Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Drazice OKC 500 NTRR/HP/SOL

- Page 1 OPERATING AND INSTALLATION MANUAL INDIRECT WATER TANKS OKC 400 NTRR/HP/SOL OKC 500 NTRR/HP/SOL Družstevní závody Dražice-strojírna s.r.o. (Works Cooperative - Dražice - Machine Plant, Ltd.) Dražice 69, 294 71 Benátky nad Jizerou tel.: +420 / 326 370 911 fax: +420 / 326 370 980 e-mail: export@dzd.cz...

-

Page 2: Table Of Contents

OBSAH PRODUCT TECHNICAL SPECIFICATION ....................... 4 FUNCTION DESCRIPTION ........................4 DESIGN AND BASIC DIMENSIONS OF TANK ..................4 1.2.1 PRODUCT DESCRIPTION......................4 1.2.2 TECHNICAL DATA ........................5 1.2.3 PRESSURE LOSSES ........................8 OPERATION AND FITTING INSTRUCTIONS ....................8 COMMISSIONING THE RESERVOIR ....................8 CONNECTING THE RESERVOIR TO HOT WATER DISTRIBUTION ............ - Page 3 CAREFULLY READ THIS MANUAL BEFORE INSTALLING THE WATER HEATER! Dear Customer, The Works Cooperative of Dražice - Machine Plant, Ltd., would like to thank you for your decision to use a product of our brand. With this guide, we will introduce you to the use, construction, maintenance and other information on electrical water heaters.

-

Page 4: Product Technical Specification

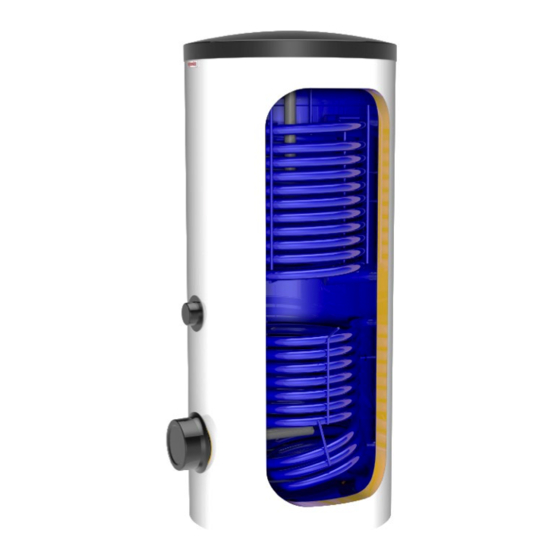

1 PRODUCT TECHNICAL SPECIFICATION 1.1 FUNCTION DESCRIPTION Indirect stationary tank OKC 400, 500 NTRR/HP/SOL is designed for water heating in conjunction with a heat pump. Reheat can be carried out by the electric heater TJ 6 / 4“. 1.2 DESIGN AND BASIC DIMENSIONS OF TANK 1.2.1 PRODUCT DESCRIPTION The tank receptacle is welded of steel plate and, as a unit, enamelled to resist hot water. -

Page 5: Technical Data

1.2.2 TECHNICAL DATA OKC 400 OKC 500 TYPE NTRR/HP/SOL NTRR/HP/SOL VOLUME HEIGHT 1644 1914 DIAMETER MAXIMUM WEIGHT WITHOUT WATER MAXIMUM OPERATING OVERPRESSURE IN THE VESSEL MAXIMUM OPERATING OVERPRESSURE IN THE EXCHANGER* MAXIMUM HEATING WATER °C TEMPERATURE MAXIMUM OPERATING °C TEMPERATURE IN THE VESSEL HEATING SURFACE OF UPPER/ 1,4 / 3,1 2 / 4,8... - Page 6 OKC 400 NTRR/HP/SOL OKC 400 NTRR/HP/SOL 1644 Figure 1 1" outer 3/4" inner 1521 5/4" inner 1/2" inner 6/4" inner 1348 1073 1173 Table 2 - 6 -...

- Page 7 OKC 500 NTRR/HP/SOL OKC 500 NTRR/HP/SOL 1914 Figure 2 1790 1023 1" outer 3/4" inner 5/4" inner 1/2" inner 6/4" inner 1618 1123 1409 Table 3 - 7 -...

-

Page 8: Pressure Losses

1.2.3 PRESSURE LOSSES OKC 400,500 NTRR/HP/SOL OKC 500 NTRR/HP/SOL OKC 400 NTRR/HP/SOL Figure 3 2 OPERATION AND FITTING INSTRUCTIONS 2.1 COMMISSIONING THE RESERVOIR After connecting the reservoir to the water distribution system, hot water heating system, respectively electrical power system and after checking the safety valve (following the instructions attached to the valve) the reservoir can be put into operation. -

Page 9: Connecting The Reservoir To Hot Water Distribution

2.2 CONNECTING THE RESERVOIR TO HOT WATER DISTRIBUTION Figure 4 Heater with volume exceeding 200 liters at the outlet hot water piping provide combined temperature and pressure safety fittings according to ČSN EN 1490, or the temperature safety fittings fitted with water temperature sensor placed in the heater or other safety valves DN 20, and the opening overpressure compliant with the maximum operating overpressure of the heater vessel. -

Page 10: Plumbing Fixture

2.3 PLUMBING FIXTURE Power water connects to pipes with ¾“ thread in the bottom part of the reservoir. Blue - cold water supply, red – hot water outlet. For potential disconnection of the tank, utility water inlets and outlets must be provided with Js 3/4“ screw coupling. The safety valve is mounted on the cold water inlet identified with a blue ring. -

Page 11: Connection Of Tank To Hot Water Distribution System

2.4 CONNECTION OF TANK TO HOT WATER DISTRIBUTION SYSTEM The tank is placed on the ground, next to the heating source, or in its vicinity. The heating circuit shall be connected to marked tank exchanger inputs and outputs, and bleeder valve installed at the highest point. It is necessary to install a filter into the circuit in order to protect pumps, three-way valve, backflow flaps and the exchanger from sedimentation. -

Page 12: Tank Cleaning And Anode Rod Exchange

2.5 TANK CLEANING AND ANODE ROD EXCHANGE Repetitive water heating causes limestone sediment on both the enamelled tank walls and chiefly the flange lid. Lime scale settling depends on hardness of heated water, its temperature and on the volume of hot water used. -

Page 13: Spare Parts

2.6 SPARE PARTS -magnesium anode When ordering spare parts always state the name of the part, the type and type number from the tank's plate. 3 IMPORTANT NOTICES 3.1 IMPORTANT NOTICES Without a proof issued by a professional company about performed electrical and plumbing fixture the warranty shall be void.

Need help?

Do you have a question about the OKC 500 NTRR/HP/SOL and is the answer not in the manual?

Questions and answers