Table of Contents

Advertisement

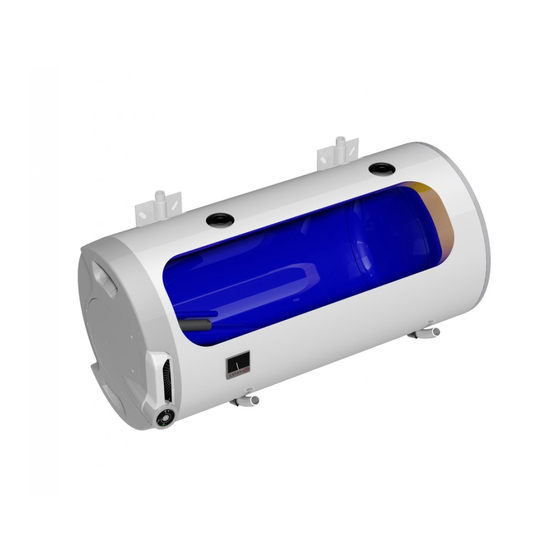

OPERATING AND

INSTALLATION MANUAL

TANK-TYPE WATER HEATERS FOR

HORIZONTAL MOUNTING

Družstevní závody Dražice - strojírna s.r.o.

Dražice 69, 294 71 Benátky nad Jizerou

Phone.: +420 /326 370 990

Fax: +420 / 326 370 980

e-mail: prodej@dzd.cz

OKCV 125

OKCV 160

OKCV 200

OKCEV 100

OKCEV 125

OKCEV 160

OKCEV 200

Advertisement

Table of Contents

Need help?

Do you have a question about the OKCV 125 and is the answer not in the manual?

Questions and answers