 CBP-31-18 GEAR (18T) 031-0390-00-0 CBP-31-15 GEAR (15T) 031-0840-00-0 40FC8 PUMP SHAFT GEAR (23T) 037-0372-00-0 2CBP PUMP SHAFT 037-1161-00-0 40FW DRIVE SHAFT... - Page 67 Booster Item Part no Description 217-0401-08-0 PLUG-1/2 NPT M.I. MAGNETIC 217-0501-00-0 PLUG-3/4 NPT M.I. 217-0501-01-0 PLUG-3/4 NPT BRASS 250-0206-06-0 206KG BEARING 250-0207-00-0 207K BEARING 250-0403-00-0 403S BEARING 250-9130-00-0 2CBP-250 FRONT SLEEVE BEARING 296-2140-00-0 2CBP-296 OIL SEAL 296-2210-00-0 60R-296 OIL SEAL 296-5050-00-0 CBP-G444 MECHANICAL SEAL ASSY 296-5050-07-0...

-

Page 68: Hydraulic Adapter

Booster HYDRAULIC ADAPTER Hydraulically driven booster pumps are equipped with a drive adapter. The adapter bolts to the standard pump gearbox. Use the part list below for reference when contacting Hale Products for service. Hydraulic Adapter Part List Item Part Number... -

Page 69: Tachometer Option

Booster TACHOMETER OPTION Connected to the pump shaft at the gearbox, the tachometer take off provides for an actual RPM of the pump when connected to a tachometer. The ratio adapter is a 10:1 reduction of the actual rotation of the shaft. The drawing and parts list below illustrate the standard installation of the assembly. - Page 70 EXPRESS WARRANTY. Hale Products Inc. (“Hale”) hereby warrants to the original buyer that products manufactured by Hale are free of defects in material and workmanship for two (2) years or 2000 hours usage, whichever shall first occur. The “Warranty Period” commences on the date the Product is first placed in service.

Need help?

Do you have a question about the AP and is the answer not in the manual?

Questions and answers